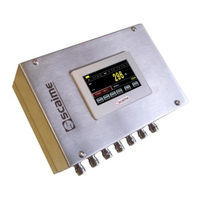

Scaime eNod4-F BOX Manuals

Manuals and User Guides for Scaime eNod4-F BOX. We have 3 Scaime eNod4-F BOX manuals available for free PDF download: Software User Manual, Quick Start Manual

Scaime eNod4-F BOX Software User Manual (90 pages)

Digital Process Transmitter

Brand: Scaime

|

Category: Transmitter

|

Size: 1 MB

Table of Contents

Advertisement

Scaime eNod4-F BOX Software User Manual (113 pages)

Digital Process Transmitter

Brand: Scaime

|

Category: Transmitter

|

Size: 2 MB

Table of Contents

Scaime eNod4-F BOX Quick Start Manual (34 pages)

Digital Process Transmitter with optional touch screen

Brand: Scaime

|

Category: Controller

|

Size: 1 MB

Table of Contents

Advertisement