Table of Contents

Advertisement

Number of instruction:

LMI-26-02/06/08/ENG

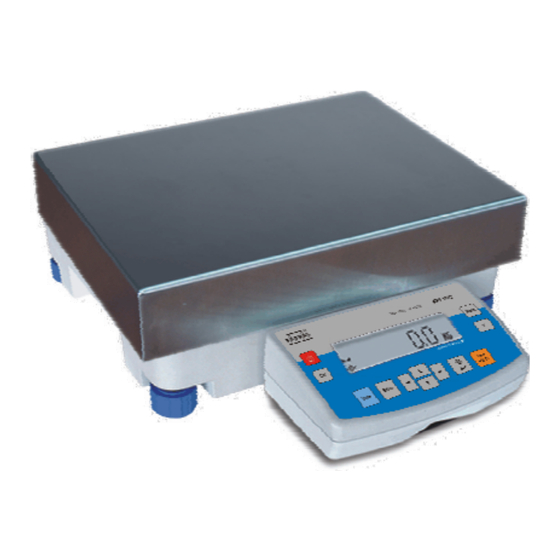

Precision balances

APP/C series

M A N U F A C T U R E R

O F E L E C T R O N I C W E I G H I N G I N S T R U M E N T S

RADWAG 26 – 600 Radom, Bracka 28 Street, POLAND

phone +48 48 38 48 800, phone/fax. +48 48 385 00 10

Sales Department +48 48 366 80 06

www.radwag.com

Advertisement

Table of Contents

Summary of Contents for RADWAG APP series

- Page 1 O F E L E C T R O N I C W E I G H I N G I N S T R U M E N T S RADWAG 26 – 600 Radom, Bracka 28 Street, POLAND phone +48 48 38 48 800, phone/fax.

- Page 2 JUNE 2008 - 2 -...

-

Page 3: Table Of Contents

Contents TECHNICAL DATA .................. 6 BASIC INFORMATION ................7 2.1. Intended use ....................7 2.2. Inappropriate use ..................7 2.3. Warranty ..................... 7 2.4. Monitoring the metrological parameters of the instrument ......8 ... - Page 4 Format of sent data for orders generated from the computer ... 65 W EIGHING LOADS UNDER BALANCE ..........66 L IST OF ORDERS IN RADWAG BALANCES ........67 E RROR MESSAGES ................68 - 4 -...

- Page 5 A DDITIONAL EQUIPMENT ..............68 19.1. Vibration damping table ................68 19.2. Additional display ..................68 19.3. Computer software ................... 68 - 5 -...

-

Page 6: Technical Data

1. TECHNICAL DATA External 10/C 25/C 30/C calibration Internal calibration 8/C/2 10/C/2 25/C/2 30/C/2 8 kg 10 kg 25 kg 30 kg Max capacity -8 kg -10 kg -25 kg -30 kg Tare range 0,2 g Min capacity 0,01 g 0,1 g Readability 0,01 g... -

Page 7: Basic Information

2. BASIC INFORMATION 2.1. Intended use Balance you have acquired serves to determine the weighing value of a load in laboratory environment. It is intended for application as a non-automatic weighing instrument only, i.e. the material to be weighed is manually and carefully placed in the center of the weighing pan. -

Page 8: Monitoring The Metrological Parameters Of The Instrument

2.4. Monitoring the metrological parameters of the instrument Metrological features of the balance should be tested by the user within regular intervals of time, within scope of quality assurance. 2.5. Data included in this user manual Please read the user manual carefully before erecting and commissioning, even if the user has is experienced with this kind of weighing instruments. -

Page 9: Unpacking

Please take special safety measures when weighing magnetic loads, as part of this balance is a strong magnet. If there is a necessity to perform measurement of such load, please use option of under hook weighing, which removes the load from area influenced by the magnet. For installation place of under hook device, please look at the bottom casing of the balance,. -

Page 10: Standard Accessories

4.4. Standard accessories • Balance. • Weighing pan. • Power adapter. • User manual. 4.5. Cleaning Balance should be cleaned with damp cloth. In order to clean the weighing pan of the balance, please remove it from the weighing chamber. Cleaning of the pan when installed may cause damage of the measuring system of the balance. -

Page 11: Basic Functions Of The Instrument

5. BASIC FUNCTIONS OF THE INSTRUMENT Electronic balance is appropriate for precise measurements mass in laboratory conditions with possibility of setting to zero in all measure range. Balance calibration is done by CAL on balance keyboard. Functions for weighing units (press Units key) select default units of weighing <StUn>, Weighing in grams, Weighing in [kg],... -

