Subscribe to Our Youtube Channel

Summary of Contents for Thermal Dynamics A-08950

-

Page 1: Service Manual

12mm CUTMASTER ™ PLASMA CUTTING SYSTEM Art # A-08950 Service Manual Rev. AH Date: April 25, 2012 Manual # 0-5077 Operating Features: 380V 400V 415V... - Page 2 1888, or visit us on the web at www.thermal-dynamics.com. This Operating Manual has been designed to instruct you on the correct use and operation of your Thermal Dynamics product. Your satisfaction with this product and its safe operation is our ultimate concern.

- Page 3 Manufacturer assumes no liability for its use. Plasma Cutting Power Supply CutMaster™ 12mm SL60 1Torch™ Service Manual Number 0-5077 Published by: Thermal Dynamics Corporation 82 Benning Street West Lebanon, New Hampshire, USA 03784 (603) 298-5711 www.thermal-dynamics.com Copyright 2009, 2010, 2011, 2012 by Thermadyne Corporation All rights reserved.

- Page 4 This Page Intentionally Blank...

-

Page 5: Table Of Contents

TABLE OF CONTENTS SECTION 1: GENERAL INFORMATION .................1-1 1.01 Notes, Cautions and Warnings ..............1-1 1.02 Important Safety Precautions ..............1-1 1.03 Publications ....................1-2 1.04 Note, Attention et Avertissement ..............1-3 1.05 Precautions De Securite Importantes ............1-3 1.06 Documents De Reference ................1-5 1.07 Declaration of Conformity ................1-6 1.08 Statement of Warranty ................1-7... - Page 6 TABLE OF CONTENTS SECTION 5 SYSTEM: SERVICE .....................5-1 5.01 General Maintenance .................5-1 5.02 Maintenance Schedule ................5-2 5.03 Common Faults ..................5-2 5.04 Fault Indicator .....................5-3 5.05 Basic Troubleshooting Guide ..............5-4 5.06 Power Supply Basic Parts Replacement ............5-6 5.07 Circuit Fault Isolation ..................5-8 5.08 Main Input and Internal Power Problems ..........5-11 5.09...

- Page 7 TABLE OF CONTENTS APPENDIX 1: SEQUENCE OF OPERATION (BLOCK DIAGRAM) ........A-1 APPENDIX 2: DATA TAG INFORMATION ................A-2 APPENDIX 3: TORCH PIN - OUT DIAGRAMS ..............A-3 APPENDIX 4: TORCH CONNECTION DIAGRAMS .............. A-4 APPENDIX 5: SYSTEM SCHEMATIC, 380/400/415V UNITS ..........A-6 APPENDIX 6: Publication History...................

- Page 8 This Page Intentionally Blank...

-

Page 9: Section 1: General Information

CUTMASTER 12mm SECTION 1: • Keep all fumes and gases from the breathing area. Keep your head out of the welding fume plume. GENERAL INFORMATION • Use an air-supplied respirator if ventilation is not adequate to remove all fumes and gases. • The kinds of fumes and gases from the plasma arc depend on 1.01 Notes, Cautions and Warnings the kind of metal being used, coatings on the metal, and the different processes. -

Page 10: Publications

CUTMASTER 12mm • Ventilate all flammable or explosive vapors from the workplace. 1.03 Publications • Do not cut or weld on containers that may have held combus- Refer to the following standards or their latest revisions for more tibles. information: • Provide a fire watch when working in an area where fire hazards 1. OSHA, SAFETY AND HEALTH STANDARDS, 29CFR 1910, may exist. obtainable from the Superintendent of Documents, U.S. • Hydrogen gas may be formed and trapped under aluminum Government Printing Office, Washington, D.C. 20402 workpieces when they are cut underwater or while using a water... -

Page 11: Note, Attention Et Avertissement

CUTMASTER 12mm 1.04 Note, Attention et Avertissement Dans ce manuel, les mots “note,” “attention,” et “avertissement” sont FUMÉE et GAZ utilisés pour mettre en relief des informations à caractère important. La fumée et les gaz produits par le procédé de jet de plasma peuvent Ces mises en relief sont classifiées comme suit : présenter des risques et des dangers de santé. NOTE •... - Page 12 CUTMASTER 12mm Nuance Minimum Nuance Suggerée • Montez et maintenez le matériel conformément au Code électrique Courant Arc Protective Numéro Numéro national des Etats-Unis. (Voir la page 5, article 9.) Moins de 300* • Débranchez l’alimentation électrique avant tout travail d’entretien ou de réparation. 300 - 400* • Lisez et respectez toutes les consignes du Manuel de consignes. 400 - 800* * Ces valeurs s’appliquent ou l’arc actuel est observé clairement.

