Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for RADWAG AS 220.R

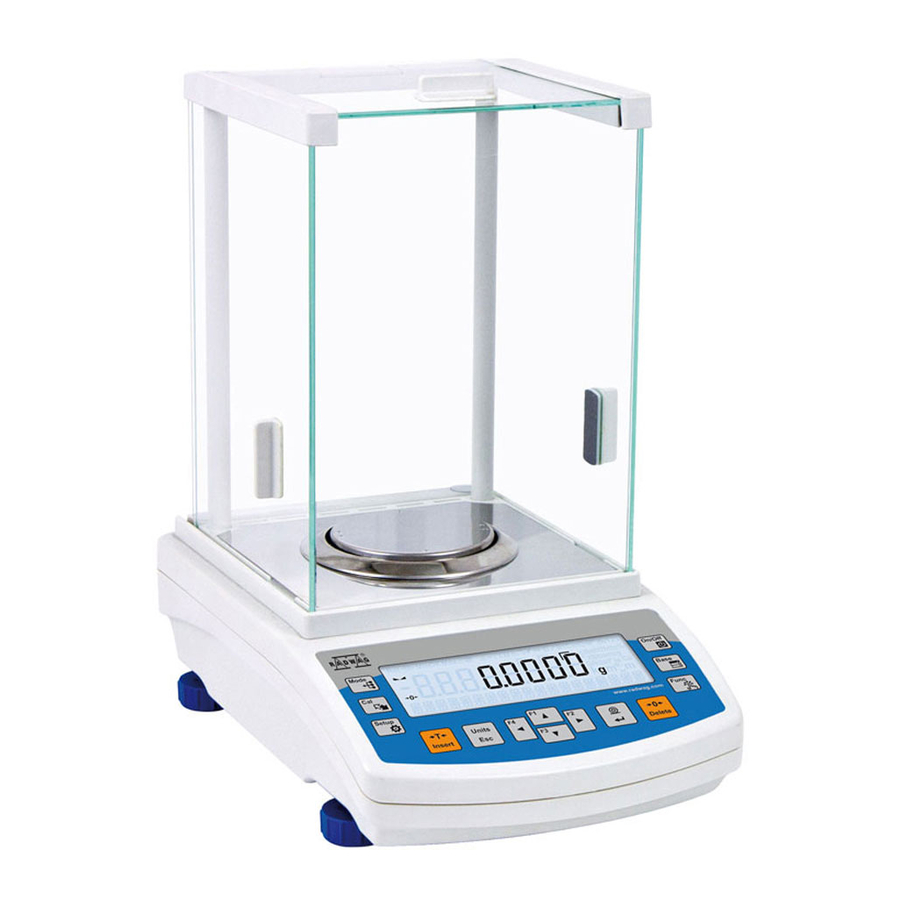

- Page 1 O F E L E C T R O N I C W E I G H I N G I N S T R U M E N T S RADWAG 26 – 600 Radom, Bracka 28, POLAND Phone +048 48 38 48 800, fax +48 48 385 00 10 Export department +0-48 48 366 80 06 www.radwag.com...

- Page 2 MAY 2014 - 2 -...

-

Page 3: Table Of Contents

TABLE OF CONTENTS 1. TECHNICAL DATA .................7 1.1. Connection ports..................11 1.2. PS R2.H series ..................11 2. BASIC INFORMATION ................ 14 2.1. Intended use ..................... 14 2.2. Inappropriate use ..................14 2.3. Warranty ....................14 2.4. Monitoring the metrological parameters of the instrument ......15 2.5. - Page 4 10.13 F button shortcuts ..................51 10.14 Dual range balance (NPS 200/2000.R2) ..........52 11 OTHER PARAMETERS ............... 53 11.1. Available menu languages ................ 53 11.4 Access levels .................... 53 11.5 ‘Beep’ sound – reaction on pressing function button ........ 53 11.6 Backlight and adjusting display brightness ..........

- Page 5 17.3.1. Declaration of mass thresholds ..........101 17.4. Dosing ....................103 17.4.1. Setting a target weight by entering values ........ 104 17.4.2. Returning to the weighing mode ..........106 17.5. Deviations % against the mass of the standard ........106 17.5.1.

- Page 6 21. COMMUNICATION PROTOCOL ............156 21.1. List of commands ..................156 21.2. Responses format for commands sent from computer level ....157 21.3. Commands description ................157 22. ERROR MESSAGES ................. 162 23. UNDER HOOK WEIGHING ............... 163 24. ADDITIONAL EQUIPMENT ............... 164 24.1.

-

Page 7: Technical Data

TECHNICAL DATA Balance XA series: XA 52.R2 XA 82/220.R2 Max capacity 52 g 82/220 g Min capacity 1 mg 1 mg Readability 0,01 mg 0,01/0,1 mg Tare range -52 g -220 g Repeatability 0,02 mg 0,02 /0.08 mg Linearity ± 0,06 mg ±... - Page 8 Balance AS series: 60/220.R2 160.R2 220.R2 310.R2 Max capacity 60/220g 160g 220g 310g Min capacity 10 mg 10 mg 10 mg Readability 0.01/0.1mg 0.1mg 0.1mg 0.1mg Tare range -220g -160 g -220 g -310 g Pan size Φ 85 mm Sensitivity drift 1 ppm/°C in temperature +10 °...

- Page 9 Balance PS series with weighing pan 128 x 128 mm: Type balance 200/2000.R2 210.R2 360.R2 600.R2 750.R2 1000.R2 200/2000g 210g 360g 600g 750g 1000g Max capacity -2000g -210g -360g -600g -750g -1000g Tare range 20mg 20mg 20mg 20mg 20mg 20mg Min capacity 1/10mg Readability...

- Page 10 Balance PS series with weighing pan 195 x 195 mm: Type balance 1200.R2 2100.R2 3500.R2 4500.R2 6000.R2 Max capacity 1200g 2100g 3500g 4500g 6000g Tare range -1200g -2100g -3500g -4500g -6000g Min capacity 500mg 500mg 500mg 500mg 500mg Readability 10mg 10mg 10mg 10mg...