Page 12: Keyboard

6. KEYBOARD Switches the display off. ON/OFF key. Function key. F key. Selects the work mode. MODE key. Changes measure units. UNITS key. Sends information to external instrument (PRINT) or confirms parameter value or function (ENTER). PRINT/ENTER Key. Sets indication to zero. Esc/TARA Key. Calibration (internal or external) Menu of balances Navigation bar... -

Page 13: User Menu

7. USER MENU Menu is divided into 7 basic groups. Each group has individual name starting with capital letter P. Names of groups and their contents is shown below. P1 CAL [Calibration] P1.1 iCAL [internal calibration] P1.2 ECAL [external calibration] P1.3 tCAL [temperature calibration]... - Page 14 P5 Unit [Mass units] P5.1 StUn | g/kg/ct/oz/ozt/dwt/t/mom/G [basic mass unit – e.g. gram] P5.2 YES/no [kg - milligram] P5.3 YES/no [ct – carat] P5.4 YES/no [oz – ounce] P5.5 YES/no [ozt – troy ounce] P5.6 YES/no [dwt – pennyweight] P5.7 YES/no [t –...

-

Page 15: Moving In User Menu

7.1. Moving in user menu User moves in menu using balance keyboard (see point no 6) 7.1.1. Return to weighing function Introduced changes in balance memory will be saved for good after return to weighing with procedure of saving changes. Press several SAvE?. -

Page 16: Choice Of Basic Weighing Unit

Don’t unplug the balance from power supply between following measurements. Switch the balance off by pressing ON/OFF key. If user presses key ON/OFF once again balance is ready to following measurements 8.1. Choice of basic weighing unit Function is used to setting the initial unit with which the balance will start after switching on. -

Page 17: Choice Of Weighing Unit (Temporary)

After choosing basic unit press ENTER/PRINT key. Chosen unit will stop pulsing. Possibilities of choice: • For EC verified balances, user can choose following units: [g], [kg], [ct] • For non-verified balances, user can choose following units: [g], [ct], [kg], [oz], [ozt], [dwt], [t], [mom], [gn]. -

Page 18: Setting Accessibility Of Balance Operating Modes

8.3. Setting accessibility of balance operating modes In this group of parameters user declares functions which are to be accessible for user after pressing SETUP key. Enter group P6 Func. 8.3.1. Choice of modes quantity accessible for user Function enables user to set if after pressing RIGHT ARROW key all operating modes will be accessible (ALL) or only one from the list chosen and used by operator, or all functions unavailable (OFF). - Page 19 After choosing setting press ENTER/PRINT key. Balance will go back to displaying name ofsubmenu.P6.1 FFun. If function other than ALL is chosen, procedure of returning to weighing differs from remaining ones. If e.g. function PcS is chosen (procedure according to 13.1 point), to return to weighing: - 19 -...

-

Page 20: Setting Contents Of P6.1 Ffun - All Parameters

Press key Esc/TARA, balance will return to weighing. 8.3.2. Setting contents of P6.1 FFun – ALL parameters Function enables switching off modes not used by operator. This causes faster access to used modes. - 20 -... -

Page 21: Main Setting Parameters

OFF – inaccessible mode On – accessible mode. Return to weighing (see - 7.1.2. – return to weighing). 9. MAIN SETTING PARAMETERS User can adjust balance to external conditions (filter range) or own needs (autozero working, memory of tare value). These parameters are in group <P3 rEAd>. These functions will help user to adjust balance to external conditions in which balance operates. -

Page 22: Setting Level Of Filtering

9.1. Setting level of filtering Procedure: using NAVIGATION BAR choose value of filter which is needed 1 - filtr FASt – (fast) 2 - filtr StAnd – (standard) 3 - filtr Slouu – (slow). Return to weighing (see - 7.1.2. – return to weighing). ATTENTION: The higher filtering level the longer time of weighing. -

Page 23: Result Confirmation

9.2. Result confirmation Because of various environmental conditions it is advisable to adjust the balance by selecting method of result confirmation as: FAST_rEL, Fast or rEL. Depending on selected option, time of weighing will be shorter or longer. Fast_rEL - fast + release Fast - fast - release. -

Page 24: Autozero Function

9.3. Autozero function In order to ensure precise indication of balance, „AUTOZERO” function was introduced. The application of this function is automatic control and correction of zero indication of balance. When function is active comparison of results takes place at declared time intervals e.g. -

