Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for WinGD X72DF

- Page 1 Marine Installation Manual X72DF Issue 2021-08...

- Page 2 © 2021 Winterthur Gas & Diesel Ltd. — All rights reserved No part of this publication may be reproduced or copied in any form or by any means (electronic, mechanical, graphic, photo- copying, recording, taping or other information retrieval systems) without the prior written permission of the copyright holder. Winterthur Gas &...

-

Page 3: List Of Changes

FPP manoeuvring steps and warm-up times Note added: Acceleration above FULL SEA 2 speed included 6.2.2 Reduction of lateral vibration Removal of hydraulic type stays of WinGD design 6.3 Longitudinal vibration (pitching) Removal of hydraulic type stays of WinGD design... - Page 4 Revision: Location of change Subject 1 Engine Description WinGD Engine Control System Engine Control System ‘UNIC’: trade name changed to function name 1.3 Components and sizes of the engine Design features This section removed; table 1-1 added on page 1-1 instead 1.4 Fuel operating modes...

- Page 5 Figure 5-6 added CPP manoeuvring steps and warm-up times Figure 5-7 added 5.6 Alarm sensors and safety functions Section rewritten 5.7 WinGD Integrated Digital Expert New section added 6 Engine Dynamics Whole chapter restructured; content updated 9.1 Classification societies Table 9-1: footnote removed 9.2 List of acronyms...

- Page 6 Date of issue: 2019-05 Location of change Subject Preface Introduction WinGD MDO/MGO definition clarified; fuel specification updated to ISO 8217:2017 1.2 Primary engine data Table 1-1: BSEC data for R1, R3, R4 updated 1.4 Fuel operating modes Section rewritten 1.5.3 Methane number calculation Link to EUROMOT webpage updated 1.6 Operation in diesel mode...

- Page 7 List of Changes X72DF Revision: Date of issue: 2018-11 Location of change Subject 1.1 Power / speed range Figure 1-1 updated 1.2 Primary engine data Table 1-1: guide feed rate of cylinder oil stated more precisely 1.4 Fuel operating modes Paragraph and illustration added 1.5.1 Torque/power meter requirement...

- Page 8 List of Changes X72DF Revision: Date of issue: 2018-03 Location of change Subject 1.2 Primary engine data Table 1-1 updated 1.5.4 Dynamic Combustion Control Note added 2.1 Pressure and temperature ranges New link to MIDS replaces former table 2-1 2.2.2 Load range...

-

Page 9: Table Of Contents

Table of Contents X72DF Table of Contents List of Changes ..........1 Preface . - Page 10 Table of Contents X72DF Engine Installation ..........3-1 Engine dimensions and masses .

- Page 11 Table of Contents X72DF 4.2.5 Cooling water treatment........4-15 4.2.6...

- Page 12 Table of Contents X72DF 4.6.4 Fuel oil treatment ........4-78 Settling tanks .

- Page 13 Requirements of WinGD and classification societies... . 5-12 WinGD integrated digital expert ......5-13 5.7.1...

- Page 14 Table of Contents X72DF Engine Emissions ..........7-1 Exhaust gas emissions .

- Page 15 List of Tables X72DF summary values for Maximum Continuous Rating (MCR)..1-1 Principal engine features and technologies ..... . 1-2 Rating points .

- Page 16 4-17 PTO/PTI/PTH arrangements for the WinGD X72DF ....4-103 4-18 Possible options for the WinGD X72DF ......4-103 4-19 Influence of options on engineering .

- Page 17 Rating field for the X72DF ........

- Page 18 List of Figures X72DF LT cooling water circuit — Dual set-point temperatures ... . 4-6 Separate SAC and LT cooling circuits ......4-7 HT cooling water circuit .

- Page 19 4-46 Air supply system ......... . . 4-82 4-47 Design proposal of WinGD’s sludge oil trap ..... . 4-87 4-48 Design proposal of a manually bottom-drained sludge oil trap .

- Page 20 List of Figures X72DF 4-54 Air filter size (example for 8-cyl. engine) ......4-98 4-55 Arrangements for PTO, PTI, PTH ....... 4-102 4-56 FPP with mandatory frequency converter .

- Page 21 List of Figures X72DF Speed dependent maximum allowable average of NOx emissions . . . 7-1 Low-pressure SCR — Arrangement ......7-2 High-pressure SCR —...

-

Page 22: Preface

0 Preface X72DF Preface WinGD provides a range of manuals and tools to help its customers at all stages of a project. From design engine to installation and maintenance, WinGD pro- vides extensive help and support. This manual is the initial guide to the installation process for this specific engine, providing an overview of the different topics which need to be considered in the project and the engine installation phase. -

Page 23: Explanation Of Symbols In This Marine Installation Manual

WinGD webpage. Example: MIDS • Documents like shipyard installation instructions and system concept guid- ance, which are provided on the WinGD webpage. Example: Fuel oil treatment • General Technical Data (GTD). This is an application provided on the WinGD webpage. -

Page 24: Marine Installation Drawing Set

Various Installation Items The latest versions of the drawing packages which are relevant for the present Links to complete drawing packages MIM are provided on the WinGD webpage under the following links: • Marine installation drawings: MIDS - complete package •... -

Page 25: General Technical Data (Gtd)

In addition to the standard output for ISO refer- ence and design conditions, further operating conditions for which information is required can be defined. The GTD application is accessible on the WinGD Customer Portal or on the WinGD webpage using the following link: https://www.wingd.com/en/media/general-technical-data... -

Page 26: Engine Summary

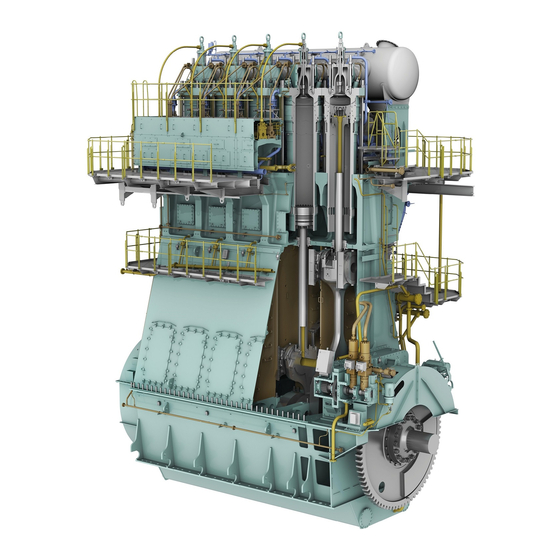

1 Engine Summary X72DF 1.1 Engine capability and features Engine Summary The WinGD X72DF is a camshaftless, low-speed, reversible and rigidly direct- coupled two-stroke engine featuring a common-rail injection system. Table 1-1 X72DF summary values for Maximum Continuous Rating (MCR) -

Page 27: Special Engine Features

The whole engine can be controlled and operated electronically. This is made possible by the Flex system (see The Flex system, 1-9). Standard data collection and monitoring system. This is known as the WinGD Integrated Digital Expert (WiDE). An engine integrated second order longitudinal vibration compensator is available. This is known as the In- 6.1.2 tegrated ELectrical BAlancer (iELBA). -

Page 28: Primary Engine Data

1.2 Primary engine data Primary engine data The engine rating field for this specific engine is displayed in Figure 1-1 together with all the WinGD X-DF engines. For detailed engine data see Table 1-3, 1-4. Output [kW] 80 000... -

Page 29: Engine Rating Field - Rating Points

1 Engine Summary X72DF 1.2 Primary engine data 1.2.1 Engine rating field - rating points The specific values for the four corners of the rating field are called rating points (see Table 1-3). Table 1-3 Rating points Bore x stroke: 720 x 3,086 [mm] No. -

Page 30: Principal Engine Dimensions And Weights

1 Engine Summary X72DF 1.2 Primary engine data 1.2.2 Principal engine dimensions and weights SM-0577 Figure 1-2 Principal engine dimensions For more details about sizing, specific dimensions and masses, see section 3.1 Engine dimensions and masses, 3-1. Table 1-4 Principal engine dimension values No. -

Page 31: Fuel Operating Modes

1 Engine Summary X72DF 1.3 Fuel operating modes Fuel operating modes The engine is designed for continuous service on gas fuel with fuel oil as a back- up fuel. Different operating modes are available within specific engine power ranges (see Figure 1-3). -

Page 32: Operation In Gas Mode

1 Engine Summary X72DF 1.3 Fuel operating modes 1.3.1 Operation in gas mode The engine operates in gas mode according to the Otto cycle with a pre-mixed lean air-gas mixture, which is ignited by a small amount of pilot fuel. The amount of injected pilot fuel used is approximately the same across the entire en- gine power range. -

Page 33: Power Meter Requirement

(see section 1.3.4, 1-12). For engine operation on distillate fuels, see the following Concept Guidance (DG 9723), as provided on the WinGD webpage: Operation on distillate fuels Marine Installation Manual 2021-08... -

Page 34: The Flex System

1 Engine Summary X72DF 1.3 Fuel operating modes The Flex system The engine is equipped with WinGD’s common-rail injection system which en- ables flexible fuel injection. Engine Control System Engine Control System Cylinder No. 1 - n Cylinder No. 1 - n... -