-

Page 13: Documents De Reference

CUTMASTER 12mm 1.06 Documents De Reference 14. Norme AWSF4.1 de l’Association Américaine de Soudage, RECOM- MANDATIONS DE PRATIQUES SURES POUR LA PRÉPARATION À Consultez les normes suivantes ou les révisions les plus récentes ayant LA COUPE ET AU SOUDAGE DE CONTENEURS ET TUYAUX AYANT été faites à celles-ci pour de plus amples renseignements : RENFERMÉ DES PRODUITS DANGEREUX , disponible auprès de la American Welding Society, 550 N.W. LeJeune Rd., Miami, FL 1. -

Page 14: Declaration Of Conformity

* Extensive product design verification is conducted at the manufacturing facility as part of the routine design and manufacturing process. This is to ensure the product is safe, when used according to instructions in this manual and related industry standards, and performs as specified. Rigorous testing is incorporated into the manufacturing process to ensure the manufactured product meets or exceeds all design specifications. Thermal Dynamics has been manufacturing products for more than 30 years, and will continue to achieve excellence in our area of manufacture. Manufacturers responsible representative: Steve Ward Operations Director... -

Page 15: Statement Of Warranty

This warranty is exclusive and in lieu of any warranty of merchantability or fitness for a particular purpose. Thermal Dynamics will repair or replace, at its discretion, any warranted parts or components that fail due to defects in material or workmanship within the time periods set out below. Thermal Dynamics Corporation must be notified within 30 days of any failure, at which time Thermal Dynamics Corporation... - Page 16 CUTMASTER 12mm This Page Intentionally Blank GENERAL INFORMATION Manual 0-5077...

-

Page 17: Section 2 System: Introduction

Acrobat PDF format INTRODUCTION by going to the Thermal Dynamics web site listed below and clicking on Thermal Dynamics and then on the 2.01 How To Use This Manual Literature link: This Service Manual applies to just specification http://www.thermal-dynamics.com... -

Page 18: Power Supply Specifications

CUTMASTER 12mm 2.04 Power Supply Specifications CutMaster 12mm Power Supply Specifications 380 VAC (360 - 440 VAC), Three Phase, 50/60 Hz Input Power 400 VAC (360 - 440 VAC), Three Phase, 50/60 Hz NOTE: Some CutMaster 12mm models will only operate on 380-400V. Please check your †... -

Page 19: Input Wiring Specifications

CUTMASTER 12mm 2.05 Input Wiring Specifications CutMaster 12mm Power Supply Input Cable Wiring Requirements Input voltage Freq Power Input Suggested Sizes Flexible Cord Volts I max I eff Fuse (amps) (AWG) 50/60 3 Phase 50/60 Line Voltages with Suggested Circuit Protection and Wire Sizes Based on National Electric Code and Canadian Electric Code NOTE Refer to Local and National Codes or local authority having jurisdiction for proper wiring requirements. -

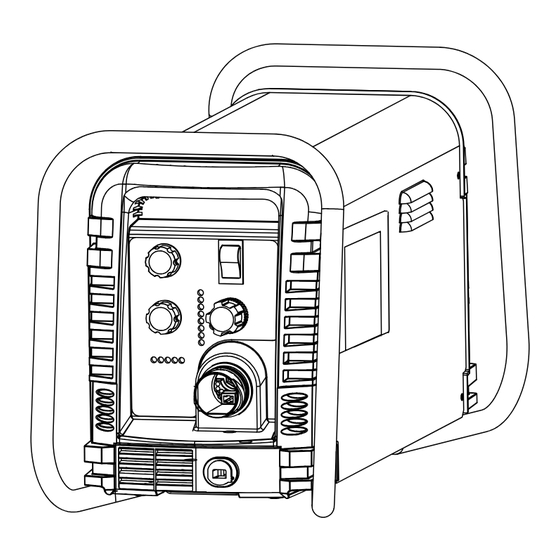

Page 20: Power Supply Features

CUTMASTER 12mm 2.06 Power Supply Features Handle and Leads Wrap Control Panel Torch Leads Receptacle Art # A-07942 Work Cable and Clamp Port for Optional Automation Interface Cable Filter Assembly Gas Inlet Port Art # A-08544 Input Power Cord INTRODUCTION Manual 0-5077... -

Page 21: Section 2 Torch: Introduction

CUTMASTER 12mm SECTION 2 TORCH: 2T.03 Specifications INTRODUCTION A. Torch Configurations 1. Hand/Manual Torch, Models 2T.01 Scope of Manual The hand torch head is at 75° to the torch handle. The hand torches include a torch handle and torch This manual contains descriptions, operating trigger assembly. -

Page 22: 04 Options And Accessories

CUTMASTER 12mm 2T.05 Introduction to Plasma F. Torch Ratings Manual Torch Ratings A. Plasma Gas Flow Ambient 104° F Plasma is a gas which has been heated to an ex- Temperature 40° C tremely high temperature and ionized so that it Duty Cycle 100% @ 60 Amps @ 400 scfh becomes electrically conductive. - Page 23 CUTMASTER 12mm B. Gas Distribution E. Parts - In - Place (PIP) The single gas used is internally split into plasma The torch includes a 'Parts - In - Place' (PIP) circuit. and secondary gases. When the shield cup is properly installed, it closes a switch.

- Page 24 CUTMASTER 12mm This Page Intentionally Blank INTRODUCTION 2T-4 Manual 0-5077...