Page 25: Light Off The Last Display Digit

9.4. Light off the last display digit Function enables light off the last digit on the display. ALuuAYS - always nEuEr - never uu_StAb - when is stable. Return to weighing (see - 7.1.2. – return to weighing). - 25 -... -

Page 26: Another Parameters

10. ANOTHER PARAMETERS User can set parameters which have influence on work with balance. These parameters are contained in P5 othEr e.g. backlight and „beep” signal. Enter to P5 Others group of submenu according to point 6.1. 10.1. Backlight of weighing result –... -

Page 27: Beep" Signal - Reaction On Pressing Key

10.2. “Beep” signal – reaction on pressing key bEEP OFF – signal of pressing key off bEEP On - signal of pressing key on. Return to weighing (see - 7.1.2. – return to weighing). 10.3. Printout of all balance parameters through RS 232 port After pressing F key, balance parameters will be send through RS 232 port. -

Page 28: Balance Calibration

11. BALANCE CALIBRATION As the acceleration value due to gravity is not the same at every location on earth, each balance must be coordinated – in compliance with the underlying physical weighing principle – to the existing acceleration due to gravity at its place of location (only if the balance has not already been adjusted to the location in the factory). - Page 29 Cycle of automatic calibration proceeds as follows: - balance software detects necessity of calibration and signalizes it by marker of Celsius degree or by black marker - from this moment time of 5 minutes is counted in which weighings can be performed - when this time elapses display indicates CAL_30 message and starts count down 30..29..28 do 0 (indicated value is the counter)

-

Page 30: Entering Calibration Menu

11.2. Entering calibration menu P1 CAL P1.1 iCAL P1.2 uCAL P1.3 tCAL P1.4 ACAL both P1.5 CALt P1.6 CALr P1.1 iCAL – Internal calibration start of internal calibration process, process is completely automatic without interference of balance operator, if pan is loaded display will indicate message about necessity of removing the load. - Page 31 P1.4 ACAL – Automatic calibration (balances with internal calibration) determination of factor, which should decide about starting the automatic internal calibration nonE – none of factors will cause start of calibration tEmP – calibration with regard to change of temperature timE –...

- Page 32 P1.5 CALt – Time of automatic calibration (balances with internal calibration) determining the time, after which automatic calibration will start. P1.6 CALr – printout from calibration report Setting printout of report after finished calibration no – printout of report off YES –...

-

Page 33: Calibration Test

11.3. Calibration test 11.3.1. Balances with internal calibration Internal calibration mass is compared to its value in the balance memory. This process is automatic. Its result is shown on the display. Process proceeds automatically and display indicates its result (if balance is connected to computer or to printer through RS 232 joint, printout of calibration test will take place). -

Page 34: Balances With External Calibration

11.3.2. Balances with external calibration It consists in comparison of mass of standard with mass previously saved in balance memory during the calibration. Process proceeds automatically and display indicates its result (if balance is connected to computer or to printer through RS 232 joint, printout of calibration test will take place). -

Page 35: Manual Calibration

11.4. Manual calibration 11.4.1. Internal calibration Press Cal key or The balance performs the calibration automatically. During this calibration do not load the pan. After this process the balance records results of the calibration in the memory and returns to weighing mode. ATTENTION: Pressing the ESC key stops the calibration process If during the calibration load is on the pan display show order about error. -

Page 36: External Calibration

11.4.2. External calibration The external calibration should be performed with external mass class F Start external calibration process balances witj internal calibration balances with external calibration Order to load off the pan appears on the display (no load on the pan). After yesing load off the pan press the ENTER key. -

Page 37: Setting Printouts For Glp Procedures

P2 GLP P2.1 P2.2 P2.3 Ptin P2.4 PdAt P2.5 P2.6 PPrJ P2.7 P2.8 PFrn Apart from information settled in menu group the report contains: difference between calibration mass remembered by balance after last calibration and calibration mass determined during actual calibration and other information. 12. -

Page 38: Setting The Contents Of Printouts For Glp Procedures

For fields: user (max 8 alphanumerical signs) design (max 8 alphanumerical signs) introduce names by the balance keyboard. For the rest select: (do not print during report) (print during report) 12.1. Setting the contents of printouts for GLP procedures P2 GLP group of parameters enabling to declare variables, which will appear on calibration printout and printout from measurement. - Page 39 • P2.1 USr Option enabling to introduce name of user who operates the scale. User has possibility to introduce the name consisting of max 8 alphanumeric characters. Introduction the name is possible by the means of scale keyboard with NAVIGATION BAR and ENTER key. - 39 -...