Page 35: Operation In Fuel Sharing Mode

1 Engine Summary X72DF 1.3 Fuel operating modes 1.3.3 Operation in fuel sharing mode NOTE Fuel sharing mode is an available engine option but must be contracted (with additional cost). The fuel sharing mode is initiated only by the operation and can be used for reaching a balance between a carrier’s LNG boil-off and the desired ship speed. -

Page 36: Fuel Sharing Mode - Energy Amount Of Different Ratios Of Fuel

1 Engine Summary X72DF 1.3 Fuel operating modes Total fuel [power %] Liquid Pilot fuel (enlarged for visibility reasons, not scaled) Engine power [%] SM-0182 Figure 1-7 Fuel sharing mode — energy amount of different ratios of fuel The liquid-gas ratio can be selected by the Remote Control System (RCS). The automatic control of the ratio of liquid fuel is based on the LNG carrier’s tank... -

Page 37: Changeover Between Operating Modes

1 Engine Summary X72DF 1.3 Fuel operating modes 1.3.4 Changeover between operating modes The changeover between operating modes is the process of the engine changing between different fuel operating modes (see section 1.3, 1-6). Depending on the type of changeover between operating modes, the time re- quired will vary. - Page 38 The fuel sharing mode must be contracted. It is an available option at an additional cost. Transfer Similar to WinGD diesel engines, changing the fuel input from HFO to either between liquid fuels MGO or MDO and vice versa can be done at any time (assuming HFO is per- mitted in the operating mode) without interruption of engine operation.

-

Page 39: Engine Power And Speed

This chapter explains the main principles in selecting a WinGD 2-stroke marine diesel and gas engine. -

Page 40: Rating Points

R1 parameters. Percentage values are used so that the same diagram can be applied to various engine arrangements. Rating points The rating points (R1, R2, R3, R4) for WinGD engines are the corner points of the engine rating field (see Figure 2-1, ... -

Page 41: Power Range

2 Engine Power and Speed X72DF 2.4 Power range Maximum propeller The maximum propeller diameter is often determined by operational require- diameter ments, such as: • Design draught and ballast draught limitations • Class recommendations concerning propeller/hull clearance (pressure im-... -

Page 42: Sea Trial Power

2 Engine Power and Speed X72DF 2.4 Power range CMCR (Rx) Maximum continuous power Contracted maximum continuous rating Continuous service power Continuous service rating Sea trial power Sea trial power Ship speed [% service speed] Engine speed [% CMCR rpm]... -

Page 43: Light Running Margin

2 Engine Power and Speed X72DF 2.4 Power range Light running margin The Light Running (LR) margin (see Figure 2-2, 2-4) is added to compensate for the expected change in speed to relative power, caused by the fouling and the deterioration of the vessel over time. -

Page 44: Power Range Limits

2 Engine Power and Speed X72DF 2.5 Power range limits Power range limits Once an engine is optimised at CMCR (Rx), the working range of the engine is limited by the following border lines (see Figure 2-3). Engine Engine Breakpoints... - Page 45 2 Engine Power and Speed X72DF 2.5 Power range limits Line 5 Admissible power limit for engine operation. The line is separated by the break- Engine Operation points listed in Figure 2-3, 2-6. Power Limit Maximum power limit for transient operation. The line is separated by the break-...

-

Page 46: Line 5 Coefficients

2 Engine Power and Speed X72DF 2.5 Power range limits Table 2-1 Line 5 coefficients Line no. Range (n / n CMCR Line 5 0.00 - 0.40 0.000 0.500 0.000 0.40 - 0.60 0.500 0.300 0.000 0.60 - 0.96 1.111 - 0.067... - Page 47 2 Engine Power and Speed X72DF 2.5 Power range limits The area above Lines 1 and 9 is the overload range. It is only permissible to op- erate engines in this range for a maximum duration of one hour during sea trials and in the presence of an authorised engine builder representative.

-

Page 48: Power Range Limits With A Power Take-Off Installation For A Fpp

The addition of a PTO installation alters the working range and operating characteristics of the engine. Two methods of incorporating the PTO are outlined in the following sections. WinGD recommends to follow Method 1. • The PTO is used for generating the navigation electric power PTO considerations •... -

Page 49: Line 10 Coefficients

2 Engine Power and Speed X72DF 2.6 Power range limits with a power take-off installation for a FPP With the addition of a constant nominal generator power across the engine power range, the engine curve is changed, so no longer directly related to a pro- peller characteristic. -

Page 50: Pto Incorporation Of Method 2

2 Engine Power and Speed X72DF 2.6 Power range limits with a power take-off installation for a FPP PTO incorporation of Method 2 With this second method, the engine’s CMCR is determined by the propeller CMCR - Method 2 power only. The PTO uses the available engine power which is not absorbed by the propeller. -

Page 51: Prohibited Operation Area

2 Engine Power and Speed X72DF 2.7 Prohibited operation area Prohibited operation area Within the higher speed range of the engine there is a prohibited operation area defined by a minimum engine power requirement. During normal operation, in- cluding Controllable Pitch Propeller (CPP) at zero pitch operation, the engine will not enter this prohibited area. - Page 52 30 minutes during testing and sea trials. This operation is only permissible at low load and in the presence of author- ised representatives of the engine builder. Further requests must be agreed upon by WinGD. NOTE The operational design range must respect the Barred Speed Range (BSR) limits from torsional vibration.

-

Page 53: Prohibited Operation Area For Different Speed Rated Engines

2 Engine Power and Speed X72DF 2.7 Prohibited operation area Prohibited operation area for different speed rated engines As the prohibited operation area of the engine is between 70 % and 100% of the R1 — R2 speed, the prohibited area is smaller when the speed rating of the engine is lowered. - Page 54 2 Engine Power and Speed X72DF 2.7 Prohibited operation area 2-9, the engine’s CMCR speed is rated at 85 % of the R1 — R2 speed. At Power / speed range for Figure CMCR [Rx] = this speed, a minimum engine power (point F) of 10.4 % is required, below this is 85 % R1—...

- Page 55 2 Engine Power and Speed X72DF 2.7 Prohibited operation area 2-10, the engine’s CMCR speed is rated at the R3 — R4 speed. At this Power / speed range for Figure CMCR [Rx] = speed, a minimum engine power (point F) of 7.9 % is required. Below this is the R3 —...

-

Page 56: Cpp Requirements For The Propulsion Control System

2.8 CPP requirements for the propulsion control system CPP requirements for the propulsion control system WinGD recommends including CPP control functions in an engine Remote Control System (RCS) from an approved supplier. This ensures, amongst others, that the requirements of the engine builder are strictly followed. -

Page 57: Engine Installation

3 Engine Installation X72DF 3.1 Engine dimensions and masses Engine Installation The purpose of this chapter is to provide information to assist in the installation of the engine. It is for guidance only and does not supersede current instructions. Engine dimensions and masses... -

Page 58: Dismantling Heights For Piston And Cylinder Liner

However, please contact WinGD or any of their representatives if these values cannot be maintained or if more detailed information is required. For details see also drawings ‘Dismantling Dimensions’ (DG 0812) provided on the WinGD webpage under the following links: 5-cyl. -

Page 59: Thermal Expansion Between The Turbocharger And Exhaust Gas

3 Engine Installation X72DF 3.1 Engine dimensions and masses 3.1.3 Thermal expansion between the turbocharger and exhaust gas piping Before making expansion pieces, enabling connections between the engine and external engine services, the thermal expansion of the engine and turbocharger has to be taken into account. -

Page 60: Content Of Fluids In The Engine

3 Engine Installation X72DF 3.1 Engine dimensions and masses 3.1.4 Content of fluids in the engine For the quantity of a specific fluid in the engine please refer to the relevant MIDS drawings as listed below: • Fuel oil —... -

Page 61: Conditions And Requirements

Conditions and requirements 3.2.1 Pressure and temperature ranges Please refer to the document ‘Usual values and safeguard settings’, which is provided by WinGD under the following link: Usual values and safeguard settings For signal processing see also 5.6.1 Signal processing, ... -

Page 62: Ancillary System Design Parameters

3 Engine Installation X72DF 3.2 Conditions and requirements 3.2.3 Ancillary system design parameters The layout of the engine’s ancillary systems is based on the rated performance (rating point Rx, CMCR). The given design parameters must be considered in the plant design to ensure a proper function of the engine and its ancillary sys-... -

Page 63: Electrical Power Requirement

3 Engine Installation X72DF 3.2 Conditions and requirements 3.2.4 Electrical power requirement Table 3-2 Electrical power requirement Power requirement [kW] Power supply cyl. Auxiliary blowers 2 x 57 2 x 70 440 V / 60Hz 2 x 88 2 x 88... -

Page 64: Engine Outline Views

3 Engine Installation X72DF 3.3 Engine outline views Engine outline views The latest versions of the Engine Outline Drawings (DG 0812) are provided on the WinGD webpage under the following links: 5-cyl. engine 6-cyl. engine 7-cyl. engine 8-cyl. engine Marine Installation Manual... -