-

Page 25: Section 3 System: Installation

CUTMASTER 12mm SECTION 3 SYSTEM: 3.03 Primary Input Power INSTALLATION Connections 3.01 Unpacking CAUTION 1. Use the packing lists to identify and ac- count for each item. Check your power source for correct voltage before plugging in or connecting the unit. 2. -

Page 26: Gas Connections

CUTMASTER 12mm 5. Connect the wires as follows. 3.04 Gas Connections For non CE units: Connecting Gas Supply to Unit The connection is the same for compressed air or high pressure cylinders. Refer to the following two subsections if an optional air line filter is to be installed. - Page 27 CUTMASTER 12mm Installing Optional Single - Stage Air Filter Installing Optional Two - Stage Air Filter Kit This optional two - stage air line filter is also An optional filter kit is recommended for im- for use on compressed air shop systems. Filter proved filtering with compressed air, to keep removes moisture and contaminants to at least 5 moisture and debris out of the torch.

- Page 28 CUTMASTER 12mm Using High Pressure Air Cylinders When using high pressure air cylinders as the air supply: 1. Refer to the manufacturer’s specifications for installation and maintenance proce- dures for high pressure regulators. 2. Examine the cylinder valves to be sure they are clean and free of oil, grease or any foreign material.

-

Page 29: Section 3 Torch: Installation

2. Put the Function Control switch in the SET If necessary, connect the torch to the Power Sup- position. ply. Connect only the Thermal Dynamics model 3. Place a welding filter lens in front of the SL60 / Manual or SL100 / Mechanical Torch to torch and turn ON the air. - Page 30 CUTMASTER 12mm Pinch Block Assembly Square Workpiece A-02585 Mechanical Torch Set - Up 3. The proper torch parts (shield cup, tip, start cartridge, and electrode) must be installed for the type of operation. Refer to Section 4T.07, Torch Parts Selection for details. INSTALLATION 3T-2 Manual 0-5077...

-

Page 31: Section 4 System: Operation

CUTMASTER 12mm SECTION 4 SYSTEM: OPERATION 4.01 Front Panel Controls / Features See Illustration for numbering Identification Output Current Control Sets the desired output current. Output settings up to 40 Amps may be used for drag cutting (with the torch tip contacting the workpiece) or standoff cutting. -

Page 32: Preparations For Operation

Check that the torch is properly connected. Only Set Operating Pressure Thermal Dynamics model SL60 / Manual or SL100 / 1. Place the Power Supply Function Control Mechanical Torches may be connected to this Power Supply. - Page 33 CUTMASTER 12mm Typical Cutting Speeds STANDOFF CutMaster 12mm Gas Pressure Settings Cutting speeds vary according to torch output am- perage, the type of material being cut, and operator Leads SL60 SL100 skill. Refer to Section 4T.08 and following for greater Length (Hand Torch) (Mechanized Torch)

- Page 34 CUTMASTER 12mm This Page Intentionally Blank OPERATION Manual 0-5077...

-

Page 35: Section 4 Torch: Operation

CUTMASTER 12mm 3. Install the replacement Electrode by push- SECTION 4 TORCH: ing it straight into the torch head until it OPERATION clicks. . Install the starter cartridge and desired tip 4T.01 Torch Parts Selection for the operation into the torch head. 5. -

Page 36: 03 General Cutting Information

CUTMASTER 12mm Bevel Angle Piloting The angle between the surface of the cut edge and Piloting is harder on parts life than actual cutting a plane perpendicular to the surface of the plate. because the pilot arc is directed from the electrode A perfectly perpendicular cut would result in a 0°... -

Page 37: 04 Hand Torch Operation

CUTMASTER 12mm Dross Torch When dross is present on carbon steel, it is com- monly referred to as either “high speed, slow speed, or top dross”. Dross present on top of the plate is normally caused by too great a torch to plate dis- tance. - Page 38 CUTMASTER 12mm Shield Cup With Straight Edge Trigger The drag shield cup can be used with a non conduc- tive straight edge to make straight cuts by hand. WARNING Trigger Release The straight edge must be non - conductive. Non-Conductive Straight Edge Cutting Guide Art # A-03383...

- Page 39 CUTMASTER 12mm Piercing With Hand Torch 1. The torch can be comfortably held in one hand or steadied with two hands. Position the hand to press the Trigger on the torch handle. With the hand torch, the hand may Trigger be positioned close to the torch head for maximum control or near the back end for Trigger Release...

-

Page 40: 05 Gouging

CUTMASTER 12mm 4T.05 Gouging NOTE The gas preflow and postflow are a charac- teristic of the power supply and not a func- tion of the torch. WARNING When the shield cup is properly installed, Be sure the operator is equipped with proper there is a slight gap between the shield cup gloves, clothing, eye and ear protection and and the torch handle. -

Page 41: 06 Mechanized Torch Operation

CUTMASTER 12mm 4T.06 Mechanized Torch Operation Current Setting Current settings depend on torch travel speed, Cutting With Mechanized Torch mode of operation (hand or machine torch), and the amount of material to be removed. The mechanized torch can be activated by remote control pendant or by a remote interface device Lead Angle such as CNC. - Page 42 CUTMASTER 12mm D i r e c t i o n o f T o r c Standoff Distance r a v Straight Arc Trailing Arc A-02586 Leading Arc Mechanized Torch Operation For optimum smooth surface quality, the travel speed should be adjusted so that only the leading edge of the arc column produces the cut.

