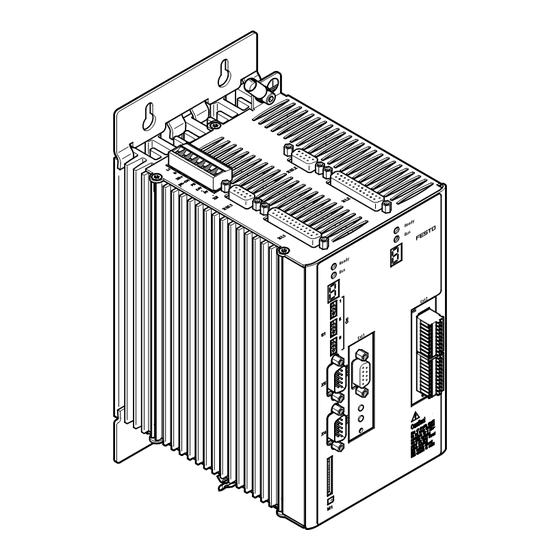

Festo CMMD-AS series Manuals

Manuals and User Guides for Festo CMMD-AS series. We have 3 Festo CMMD-AS series manuals available for free PDF download: Description, Installation Manual, Manual

Festo CMMD-AS series Description (246 pages)

Motor controller

Brand: Festo

|

Category: Controller

|

Size: 2 MB

Table of Contents

Advertisement

Festo CMMD-AS series Installation Manual (131 pages)

Motor controller

Brand: Festo

|

Category: Controller

|

Size: 6 MB

Table of Contents

Festo CMMD-AS series Manual (20 pages)

CANopen for Motor Controller

Brand: Festo

|

Category: Controller

|

Size: 2 MB

Table of Contents

Advertisement