Page 65: Platform Arrangement

3 Engine Installation X72DF 3.4 Platform arrangement Platform arrangement 3.4.1 Drawings For platform arrangement see the links given in section 3.3, 3-8. 3.4.2 Minimum requirements for escape routes The platforms shown in the relevant drawings are arranged in such a way as to ensure safe escape routes for the crew. -

Page 66: Seating

(DG 9710) on the WinGD webpage under the following link: Fitting instruction - Engine seating and foundation The latest version of the Marine Installation Drawing Set relevant for engine seating and foundation (DG 9710) is provided on the WinGD webpage under the following link: MIDS... -

Page 67: Assembly

3 Engine Installation X72DF 3.6 Assembly Assembly Engines may be installed as complete units or assembled from subassemblies in the vessel, which may be afloat, in dry dock, or on the slipway. 3.6.1 Assembly of subassemblies When the engine seating has been approved, the bedplate is lowered onto blocks placed between the chocking points. -

Page 68: Installation Of A Complete Engine

3 Engine Installation X72DF 3.6 Assembly 3.6.2 Installation of a complete engine In the event that the engine is shipped in part deliveries and assembled at the shipyard before installation in the vessel, the shipyard is to undertake assembly work in accordance with the demands of a representative of the engine builder and the classification society. -

Page 69: Engine And Shaft Alignment

Instructions and limits Alignment can be done with either jacking screws or wedges. For detailed alignment procedures refer to the latest version of Engine Align- ment Documents (DG 9709) provided on the WinGD webpage under the fol- lowing link: Engine alignment 3.7.2... -

Page 70: Engine Coupling

3.8.4 Installation drawing The latest version of the drawing relevant for the Connection Crank / Propeller Shaft (DG 3114) is provided on the WinGD webpage under the following link: Connection crank/propeller shaft Marine Installation Manual 2021-08... -

Page 71: Engine Stays

6-6) and longitudinal stays (refer to 6.3 Longitudinal vibration (pitching), 6-10). The latest version of the Marine Installation Drawing Set relevant for engine stays (DG 9715) is provided on the WinGD webpage under the following link: MIDS Marine Installation Manual 2021-08... -

Page 72: Propulsion Shaft Earthing

3 Engine Installation X72DF 3.10 Propulsion shaft earthing 3.10 Propulsion shaft earthing Electric current flows when a potential difference exists between two materials. The creation of a potential difference is associated with thermoelectric by the ap- plication of heat, tribo-electric between interactive surfaces, electrochemical when an electrolytic solution exists, and electromagnetic induction when a conducting material passes through a magnetic field. -

Page 73: Typical Shaft Earthing Arrangement

3 Engine Installation X72DF 3.10 Propulsion shaft earthing Section A-A Typical arrangement for the propeller shaft View on ‘A’ (brush gear omitted) Slip ring Tension bands Twin holder Brushes Connection to the ship’s hull Steel spindle Connection to the voltmeter... -

Page 74: Typical Shaft Earthing With Condition Monitoring Facility

3 Engine Installation X72DF 3.10 Propulsion shaft earthing Slip ring condition voltmeter 50 mV 250 mV Shaft earth (hull) Shaft monitoring Additional terminals are provided as necessary for multi-shaft vessels. 2.5 mm 2.5 mm 35 mm Insulated spindle Propeller shaft... -

Page 75: Fire Protection

3 Engine Installation X72DF 3.11 Fire protection 3.11 Fire protection Fires may develop in areas such as scavenge air receiver / piston underside. The engine is fitted with a piping system which leads the fire extinguishing agent into the critical areas. -

Page 76: Ancillary Systems

Rx rating within the engine rating field to be obtained. However, for convenience or final confirmation when opti- mising the plant, WinGD provides a computerised calculation service. All pipework systems All pipework systems and fittings are to conform to the requirements laid down must be flushed and by the legislative council of the vessel’s country of registration and the classifica-... -

Page 77: Twin-Engine Installation

4.1 Twin-engine installation Twin-engine installation A vessel equipped with two separate main propulsion engines is considered a twin-engine installation. The installation of two WinGD 2-stroke engines allows combining individual engine auxiliary systems. Table 4-1 WinGD provides information based on engines’ requirements. -

Page 78: Cooling Water System For Twin-Engine Installation

4 Ancillary Systems X72DF 4.1 Twin-engine installation Main Engine 1 8 (set-point: 25 °C) 1 Scavenge air cooler (SAC) 2 HT cooling water cooler (engine 1) 3 Lubricating oil cooler (engine 1) 4 HT cooling water cooler (engine 2) 5 Lubricating oil cooler (engine 2) -

Page 79: Cooling Water System

X72DF 4.2 Cooling water system Cooling water system The latest version of the Marine Installation Drawing Set relevant for the cooling water system (DG 9721) is provided on the WinGD webpage under the following link: MIDS Freshwater cooling The main engine high-temperature (HT) and low-temperature (LT) cooling cir- system cuits use freshwater as their cooling medium. -

Page 80: Low-Temperature Circuit

4 Ancillary Systems X72DF 4.2 Cooling water system 4.2.1 Low-temperature circuit The LT cooling water circuit for the main engine provides cooling for the SAC, the LO cooler and the MDO/MGO cooler. For the main engine SAC, the automatic temperature control valve must be set to... -

Page 81: Arrangement 1

Arrangement 1 To maintain the required SAC inlet temperature, the automatic temperature con- trol valve of the central freshwater cooling system is set to 25 °C (WinGD speci- fication). In this arrangement, the ancillary plant and other cooler temperatures are controlled and maintained by this single temperature set-point. -

Page 82: Arrangement 3

This includes: • Circuit 1: The ME SAC is cooled with freshwater with a temperature set-point of 25 °C (WinGD specification). With this arrangement, only the ME SAC re- quires maximum design seawater flow for cooling. • Circuit 2: All other ME and ancillary plant coolers are cooled with freshwater with a set-point customised by the shipyard or ship designer. -

Page 83: Low-Temperature Circuit Components

4 Ancillary Systems X72DF 4.2 Cooling water system Low-temperature circuit components The seawater circulating pump delivers seawater from the high and low sea Seawater circulating pump chests to the central seawater cooler. Pump type Centrifugal Capacity According to GTD: The seawater flow capacity covers the... -

Page 84: High-Temperature Circuit

As stated above, the automatic temperature control valve for the cooling water to temperature control valve the SAC must be set to 25 °C (WinGD specification). Temperature control of other ancillary plant is to be determined by the shipyard. Valve type... -

Page 85: High-Temperature Circuit Components

4 Ancillary Systems X72DF 4.2 Cooling water system Main Engine HT Pumps Pre-heater pump (optional) Pre-heater for ME HT Cooler (HTC) Automatic temp. control valve Throttling disc Freshwater generator HT Circuit buffer unit Buffer unit supply pump 10 CW feed & drain tank... - Page 86 4.2 Cooling water system To supply the cooling water system with the desired static pressure and compen- sate for the cooling water volume change during engine operation, WinGD pro- poses two possible solutions, namely installing either an expansion tank or a buffer unit.

- Page 87 4 Ancillary Systems X72DF 4.2 Cooling water system Buffer unit supply pump The buffer unit supply pump compensates for losses in the CCW system. This pump is automatically controlled by the water level in the buffer unit. It is also advisable to monitor the running period of the supply pump. Moni- toring of the pump running period will warn when the running period exceeds a pre-set value, indicating unusual water losses in the system.

-

Page 88: Pre-Heating

4 Ancillary Systems X72DF 4.2 Cooling water system 4.2.3 Pre-heating To prevent corrosive liner wear when not in service or during short stays in port, it is important that the ME is kept warm. Warming-through can be provided by a dedicated heater, using boiler raised steam or hot water from the diesel auxilia- ries, or by direct circulation from the diesel auxiliaries. -

Page 89: Freshwater Generator

The latest version of the Concept Guidance for freshwater generator installation (DG 9721) is provided on the WinGD webpage under the following link: Freshwater generator installation Marine Installation Manual... -

Page 90: Cooling Water Treatment

Nitrites attack the zinc lining of galvanised piping and create sludge. For further information about permissible cooling water additives please refer to the document Cooling water and additives, which is provided on the WinGD webpage under the following link: Cooling water and additives... -

Page 91: General Recommendations For The Cooling Water System Design

4 Ancillary Systems X72DF 4.2 Cooling water system 4.2.6 General recommendations for the cooling water system design • The number of valves in the system must be kept to a minimum to reduce the risk of incorrect setting. • Valves are to be locked in the set position and labelled to eliminate incorrect handling. -

Page 92: Lubricating Oil Systems

X72DF 4.3 Lubricating oil systems Lubricating oil systems The latest version of the Marine Installation Drawing Set relevant for the lubri- cating oil system (DG 9722) is provided on the WinGD webpage under the fol- lowing link: MIDS 4.3.1 Lubricating oil requirements The validated lubricating oils were selected in co-operation with the oil suppliers. -

Page 93: Main Lubricating Oil System Components

4 Ancillary Systems X72DF 4.3 Lubricating oil systems Main lubricating oil system components Positive displacement screw pumps with built-in safety valves, or centrifugal Lubricating oil pump pumps (for pump capacities refer to GTD): Type: Positive displacement The flow rate is to be within a tolerance of 0 to + 10 % of... - Page 94 4 Ancillary Systems X72DF 4.3 Lubricating oil systems Full-flow filter The drain from the filter is to be sized and fitted to allow free flow into the lubri- cating oil drain tank. The output required for the main lubricating oil pump to ‘back-flush’ the filter...