-

Page 43: 07 Parts Selection For Manual And Mechanized Torch Cutting

CUTMASTER 12mm 4T.07 Parts Selection for Manual and Mechanized Torch Cutting Tips: Shield DRAG TIP Cup Body, Shield Cap, Deflector 9-8237 CUTTING 9-8243 20A 9-8205 30A 9-8206 Shield Cup 40A 9-8207 9-8218 60A 9-8252 O-Ring No. 8-3488 Shield Cap, Drag DRAG SHIELD 40A 9-8244 CUTTING... -

Page 44: 08 Recommended Cutting Speeds For Sl60 Torch With Exposed Tip

CUTMASTER 12mm 4T.08 Recommended Cutting Speeds for SL60 Torch With Exposed Tip Type Torch: SL60 With Exposed Tip Type Material: Mild Steel Type Plasma Gas: Air Type Secondary Gas: Single Gas Torch Thickness Output Amperage Speed (Per Minute) Standoff Plasma Gas Press Flow (CFH) Pierce Pierce Height... -

Page 45: 09 Recommended Cutting Speeds For Sl60 Torch With Shielded Tip

CUTMASTER 12mm 4T.09 Recommended Cutting Speeds for SL60 Torch With Shielded Tip Type Torch: SL60 With Shielded Tip Type Material: Mild Steel Type Plasma Gas: Air Type Secondary Gas: Single Gas Torch Thickness Output Amperage Speed (Per Minute) Standoff Plasma Gas Press Flow (CFH) Pierce Pierce Height... -

Page 46: Patent Information

CUTMASTER 12mm PATENT INFORMATION Plasma Cutting Torch Patents The following parts are covered under U.S. and Foreign Patents as follows: Catalog # Description Patent(s) 9-8215 Electrode US Pat No(s) 6163008; 6987238 Other Pat(s) Pending 9-8213 Cartridge US Pat No(s) 6903301; 6717096; 6936786; 6703581;... - Page 47 CUTMASTER 12mm Catalog # Description Patent(s) 9-8245 Shield Cap US Pat No(s) 6914211; D496951 Other Pat(s) Pending The following parts are also licensed under U.S. Patent No. 5,120,930 and 5,132,512: Catalog # Description 9-8235 Shield Cap 9-8236 Shield Cap 9-8237 Shield Cup 9-8238 Shield Cap...

- Page 48 CUTMASTER 12mm This Page Intentionally Blank OPERATION 4T-14 Manual 0-5077...

-

Page 49: Section 5 System: Service

CUTMASTER 12mm SECTION 5 SYSTEM: SERVICE 5.01 General Maintenance Maintain more often Warning! if used under severe Disconnect input power before maintaining. conditions Each Use Visual check of torch tip and electrode Weekly Visually inspect the cables and leads. Replace as needed Visually inspect the torch body tip, electrode, start cartridge and shield cup 3 Months... -

Page 50: Maintenance Schedule

3. Metal too thick. ment. 4. Worn torch parts 5. Cutting current too low. Daily Operational Checks or Every Six Cutting 6. Non - Genuine Thermal Dynamics Hours: parts used 7. Incorrect gas pressure Check torch consumable parts, replace if dam-... -

Page 51: Fault Indicator

CUTMASTER 12mm 5.04 Fault Indicator Explanation of Faults " UNDER PRESSURE: Indicates that operating pres- At initial power up, two lights will temporarily illumi- sure is set too low and power supply output nate for 2-3 seconds to show the version of software used. power will be disabled. -

Page 52: Basic Troubleshooting Guide

CUTMASTER 12mm 5.05 Basic Troubleshooting Guide WARNING There are extremely dangerous voltage and power levels present inside this unit. Do not attempt to diagnose or repair unless you have had training in power electronics measurement and troubleshooting techniques. Problem - Symptom Possible Cause Recommended Action ON / OFF Switch 1. - Page 53 CUTMASTER 12mm Problem - Symptom Possible Cause Recommended Action FAULT & 80 PSI 1. Torch shield cup is loose. 1. Tighten shield cup by hand. Do not overtighten. indicators flashing. 2. Torch tip, electrode or starter 2. Turn OFF power supply. Remove shield cup. Install Gas flow is cycling cartridge missing. missing parts. ON and OFF. 3. Torch start cartridge is stuck. 3. Turn OFF power supply. Bleed down system pressure.

-

Page 54: Power Supply Basic Parts Replacement

CUTMASTER 12mm 5.06 Power Supply Basic Parts C. Filter Element Assembly Replacement Replacement The Filter Element Assembly is in the rear panel. For better system performance, the filter element should be checked per the Maintenance Schedule (Subsection 5.02), and either cleaned or replaced. WARNING 1. - Page 55 CUTMASTER 12mm 6. Disconnect the input line from the filter element assembly. Housing 7. Remove the filter element assembly through the rear opening. NOTE Filter Element If replacing or cleaning just the filter element refer (Cat. No. 9-7741) to the following illustration for disassembly. Spring O-ring (Cat.

