Summary of Contents for ESAB Mig C170 3ph

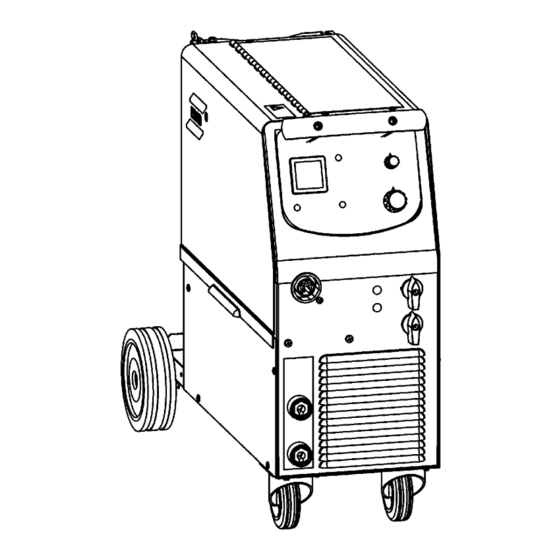

- Page 1 Mig C170 3ph Mig C200 3ph Mig C250 3ph ™ ™ ™ ™ Origo Instruction manual 0349 301 116 070103 Valid for serial no. 626...

-

Page 2: Table Of Contents

ENGLISH 1 DIRECTIVE ............2 SAFETY . -

Page 3: Directive

ESAB AB, Welding Equipment, SE--695 81 Laxå, Sweden, gives its unreserved guarantee that weld- ing power source Origo Mig C170 3ph/C200 3ph/C250 3ph from serial number 626 complies with standard IEC/EN 60974--1, in accordance with the requirements of directive (73/23/EEC) and adden- dum (93/68/EEC) and with standard IEC/EN 60974--10 in accordance with the requirements of direc- tive (89/336/EEC) and addendum (93/68/EEC). - Page 4 WARNING! Read and understand the instruction manual before installing or operating. WARNING ARC WELDING AND CUTTING CAN BE INJURIOUS TO YOURSELF AND OTHERS. TAKE PRECAU- TIONS WHEN WELDING. ASK FOR YOUR EMPLOYER’S SAFETY PRACTICES WHICH SHOULD BE BASED ON MANUFACTURERS’ HAZARD DATA. ELECTRIC SHOCK - - Can kill Install and earth the welding unit in accordance with applicable standards.

-

Page 5: Introduction

INTRODUCTION Origo Mig C170 3ph/C200 3ph/C250 3ph are step controlled power sources in a compact design, intended for welding with solid steel, stainless steel or aluminium wire as well as tubular wire with or without shielding gas.The possibility of welding with homogeneous wire/shielding gas and welding with gasless tubular wire is obtained by switching the + and -- connections on the switching terminal by the wire feed unit. -

Page 6: Installation

Duty cycle The duty cycle refers to the time as a percentage of a ten--minute period that you can weld at a cer- tain load without overloading. Enclosure class The IP code indicates the enclosure class, i. e. the degree of protection against penetration by solid objects or water. -

Page 7: Electrical Installation

Check that the unit is connected to the correct mains power supply voltage, and that it is protected by the correct fuse size. A protective earth connection must be made, in accordance with regulations. Rating plate with supply connection data Origo Mig C170 3ph Origo Mig C200 3ph Origo... -

Page 8: Operation

OPERATION General safety regulations for the handling of the equipment can be found on page 3. Read through before you start using the equipment! WARNING! Rotating parts can cause injury, take great care. WARNING! To prevent the reel sliding off the hub: Lock the reel in place by turning the red knob as shown on the warning label attached next to the hub. -

Page 9: Welding Without Gas

Welding without gas Wire feed pressure Start by making sure that the wire moves smoothly through the wire guide. Then set the pressure of the wire feeder’s pressure rollers. It is important that the pressure is not too great. Fig 1 Fig 2 To check that the feed pressure is set correctly, you can feed out the wire against an insolated object, e.g. -

Page 10: Overheating Protection

Straighten out the new wire 10--20 cm. File away burrs and sharp edges from the end of the wire before inserting it into the wire feed unit. Make sure that the wire goes properly into the feed roller track and into the outlet nozzle and the wire guide. -

Page 11: Fault Tracing

ORDERING OF SPARE PARTS Origo Mig C170 3ph/C200 3ph/C250 3ph is designed and tested in accordance with the international and European standards IEC/EN 60974- -1 and EN 60974- -10. It is the obligation of the service unit which has carried out the service or repair work to make sure that the product still conforms to the said standard. -

Page 12: Diagram

Diagram Origo Mig C170 3ph, 400- - 415V - - 12 - - dOC17253... - Page 13 Origo Mig C200 3ph, 400- - 415V - - 13 - - dOC17253...

- Page 14 Origo Mig C250 3ph, 400- - 415V - - 14 - - dOC17253...

- Page 15 Origo Mig C250 3ph, 230/400- - 415V - - 15 - - dOC17253...

-

Page 16: Ordering Numbers

Origo Mig C170 3ph/C200 3ph/C250 3ph Valid for serial no. 626- -XXX- -XXXX Ordering numbers 0349 308 670 Origo Mig C170 3ph 400--415V 3∼ ∼ ∼ ∼ 50/60Hz 0349 308 290 Origo Mig C200 3ph 400--415V 3∼ ∼ ∼ ∼ 50/60Hz... -

Page 17: Wear Components

Origo Mig C170 3ph/C200 3ph/C250 3ph Wear components (W. F. Mechanism 0455 890 890) Item Denomination Ordering no. Notes Pressure roller 0455 907 001 0367 556 001 Ø 0.6--0.8mm Fe, Ss, cored wire. 0367 556 002 Ø 0.8--1.0mm Fe, Ss, cored wire. -

Page 18: Accessories

Origo Mig C170 3ph/C200 3ph/C250 3ph Accessories Digital meter ......0349 302 598 Transformer kit for CO heater . - Page 19 - - 19 - - hints...

- Page 20 - - 20 - - hints...

- Page 21 - - 21 - - hints...

- Page 22 ESAB subsidiaries and representative offices Europe Asia/Pacific Representative offices NORWAY AS ESAB AUSTRIA BULGARIA CHINA Larvik ESAB Ges.m.b.H ESAB Representative Office Shanghai ESAB A/P Tel: +47 33 12 10 00 Vienna- -Liesing Sofia Shanghai Fax: +47 33 11 52 03 Tel: +43 1 888 25 11 Tel/Fax: +359 2 974 42 88 Tel: +86 21 5308 9922...

Need help?

Do you have a question about the Mig C170 3ph and is the answer not in the manual?

Questions and answers