-

Page 95: System Oil

4 Ancillary Systems X72DF 4.3 Lubricating oil systems System oil The pistons of the WinGD X72DF engine feature highly efficient jet-shaker oil cooling. The system oil must have basic properties as follows: • Additive-type oil • A viscosity of SAE 30 •... -

Page 96: Changeover Between Cylinder Lubricating Oils

The validated additives and oils which can be used for this purpose can be found in the document Lubricants, which is provided on the WinGD webpage under the following link: Lubricants For additional information please contact the oil supplier. -

Page 97: The Icat Changeover Unit

4 Ancillary Systems X72DF 4.3 Lubricating oil systems Cyl. #1 Cyl. #2 Cyl. #3 HIGH BN / GRADE 1 LOW BN / GRADE 2 SM-0188 Figure 4-9 The iCAT changeover unit The following installation drawings are for twin-engine installations. The princi- ples of these drawings are also valid for single engine installations. -

Page 98: Dual Cylinder Lubricating Oil Installation Without Icat, Enabling

4 Ancillary Systems X72DF 4.3 Lubricating oil systems Manual changeover Alternatively, a manual changeover valve can be applied, if the specified max- imum sulphur content of the fuel exceeds 0.10 % sulphur m/m. This enables se- lection of the preferred cylinder lubricating oil (according to the fuel in use). -

Page 99: Service Tank And Storage Tank

4 Ancillary Systems X72DF 4.3 Lubricating oil systems Single grade cylinder In case the engine is specified for operation on liquid fuel with a sulphur content lubricating oil application of up to 0.10 % sulphur m/m (ultra low sulphur), then it is in any case sufficient to install a single low BN cylinder lubricating oil tank and consequently, no changeover device is required. -

Page 100: Electrical Trace Heating For System Side Cylinder Lubricating Oil

Spiral wrap pipe heating cable installation SM-0412 Figure 4-13 Trace heating cable arrangement Considering the ME power, LO feed rate and environment condition, WinGD specifies a minimum heating cable length ‘Lc’ as listed in the following table: Table 4-3 Heating cable specification No. - Page 101 The following requirements must be considered: • Insulation material such as mineral wool, glass fibre, or other material of class approved type can be applied. • WinGD recommends an insulation thickness of minimum 25 mm. Marine Installation Manual 2021-08 4-26...

-

Page 102: Maintenance And Treatment Of Lubricating Oil

4 Ancillary Systems X72DF 4.3 Lubricating oil systems 4.3.6 Maintenance and treatment of lubricating oil It is essential that engine lubricating oil is kept as clean as possible. Water and solid contaminants held in suspension are to be removed using centrifugal sep- arators which operate in bypass to the engine lubricating system. -

Page 103: Drain Tank

4 Ancillary Systems X72DF 4.3 Lubricating oil systems 4.3.7 Drain tank The engine is designed to operate with a dry sump: the oil returns from the bear- ings, flows to the bottom of the crankcase and through strainers into the lubri- cating oil drain tank. -

Page 104: Arrangement Of Vertical Lubricating Oil Drains For 6-Cylinder Engines

4 Ancillary Systems X72DF 4.3 Lubricating oil systems Arrangement of vertical lubricating oil drains Proposal to determine final position in accordance with shipyard Alternatively the oil drains may also be arranged symmetrically on port/fuel pump side. SM-0038 Figure 4-15 Arrangement of vertical lubricating oil drains for 6-cylinder engines... - Page 105 4 Ancillary Systems X72DF 4.3 Lubricating oil systems NOTE The data in the following tables represent the state of data as of the year 2021 and earlier. To obtain the latest data please contact the rele- vant classification society. Table 4-4...

- Page 106 4 Ancillary Systems X72DF 4.3 Lubricating oil systems Table 4-5 Minimum inclination angles for full operability of the engine (2) Classification societies (overview see Appendix, Table 9-1, 9-1) Year of latest update by Class 2018 2020 2018 Main and auxiliary engine Abbreviation 4/1/3/2.2/2.2.1...

- Page 107 4 Ancillary Systems X72DF 4.3 Lubricating oil systems Table 4-6 Minimum inclination angles for full operability of the engine (3) Classification societies (overview see Appendix, Table 9-1, 9-1) RINA Year of latest update by Class 2020 2019 2021 2018...

-

Page 108: Fuel Gas System

The latest version of the Marine Installation Drawing Set relevant for the gas fuel system (DG 9727) is provided on the WinGD webpage under the following link:... -

Page 109: Operating Principles

4.4.2 Operating principles The WinGD X-DF engines are normally installed for dual-fuel operation, where the engine can operate in either gas or diesel mode. The operating mode can be changed while the engine is running, within certain limits, without interruption of power generation. - Page 110 4 Ancillary Systems X72DF 4.4 Fuel gas system Compression & Ignition Scavenging gas admission Expansion SM-0112 Figure 4-16 Lean burn with pilot ignition Air to fuel gas ratio SM-0111 Figure 4-17 Lean-burn operation window Marine Installation Manual 2021-08 4-35...

-

Page 111: Gas Specifications

4 Ancillary Systems X72DF 4.4 Fuel gas system 4.4.3 Gas specifications As a dual-fuel engine, the X-DF engine is designed for continuous service in gas or in diesel operating mode. For continuous operation without reduction in rated output, the gas which is used as the main fuel in gas operating mode must fulfil... -

Page 112: Methane Number Dependent Engine Output

4 Ancillary Systems X72DF 4.4 Fuel gas system Methane number dependent engine output The Methane Number (MN) has an influence on the maximum available power output. maximum engine power SM-0036 Figure 4-18 Maximum achievable power Methane number calculation An application provided by the European Association of Internal Combustion Engine Manufacturers (EUROMOT) allows calculating the methane number of natural gas mixtures. -

Page 113: Fuel Gas Supply System

4 Ancillary Systems X72DF 4.4 Fuel gas system 4.4.4 Fuel gas supply system Fuel gas can typically be stored as LNG at atmospheric pressure, or be pressur- ised. The design of the external Fuel Gas Supply System (FGSS) may vary, how- ever it should provide natural gas with the correct temperature and pressure to the engine. -

Page 114: Section View Of An Integrated Membrane Tank

4 Ancillary Systems X72DF 4.4 Fuel gas system Ship hull Fixtures Fuel tank Insulation wall SM-0740 Figure 4-19 Section view of an integrated membrane tank As specified by the IGC Codes, the Type A tank must have a second barrier to Free-standing –... -

Page 115: Section View Of A Free-Standing Type B Tank Of Moss Design

4 Ancillary Systems X72DF 4.4 Fuel gas system Free-standing – Same as the Type A tank, the Type B tank is also designed to be non-pressurised Type B tank and will respond to pressure increase by expansion. Consequently, it is also as important to control the pressure increase. - Page 116 4 Ancillary Systems X72DF 4.4 Fuel gas system Depending on the arrangement of the vessel, the Type C tank can also be ar- ranged top-side (on the deck) if this is preferred (see Figure 4-23). For example, this could be particularly useful if the hold space is used for other bulk materials.

-

Page 117: Supplying Fuel Gas

LNG is forced to evaporate by an external heat source, the resulting gas is re- ferred to as Forced Boil-Off Gas (FBOG). For WinGD’s low-pressure X-DF en- gines this is at a maximum pressure of 16 bar (g). The fuel gas produced from the vaporiser can also feed the gensets by passing through a pressure reduction valve to match the required pressure. -

Page 118: Pressurised Type C Tank Solution With Nbog Handling By The

4 Ancillary Systems X72DF 4.4 Fuel gas system Pressurised FGSS If an LNG tank is designed to withstand pressure (along with the FGSS), then generally the system will be less complex than a system with a non-pressurised tank (along with the FGSS). The system will be less complex since the NBOG management will not be as demanding as for the other non-pressurised systems. -

Page 119: Pressurised Type C Tank Solution With Nbog Handling By The

4 Ancillary Systems X72DF 4.4 Fuel gas system Pressurised Type C tank solution Emergency pressure release with NBOG handling by From the bunkering station the gensets and the main engine Low-pressure vaporiser Up to 16 bar(g) Type C tank X-DF... -

Page 120: Re-Liquefaction Process

4 Ancillary Systems X72DF 4.4 Fuel gas system Re-liquefaction process An on-board re-liquefaction system recovers excess NBOG in the FGSS and re- turns it to the cargo tanks. This re-liquefaction process reduces the pressure in the system without having to dispose the fuel gas through the GCU, which is also known as NBOG flaring. - Page 121 4 Ancillary Systems X72DF 4.4 Fuel gas system Sub-cooler Refrigerator Ship hull Fixtures Fuel tank Insulation wall Cryogenic submerged pump SM-0745 Figure 4-27 An LNG sub-cooler within an integrated tank The advantages of this approach are that it is a much simpler system setup re- quiring usually a smaller plant size.