-

Page 56: Circuit Fault Isolation

CUTMASTER 12mm 5.07 Circuit Fault Isolation Optional Two-Stage Filter Element Replacement The Two-Stage Air Filter has two Filter Elements. When WARNING the Filter Elements become dirty the Power Supply will continue to operate but cut quality may become unac- The following procedures should not be attempted ceptable. - Page 57 CUTMASTER 12mm C. Pre Power Up Tests E. Main Input and Internal Power Test 1. Connect Primary Line power to the unit. Prior to applying primary line power to the unit, perform the following checks to prevent component 2. Turn the ON/OFF SWITCH (SW1) to ON position failure or blowing primary fuses.

- Page 58 CUTMASTER 12mm F. Pilot Arc Test 4. While cutting keep the torch switch closed, bring the torch OFF the edge of the material. Activate or depress the torch switch (Activate • Cutting arc extinguishes START signal) to establish a pilot arc and note the following •...

-

Page 59: Main Input And Internal Power Problems

CUTMASTER 12mm 5.08 Main Input and Internal Power H. CNC INTERFACE TEST Problems If the unit has one of the two factory supplied options for CNC interface installed, proceed with this section, A. Primary input line fuse blows as soon as otherwise the tests are complete. - Page 60 CUTMASTER 12mm C. Gas flows with ON/OFF SWITCH in OFF F. UNDER PRESSURE FAULT. AC LED ON, position FAULT Indicator and 60 PSI LED flashing. Foreign debris has lodged in gas solenoid. 1. Air pressure source to unit is too low. a) Replace gas solenoid.

- Page 61 CUTMASTER 12mm H. PARTS-IN-PLACE (PIP) FAULT. The 4. Defective Logic PCB (PCB 3) FAULT Indicator and 70 PSI LED is a) Measure voltage at Main PCB between J2-16 flashing. to test point GND1 for 12VDC. If voltage is present, replace Logic PCB 1.

- Page 62 CUTMASTER 12mm K. AC LED ON, yellow TEMP LED is ON, red M. INTERNAL ERROR FAULT Indicator is flashing. FAULT Indicator and 90 PSI Indicator flashing Air flow through unit is restricted 1. There has been a microprocessor problem. a) Provide adequate airflow. See Ventilation a) Turn ON/OFF SWITCH to OFF position and Clearance Requirements section 2.04.

-

Page 63: Pilot Arc Problems

CUTMASTER 12mm 5.09 Pilot Arc Problems P. AC LED ON, TEMP LED OFF, GAS LED ON, Gas does not flow in SET mode using A. AC LED ON, TEMP LED OFF, GAS LED a machine torch with remote solenoid. ON. Nothing happens when torch switch Disconnect the gas solenoid SOL1 from the back of or remote switch is closed (Or CNC START the ATC connector. - Page 64 CUTMASTER 12mm B. SHORTED TORCH FAULT C. AC LED ON, TEMP LED OFF, GAS LED ON, gas flowing, DC LED OFF, Fault After torch switch is closed, gas flows for two (2) Indicators OFF, No arc in torch seconds then momentarily shuts OFF then back ON, FAULT INDICATOR flashes, and 85 PSI LED flashes.

-

Page 65: Main Arc And Controls Problems

CUTMASTER 12mm 5.10 Main Arc and Controls 5.11 CNC Interface Problems Problems A. Nothing happens when jumper is installed between J2-3 to J2-4. A. Main arc will not establish, LED D59 ON Main PCB remains ON while pilot arc is 1. -

Page 66: Test Procedures

CUTMASTER 12mm 5.12 Test Procedures B. Input Diode Module Test 1. Using an ohmmeter perform the tests in the A. Main Contactor (W1) Test chart Check continuity between: Input Diode Module L1 to T1 Meter (+) Meter (-) Indication MTH 2 Forward Bias L2 to T2 MTH 2... - Page 67 CUTMASTER 12mm D. IGBT Modules Test E. Output Diode Module Test 1. Disconnect transformer wires from Main PCB 1 1. Disconnect transformer wires from Main PCB terminals PRI 1 (A) and PRI 4 (D). terminal SEC 1. 2. Using an ohmmeter perform the following 2.

-

Page 68: Capacitor Pcb Layout & Signals

CUTMASTER 12mm 5.13 Capacitor PCB Layout & Signals MTH1 MTH8 MTH7 MTH5 MTH6 MTH3 MTH4 MTH2 Art # A-08841 *J3 CONNECTOR PINOUT CAPACITOR PCB 2 LAYOUT A. CAPACITOR PCB SIGNALS Signal Source-Destination J1-1 Capacitor bank A+ J1-5 Capacitor bank A- J2-1 Capacitor Bank B+ J2-5... - Page 69 CUTMASTER 12mm This Page Intentionally Blank Manual 0-5077 5-21 SERVICE...

