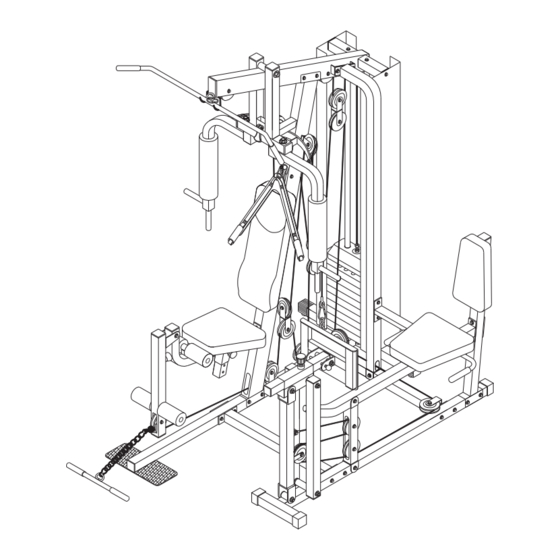

Summary of Contents for Bodyworx L7800LP

- Page 3 PART LIST PART NO: DESCRIPTION Q’TY MAIN BASE GUIDE ROD LEFT BASE RIGHT BASE SELECTOR SHAFT TOP PLATE WEIGHT STACK RUBBER DOUNT VERTICAL BEAM TOP CROSS BEAM SEAT SUPPORT SEAT ASSEMBLY UNIT LEG EXTENSION/ARM CURL BAR PRESS BAR LEFT PEC DECK ARM RIGHT PEC DECK ARM PRESS PIN SEAT...

- Page 4 PART NO: DESCRIPTION Q’TY PRESS BAR SHAFT M12*80MM HEX BOLT M10*125MM HEX BOLT M10*75MM HEX BOLT M10*70MM HEX BOLT M10*45MM HEX BOLT M10*30MM HEX BOLT M10*25MM HEX BOLT M8*115MM HEX BOLT M8*60MM HEX BOLT M8*45MM HEX BOLT M8*15MM HEX BOLT NYLON NUT NYLON NUT NYLON NUT...

- Page 5 STEP 01 PLACE RUBBER END CAP (39) ONTO BOTH ENDS OF LEFT BASE (03). INSERT GUIDE RODS (02) TO LEFT BASE (03) WITH M10*25MM BOLT (60), M10 WASHER (72) AS SHOWN. ATTACH MAIN BASE (01) TO LEFT BASE (03) USE STEEL PLATE (SHORT) (51) WITH M10*75MM BOLT (56), M10 WASHER (72) AND M10 NYLON NUT (68) AS SHOWN.

- Page 6 STEP 02 ATTACH THE RUBBER DOUNT (08) ONTO THE GUIDE ROD (02). SLIDE THE WEIGHT PLATE (07) AND TOP PLATE (06) OVER GUIDE ROD (02). GROOVED SIDE OF WEIGHT PLATES SHOULD FACE DOWN INSTALL 25MM ROUND BUSHING (45) INTO THE SELECTOR SHAFT (05). WITH PIN (46) THEN ATTACH THE SELECTOR SHAFT (05) INTO THE TOP PLATE (06) AS SHOWN.

- Page 7 STEP 03 PLACE 50*100MM SQUARE CAP (98) ONTO TOP CROSS BEAM (10). ATTACH TOP CROSS BEAM (10) ONTO THE VERTICLE BEAM (09) WITH M10*70MM BOLT (57), M10 WASHER (72) AND M10 NYLON NUT (68) AND CONNECT THE GUIDE RODS (02) TO THE TOP CROSS BEAM (10) AS SHOWN.

- Page 8 STEP 04 PLACE 50MM SQUARE CAP (41) ONTO BOTH ENDS OF LEG EXTENSION /ARM CURL BAR (13). ATTACH SEAT SUPPORT (11) TO VERTICLE BEAM (09), WITH STEEL PLATE (50) M10*125MM BOLT (55), M10 WASHERS (72), AND M10 NYLON NUT (68). ATTACH SEAT ASSEMBLY UNIT (12) TO SEAT SUPPORT (11) AS SHOWN.

- Page 9 STEP 05 1. PLACE 50MM SQUARE CAP (41) INTO BOTH ENDS OF PRESS BAR (14). 1. INSTALL OIL BUSHING (52) INTO THE PRESS BAR (14). 2. PLACE BUFFER (75) TO PRESS BAR (14) AS SHOWN. STEP 06 1. ATTACH PRESS BAR (14) TO TOP CROSS BEAM (10) WITH PRESS BAR SHAFT (53) AND OIL BUSHING (52) M16 WASHER (70) M16 NYLON NUT (66) AS SHOWN.

- Page 10 STEP 07 PLACE RUBBER CAP (40) ONTO BOTH ENDS OF LEFT BASE (79). ATTACH RIGHT BASE (04) AND RIGHT BACK BASE (93) ONTO LEFT BASE (79) AND MAIN BASE (01) USE WITH M10*70MM BOLT (57), M10 WASHER (72) AND M10 NYLON NUT (68) AS SHOWN. ATTACH LEFT UPRIGHT FRAME (80) ONTO RIGHT BACK BASE (93) AND TOP CROSS BEAM (10) AS SHOWN.

- Page 11 STEP 08 PLACE 50MM SQUARE END CAP (41) TO BOTH ENDS OF LEG PRESS CONNECTOR (84) AND LEG PRESS SUPPORT (85) AS SHOWN. INSTALL OIL BUSHING (52) INTO THE LEFT BASE (79) AND LEG PRESS SUPPORT (85) AS SHOWN. ATTACH LEG PRESS CONNECTOR (83,84), TO THE LEFT BASE (79), AND LEG PRESS SUPPORT (85) SECURE PRESS BAR SHAFT (89,90), M16 WASHERS (70), AND M16 NUTS (66) AS SHOWN.

- Page 12 -10-...

- Page 13 -11-...

- Page 14 CABLE ASSEMBLY START WITH WEIGHT STACK CABLE 2500MM (23) START BY THREADING END OF THE CABLE WITHOUT THE BALL OVER INTO PULLEY NO.1, OVER PULLEY NO.2, DOWN AND AROUND PULLEY NO.3 IN FLOATING PULLEY LOCK, UP AND OVER PULLEY NO.4 DOWN AND ATTACH TO WEIGHT STACK WITH M12 BOLT AS SHOWN.

- Page 15 -13-...

Need help?

Do you have a question about the L7800LP and is the answer not in the manual?

Questions and answers