- Page 40 Available characters and their equivalents displayed by scale are shown on the drawing below: Exemplary user name introduced to scale with capital letters: OP1_WILK (operator 1 WILK) Exemplary user name introduced to scale with small letters: op1_wilk (operator 1 wilk) - 40 -...

- Page 41 • P2.2 PrJ Option enabling to introduce the Project name (e.g. associated with specific weighing type). Exemplary project name introduced to scale with capital letters: PRRADWAG Exemplary project name introduced to scale with small letters: prradwag • P2.3 Ptin Option enabling to print time of performed measurement. •...

-

Page 42: Balance Operating Modes

13. BALANCE OPERATING MODES Weighing mode (basic) Counting pieces +/- control referring mass of set standard Control of % deviation referring mass of standard Definition thickness of solids and liquids. Summing Press MODE key: - 42 -... -

Page 43: Counting Details Of The Same Mass

After pressing MODE key, name of first available function will be indicated. Each next pressing DOWN or TOP ARROW key causes displaying name of next available functions, way of setting the functions is described in further part of this manual. 13.1. - Page 44 • if you want to choose one them e.g. 20pcs press ENTER/PRINT and proceed as shown on picture − If option FrEE was chosen, you must enter quantity of sample, which will serve to determine mass of single detail - 44 -...

- Page 45 − Pressing RIGHT ARROW key chooses digit which will be changed Pressing TOP ARROW changes value of digit − • Confirm entered value by pressing ENTER/PRINT key • Display will indicate LoAd message – place on the pan as many details as entered during option •...

- Page 46 Return to weighing (see - 7.1.2. – return to weighing). ATTENTION: If user presses ENTER key when details are not placed on the pan, message Er8 outr will be indicated for few second and balance will automatically return to weighing. - 46 -...

-

Page 47: Control Referring Mass Of Set Standard

13.2. +/- control referring mass of set standard Procedure of operating: Enter to function During setting threshold values following dependences take place: - 47 -... - Page 48 SET LOWER THRESHOLD RIGHT ARROW – choice of set digit; TOP/DOWN ARROW - choice of value of digit; ENTER/PRINT – confirmation of entered values SET UPPER THRESHOLD RIGHT ARROW – choice of set digit; TOP/DOWN ARROW - choice of value of digit;...

-

Page 49: Control Of % Deviation Referring Mass Of Standard

ATTENTION: If user by mistake enters value of lower threshold higher than upper, balance will indicate error message and will return to weighing. Return to weighing (see - 7.1.2. – return to weighing). 13.3. Control of % deviation referring mass of standard Balance software enables control of deviation (in %) of weighed loads mass referring mass of standard. -

Page 50: Mass Of Standard Determined By Its Weighing

13.3.1. Mass of standard determined by its weighing Procedure: • Enter to function • place on the pan load which mass will be accepted as standard • press ENTER/PRINT to confirm this operating mode • after few seconds indication 100,00% will be displayed. From this moment display will not indicate mass of weighed load but deviation of load mass placed on the pan referring mass of standard (in %). -

Page 51: Mass Of Standard Entered To Balance Memory By User

13.3.2. Mass of standard entered to balance memory by user Procedure: • Enter to function. • Display will show indication as above • Using keys choice of set digit and choice of digit value set value of mass of standard, enter it to balance memory using PRINT key –... -

Page 52: Defining Thickness Of Solids And Liquids

(see - 7.1.2. – return to weighing). 13.4. Defining thickness of solids and liquids There is equipment to defining thickness of solids and liquids in additional equipment. For user request RADWAG service can render special software to determine thickness by balance accessible. 13.4.1. Testing thickness solids Thickness of solids can be tested in one of 3 liquids: •... -

Page 53: Testing Thickness Of Liquid

13.4.2. Testing thickness of liquid Basic element for measuring thickness of liquid is plunger. It has precise capacity. Before final measurements this value should be introduced to balance memory. To test thickness of liquid weigh plunger on pan and in tested liquid. Result of testing is shown on display automatically after introducing mass of plunger. - Page 54 - 54 -...