-

Page 70: Logic Pcb Layout & Signals

CUTMASTER 12mm 5.14 Logic PCB Layout & Signals *J1 Pinout Art # A-08504_AB A. LOGIC PCB SIGNALS (Same for MAIN PCB J2) Signal Source/Destination J1-1 -VOUT (-) OUTPUT VOLTAGE J1-2 /TIP VOLTS Active high when tip is installed J1-3 TIP_SEN Approx. 100VDC while cutting with tip not in M-L contact w/work piece, Active low when tip... - Page 71 CUTMASTER 12mm Signal Source/Destination J1-5 J1-6 CUR_SET Current demand signal. Variable 1-4VDC J1-7 /RAR Active low when in Rapid Auto Restart mode J1-8 /INRUSH Active low after inrush time expires L-M J1-9 /W1_ON Active low to enable W1 contactor J1-10 SHDN Active low enables PWM circuit J1-11 /TRCH_SOL Active low to enable Torch Solenoid...

- Page 72 CUTMASTER 12mm B. LOGIC PCB LED INDICATORS NORMAL INDICATION FIRMWARE VERSION ERROR MESSAGE +12VDC MAX PRESSURE Over Pressure 90 PSI Internal Error 85 PSI Shorted torch 80 PSI Tip Missing 75 PSI Start Signal active during power up 70 PSI Parts-In-Place Fault (PIP) 65 PSI Input Power Fault...

- Page 73 CUTMASTER 12mm This Page Intentionally Blank Manual 0-5077 5-25 SERVICE...

-

Page 74: Main Pcb Layout & Signals

CUTMASTER 12mm 5.15 Main PCB Layout & Signals *J2 PINOUT PRI_4 J4 J3 I_DMD1 PRI_1 GND1 PRI_3 PRI_2 TIP1 SEC1 ELECTRODE1 +48V2 +12V2 -V_OUT1 +48V1 J8 J7 J6 J5 Art # A-08518_AB CHOKE1 SEC2 GND2 +12V1 WORK_1 MAIN PCB LAYOUT A. - Page 75 CUTMASTER 12mm B. LED INDICATORS J4-1 3.3VDC D59 PCR Indicates Pilot IGBT gate signal is ON D78 CSR I ndicates cutting arc has been established J4-2 J4-3 C. MAIN PCB TEST POINTS J4-4 Common GND1 Common J4-5 GND2 Common GND3 Common +12V1 +12VDC J5-1 +12VDC +48V1 +48VDC J5-2...

-

Page 76: Main Pcb Wiring Diagram

CUTMASTER 12mm 5.16 Main PCB Wiring Diagram To SW2 To Logic Pcb To SW1 To PCB2 SEC1 SEC1 CHOKE1 SEC2 SEC2 ELEC-1 Work Art # A-08902 Cable To ATC To ATC connector To SOL1 CM52 - Jumper To Automation To Fan To Fan To W1 CM82 - TS2... - Page 77 CUTMASTER 12mm This Page Intentionally Blank Manual 0-5077 5-29 SERVICE...

- Page 78 CUTMASTER 12mm This Page Intentionally Blank SERVICE 5-30 Manual 0-5077...

-

Page 79: Section 5 Torch: Service

CUTMASTER 12mm SECTION 5 TORCH: SERVICE Upper Groove 5T.01 General Maintenance with Vent Holes Must Remain Open NOTE Upper O-Ring in Correct Groove Refer to Previous "Section 5 System" for common and fault indicator descriptions. Threads Cleaning Torch Lower O-Ring Art # A-03725 Torch Head O-Ring Even if precautions are taken to use only clean air... -

Page 80: 02 Inspection And Replacement Of Consumable Torch Parts

CUTMASTER 12mm 5T.02 Inspection and Replacement 4. Remove the tip. Check for excessive wear (indi- cated by an elongated or oversized orifice). Clean of Consumable Torch Parts or replace the tip if necessary. Good Tip Worn Tip WARNING Disconnect primary power to the system before disassembling the torch or torch leads. -

Page 81: Section 6: Parts Lists

CUTMASTER 12mm SECTION 6: PARTS LISTS 6.01 Introduction A. Parts List Breakdown The parts list provide a breakdown of all replaceable components. The parts lists are arranged as follows: Section "6.03 Power Supply Replacement" Section "6.04 Major External Replacement Parts" Section "6.05 Front Panel Replacement Parts"... -

Page 82: Major External Replacement Parts

CUTMASTER 12mm 6.04 Major External Replacement Parts Item # Description Catalog # Cover with labels 9-0220 Base Enclosure Assembly 9-0118 Tube, roll handle 9-0121 Front Panel 9-0226 Rear Panel 9-0101 Art # A-08120 NOTE Illustration may vary slightly from unit. PARTS LIST Manual 0-5077... -

Page 83: Front Panel Replacement Parts

CUTMASTER 12mm 6.05 Front Panel Replacement Parts Item# Description Ref. Catalog # Output Current Control and Function Control Knobs 9-8527 Toggle - On/Off Switch SW1 9-0109 Work Cable with Clamp, 20 Ft / 6.1 m 9-0184 Not Shown: Wire harness (from SW1) w/EMI Choke (CE Power Supplies Only) 9-0247 Art # A-08123 NOTE... -

