Table of Contents

Advertisement

OWNER'S MANUAL

System HVLP Turbine Sprayers

Important Safety Instructions

Read all warnings and instructions in this

manual. Save these instructions.

120V AC 50/60 Hz

System 2500t Sprayer with Two-Stage Turbine

Model 826000

5 psi (34 kPa, 0.3 bar) Maximum Working Pressure

System 3800t Sprayer with Three-Stage Turbine

Model 826001

6 psi (41 kPa, 0.4 bar) Maximum Working Pressure

System 4900t Sprayer with Four-Stage Turbine

Model 826004

8 psi (55 kPa, 0.5 bar) Maximum Working Pressure

Model descriptions are in Turbine Components Table on page 4.

Related Manuals

System ProCartt

. . . . . . . . . . . . . . . . . . . . . . . .

HVLP Turbine Gun

. . . . . . . . . . . . . . . . . . . . . . .

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440–1441

309247

309205

ECOPYRIGHT 2000, GRACO INC.

Graco Inc. is registered to I.S. EN ISO 9001

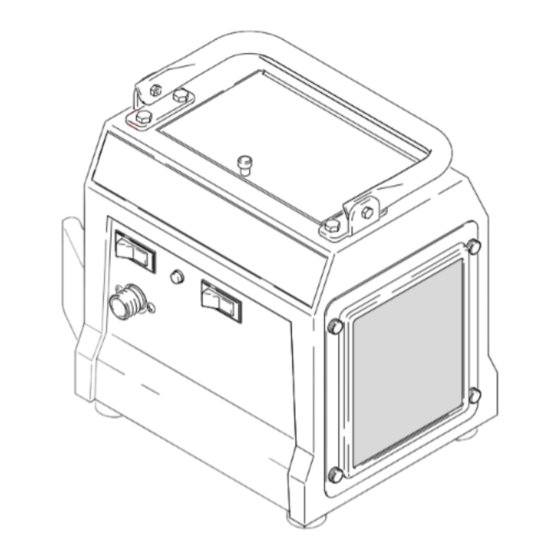

System 4900t Shown

309246

Rev. J

7947A

Advertisement

Table of Contents

Summary of Contents for Graco System 2500

-

Page 1: Related Manuals

..... . . 309205 7947A System 4900t Shown GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440–1441 ECOPYRIGHT 2000, GRACO INC. Graco Inc. is registered to I.S. EN ISO 9001... -

Page 2: Table Of Contents

....... . . This symbol alerts you to the possibility of damage to Graco Standard Warranty ..... . - Page 3 D Read all instruction manuals, tags, and labels before you operate the equipment. D Use the equipment only for its intended purpose. If you are not sure, call your Graco distributor. D Do not alter or modify this equipment. Use only genuine Graco parts.

-

Page 4: General Information

General Information System HVLP Turbine Sprayers Unpacking Turbine Sprayer The System 2500t, 3800t, and 4900t Sprayer, Unpack the turbine sprayer from the shipping carton, System ProCartt, and HVLP–Turbine Gun can spray and inspect for any possible shipping damage. If there most coatings or finishes currently being used for is any damage, call your distributor. -

Page 5: Component Identification And Function

Component Identification and Function 7947A Fig. 1 Air outlet Connection for air supply to HVLP–Turbine Guns (System 4900t units include quick connector) Power switch ON/OFF switch for turbine sprayer and rear outlet Storage compartment Provides storage for fluid set components Handle Folds flat for minimum storage space Cover... -

Page 6: Setup

Setup Grounding Prepare the Fluid D Always strain the fluid before you spray; this WARNING includes color, reducer, and hardeners if used. Improper installation or alteration of the grounding D When using a System HVLP Turbine Sprayer use a plug will result in a risk of electric shock, fire or slower-drying reducer or thinner to compensate for explosion that could cause serious injury or death. - Page 7 Setup Connect the Fluid and Air Supply 2. If using a spray gun cup (D): connect the cup to the gun fluid inlet (E). See Fig. 3 If using accessory remote pressure pot (F): D The System ProCartt provides the air supply for connect fluid supply hose (G) between remote the remote pressure pot.

- Page 8 Setup Fill the Cup or Remote Pressure Pot Spray Gun Cup WARNING The spray gun cup is pressurized by the gun’s air supply. To reduce the risk of serious injury from pressurized fluid or accidental spray from the gun, always turn off the air supply to the gun before you remove the spray gun cup.