-

Page 11: Connection Ports

Balance APP series: 10.R2 35.R2 Max capacity 10 kg 35 kg Tare range -10 kg -35 kg Min capacity Readability 0.01 g 0.1 g Working temperature +10 °C - +40 °C Power supply 12 ÷ 16 V DC / 2,1 A 1.1. - Page 12 Additional asset of PS R2.H balances are their interfaces build-in a hermetic closed housing which is separated from the balance. The interfaces include 2×RS 232, USB type A, USB type B, and WiFi optionally. Balance housing is made of plastic, whereas its pan of stainless steel. PS R2.H series metrological parameters are identical like those of standard design balances.

- Page 13 Balance assembly Upon unpacking the balance remove protective elements and assembly the balance: - assembly the metal pan (2) on the balance base, mounted onto the balance - assemlby draft shield (1), only for balances with pan Φ 115 mm - plug the power adapter interface into the port of interfaces...

-

Page 14: Basic Information

BASIC INFORMATION 2.1. Intended use The purchased balanced serves to determine the weighing value of loads in laboratory environment. It is intended for application as a non-automatic weighing instrument only, i.e. the material to be weighed is manually and carefully placed in the centre of the weighing pan. Weighing result should be read only after stable reading has been obtained. -

Page 15: Monitoring The Metrological Parameters Of The Instrument

2.4. Monitoring the metrological parameters of the instrument Metrological characteristics of the balance require periodical inspection to be carried out by its user. Inspection frequency is dependent on ambient conditions in which the balance is used, types of performed processes and accepted quality management system in organisation. -

Page 16: Unpacking, Assembling And Start-Up

UNPACKING, ASSEMBLING AND START-UP 4.1. Assembling and place of use • The balance should be stored and used in locations free of vibrations and shakes, free of air movement and dust, • ambient air temperature should not exceed the range of: +10 °C ÷ +40 °C, •... -

Page 17: Unpacking

4.2. Unpacking Cut the sealing tape. Take the balance out of the packaging. Open the box with accessories and take the items necessary for correct balance operation. Upon placing the balance in the desired location assembly its weighing pan and other parts in accordance with the following instruction. - Page 18 AS balance with d=0.01/0.1 mg AS balance with d=0.1 mg - 18 -...

- Page 19 • open side doors of the weighing chamber, • remove transport lock (1) – press the lock gently and turn it accordingly to OPEN/CLOSE instruction, next remove the lock; please retain the lock should the device be transported in the future, •...

- Page 20 rubber bumpers (1), - assemble the glass anti-draft shield (3) - after assembling the balance components, check whether the weighing pan is firmly placed on the rubber bumpers. Balance APP Remove the adhesive tape. Carefully remove the balance from its packaging. Remove all the elements necessary for correct operation from the accessory box.

- Page 21 • Assemble the weighing pan (for APP 10.R, one of the pans only). • Make sure the weighing pan is placed properly on the shock absorbers: the weighing pan cannot touch the housing and should be stable. • Place the balance at the workplace. •...

-

Page 22: Levelling

4.3. Levelling Before plugging to mains, level the balance by turning the adjustable feet in a way that the air bubble of the level is in its central ring. The balance should be placed at the workplace firmly on all of its feet. 4.4. - Page 23 Remove the back glass wall. - 23 -...

- Page 24 Remove the side glass walls. The side glass walls are not replaceable, so it is important to remember which one is left and right, and after cleaning install them back properly in the draft shield. CAUTION: do not remove the front glass wall. Remove the weighing pan, the weighing pan safety rings and the bottom metal plates, so as not to damage the balance mechanism durin the cleaning.

- Page 25 Steps for AS.R2 series balance: Twist off and remove the top glass wall safety frame, and slide the top glass wall out of the slideway. Remove the back glass wall. Remove the side glass walls. The side glass walls are not replaceable, so it is important to remember which one is left and right, and after cleaning install them back properly in the draft shield.

- Page 26 CAUTION: do not remove the front glass wall. Remove the weighing pan, the weighing pan safety rings and the bottom metal plates, so as not to damage the balance mechanism durin the cleaning. Thus prepared draft shield and glass walls can be properly cleaned. All the operations should be done carefully.

-

Page 27: Plugging To Mains

4.5. Plugging to mains Balance can be connected to mains only with a power adapter that comes standard with the balance. Nominal power supply of the power adapter (specified on the data plate of the power adapter) should be compatible to the power from mains. Plug the balance to mains –... -

Page 28: Basic Functions

BASIC FUNCTIONS • functions related to measuring units weighing in grams [g], weighing in milligrams [mg] (in balances with d≤0.001g), weighing in kilograms [kg] (in balances with d≥0.01g, weighing in carats [ct], weighing in units from beyond SI (available only in non-verified instruments): [lb], [oz], [ozt], [dwt], [tlh], [tls], [tlt], [tlc], [mom], [gr], [ti], [N], [baht], [tola] •... -

Page 29: Keyboard

KEYBOARD ON/OFF button enables switching on and off balance’s display. If switched off balance components other than the display are powered, and balance is in stand-by mode. F9 button of the computer keyboard. Direct access to data stored in a databese: user, product, tare. -

Page 30: Start-Up

Navigating arrows for moving in balance’s menu or changing parameter value. START-UP When plugged to mains, the balance displays name and number of software, and afterwards proceeds to weighing mode. 7.1. Connecting peripheral devices The balance must be unplugged from the mains before connecting or disconnecting peripheral devices (printer or computer). -

Page 31: User Menu

USER MENU Balance menu is divided into 6 basic function groups. Each group has individual name starting with capital letter P. 8.1. Moving through user menu A user moves through balance menu using buttons on overlay’s keyboard: Setup button. Entering balance’s main menu. Selecting group of parameter one by one downwards or changing parameter value by one value downwards. - Page 32 Name of function groups and their content: P1 ADJUSTMENT P1.1 INT. CALIB. [internal adjustment] P1.2 EXT. CALIB. [external adjustment] P1.3 USER CALIBRATION [user adjustment] P1.4 CALIBRATION TEST [adjustment test] P1.5 AUTO. CALIB. |NONE [automatic adjustment] P1.6 AUTO. CALIB. C. |1 [time of automatic adjustment] P2 OPERATION MODE P2.1 ACCESSIBILITY...