Page 84: Left Side Replacement Parts

CUTMASTER 12mm 6.06 Left Side Replacement Parts Item # Description Catalog # Main PCB Assembly PCB 1 9-0108 Logic PCB PCB 3 9-0214 Center Chassis Molded Plastic 9-0102 Fan, MOT 1, MOT 2 9-0104 Transformer, Main 9-0106 Inductor, Output 9-0105 Not Shown: Power Cable Strain Relief, for all units 9-0111... -

Page 85: Right Side Replacement Parts

CUTMASTER 12mm 6.07 Right Side Replacement Parts Item # Description Catalog # Contactor, 4 Pole 9-8587 Solenoid, 12V SOL1 9-0114 Spare Parts Box 7-3267 Spare Parts Box Cover 7-3266 Console Quick Disconnect 9-0161 Regulator, with knob and mounting nut 9-0115* Assembly, PCB, Input Capacitors PCB 2 9-0475... -

Page 86: Options And Accessories

CUTMASTER 12mm 6.08 Options and Accessories Description Catalog # Single - Stage Filter Kit (includes Filter & Hose) 7-7507 Replacement Filter Body 9-7740 Replacement Filter Hose (not shown) 9-7742 Replacement Filter Element 9-7741 Two - Stage Filter Kit (includes Hose & Mounting Screws Bracket, Filter Mounting (not shown) 9-9387 Two - Stage Air Filter Assembly... -

Page 87: Replacement Parts For Hand Torch

CUTMASTER 12mm 6.09 Replacement Parts for Hand Torch Item # Description Catalog # Torch Handle Replacement Kit (includes items No. 2 & 3) 9-7030 Trigger Assembly Replacement Kit 9-7034 Handle Screw Kit (5 each, 6-32 x 1/2” cap screw, and wrench) 9-8062 Torch Head Assembly Replacement Kit (includes items No. -

Page 88: Replacement Parts - For Mechanized Torches With Unshielded Leads

CUTMASTER 12mm 6.10 Replacement Parts - for Mechanized Torches with Unshielded Leads Item No. Qty Description Catalog No. Torch Head Assembly without leads (includes items 2, 3, and 14) 9-8220 Large O-ring 8-3487 Small O-ring 8-3486 PIP Switch Kit 9-7036 Unshielded Automated Leads Assemblies with ATC connectors 5 - foot / 1.5 m Leads Assembly with ATC connector 4-7850... - Page 89 CUTMASTER 12mm 5 & 6 A-07994_AB Manual 0-5077 PARTS LIST...

-

Page 90: Torch Consumable Parts Manual And Mechanized Torches

CUTMASTER 12mm 6.11 Torch Consumable Parts Manual and Mechanized Torches Tips: Shield DRAG TIP Cup Body, Shield Cap, Deflector 9-8237 CUTTING 9-8243 20A 9-8205 30A 9-8206 Shield Cup 40A 9-8207 9-8218 60A 9-8252 O-Ring No. 8-3488 Shield Cap, Drag DRAG SHIELD 40A 9-8244 CUTTING Shield... -

Page 91: Section 7: Replacement Procedures

CUTMASTER 12mm SECTION 7: REPLACEMENT B. Procedure PROCEDURES 1. Open the wrist strap and unwrap the first two folds of the band. Wrap the adhesive side firmly around your wrist. 7.01 Scope 2. Unroll the rest of the band and peel the liner from the copper foil at the opposite end. -

Page 92: Major External Parts

CUTMASTER 12mm 7.04 Major External Parts C. Tube Handle Replacement Tools required: T20 Torx Driver A. Cover Removal 1. Disconnect the Torch and Leads from the unit. Tools required: T20 Torx Driver 2. Remove the cover per subsection 7.04-A. 1. Remove the upper and lower screws which 3. -

Page 93: Front Panel Parts Replacement

CUTMASTER 12mm 7.05 Front Panel Parts Replacement D. Air Regulator Replacement Tools required: T20 Torx Driver Refer to section 6.05 for Front Panel Replacement Parts and overall detailed drawing. 1. Remove the cover per subsection 7.04-A. A. Current Control Potentiometer (A) Knob 2. -

Page 94: Left Side Internal Parts Replacement

CUTMASTER 12mm G. ON/OFF Switch (SW1) Replacement B. Main Transformer (T1) Replacement Tools required: T20 Torx Driver Tools required: T20 Torx Driver, ½” Nut Driver 1. Remove the cover per subsection 7.04-A. 1. Remove the Cover per subsection 7.04-A. 2. Disconnect the wires on the rear of the switch, 2. -

Page 95: Rear Panel Parts Replacement

CUTMASTER 12mm 7.07 Rear Panel Parts Replacement C. Output Inductor (L1) Tools required: T20 Torx Driver, ½” Nut Driver A. Filter Element Assembly Replacement 1. Remove the Cover per subsection 7.04-A. The Filter Element Assembly is in the rear panel. For 2. - Page 96 CUTMASTER 12mm B. Optional Single-Stage Filter Element 6. Disconnect the input line from the filter element assembly. Replacement 7. Remove the filter element assembly through the These instructions apply to power supplies where the rear opening. optional Single-Stage Filter has been installed. The Power Supply shuts down automatically when NOTE the Filter Element becomes completely saturated.