- Page 9 Setup Prepare Surface to be Sprayed System ProCartt Cold Weather Operation To get proper adhesion, make sure surface is The System ProCartt uses a diaphragm compressor. completely clean. A new diaphragm may be stiff in cold weather. If cold enough, the diaphragm is too stiff to allow the Operating System HVLP Turbine Sprayer compressor motor to start (the unit hums).

-

Page 10: Shutdown

Shutdown Pressure Relief Procedure WARNING PRESSURIZED EQUIPMENT HAZARD The equipment stays pressurized until pressure is manually relieved. To reduce the risk of a serious injury from pressurized fluid, accidental spray from the gun, or splashing fluid, follow the Pressure Relief Procedure whenever you D Are instructed to relieve the pressure gallon 2 quart... -

Page 11: Maintenance

Maintenance Daily WARNING The System HVLP Turbine Sprayers are lifetime To avoid damage to the turbine and possible elec- lubricated. The only maintenance required is filter tric shock, never install a damp filter in the turbine. cleaning and replacement. The turbine filter must be clean at all times to provide CAUTION sufficient air flow to cool motor and atomize the fluid. - Page 12 Notes 309246...

-

Page 13: Troubleshooting

Troubleshooting PROBLEM CAUSE SOLUTION No fluid delivery No material, no remote Check container for material. container pressurization, hose or pickup tube clogged Check for leaks at the container gasket (2-quart pressure pot cover or 2 -gallon pressure pot wing nuts). Tighten wing nuts if loose. Check for air flow from male quick disconnect at compressor outlet (should be approx. -

Page 14: Repair

Repair Motor Brush Replacement WARNING NOTE: It is recommended that this procedure be Turn off turbine and unplug power for the following performed by an authorized service center. procedures. 1. Use System HVLP Turbine Sprayer System HVLP Turbine Sprayer Disassembly procedure on page 14 to take turbine apart. - Page 15 Repair Turbine/Motor Replacement The System 2500t, System 3800t, and System 4900t Turbine Sprayers each use a different turbine/motor. See the Turbine/Motor Replacement Kits in the Parts List on page 17 for a listing of replacement kit parts. See parts drawing on page 17. 1.

-

Page 16: Parts Drawing

Parts Drawing 16, 17 32, 40 7943C 309246... -

Page 17: Parts List

Parts List Part No. Description Part No. Description 276674 COVER, turbine 114279 SENSOR, pressure (System 197111 BASE PLATE, turbine 3800t and System 4900t) (System 2500t) 114280 LIGHT, indicator (System 3800t 192775 BASE PLATE, turbine and System 4900t) (System 3800t) 114293 SWITCH, rocker, red 192774 BASE PLATE, turbine... -

Page 18: Accessories

Accessories -Gallon (9.5 liter) PTFER coated Pot 240045 50 psi (345 kPa, 3.5 bar) Maximum Inlet Air Pressure -gallon (9.5 liter) capacity, steel tank. Includes air pressure regulator, gauge, and pressure relief valve. -gal (9.5 liter) paint tank liner (5 pack) 112077 04957 Ref. - Page 19 Accessories Notes: Standard Turbine Air Hose D See HVLP Fine Finish Systems Length (ft) Number brochure 300564 for all accessories. 241413 D Non-Silicone Lubricant 111265 (4 oz) is available for fluid seals and wear areas. Fluid Set (FS)/Spray Gun Number None 244115 244118...

- Page 20 Accessories 2-Quart (1.9 liter) Pressure Pot 287819 50 psi (345 kPa, 3.5 bar) Maximum Inlet Air Pressure 2-quart (1.9 liter) capacity, aluminum cup. Includes air pressure regulator, gauge, pressure relief valve, and rigid hook handle. WARNING Do not use 1,1,1-trichloroethane, methylene chloride, other halogenated hydrocarbon solvents, or fluids containing such solvents in the turbine spray system, which contains aluminum and/or galvanized-coated parts.

-

Page 21: Specifications

Accessories Lubricant Fluid Strainer (3 each) 240267 One, 4–ounce (113 gram) tube sanitary (non–silicone) Install on the end of the cup to strain the fluid and help lubricant for fluid seals and wear areas. eliminate surface blemishes and plugged tips. 100 mesh screen. -

Page 22: Graco Standard Warranty

With the exception of any special, extended, or limited warranty published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by Graco to be defective.

Need help?

Do you have a question about the System 2500 and is the answer not in the manual?

Questions and answers