- Page 33 P4.4 ADD. DISPLAY |COM 1/COM 2/NONE [additional display port] P4.5 EXT. BUTTONS |TARE / PRINT P5 PRINTOUT P5.1 CAL. REPORT [contents of the adjustment report] P5.2 HEADER [contents of the header print-out] P5.3 GLP PRNT. [contents of the weighment result prnt.] P5.4 FOOTER [contents of the footer print-out] P5.5 NSD.PRN.1...

-

Page 34: Logging In

LOGGING IN In order to have full access to the user’s parameters and editing of database, the person operating the balance, should log in as <ADMINISTRATOR> each time they turn it on. The software enables the entry of 10 users with varying degrees of authority. - Page 35 Access levels The balance software features three access levels: ADMINISTRATOR, ADVANCED, USER. When you turn the balance on, the display is active all the time, which enables carrying out mass measuring processes. The table below shows the access to the edition of user parameters, databases and software functions depending on the access level.

-

Page 36: Weighing

10. WEIGHING 10.1. Required weighing procedures In order to ensure long lasting use of a balance and reliable measurement of weighed loads, follow below procedures: Start the balance with no load on the weighing pan (permissible value of load on the weighing pan on balance start is ±10% of its maximal capacity). - Page 37 Before the start of weighing process or in case of drastic change of ambient conditions at a workstation (e.g. ambient temperature change at a workstation more than 3°C) the balance requires adjusting. The procedure of balance adjustment is described further in this user manual. •...

-

Page 38: Zeroing

10.2. Zeroing In order to zero mass indication press button. The mass indication on the display should equal zero, and precise zero and stability marker should appear. Zeroing process is tantamount to determining new zero point recognised by the balance as precise zero. Zeroing is possible only in stable status of display indication. - Page 39 Manual tare determination Procedure: • While in optional mode press quick access button F, to which the option <ENTER TARE> is assigned in <SHORTCUTS> settings (description of the setting further in this user manual, point <F button shortcuts>), • which opens a window, •...

-

Page 40: Settings For Mode

AUTOTARE Function allowing for automatic taring of the packaging during the weighing process, when packaging mass for each of the product is different. Description of this function is to be found further down this manual. Deleting tare Entered tare value can be deleted by pressing button on the balance’s overlay or by entering tare value of 0.000g (see description above). -

Page 41: Setting Level Of Filtering

10.4.1. Setting level of filtering Depending on the balance working conditions you should set the filter. In ideal conditions you can set the filter to be very fast (parameter value P.2.2.1.1 Filter to be V.FAST); however, if the working conditions are bad (shakes, drafts), the filter should be set to slow or very slow (parameter value P.2.2.1.1 to SLOW or V. -

Page 42: Autozero Function

10.4.3. Autozero function In order to ensure balance’s precise mass indication, autozero (Auto) software parameter has been introduced. The application of this function is automatic control and correction of zero indication. When the function is enabled, it compares balance indications at declared time interval e.g. 1s, on condition that weighing pan is unloaded and display indication is close to zero. -

Page 43: Balance Ambient Conditions

10.4.5 Balance ambient conditions This parametre has two settings: STABLE and UNSTABLE. Setting on STABLE mode makes the balance work much faster than on UNSBABLE mode. This parametre relates to the ambient conditions in which the balance operates. If the ambient conditions are unstable it is recommended to use UNSTABLE mode. -

Page 44: Printing Mode

• Take off the product together with the packaging; • The balance will cancel tara value (the packaging mass saved in balance storage during the first step of the operating process) after the gross mass value (set in < P 2.2.3.2 AUTO THRES> parameter) has been exceeded;... - Page 45 Automatic operation proceeds as follows: Press button to zero the balance (marker of stable measurement and zero marker are shown on display) Place the load, the balance sends the first stable measurement to the printer port, Remove the load from the balance, ...

-

Page 46: Temporary Measuring Unit

10.7 Temporary measuring unit This function is only available in <WEIGHING> mode. In other modes measurements are only possible in basic unit [g]. Function enables selecting a measuring unit which will be indicated next to mass reading during the weighing process. Set measuring unit will be in use from the moment of its activation until its change or switching off and on the balance. -

Page 47: Availability Of Measuring Units

10.9 Availability of measuring units This function is only available in <WEIGHING> mode. In other modes measurements are only possible in basic unit [g]. The user can declare the weighing units which will be available when selecting temporary unit by pressing button. -

Page 48: User Unit

10.10 User unit A user can declare two weighing units. User unit is the result of balance indication multiplied by the factor that was introduced for user unit. User units are marked as [u1] – user 1 unit and [u2] – user 2 unit. The way of declaring factor for an individual user is shown below User units are available only for non-verified balances. -

Page 49: Information

10.11 Information Function enables displaying additional information in the bottom line. Depending on the needs, a user can choose the following options, which are shown while working in mode <WEIGHING>: - 49 -... -

Page 50: Non-Standard Information

10.12 Non-standard information Function enables declaring non-standard information, which is to be displayed in the bottom line of the display. A user can insert any text consisting of maximum 19 characters. It should be remembered though, that the declared non-standard information is visible. -

Page 51: F Button Shortcuts

10.13 F button shortcuts Function enables assigning quick access option for weighing functions which are accessible by choosing F1, F2, F3 or F4. A user can choose the following options in <WEIGHING> mode, which can be assigned to any of the F buttons<... -

Page 52: Dual Range Balance (Nps 200/2000.R2)

10.14 Dual range balance (NPS 200/2000.R2) Balance NPS 200/2000.R2 series is a dual range weighing instrument. The accuracy of the I weighing range is d =0.001g, and of the II weighing range is =0.01g. Transfer from weighing with the accuracy of the I weighing range to weighing with the accuracy of the II weighing range takes place automatically on exceeding 200g (with no user activity needed). -

Page 53: Other Parameters

OTHER PARAMETERS A user can set up parameters which have an influence on working with the balance. These parameters are included in group P6 OTHER. Changing settings for particular parameters is the same as described in the previous paragraph of this user manual. P6 OTHER P6.1 LANGUAGE |POLISH / ENGLISH [menu languages]... -

Page 54: Backlight And Adjusting Display Brightness

11.6 Backlight and adjusting display brightness Enables setting the brightness of the backlight or switching off the display brightness completely. - maximum brightness of the backlight - minimum brightness of the backlight - display brightness switched off NONE 11.7 Date Enables setting the current date. -

Page 55: Time Format

11.10 Time format Enables choosing the time format on the printout [12H / 24H]. For the set value [12H], in parameter P6.6 TIME letters <A> or <P> will be displayed next to the time value. Where: A stands for hours before noon, P stands for hours after noon. Letters AM or PM are printed out next to the time value. - Page 56 Example of a report: ............. --------- Autotest GLP: Report --------- Balance type PS 3000.R2 Balance ID 400010 User Admin Software rev. v.0.4.9 Date 2013.07.16 Time 09:17:16 ---------------------------------------- Number of measurements Reading unit 0.001/0.01 g Internal weight mass 1402.094 g Filter Normal Value release Fast &Reliable...