-

Page 97: Right Side Internal Parts Replacement

CUTMASTER 12mm 7.08 Right Side Internal Parts Replacement A. Capacitor PCB (PCB 2) Replacement Tools required: T20 Torx Driver 1. Remove the Cover per subsection 7.04-A. 2. Remove the eight screws securing PCB 2 to the Main PCB. 3. Install the replacement PCB by reversing the above steps. - Page 98 CUTMASTER 12mm This Page Intentionally Blank PARTS REPLACEMENT Manual 0-5077...

-

Page 99: Appendix 1: Sequence Of Operation (Block Diagram

CUTMASTER 12mm APPENDIX 1: SEQUENCE OF OPERATION (BLOCK DIAGRAM) ACTION: ACTION: ACTION: ACTION: RUN / Rapid Auto Restart / ON / OFF switch to ON Close external RUN / SET / LATCH disconnect switch. Rapid Auto Restart / switch to RUN RESULT: SET / LATCH switch RESULT:... -

Page 100: Appendix 2: Data Tag Information

CUTMASTER 12mm APPENDIX 2: DATA TAG INFORMATION West Lebanon, NH USA 03784 Manufacturer's Name and/or Logo, Location, Model and Revision Level, Serial Number M odel : and Production Code Dat e of M f r : Made in USA Type of Power Regulatory Standard Covering 1/ 3 Supply (Note 1) -

Page 101: Appendix 3: Torch Pin - Out Diagrams

CUTMASTER 12mm APPENDIX 3: TORCH PIN - OUT DIAGRAMS A. Hand Torch Pin - Out Diagram ATC Female Receptacle ATC Male Connector Front View Front View Negative / Negative / Plasma Plasma 8 - Open 8 - Ground 4 - Green / Switch 4 - Switch 7 - Open... -

Page 102: Appendix 4: Torch Connection Diagrams

CUTMASTER 12mm APPENDIX 4: TORCH CONNECTION DIAGRAMS A. Hand Torch Connection Diagram Torch: SL60 / SL100 Hand Torch Leads: Torch Leads with ATC Connector Power Supply: with ATC Receptacle Male ATC Leads ATC Female Receptacle Power Connector Torch Torch Supply Head Leads Black... - Page 103 CUTMASTER 12mm C. Automation Torch Connection Diagram Automated CutMaster Power Supply with ATC Torch Receptacle, Automated SL100SV Torch (w/ Solenoid on Positioning Tube), Torch Lead with ATC Connector ATC Female ATC Male Torch Receptacle Torch Leads Connector Power Supply Torch Head Torch Leads Socket Pin No.s...

-

Page 104: Appendix 5: System Schematic, 380/400/415V Units

CUTMASTER 12mm APPENDIX 5: SYSTEM SCHEMATIC, 380/400/415V UNITS PRI 2 PRI 2 PRI 1 PRI 1 PRI 4 PRI 4 PRI 3 PRI 3 BIAS SUPPLY MTH2 MTH2 MTH1 MTH1 +12VDC + C1-C4* + C1-C4* CHOKE /INRUSH CE UNITS ONLY MTH3 MTH3 MTH4... - Page 105 St Louis, MO 63017 USA St Louis, MO 63017 USA Date: Date: Date: Information Proprietary to THERMAL DYNAMICS CORPORATION. Information Proprietary to THERMAL DYNAMICS CORPORATION. Information Proprietary to THERMAL DYNAMICS CORPORATION. Thursday, March 27, 2008 Thursday, March 27, 2008 Thursday, March 27, 2008 Not For Release, Reproduction, or Distribution without Written Consent.

-

Page 106: Appendix 6: Publication History

CUTMASTER 12mm APPENDIX 6: Publication History Cover Date Rev. Change(s) Jan 9,2009 Manual released. May 29, 2009 Updated 400V/600V schematic in appendix per ECOB1399 Feb. 25, 2010 Updated CNC cable part numbers in section 6 per ECOB1637. Aug. 31, 2010 Correct Logic PCB part numbers and information in section 6 per ECOB1800. - Page 107 This Page Intentionally Blank...

- Page 108 THE AMERICAS Denton, TX USA U.S. Customer Care Ph: 1-800-426-1888 (tollfree) Fax: 1-800-535-0557 (tollfree) International Customer Care Ph: 1-940-381-1212 Fax: 1-940-483-8178 Miami, FL USA Sales Office, Latin America Ph: 1-954-727-8371 Fax: 1-954-727-8376 Oakville, Ontario, Canada Canada Customer Care Ph: 1-905-827-4515 Fax: 1-800-588-1714 (tollfree) EUROPE Chorley, United Kingdom...

Need help?

Do you have a question about the A-08950 and is the answer not in the manual?

Questions and answers