-

Page 122: Fuel Gas Supply Pressure

4 Ancillary Systems X72DF 4.4 Fuel gas system 4.4.5 Fuel gas supply pressure Layout of the The engine and the FGSS are laid out such that unrestricted engine power output fuel gas supply system is ensured for all gas qualities down to a lower heating value of 28 MJ/Nm . -

Page 123: Design Fuel Gas Supply Pressure Requirements

Rating on R2 ... R4 line Minimum gas pressure [bar(g)] SM-0739 Figure 4-28 Design fuel gas supply pressure requirements Rating-specific information is available from WinGD’s engine layout applica- tion GTD. Case 1 — Example of fuel Assumptions: gas supply pressure •... - Page 124 This would result in compressor operation of a lower efficiency. • WinGD recommends selecting an LHV of 32 MJ/Nm for normal condi- tion. Even if designed for this LHV, the engine can still operate with high output if the fuel gas is supplied with an LHV of 28MJ/Nm (e.g.

-

Page 125: Fuel Gas Supply Pressure Control At The Engine Inlet

X72DF 4.4 Fuel gas system Advantage of variable WinGD recommends energy-saving variable fuel gas supply pressure to the fuel gas supply pressure iGPR or the GVU inlet. If the fuel gas is supplied by means of a compressor, the savings can be significant, while for supply by means of an LNG pump, the sav- ings are minor. -

Page 126: Fuel Gas Supply Pressure Control At The Gvu Inlet

4 Ancillary Systems X72DF 4.4 Fuel gas system set-point offset Fuel Gas Propulsion Supply System Control System (FGSS) (PCS) set-point Engine Control System (ECS) - Set-point of the fuel gas supply pressure at the GVU inlet set-point - Fuel gas supply pressure offset to compensate for:... -

Page 127: On-Engine Integrated Gas Pressure Regulation Unit

On-engine integrated gas pressure regulation unit The X-DF engine requires precise regulation of gas pressure with a timely re- sponse to changing load conditions. WinGD has developed the Integrated Gas Pressure Regulation (iGPR) unit, which encompasses all performance and safety... - Page 128 4 Ancillary Systems X72DF 4.4 Fuel gas system The iGPR consists of the following main components: Fuel gas pressure The fuel gas feed pressure to the engine must be adjusted within a narrow, regulating valve load-dependent pressure range. This adjustment will ensure that the fuel gas pressure in the engine’s common-rail piping fits to the load command.

-

Page 129: Off-Engine Gas Valve Unit

GVU performs a gas leakage test before the engine starts operating on fuel gas. WinGD supports two different types of gas valve units: The GVU without housing, e.g. GVU-OD™ (open design) from Wärtsilä (see GVU without housing Figure 4-33), must be installed in an explosion-proof GVU room. - Page 130 4 Ancillary Systems X72DF 4.4 Fuel gas system from fuel gas supply system Forced engine room ventilation Engine room: gas safe area Double-wall fuel gas pipe Gas venting pipe GVU enclosure Annular pipe / GVU enclosure venting Gas detector Piston underside gas detection...

-

Page 131: Fuel Gas Venting

4 Ancillary Systems X72DF 4.4 Fuel gas system Gas filter The filter is a full-flow unit, preventing impurities from entering the engine’s fuel gas system. The pressure drop over the filter is monitored and an alarm is acti- vated when the pressure drop is higher than the permitted value, which is caused by a dirty filter. -

Page 132: Purging By Inert Gas

GVU. The fuel gas piping system must be depressurised and any remaining fuel gas must be removed by an inert gas (e.g. nitrogen). For this purpose, the piping of the WinGD main engine and the iGPR or the GVU are equipped with inert gas connections. -

Page 133: Purity Of Inert Gas (Engines With Igpr)

4 Ancillary Systems X72DF 4.4 Fuel gas system Purging gas properties For purging, WinGD requires an inert gas (typically nitrogen) with the following properties: Table 4-8 Purity of inert gas (engines with iGPR) Requirement Property Value IGF requirements Content of mixture out of N... - Page 134 4 Ancillary Systems X72DF 4.4 Fuel gas system The design principles of an inert gas release valve are similar to that of a safety valve. The valve opening section is designed based on the desired flow velocity and the pressure differential before and after the valve. The valve supplier must...

-

Page 135: Fuel Gas Leak Test

4 Ancillary Systems X72DF 4.4 Fuel gas system 4.4.10 Fuel gas leak test After first-time system assembly or maintenance work on the fuel gas piping, a leak test of the fuel gas pipe on the engine side and plant side is required to ensure that the fuel gas pipe is tight and that the components in the gas piping are working properly. -

Page 136: Pilot Fuel Oil System

Pilot fuel oil system Relevant installation information for the pilot fuel system is included in the fuel oil system Marine Installation Drawing Set (DG 9723), which is provided on the WinGD webpage under the following link: MIDS Flushing the pilot fuel oil... - Page 137 Pilot injection valves and pre-chambers are electronically controlled by the WinGD Engine Control System, which al- lows exact timing and duration of the injection. To have the best ignition and combustion stability, the pilot injection valves are combined with pre-chambers.

-

Page 138: Specification Of The Pilot Fuel Oil Filter On The System Side

4 Ancillary Systems X72DF 4.5 Pilot fuel oil system A 10 m filter is provided in the engine’s pilot fuel unit. Pilot fuel oil filter On the system side, a 10 m (absolute sphere passing mesh size) duplex filter as... -

Page 139: Fuel Oil System

X72DF 4.6 Fuel oil system Fuel oil system The latest version of the Marine Installation Drawing Set relevant for the fuel oil system (DG 9723) is provided on the WinGD webpage under the following link: MIDS Figure 4-39 shows the installation principle for maximum fuel flexibility. -

Page 140: Feed Pump - Low-Pressure Fuel Oil

4 Ancillary Systems X72DF 4.6 Fuel oil system Feed pump — Low-pressure fuel oil Type Positive displacement screw pump with built-in safety valve Capacity According to GTD: The capacity is to be within a tolerance of 0 to + 20 % of the GTD value, plus back-flushing flow of automatic self- cleaning filter, if such filter is installed. -

Page 141: Pressure Regulating Valve

4 Ancillary Systems X72DF 4.6 Fuel oil system Pressure regulating valve The pressure regulating valve returns the excess fuel oil that is not required by the main engine, recirculating more when the engine is at lower power. To avoid heating-up of the fuel by recirculation, the return pipe is designed with cooling ribs. -

Page 142: Mixing Unit

For changing over between heavy fuel oil and marine diesel oil (MDO/MGO) and vice versa, as well as for operation on distillate fuel, refer to the separate Concept Guidance (DG 9723), which is provided on the WinGD webpage under the following link:... -

Page 143: Booster Pump - High-Pressure Fuel Oil

4 Ancillary Systems X72DF 4.6 Fuel oil system Booster pump — High-pressure fuel oil The fuel oil booster pump delivers the fuel to the engine via a fuel oil end-heater for HFO operation. Type Positive displacement screw pump with built-in safety valve... -

Page 144: Viscometer

A chiller unit (cooling from refrigeration) is not required if the fuel properties are in line with the latest ISO 8217:2017 specification. Such a unit would only be needed for off-spec fuels that are not supported by WinGD. Type Tubular or plate type heat exchanger, suitable for diesel oils... -

Page 145: Fuel Oil Filters - Arrangement 'A

(from 60 % to 90 % approximately). Because of the complication this vari- ation can cause, the nominal grade for filtration is not used in the following. NOTE WinGD provides all filter mesh sizes in absolute (abs.) values. Arrangement ‘A’ of fuel oil filters (see Figure 4-42, ... -

Page 146: Fuel Oil Filter Arrangement 'A

4 Ancillary Systems X72DF 4.6 Fuel oil system Option 1 & Option 2: Only 1 automatic self-cleaning filter to be installed: either before the HFO/LSHFO piping HFO/LSHFO MDO/MGO engine inlet (hot side), or after the MDO/MGO piping low-pressure feed pump... -

Page 147: Specification Of Automatic Self-Cleaning Filter In Feed System

4 Ancillary Systems X72DF 4.6 Fuel oil system The 10 m abs. filter can be installed in two different locations: Option 1 Filter installation in the feed system: In this position the maximum 10 m abs. filter can be designed for a lower flow rate compared to the installation in the booster system. -

Page 148: Specification Of Automatic Self-Cleaning Filter In Booster System

4 Ancillary Systems X72DF 4.6 Fuel oil system Option 2 Filter installation in the booster circuit: The maximum 10 m abs. filter is installed in the booster circuit close to engine inlet. The filter needs to be laid out for a maximum working temperature of 150 °C. -

Page 149: Specification Of Duplex Filter In Booster System

4 Ancillary Systems X72DF 4.6 Fuel oil system Duplex filter The second filter in Arrangement ‘A’ is a duplex filter of recommended max- imum 25 m abs. A coarser filter is also acceptable. The duplex filter is of manual cleaning type and is installed in the booster system close to engine inlet. This filter type is sufficient as most particles are already removed by the 10 m filter as... -