-

Page 57: Information About The Balance

INFORMATION ABOUT THE BALANCE This menu includes information about the balance and its installed software. The parameters are strictly informative. Once the parameter <PRINT. SET>> is chosen, the balance settings are sent to the printer (all parameters). The parameters are transferred via port that was chosen for <PRINTERS>. -

Page 58: Balance Adjustment

BALANCE ADJUSTMENT In order to ensure the highest weighing accuracy, it is recommended to periodically introduce to balance memory a corrective factor of indications in relation to a mass standard – i.e. balance adjustment. Adjustment should be carried out: Before the beginning of weighing procedure, If long breaks between following measuring series occur, If temperature inside the balance changes more than: 3°C. -

Page 59: Internal Adjustment

13.1. Internal adjustment Adjustment process can be initiated automatically and manually. Manual means of activating adjustment procedure is achieved by pressing . System of automatic adjustment will carry out the process fully automatically and will inform the user on successive process stages. Cycle of automatic adjustment process: - Balance software detects the necessity of carrying out adjustment and signals it by displaying a thermometer pictogram and <Cal>... -

Page 60: Menu Adjustment Settings

Automatic adjustment process takes place in three different areas: • Adjustment on plugging the balance to mains – verified balances. • Adjustment triggered by temperature change inside the balance. The balance is equipped with very precise system for monitoring temperature. At each adjustment process, the temperature is saved in the system. - Page 61 • P1.1 INT. CALIB. – Internal adjustment Start of internal adjustment process. Adjustment is conducted automatically, and no user assistance is required. If weighing pan of the balance is loaded, balance will display a command to unload the weighing pan. If weighing pan is loaded with a relatively small mass (up to 4% of balance max capacity) then adjustment process will be carried out automatically, but measuring results may differ by the amount that was present on balance weighing pan.

- Page 62 • P1.4 CALIB. TEST – Adjustment test This fuction enables comparing the result of internal automatic adjustment with the value of internal weight saved in balance’s factory parameters. The process is conducted automatically and its result is shown on the display (if the balance is connected via RS 232 port with a computer or printer, the adjustement result will be printed out).

-

Page 63: Manual Adjustment

13.3. Manual adjustment 13.3.1. Internal adjustments Press Cal button balance performs internal adjustment automatically. During adjustment process do not load the weighing pan with any load. The message is displayed <DO NOT TURN OFF CALIBRATION> in the bottom line. Once adjustment process is completed, balance saves its result in memory and returns to weighing mode. -

Page 64: External Adjustment

13.3.2. External adjustment The external adjustment in balances NPS series should be carried out with external mass standard / weigh class F Start of external adjustment process, Balance will display a command ordering unloading of weighing pan <REMOVE MASS> (weighing pan must be empty). When weighing pan is unloaded, press button. -

Page 65: Adjustment Report Printout

The first procedure of the process is to enter the mass of the weight that is to be used for adjustment. The mass must be ≥ 30% Max capacity. Once the mass of the weight is entered and confirmed, the message is displayed which asks you to remove the weight from the pan <REMOVE MASS>... -

Page 66: Determining Content Of A Prinout

14. DETERMINING CONTENT OF A PRINOUT 14.1. Adjustment report P5.1 CAL. REPORT, is a group of parameters which enable declaring data that is on an adjustment printout. P5.1 CAL. REPORT P5.1.1 PROJECT P5.1.2 CALIB. TYPE P5.1.3 USER P5.1.4 PROJECT P5.1.5 DATE P5.1.6 TIME P5.1.7 BALANCE ID P5.1.8 CAL.DIFFER. - Page 67 • P5.1.4 PROJECT Enables printing out the name of the project. (see parameter P5.0.1) • P5.1.5 DATE Enables printing out the date of the carried out adjustment. • P5.1.6 TIME Enables printing out the time of the carried out adjustment. •...

-

Page 68: Header Printout

14.2. Header printout P5.2 HEADER, is a group of parameters which enable declaring data that is on the header printout. P5.3 HEADER P5.2.1 DASHES P5.2.2 WORKING MODES P5.2.3 DATE P5.2.4 TIME P5.2.5 SCALE TYPE P5.2.6 BALANCE ID P5.2.7 USER P5.2.8 PRODUCT P5.2.9 VARIABLE 1 P5.2.10 VARIABLE 2 P5.2.11 EMPTY LINE... - Page 69 • P5.2.6 BALANCE ID Enables printing out balance ID number. • P5.2.7 USER Enables printing out the name of a logged-in user. • P5.2.8 PRODUCT Enables printing out the name of a selected product. • P5.2.9 VARIABLE 1 Enables printing out the value of VARIABLE 1. •...

-

Page 70: Measurement Result Printout - Glp Printout

Example of a header printout: 14.3. Measurement result printout – GLP PRINTOUT P5.3 GLP PRINTOUT, is a group of parameters which enable declaring data that is on the measurement result printout. P5.3 GLP PRNT. P5.3.1 DATE P5.3.2 TIME P5.3.3 USER P5.3.4 PRODUCT P5.3.5 VARIABLE 1 P5.3.6 VARIABLE 2... - Page 71 • P5.3.4 PRODUCT Enables printing out the name of the product that was weighed. • P5.3.5 VARIABLE 1 Enables printing out the value of VARIABLE 1. • P5.3.6 VARIABLE 2 Enables printing out the value of VARIABLE 2. • P5.3.7 TARE Enables printing out the tare value.