-

Page 55: Functions For Using Rs 232

Return to weighing (see - 7.1.2. – return to weighing). 14. FUNCTIONS FOR USING RS 232 Choose speed of transmission Define sent data as: stable / not stable Continuous work Setting data as additional element of parameter in printouts Turn on/off sign of last digit in printout automatic operating for RS 232. -

Page 56: Speed Of Transmission

14.1. Speed of transmission Method of setting speed of transmission: − choose required speed of transmission - 2400 bit/s - 4800 bit/s - 9600 bit/s - 19200 bit/s. Return to weighing (see - 7.1.2. – return to weighing). - 56 -... -

Page 57: Continuous Transmission

14.2. Continuous transmission 14.2.1. Continuous transmission off in actual interval Procedure: CntA – continuous transmission off CntA YES - continuous transmission on. Return to weighing (see - 7.1.2. – return to weighing). - 57 -... -

Page 58: Continuous Transmission Of In Basic Units

14.2.2. Continuous transmission of in basic units Procedure: Cntb – continuous transmission off Cntb YES - continuous transmission on. Return to weighing (see - 7.1.2. – return to weighing). - 58 -... -

Page 59: Setting Type Of Operating For Rs 232 Joint

14.3. Setting type of operating for RS 232 joint Procedure: rEPL no – manual operating / after pressing PRINT key rEPL YES - automatic operating / after stabilization of weighing result. Return to weighing (see - 7.1.2. – return to weighing). Automatic operating takes place according to following scheme: press TARE key to zero the balance (display will indicate marker of stable measurement and marker of zero) -

Page 60: Designation Of Data Type Sent Through Rs 232 Joint

14.4. Designation of data type sent through RS 232 joint (only for non-verified balances) Procedure: PStb no – sending stable or temporary result of weighing PStb YES – sending stable result of weighing. Return to weighing (see - 7.1.2. – return to weighing). - 60 -... -

Page 61: Designation Of Minimum Mass For Operating Of Some Functions

14.5. Designation of minimum mass for operating of some functions Software enables setting operating of function automatic operating. for automatic operating result will not be sent to computer or printer until indication of mass goes below set Lo net value Procedure: Return to weighing (see - 7.1.2. -

Page 62: Cooperation With Printer Or Computer

15. COOPERATION WITH PRINTER OR COMPUTER Every pressing of key < PRINT > sends signal of current display state with measuring units to computer or printer. Balance has factory setting speed of transmission 4800 bit/s. If external mechanism (printer, computer) require different setting of speed of transmission, change factory setting on speed in menu (parameter bod) Transmission parameters programmed in balance:... -

Page 63: Schedules Of Connecting Conductors

15.1. Schedules of connecting conductors WEIGHT COMPUTER 2 (RxD) 3 (TxD) 3 (TxD) 2 (RxD) 4 (DTR) 6 (DSR) 5 (GND) 5 (GND) 6 (DSR) 6 (DTR) 7 (RTS) 8 (CTS) 8 (CTS) 7 (RTS) - 63 -... -

Page 64: Printing Data With Date And Time

15.2. Printing data with date and time Every printout of weighing can be printed with date and time of measurement. It’s possible if balance is connected to printer Kafka 1/Z or Kafka SQ S. After connecting balance and printer set in balance menu parameters of P2 GLP group: PdAt on value YES Ptin on value YES... -

Page 65: Format Of Sent Data After Pressing The Print Button

15.4.1. Format of sent data after pressing the PRINT button Depending on setting of P4.5 PStb parameter only stable measurement or mass of instantaneous mass will be sent. For verified balance printout of temporary measurements will be blocked for instantaneous measurements. Format of printout 4 - 12 14 - 16... -

Page 66: Weighing Loads Under Balance

And afterwards 1 - 3 8 - 16 18 - 20 Command – 1 ÷ 3 marks stability marker – [space] if stable [?] if unstable [^] if there is an error of exceeding the range on + [v] if there is an error of exceeding the range on - mark –... -

Page 67: List Of Orders In Radwag Balances

17. LIST OF ORDERS IN RADWAG BALANCES Function TARA T CR LF (setting to tare) Format Function ZERO Z CR LF (setting to zero) Format Function PRINT SI CR LF (sending results when stab) Format Function PRINT S CR LF (sending results now) -

Page 68: Error Messages

19.3. Computer software PW-WIN 2004 – gathering data from any balance made by RADWAG. RAD-KEY 2000 – enables to introduce result of weighing to Exel. REC-FS 2000 – making mixtures. It has its own programmed contents base according to recipes are made. - Page 69 MANUFACTURER OF ELECTRONIC WEIGHING INSTRUMENTS RADWAG 26-600 Radom Bracka 28 Street POLAND Central phone +48 48 38 48 800 phone/fax. + 48 48 385 00 10 Sales Department + 48 48 366 80 06 www.radwag.com - 69 -...

Need help?

Do you have a question about the APP series and is the answer not in the manual?

Questions and answers