Page 150: Fuel Oil Filter - Arrangement 'B

Arrangement ‘B’ does not include secondary duplex filtration. It lacks the indi- cation of overall performance of the fuel oil treatment system and gives no indi- cation when the automatic self-cleaning filter fails. NOTE WinGD recommends Arrangement ‘A’, as this is a best practice solu- tion. Marine Installation Manual 2021-08... -

Page 151: Fuel Oil System With Only Mdo/Mgo Or Mgo

4 Ancillary Systems X72DF 4.6 Fuel oil system 4.6.2 Fuel oil system with only MDO/MGO or MGO If the main engine is designed for only MDO/MGO or MGO fuel oil, the system may be simplified in comparison to the conventional system specified in section 4.6.1, ... -

Page 152: Fuel Oil Feed Pump

Flushing the fuel oil system For flushing of the fuel oil system refer to the latest version of the relevant In- struction (DG 9723), which is provided on the WinGD webpage under the fol- lowing link: Instruction for flushing - Fuel oil system... -

Page 153: Fuel Oil Treatment

4.6.4 Fuel oil treatment The latest version of the Concept Guidance for fuel oil treatment (DG 9723) is provided on the WinGD webpage under the following link: Fuel oil treatment Settling tanks Gravitational settling of water and sediment from modern heavy fuel oils is an extremely slow process due to the small difference in densities. - Page 154 4 Ancillary Systems X72DF 4.6 Fuel oil system Separators without These separators are self-adjusting to the fuel properties and self-cleaning. Sep- gravity discs arators without gravity discs operate as combined purifiers-clarifiers; thus water and sediment separation is integrated in one unit. The manufacturers claim ex- tended periods between overhaul.

-

Page 155: Pressurised Fuel Oil System

A best-practice automatic control of diesel oil cooler activation 4.6.6 Fuel oil specification The validated fuel oil qualities are published in the document Diesel engine fuels provided on the WinGD webpage under the following link: Fuel qualities Marine Installation Manual 2021-08... -

Page 156: Fuel Oil Viscosity-Temperature Dependency

4 Ancillary Systems X72DF 4.6 Fuel oil system 4.6.7 Fuel oil viscosity-temperature dependency The fuel oil viscosity depends on its temperature. This dependency is shown as graph in Figure 4-45. 150 160 400 000 100 000 400 000 200 000... -

Page 157: Air Supply System

4.7 Air supply system Air supply system The latest version of the Marine Installation Drawing Set relevant for the air supply system (DG 9725) is provided on the WinGD webpage under the fol- lowing link: MIDS Compressed air is required for engine starting and control, exhaust valve air springs, the washing plant for the scavenge air cooler(s), and general services. -

Page 158: Capacities Of Air Compressor And Receiver

4 Ancillary Systems X72DF 4.7 Air supply system 4.7.1 Capacities of air compressor and receiver The capacity of the air compressor and receiver depends on the total inertia (J of the propulsion system’s rotating parts. • Total inertia = engine inertia + shafting and propeller inertia •... -

Page 159: Control Air

4 Ancillary Systems X72DF 4.7 Air supply system 4.7.3 Control air Control air supply system Control air is supplied from the board instrument air supply system (see Figure 4-46, 4-82) providing air at 8 bar gauge pressure (within a range of 7.0-9.0 bar). -

Page 160: Leakage Collection System And Washing Devices

4.8 Leakage collection system and washing devices Leakage collection system and washing devices The latest version of the Marine Installation Drawing Set relevant for the leakage collection and washing system (DG 9724) is provided on the WinGD webpage under the following link: MIDS 4.8.1... -

Page 161: Solution 1: A Constantly-Drained Sludge Oil Trap With Separate Sludge Accumulation

A design proposal for the WinGD sludge oil trap is provided in Figure 4-47, ... -

Page 162: Solution 2: A Manually Bottom-Drained Sludge Oil Trap

Figure 4-47 Design proposal of WinGD’s sludge oil trap Operation of the For monitoring the operation of the sludge oil trap, WinGD recommends sludge oil trap checking the solids level in the sludge oil trap. The solids level can be assessed by opening the ‘Test valve A’... -

Page 163: Design Proposal Of A Manually Bottom-Drained Sludge Oil Trap

4 Ancillary Systems X72DF 4.8 Leakage collection system and washing devices The piston underside drain is collected in the sludge oil trap. The flow is ensured by venting some air at the top of the sludge oil trap and through an orifice (5 to 10 mm inner diameter) to the atmosphere. -

Page 164: Solution 3: An Automatically Bottom-Drained Sludge Oil Trap

4 Ancillary Systems X72DF 4.8 Leakage collection system and washing devices Solution 3: An automatically bottom-drained sludge oil trap Solution 3 description For the automatic bottom-drain solution, there is no continuous drain to the sludge oil tank. The advantage of this solution is that it provides fully automatic operation of the bottom drain without manual crew operation. -

Page 165: Design Proposal Of An Automatically Bottom-Drained Sludge Oil Trap

4 Ancillary Systems X72DF 4.8 Leakage collection system and washing devices Sight glass Orifice 5 - 10 mm Sludge oil drain Level Switch, High from piston underside (LSH) Pressure gauge Heating media outlet Thermometer Heating media inlet to the internal... -

Page 166: Draining Of Exhaust Uptakes

4 Ancillary Systems X72DF 4.8 Leakage collection system and washing devices 4.8.2 Draining of exhaust uptakes Engine exhaust uptakes can be drained automatically using a system as shown in Figure 4-50. Sectional detail for view A Ø108 x 5 Filling funnel... -

Page 167: Exhaust Gas System

4.9 Exhaust gas system Exhaust gas system The drawings relevant for the exhaust system (DG 9726) are provided on the WinGD webpage under the following link: MIDS An explosion relief device, examined and certified by the maker, with flameless Explosion relief devices... -

Page 168: Engine Room Ventilation

These values consider the ISO 8861 standard, however, in some circumstances the results are different from the standard calculations. In these cases, WinGD has provided the specific engine values and these should be considered before ISO 8861. It should be noted that the engine requires less combustion air when not running at full load. -

Page 169: Ventilation Arrangement

4 Ancillary Systems X72DF 4.10 Engine room ventilation 4.10.2 Ventilation arrangement It is important to follow the best practice methods for supplying the combustion air for main engine as described in this section. However, the final layout of the engine room ventilation is at the discretion of the shipyard. -

Page 170: Ventilation System Arrangement 1 - Engine Room Ventilation

This can reduce the effort required for scavenge air cooler cleaning. NOTE WinGD recommends selecting the optional secondary filter to further assist with removing fine particles and oil mist that may be present in the engine room. -

Page 171: Ventilation System Arrangement 2 - Direct Engine Ventilation

4 Ancillary Systems X72DF 4.10 Engine room ventilation Arrangement 2 — Direct engine ventilation system In this arrangement, the ventilation outlets are coupled with the turbocharger in- Layout lets. As the turbochargers directly receive all the outside ambient air drawn via the ventilation system, there is little chance for the temperature to increase. -

Page 172: Air Intake Quality

, there is a risk of increased wear to the piston rings and cylinder liners. NOTE WinGD advises to install a filtration unit on vessels regularly trans- porting dust creating cargoes, or trading in areas of atmospheric dust. Table 4-15 Guidance for air filtration... - Page 173 4 Ancillary Systems X72DF 4.10 Engine room ventilation Filter surface 8X72DF: MCR = 25.8 MW 14 16 Engine power [MW] SM-0167 Figure 4-54 Air filter size (example for 8-cyl. engine) Marine Installation Manual 2021-08 4-98...

-

Page 174: Outside Ambient Air Temperature

(i.e. no separate scavenge air heater is required). When operating below -10 °C, the exhaust gas waste gate must be designed project specifically. There- fore, please contact WinGD to get the project-specific layout. In addition, the re- quirements of the turbocharger maker as outlined in... -

Page 175: Piping

4.11.2 Flow rates and velocities For the different media in piping, WinGD recommends flow rates and velocities as stated in the document ‘Fluid velocities and flow rates’. Note that the given values are guidances figures only and that national standards may also be applied. -

Page 176: Pto, Pti, Pth And Primary Generator Applications

4.12 PTO, PTI, PTH and primary generator applications WinGD proposes various power take-off (PTO) and power take-in (PTI) ar- rangements that improve the efficiency and usability of the vessel’s propulsion chain. Some of the proposals are even suitable as power take-home devices (PTH), which enable the vessel to immobilise the main engine while staying ca- pable to move. -

Page 177: Arrangements For Pto, Pti, Pth

4 Ancillary Systems X72DF 4.12 PTO, PTI, PTH and primary generator applications [10] [11] [12] [13] [14] [15] [16] 2-speed Torsional Gear Tunnel Clutch tunnel elastic gear box gear box coupling Torsional/ bending Generator Frequency converter Clutch, elastic grey:depending on... -

Page 178: Application Constraints

The following table itemises the arrangements corresponding to the numbers in Figure 4-55, 4-102. Table 4-17 PTO / PTI / PTH arrangements for the WinGD X72DF [10] [11] [12] [13] [14] [15] [16] = the arrangement is possible = the arrangement may not be possible (too high nominal generator / el. motor torque due to too low nominal engine speed and/or high generator / el. - Page 179 The PTO / PTI / PTH application has to be analysed via the licensee with the Impact on ECS Propulsion Control System supplier and with WinGD for the Engine Control System. Shaft alignment study The added components can have an influence on the alignment layout.