-

Page 72: Footer Printout

14.4. Footer printout P5.4 FOOTER, is a group of parameters which enable declaring the data that is on the footer printout. P5.4 FOOTER P5.4.1 WORKING MODES P5.4.2 DATE P5.4.3 TIME P5.4.4 SCALE TYPE P5.4.5 BALANCE ID P5.4.6 USER P5.4.7 PRODUCT P5.4.8 VARIABLE 1 P5.4.9 VARIABLE 2 P5.4.10 DASHES... - Page 73 • P5.4.6 USER Enables printing out the name of a logged-in user. • P5.4.7 PRODUCT Enables printing out the name of a selected product. • P5.4.8 VARIABLE 1 Enables printing out the value of VARIABLE 1 • P5.4.9 VARAIBLE 2 Enables printing out the value of VARIABLE 2 •...

-

Page 74: Non-Standard Printouts

Example of a footer printout: 14.5. Non-standard printouts The balance’s software enables entering 4 non-standard printouts. Each of them can have approximately 160 characters. Non-standard printout can include: − Variables depending on the working mode and other user’s needs (mass, date etc.) −... - Page 75 Every single print-out can have max 160 characters (letters, numerals, non- standard characters, spaces). A user can apply non-standard characters in order to the variables depending on the needs. Example 1: “RADWAG” DATE: <current measurement date> TIME: <current measurement time> PRODUCT MASS: <current mass indicator>...

- Page 76 You should enter the printout of the content setting and design the printout using appropriate variables and text format characters. Example 2: To crop the paper after the printout had been carried out by EPSON printer (if the printer is equipped witht an autocutter blade) the user must select (for a given printout: HEADER, GLP PRINTOUTor FOOTER) an option of non-standard printout 1,2,3 or 4 with <%E>...

-

Page 77: Variables

Inserting a character − By the means of computer keyboard of the USB type A computer keyboard of the USB type can be connected, which enables easier and quicker editing of the print-outs. In order to insert text, you should enter the appropriate option in the menu and with help of the keyboard insert the text and confirm by pressing Enter key. -

Page 78: Database

15. DATABASE The balance software has 3 databases that can be edited (USERS, PRODUCTS, TARES) as well as 2 databases (WEIGHMENTS AND ALIBI), in which all the measurements carried out on the balance are saved. Data range that can be saved in particular databases: USERS –... - Page 79 Access Access levels Access to parameters in the submenu: <Reading> and USER setting in parameter group <Others> except for <Date and Time>. All the weighing processes can be started and carried out at this time. The user has the access to the information preview in <Databases>, and can also define universal variables.

- Page 80 Once the user’s name is added, follow the procedures shown below: User’s code – Max 6 characters User’s password – Max 8 numbers Select the access level Select the language Once all of the data is inserted, you can return to the weighing mode. In order to select a user, follow the logging-in procedure described in section 9 in this manual.

-

Page 81: Products

• Select the user that is to be removed from the list • Press button • The software shows <DELETE?> in the bottom line • Confirm by pressing button • When confirmed, the software removes the selected user from the list •... -

Page 82: Tares

15.3. Tares TARES – 100 different masses of the packaging. The following data can be inserted for each packaging: NAME (30 characters), TARE (mass of the packaging, enter the value with the accuracy of balance reading unit). In order to add tare – mass of the packaging, enter the tare database and insert a name for the tare (follow the procedure as in the section above). -

Page 83: Weighments

Next, insert the details about the packaging. 15.4. Weighments Weighments database is non-editable i.e. the data relating to the weighments is saved automatically. A user has a possibility of viewing this data and printing it out or exporting to PENDRIVE; if such a need occurs (procedure is described further on in this manual). - Page 84 The measurements saved in the balance’s memory cannot be deleted. It is possible for a user to view and print out the data saved in the memory. Procedure: Each measurement is saved with its individual number. The format is: b4.4.n, where <n>...

- Page 85 Example of a printout Date 21.06.2013 Time 13:05:02 User Product Tare 0.000 g Gross 0.000 g 0.000 g --------------Cal. report.--------------- Cal. type Internal User Project 1234567890123459 Date 16.07.2013 Time 13:27:09 Balance ID 10353870 Cal. diff. -0.004 g ---------------------------------------- Signature ........The data that is to be printed out, depends on the settings in parameter P5.3 GLP PRINTOUT.

-

Page 86: Alibi

15.5. ALIBI The balance is equipped with “ALIBI”, a type of memory that allows you to save and store up to 100 000 measurements carried out on the balance. If the “ALIBI” memory is installed in the balance, the saving of the measurements occurs automatically, by pressing <PRINT>... - Page 87 To view the remaining data relating to the measurement, press after selecting the measurement in question: The software will automatically show the data relating to the measurement in the bottom line of the balance display. To move through the data relating to the measurement, press The data relating to the measurement can be printed out by selecting the option <PRINT>...

-

Page 88: Export And Import Of Database

16. EXPORT AND IMPORT OF DATABASE This option allows you to: • Archive the data relating to the weighments carried out– WEIGHMENT database and ALIBI database • Copy the products databases and tares databases between the balances of this series This can be accomplished by using external memory PENDRIVE. -

Page 89: Export Database

Special computer softwares manufactured by RADWAG company are used to read the data from the database files: ALIBI and WEIGHMENTS. The data from the files, in which the data from the PRODUCTS, USERS, and TARES databases is saved, is read automatically by the balance software in the option <IMPORT>. -

Page 90: Import Database

16.2. Import database The function <IMPORT> allows you, amongst others, to transfer the data saved in the balance database. In this balance, the data to be entered in the new balance is entered. This is a quick and reliable way to enter the data without any mistakes. To import the database, plug a PENDRIVE in USB port and next select IMPORT and choose one of the following options The following options are available:... - Page 91 The data can be printed out on any printer connected to the computer. More data can be saved in the same file. The balance software will add the date in the file that has already been created on the pendrive. Consequently, a user can continue with saving the measurements in the same file once created.

-

Page 92: Balance Working Modes

17. BALANCE WORKING MODES Weighments Counting pieces Checkweighing Dosing Deviations % against the mass of the standard Animal weighing Density determination of solids Density determination of liquids Statistics Totalising Peak hold In order to initiate a particular mode press button, and follow by selecting the mode from the list. -

Page 93: Setup For Availability Of Working Modes

Once the button has been pressed, the name of the first available function is shown. - select the working mode - enter the selected working mode The setup for the functions is described further in this manual. 17.1. Setup for availability of working modes In this group of parameters, a user declares functions which are to be available for the user after pressing button. -

Page 94: Counting Parts Of The Same Mass

17.2. Counting parts of the same mass The balance, in the standard version, is equipped with the option of counting small objects of the same mass. • Start Counting Pieces function When the function is initiated for the first time, the standard mass equals 0.0000g. -

Page 95: Setup For Mode Counting Pieces

17.2.1. Setup for mode COUNTING PIECES The software allows entering settings for each working mode. Some the settings are identical in all working modes. They are described in section relating to the mode <WEIGHING>. This section covers only the settings relating to the mode <COUNTING PIECES>. -

Page 96: Setting The Reference Mass By Determining From The Sample Of Known Quantity

17.2.2. Setting the reference mass by determining from the sample of known quantity While determining the mass of a single piece the function ACAI (Automatic Accuracy Correction) is in use. Means of operation of ACAI function: Number of pieces ( on adding) on balance’s weighing pan has to be greater than has been previously Number of pieces (on adding) on balance’s weighing pan must be less than twice the amount of which was visible on the display before... - Page 97 • Zatwierdzić wybraną liczność próbki, zostanie wyświetlony komunikat <PLACExx PCS>. • Place the declared number of pieces in the container and when the result is stable (the symbol is displayed) and confirm their mass by pressing button, • The balance software automatically counts a single sample mass and enters the mode <COUNTING PIECES>...

-

Page 98: Setting The Reference Mass By Entering Its Mass

• The total mass of all the pieces put on the weighing pan must not be greater than the balance’s maximum weighing range. • The mass of a single piece cannot be lower than the 0,1 reading unit of the balance. -

Page 99: Returning To The Weighing Mode

• The balance software automatically counts a single sample mass and enters the mode <COUNTING PIECES> displaying the number of pieces which are on the pan (pcs). In the bottom line, a single sample mass value is shown (if the option for the function <INFORMATION>has been selected). -

Page 100: Checkweighing

17.3. Checkweighing Checkweighing is a working mode that uses two thresholds (LOW and HIGH) in order to check the mass of the samples. It is generally assumed that the mass is correct if it is contained within the threshold values. F button shortcuts The function enables the option of quick access for weighing functions, which are available when buttons F1, F2, F3 or F4 are pressed. -

Page 101: Declaration Of Mass Thresholds

17.3.1. Declaration of mass thresholds Procedure: • Press one of the F buttons, to which the function <ASSIGN THRESHOLDS>is assigned, the editing window is displayed and the value of MIN low threshold can be ascribed. • Use the arrow buttons to ascribe the value of the low threshold •... - Page 102 • Confirm the inserted mass by pressing button, • The balance software proceeds to the mode <CHECKWEIGHING> and states the values of declared thresholds in the bottom line (if such an option for the function <INFORMATION> has been selected). • At the top of the display the message <Min>...

-

Page 103: Dosing

17.4. Dosing The dosing is the mode which consits in the process of sample weighing until target mass is reached. The target mass is defined along with dosing tolerance. Tolerance value is set as a percentage of the target mass, entering the value percentage. -

Page 104: Setting A Target Weight By Entering Values

17.4.1. Setting a target weight by entering values Procedure: • Press one of the F buttons, to which the function <ENTER SAMPLE> is assigned, and the editing window <ENTER SAMPLE> is displayed • Use the arrow buttons to enter the target weight •... - Page 105 • Use the arrow buttons to set the tolerance value • Confirm the entered tolerance by pressing button, • The balance software automatically enters the mode <DOSING> and displays the target mass value with a minus sign, and in the bottom line standard mass value –...

-

Page 106: Returning To The Weighing Mode

17.4.2. Returning to the weighing mode 17.5. Deviations % against the mass of the standard The balance software has the option of deviation control (in percentage) between weighed loads mass samples and the reference mass standard. The mass of the standard can be determined by its weighment or by typing into the balance’s memory by its user. -

Page 107: Setup For Reference Mass Determined By Weighing

VARIABLE 1 – function initiates the selection and editing of variable 1 VARIABLE 2 – function initiates the selection and editing of variable 2 The way of declaring the function is described in the section relating to the weighing mode settings <F button shortcuts>. 17.5.1. -

Page 108: Setup For Reference Mass By Typing Its Mass

17.5.2. Setup for reference mass by typing its mass Procedure: • Press one of the F buttons to which the function <ENTER SAMPLE> is assigned and the editing window will be displayed <ENTER SAMPLE> • Using the arrow buttons enter the known reference mass. •... -

Page 109: Returning To The Weighing Mode

17.5.3. Returning to the weighing mode 17.6. Animal weighing Working mode <Animal weighing> enables reliable determining mass of objects in motion. In principle, these types of objects generate unstable measurement, thus it requires using a different filtering method of measurement signal. 17.6.1. - Page 110 F button shortcuts The function enables the option of quick access for weighing functions, which are available when buttons F1, F2, F3 or F4 are pressed. In the mode <ANIMAL WEIGHING> the following options are available, which a user can assign to each of the F buttons: NONE –...

-

Page 111: Method Of Operation To Manually Start The Process

17.6.2. Method of operation to manually start the process To manually start the process of weighing select the option <AUTOSTART> and <NO> in the mode settings. Procedure: After altering the setting, return to the main window by pressing button repeatedly. Next, set the averaging time in seconds. - Page 112 Place the container in which the measurement is to be carried out on the weighing pan and when the indication is stable tare its mass. Next, enter the mode options and start the measurement procedure following the diagram below. - 112 -...