-

Page 180: Service Conditions

4 Ancillary Systems X72DF 4.12 PTO, PTI, PTH and primary generator applications 4.12.4 Service conditions The service condition depends on the selected PTO/PTI/PTH option. De- pending on engine type there are one or several cases, which are illustrated below. Operation area... - Page 181 4 Ancillary Systems X72DF 4.12 PTO, PTI, PTH and primary generator applications power power curve 100% Valid for CPP with a frequency converter. Applicable to options: 2, 6, 8, 10, 12, 14 speed 100% prohibited operation area operation area SM-0202...

- Page 182 4 Ancillary Systems X72DF 4.12 PTO, PTI, PTH and primary generator applications power power curve 100% Valid for CPP without a frequency converter in combination with a two- speed tunnel gear. Applicable to options: 3, 4 speed 100% prohibited operation area...

-

Page 183: Engine Automation

SM-0261 Figure 5-1 Engine automation architecture DENIS WinGD’s standard electrical interface is DENIS, which is in line with approved propulsion control systems. DENIS The Diesel Engine CoNtrol and optImising Specification (DENIS) interface contains specifications for the engine management of all WinGD two-stroke marine diesel engines. -

Page 184: Denis Concept

5.2.1 Interface definition The WinGD interface defines the division of responsibilities between engine builder and PCS and AMS supplier, enabling the authorised suppliers to adapt their systems to the common rail system engines. The data bus connection pro- vides clear signal exchange. -

Page 185: Denis Specification

The intellectual property rights of this specification remain with WinGD. Hence the document is licensed only to the partner companies of WinGD developing propulsion control systems. These companies offer systems which are built ex- actly according to the engine designer’s specifications and are finally tested and approved by WinGD. -

Page 186: Propulsion Control Systems

The safety and the telegraph systems work independently and are fully operative even with the RCS out of order. Approved remote WinGD has an agreement with the marine automation suppliers listed in Table control system suppliers concerning development, production, sale and servicing of the RCS and the safety system. - Page 187 5 Engine Automation X72DF 5.4 Propulsion control systems Remote Control System Bridge Bridge wing (option) Bridge wing (option) Control room Remote Control & Safety Control Ship Alarm System Engine room Engine Control System Local panel SM-0282 Figure 5-3 Remote control system The electronic modules are in most cases built to be placed either inside the ECR console, or in a separate cabinet to be located in the ECR.

-

Page 188: Functions Of The Propulsion Control System

5 Engine Automation X72DF 5.4 Propulsion control systems 5.4.1 Functions of the propulsion control system Remote control system • Main functions Start, stop, reversing • Speed setting • Automatic speed program • The RCS is delivered with control panels for local, ECR and bridge control, Indications including all necessary order input elements and indications, e.g. -

Page 189: Options

5 Engine Automation X72DF 5.4 Propulsion control systems Options • Bridge wing control • Command recorder FULL HALF SLOW DEAD SLOW STOP DEAD SLOW SLOW HALF FULL SM-0099 Figure 5-4 Propulsion control Marine Installation Manual 2021-08... -

Page 190: Recommended Manoeuvring Characteristics

5 Engine Automation X72DF 5.4 Propulsion control systems 5.4.2 Recommended manoeuvring characteristics The vessel speed is adjusted by the engine telegraph. Manoeuvring, e.g. for leaving a port, is available from full astern to full ahead. For regular full sea op- eration, the engine power can be further increased up to 100 % CMCR power. -

Page 191: Recommended Manoeuvring Steps And Warm-Up Times For Fpp

5 Engine Automation X72DF 5.4 Propulsion control systems FPP manoeuvring steps The recommended manoeuvring steps and warm-up times for engine speed in- and warm-up times crease are indicated in Table 5-2. The engine speed-up/down program is included in the ECS. -

Page 192: Recommended Manoeuvring Steps And Warm-Up Times For Cpp

5 Engine Automation X72DF 5.4 Propulsion control systems CPP manoeuvring steps The recommended manoeuvring steps and warm-up times for engine power in- and warm-up times crease are shown in Table 5-3. The shipyard needs to include the engine power- up/down program in the PCS. -

Page 193: Alarm And Monitoring System

Flex system parameters such as fuel pressure, servo oil pressure, etc. º Flex system alarms provided by the ECS • WinGD provides Modbus lists specifying the display values and alarm con- ditions as part of the DENIS specification. Marine Installation Manual 2021-08... -

Page 194: Alarm Sensors And Safety Functions

This includes the alarm function and alarm level with corresponding setting and response time. The document Usual values and safeguard settings for the WinGD X72DF can be found under the following link: Usual values and safeguard settings Please note that the signalling time delays given in this document are maximum values. -

Page 195: Wingd Integrated Digital Expert

All the data is stored for the engine lifetime and is ac- cessible for the customer by a protected user account. With the permission of the customer, DCM enables WinGD to review ship com- pany data when required, allowing the first step towards remote support collab- oration. -

Page 196: Engine Diagnostic System

• An algorithm rule set is used to monitor, analyse and diagnose the sub- system components. It encapsulates WinGD’s expert knowledge by consid- ering calculations, documentation and investigations. •... -

Page 197: Wide Installation Process

With the integrated WinGD Spare Parts Cata- logue (SPC), component information and creating orders is simplified. WinGD provides the EDS software for a limited ‘free-trial’ period on all their en- Software availability gines. If there are any questions regarding this, please contact the WinGD repre- sentative. -

Page 198: Engine Dynamics

These must be considered throughout the design process of the vessel to avoid adverse impact on the vessel. In the document External forces and moments WinGD provides a complete list of the external forces and moments for each engine type. The latest version of... -

Page 199: External Mass Forces And Moments

6 Engine Dynamics X72DF 6.1 External mass forces and moments External mass forces and moments The external mass forces and moments are the resulting forces and moments pro- duced by reciprocating and rotating masses of the running gear (i.e. the engine's main oscillating masses) that are transmitted to the surrounding vessel via the foundation. -

Page 200: Countermeasures For Second Order Vertical Mass Moments

In cases where the investigation reveals a pos- sible problem, WinGD recommends to consider the installation of one of the fol- lowing countermeasures, designed to reduce the effects of second order vertical mass moments to acceptable values. -

Page 201: Electrically-Driven Compensator (External Compensator)

6 Engine Dynamics X72DF 6.1 External mass forces and moments If the mode shapes of the vertical hull girder vibrations are known, it might be possible to install only one iELBA on one of the engine sides. The calculation of... -

Page 202: Power Related Unbalance

6 Engine Dynamics X72DF 6.1 External mass forces and moments Power related unbalance The power related unbalance (PRU) values can be used to estimate the risk of un- acceptable levels of hull vibrations caused by external mass moments of first and second order. -

Page 203: External Lateral Forces And Moments

6 Engine Dynamics X72DF 6.2 External lateral forces and moments External lateral forces and moments The external lateral forces and moments (lateral engine vibrations resulting in ‘rocking’) are generated by the combustion process and to a small extent by the reciprocating masses of the running gear. -

Page 204: Lateral Vibration Types

6 Engine Dynamics X72DF 6.2 External lateral forces and moments 6.2.1 Lateral vibration types The resulting lateral forces and moments generate two different modes of lateral engine vibration, the H-type and X-type vibration; refer to Figure 6-5. The table of H-type and X-type vibration values is also provided in the link... -

Page 205: Reduction Of Lateral Vibration

NOTE WinGD recommends a stiff engine foundation design in the longitudinal and lateral directions, as this is always best practice in minimising hull vibrations. Lateral hydraulic type stays If needed, lateral stays must be fitted between the upper engine platform and the ship hull to avoid harmful resonance conditions. -

Page 206: Electrically-Driven Compensator

6 Engine Dynamics X72DF 6.2 External lateral forces and moments two stays two stays on fuel side on exhaust side SM-0097 Figure 6-7 General arrangement of hydraulic type stays for both-side installation Electrically-driven compensator If lateral stays cannot be installed, the following can be used to reduce lateral en- gine vibrations: •... -

Page 207: Longitudinal Vibration (Pitching)

Fuel Side SM-0211 Figure 6-8 Arrangement of longitudinal stays NOTE If longitudinal stays are required, WinGD recommends to install friction type stays according to WinGD design or alternatively, hy- draulic type stays from third-party suppliers. Marine Installation Manual 2021-08 6-10... - Page 208 6.3 Longitudinal vibration (pitching) Friction type stays Friction type stays can be installed according to WinGD design, on either the en- gine’s free end or driving end side. The layout of WinGD friction type stays, which is linked to the ‘Engine stays’ drawing for the application of longitudinal stays, must conform with the specifications.