-

Page 113: Method Of Operation To Automatically Start The Process

After finalising the weighing process measurement result is locked and automatically printed. In order to finish the measurement press button. The program automatically returns to the main window mode. 17.6.3. Method of operation to automatically start the process In order to start the process of weighing in manual mode, select <AUTOSTART> <YES>... -

Page 114: Density Of Solids

17.7. Density of solids Density of solids is a function that allows the determination of the density of the material determined for the reference mass sample. Using this function entails the additional kit for determining density of solids and liquids (optional equipment). In order to assemble the density kit on the balance, remove the weighing pan and anti-draft shield from the balance. - Page 115 The kit suitable for AS balances. Components of the kit: Beaker basis Hook Top weighing pan of density Weighing pan stand determining kit for solids Sinker Weighing pans flexible connector Bottom weighing pan of density Beaker determining kit for solids Thermometer handle Additional weight Additional stand for set of pans or a...

- Page 116 How to assemble the set AS balances PS balances CAUTION: • The kit components should be stored in the kit, • The set of pans or the sinker components should not be put on the table top as it may damage them, •...

-

Page 117: Density Determination Of Solids

F button shortcuts The function enables the option of quick access for weighing functions, which are available when buttons F1, F2, F3 or F4 are pressed. In the mode <DENSITY OF SOLIDS> and <DENSITY OF LIQUIDS> there are options which a user can assign to each of the F buttons: NONE –... - Page 118 sample first in the air (top weighing pan (4) of the density kit), and then weighing the same sample in liquid (on the bottom weighing pan (2) of the density kit). As the same sample is weighed in liquid, the result of density determination is automatically indicated on balance display.

- Page 119 If <ANOTHER> liquid of determined density has been chosen, you should insert its density After inserting this data, the program will pass on to the proper measuring process, 10. First, a mass sample should be placed on the top weighing pan of the kit (weighing in the air), and after the indication stabilization the result is approved 11.

- Page 120 On te second measurement result approval, the program will automatically calculate the tested solid object density and it will be indicated on a balance display. At the same time, the measuring report will be sent to a selected printer port Example of a report: Another copy of the report can be printed out on pressing button.

-

Page 121: Density Of Liquid

measurement. The balance remembers the recently inserted data (liquid, temperature), which shortens the measuring procedure considerably. 17.8. Density of liquid Density of liquid function enables determination of any liquid density. Using this function requires an additional kit for density determination (optional equipment). - Page 122 On inserting the data, the program will pass on to the proper process of measuring. First, the sinker should be placed on the hook (a sample mass determination in the air), and after the indication stabilization the measurement result is approved Next, take the sinker out of the hook and put the tested sample with liquid on the beaker’s basis (the beaker cannot touch the hook).

- Page 123 10. On the second measurement result approval, the program will automatically calculate density of the tested liquid which will be indicated on the display. The measuring report will be sent to a selected printer port Example of a report: Another copy of the report can be printed out on pressing button.

-

Page 124: Statistics

17.9. Statistics Statistics allows you to collect data of the series of measurements and use them to generate statistics. The range of statistics data created depends on the setting of internal functions. F button shortcuts The function enables the option of quick access for weighing functions, which are available when buttons F1, F2, F3 or F4 are pressed. -

Page 125: Means Of Operation

Statistical data that is counted for every measuring series (number of samples) o SUM (total number of samples) o AVG (average value in a series) o MIN (minimal value in a series) o MAX (maximal value in a series) o SDV (standard deviation) o DIF (difference between MAX and MIN in a series) - Page 126 • When the indication is stable, confirm the measurement by pressing button, • The measurement is saved in the balance memory and is automatically printed out with the measurement number. • Remove the load from the weighing pan • Carry out measurements for other loads within this series When all the measurements are saved, it is possible to check the results of the statistics by pressing button:...

- Page 127 The information about the number of saved measurements is displayed in the bottom line. On pressing , the type of the information displayed changes. Selecting the option <PRINT> and pressing button initiates printing out the statistics data as a report. Example of a report: -------------- Statistics -------------- 455.600 g...

-

Page 128: Deleting Statistics

17.8.3. Deleting statistics To delete the statistics data carried out for the series of measurements, you should follow this procedure: Activating the option <FINISH> results in printing out the statistics data and moving to the window <RESULT>, from which it is possible to check the data and print it out again, if necessary. -

Page 129: Returning To The Weighing Mode

17.8.4. Returning to the weighing mode 17.10. Totalising The function Totalising allows a user to weigh individual ingredients of the mixture and totalising their total mass. The software enables adding up approximately 30 ingredients in one mixture. F button shortcuts The function enables the option of quick access for weighing functions, which are available when buttons F1, F2, F3 or F4 are pressed. -

Page 130: Means Of Operation

PRINT FOOTER – function initiates the print-out of a designed footer VARIABLE 1 – function initiates the selection and editing of variable 1 VARIABLE 2 – function initiates the selection and editing of variable 2 The way of declaring the function is described in the section relating to the weighing mode settings <F button shortcuts>. - Page 131 The software adds the mass of the ingredient to the total which is followed by automatic taring of the indication (zero indication is shown on the main display). In the bottom line the data relating to the number of ingredients and total sum is flactuated. •...

- Page 132 The message <RESULT> is displayed in the bottom line, which means that the total result of all the ingredients that have been weighed are shown on the main display. Additionally, the end report, in which all the information about the masses of individual ingredients, total sum and mass of the applied tare, is printed out.

-

Page 133: Returning To The Weighing Mode

17.8.6. Returning to the weighing mode 17.11. Peak hold This function enables peak hold applied to the weighing pan during a single checkweighing process. Apart from standard settings for this mode (described in the weighing mode), additional setting has been introduced. The option is available in the settings for mode <PEAK HOLD>... -

Page 134: Means Of Operation

ENTER TARE – function initiates the option of inserting packaging mass SELECT TARE – function initiates the option of selecting packaging mass from product database PRINT HEADER – function initiates the print-out of a designed header PRINT FOOTER – function initiates the print-out of a designed footer VARIABLE 1 –... -

Page 135: Returning To The Weighing Mode

In order to operate properly, you should set the threshold in grams. It is the indicating point beyond which the function starts to register maximal force apllied. • From now on the balance registers and holds every single weighment which is above the threshold, and is higher than the result of the previous peak hold. -

Page 136: Pipettes Calibration

17.12. Pipettes calibration Pipettes calibration function applies to fixed volume pipettes and adjustable volume pipettes. During volume testing procedure, the software determines accuracy and repeatability errors for tested volume. In case of pipettes with adjustable volume errors for Max, Min and ½ Max volume are estimated. All pipettes are tested for accordance with requirements of PN-EN ISO 8655:2003. -

Page 137: Means Of Operation

F button shortcuts The function enables the option of quick access for weighing functions, which are available when buttons F1, F2, F3 or F4 are pressed. In the mode <PIPETTES CALIBRATION> the following options are available, which a user can assign to each of the F buttons: no function assigned to the button NONE –... - Page 138 • Start the proces. • Following the displayed messages set the correct options. • Enter the ambient temperature, next press ENTER for confirmation. The computer software proceeds to the next step, i.e. ambient humidity settings. • Set the ambient humidity, next press ENTER for confirmation. The computer software proceeds to the next step, i.e.