-

Page 209: Torsional Vibration

6 Engine Dynamics X72DF 6.4 Torsional vibration Torsional vibration Torsional vibrations are generated by gas and inertia forces as well as by the ir- regularity of the propeller torque. It does not cause hull vibration (except in very rare cases) and is not perceptible in service, but produces additional dynamic stresses in the shafting system. -

Page 210: Low-Energy Vibrations

±50%. In case of uncertainty with regards to the oil flow, WinGD recommends in- stalling the main lubricating oil pumps with a higher flow capacity margin. The arrangement of the lubricating oil system (see Figure 4-8, ... -

Page 211: Pto/Pti Systems Effect On Torsional Vibration

(e.g. speed reduction, de-clutching of PTO / PTI branch) to be applied automatically, protecting the PTO / PTI components. For additional consideration about PTO / PTI application refer to section 4.12, 4-101, and for support regarding system layout, please contact WinGD. Marine Installation Manual 2021-08 6-14... -

Page 212: Axial Vibration

Axial vibration damper To limit the influence of axial excitations and reduce the level of vibration, all present WinGD engines are equipped with an integrated axial vibration damper. In most cases, this lowers the axial vibrations in the crankshaft to acceptable values, meaning no further countermeasures are required. -

Page 213: Whirling Vibration

6 Engine Dynamics X72DF 6.6 Whirling vibration Whirling vibration Whirling vibrations are generated when the shaft rotates and goes into transverse oscillations. If the shaft is out of balance, the resulting centrifugal forces will in- duce the shaft to vibrate. This vibration is commonly known as whirling vibration, bending vibration or lateral shaft vibration. -

Page 214: Hull Vibration

WinGD can provide, on request, a simplified FE engine model to enable the shipyard or design institute to predict the influence of the engine forces and mo- ments on the ship hull. -

Page 215: Countermeasures For Dynamic Effects

Where installations incorporate PTO arrangements (see Figure 4-55, 4-102), further investigation is required and WinGD should be contacted. Table 6-1 Countermeasures for external mass moments No. of cyl. Second order compensator... -

Page 216: Synchro-Phasing System In Twin Engines

Synchro-Phasing System in twin engines An available countermeasure for vibration reduction in twin engine vessels is WinGD’s Synchro-Phasing System (SPS). By changing the relative phase differ- ence of the two engines operating with the same speed, it is possible to neutralise vibrations of a selected frequency and the resulting resonance on the ship’s hull... -

Page 217: Components And Control

Main controller and user interface in ECR terface, where the relative phase difference angle (provided by WinGD vibration experts) can be entered. This enables the system to implement a closed loop con- trol of the set-points, which are a function of the difference between the reference phase angle and current phase angle. -

Page 218: Operating Modes And Restrictions

6.8 Countermeasures for dynamic effects NOTE Any phase angle value entered into the user interface must be previ- ously approved by WinGD’s Dynamics experts, as incorrect settings can lead to excessive vibrations. Operating modes and restrictions There are three operating modes: •... -

Page 219: Order Forms For Vibration Calculation & Simulation

6.9 Order forms for vibration calculation & simulation Order forms for vibration calculation & simulation WinGD provides additional support services to assist with system dynamics and vibration analysis. All questionnaires and forms can be downloaded from the WinGD webpage under the following link:... -

Page 220: Engine Emissions

7 Engine Emissions X72DF 7.1 Exhaust gas emissions Engine Emissions In 1973 an agreement on the International Convention for the Prevention of Pol- lution from Ships was reached. It was modified in 1978 and is now known as MARPOL 73/78. -

Page 221: Selective Catalytic Reduction

Low-pressure SCR The SCR reactor is located on the low-pressure side, after the turbine. For low-pressure SCR applications, WinGD has developed a 2-stroke engine in- terface specification that complies with the known low-pressure SCR system pro- viders. Low-pressure SCR is typically larger in volume than high-pressure SCR, but more flexible in installation position, as any after-turbocharger position is ac- ceptable. -

Page 222: High-Pressure Scr

Integrating the SCR reactor before the turbine allows the reactor to be designed in the most compact way due to the higher density of the exhaust gas. WinGD has developed and is systematically deploying high-pressure SCR solu- tions for the complete 2-stroke engine portfolio with single- and multi-turbo- charger applications. -

Page 223: Engine Noise

7 Engine Emissions X72DF 7.2 Engine noise Engine noise As the ship’s crew / passengers must be protected from the effects of machinery space noise, the maximum acceptable noise levels are defined by rules. In gen- eral, for new building projects, the latest IMO Resolution MSC.337 ‘Code of Noise Levels Onboard Ships’... - Page 224 7 Engine Emissions X72DF 7.2 Engine noise Lp [dB] LpA in dB(A) Airborne sound pressure levels with standard noise reduction 1) 2) Overall Max. overall average single point NR80 NR70 31.5 1) 8X72DF Octave band centre frequency in [Hz] 2) 5X72DF...

-

Page 225: Exhaust Noise

7 Engine Emissions X72DF 7.2 Engine noise 7.2.2 Exhaust noise In the engine exhaust gas system, the sound pressure level at funnel top (see Figure 7-6, 7-7) is related to: • Distance of 1 m from edge of exhaust gas pipe opening (uptake) •... -

Page 226: Sound Pressure Level At Funnel Top Of Exhaust Gas System

7 Engine Emissions X72DF 7.2 Engine noise Overall average Lp [dB] LpA in dB(A) 8X72DF 5X72DF 8X72DF 5X72DF NR60 31.5 Octave band centre frequency in [Hz] SM-0142 Figure 7-6 Sound pressure level at funnel top of exhaust gas system Marine Installation Manual... -

Page 227: Structure-Borne Noise

7 Engine Emissions X72DF 7.2 Engine noise 7.2.3 Structure-borne noise The vibrational energy is propagated via engine structure, bedplate flanges and engine foundation to the ship’s structure, which starts to vibrate and thus emits noise. The sound pressure levels in the accommodations can be estimated with the aid of standard empirical formulas and the vibration velocity levels. -

Page 228: Engine Dispatch

For further details refer to the latest version of the relevant Guideline (DG 0345), which is provided on the WinGD webpage under the following link: Guideline for engine protection Removal of rust preventing oils after transport 8.3.1... -

Page 229: Appendix

9 Appendix X72DF 9.1 Classification societies Appendix The Appendix gives an overview of the relevant classification societies and lists acronyms mentioned throughout this document in alphabetical order. Tables of SI dimensions and conversion factors can also be found here. Classification societies... -

Page 230: List Of Acronyms

9 Appendix X72DF 9.2 List of acronyms List of acronyms Table 9-2 List of acronyms Auxiliary Engine Diesel Fuel Oil, covering MDO (DMB, DFB) and MGO (DMA, DFA, DMZ, DFZ) Alarm Design Group Alarm and Monitoring System DMB, DFB /... - Page 231 9 Appendix X72DF 9.2 List of acronyms iCER Intelligent Control by Exhaust Recycling Marine Gas Oil (DMA, DFA, DMZ, DFZ) iELBA Integrated Electrical Balancer MIDS Marine Installation Drawing Set IGC (Code) Int. Code of the Construction and Equipment of Marine Installation Manual...

- Page 232 Steam Production Power Variable Exhaust Closing Synchro-Phasing System Viscosity Index Standard tuning Variable Injection Timing Seawater WECS WinGD Engine Control System Time Between Overhauls Waste Heat Recovery Turbocharger WiCE WinGD Integrated Control Electronics tEaT Temperature Exhaust gas After Turbocharger WiDE...

-

Page 233: Dimensions For Internal Combustion Engines

9 Appendix X72DF 9.3 SI dimensions for internal combustion engines SI dimensions for internal combustion engines Table 9-3 SI dimensions Symbol Definition SI-Units Other units Acceleration Area , cm , mm BSFC Brake specific fuel consumption kg/J, kg/(kWh), g/(kWh) Specific heat capacity... - Page 234 9 Appendix X72DF 9.3 SI dimensions for internal combustion engines Symbol Definition SI-Units Other units W, E, A, Q Energy, work, quantity of heat J, kJ, MJ, kWh Z, W Section modulus ΔT, ΔΘ, ... Temperature interval K, °C α...

-

Page 235: Approximate Conversion Factors

9 Appendix X72DF 9.4 Approximate conversion factors Approximate conversion factors Table 9-4 Conversion factors 1 in 25.4 mm 1 ft = 12 in 304.8 mm Length 1 yd = 3 feet 914.4 mm 1 statute mile = 1760 yds 1609.3 m... - Page 236 9 Appendix X72DF 9.4 Approximate conversion factors 1 in 6.45 cm 1 ft 929 cm Area 1 yd 0.836 m 1 acre 4047 m 1 sq mile (of land) = 640 acres 2.59 km Marine Installation Manual 2021-08...

- Page 237 Winterthur Gas & Diesel in brief Winterthur Gas & Diesel Ltd. (WinGD) is a leading developer of low-speed gas and diesel engines used for propulsion power in merchant shipping. WinGD sets the industry standard for environmental sustainability, reliability, efficiency and safety. WinGD provides designs, training and technical support to engine manufacturers, shipbuilders and ship operators worldwide.

Need help?

Do you have a question about the X72DF and is the answer not in the manual?

Questions and answers