- Page 139 • Enter (V1) control volume. For fixed volume pipettes (P2.13.5 VOLUME DETERMINATION parameter set to value <1>) this is the one and only value to be entered. The computer software proceeds to the next step, i.e. entering the second control volume (V2) for a tested pipette.

- Page 140 • computer software records the measuremnt. If P2.3.7 AUTOMATING TARRING parameter is set to value <YES> than the indication is automatically tared. If P2.3.7 AUTOMATING TARRING parameter is set to value <NO> than the user must press TARE button in order to tare the indication before (s)he doses another porcion of water.

-

Page 141: Returning To The Weighing Mode

• Example of a report: 17.8.11. Returning to the weighing mode - 141 -... -

Page 142: Communication

COMMUNICATION The menu Communication enables the configuration of port settings, to which you can get access by pressing button. The balance enables communicating with peripheral devices through the following ports: • COM 1 (RS232), • COM 2 (RS232), • USB type A •... -

Page 143: Wifi Port Settings

18.2. WIFI port settings CAUTION: 1. The transmission parameters must be matched to the client’s local network. 2. Most Wi-Fi modules work on one channel, which is defined in the configuration of the Wi-Fi network. 3. To ensure proper operation of the Wi-Fi router, automatically changing channels when configuring the connection set <AUTOCHANNEL>... - Page 144 <CONNECTIVITY>, it is likely that network parameters have been incorrectly entered. − Ensure that the settings are correctly entered, and repeat the process of joining the network. − If this fails, contact your RADWAG service representative. - 144 -...

-

Page 145: Peripherals

19. PERIPHERALS The menu PERIPHERALS is to be found in the menu Parameters to which you can get access by pressing button. In the menu there is a list of devices which can cooperate with the balance. 19.1. Computer In the submenu < COMPUTER> you should select a port, to which the computer with software that enables communication with the balance is connected. -

Page 146: Continuous Transmission

19.1.2. Continuous transmission Continuous transmission parameter enables turning on/off continuous transmission of a measurement. It is possible to set one of three available options: • Continuous transmission in calibration unit <CAL. UNIT>, independently from currently chosen mass unit, measurements are transmitted in unit set on a main measuring device (calibration unit) •... -

Page 147: Printer

USB type A – USB port, to which PCL printer or EPSON printer is connected WIFI –WIFI port, which can send data to special software manufactured by RADWAG e.g. WIN measurement, opened on the computer connected to the balance via WIFI. USB flash drive –USB port type A, to which external memory flash drive is connected USB PC –USB port type B, to which the computer with the special... - Page 148 user wishes for one whole printout to consist of: HEADER, GLP PRINTOUT and FOOTER and to be cropped underneath the FOOTER then the paper crop command should be inserted only for FOOTER settings as a non-standard printout with <%E> value (paper crop for EPSON printer). In such case <SUFFIX> command must remain empty.

-

Page 149: Bar Code Reader

• SUFFIX - 1D564108 (paper crop for EPSON printers equipped with an auto cutter blade) If on the printout in the place of the last digit there are any unexpected signs (for verified balances), than <P4.2.2 PREFIX> parameter should incorporate, apart from code page, code of the UK signs chart: 1B5203. -

Page 150: External Buttons

COM 1, COM 2 CAUTION: The balance cooperates with an additional display manufactured by RADWAG. Ensuring correct cooperation between the balance and the additional display requires that the parameter of the baud rate value set to 115200 bit/s for the port to which the additional display is plugged. - Page 151 press TARE and PRINT external button, the balance will react like for TARE and PRINT buttons on the balance keyboard. If you need to use only one button, connect it directly to COM 2 port or use the socket outlet adapter. CAUTION: In order to ensure the proper cooperation, you need to remember: •...

-

Page 152: Working With External Devices Such As Printer Or

20. WORKING WITH EXTERNAL DEVICES SUCH AS PRINTER OR COMPUTER CAUTION A peripheral devices that is connected to RS 232 or USB port of a balance, has to be powered from the common low voltage power network equipped with common anti-shock protection in a way to preclude possible occurrence of different potentials in zero cables of the peripheral device and the balance. -

Page 153: Cable Pinout Diagram

20.1. Cable pinout diagram Cable: balance – computer (RS232) Cable: balance – printer KAFKA Cable: balance – printer (CITIZEN, EPSON) - 153 -... -

Page 154: Format Of Data Setting

20.2. Format of data setting The measurement result can be sent from the balance to an external device by pressing button on the balance or through sending a command from the computer. 20.3. Format of data sent on pressing of PRINT button CAUTION Unstable measurement print-out is not available for a verified balance. - Page 155 and then: 1 – 3 8 – 16 18 - 20 command - 1 ÷ 3 - characters stability marker - [space] – when stable - [?] – when unstable - [^] – if there is an error exceeding the maximal range + - [v] –...

-

Page 156: Communication Protocol

21. COMMUNICATION PROTOCOL General information A. A character based communication protocol balance-terminal is designed for establishing communication between a RADWAG balance and peripheral devices via RS 232 interface. B. It consists of commands sent from a peripheral device to the balance and responses from the balance. -

Page 157: Responses Format For Commands Sent From Computer Level

21.2. Responses format for commands sent from computer level On receipt of a command, the terminal sends a response in one of the following formats: XX_A CR LF command understood and in progress XX_D CR LF command carried out (appears only after the command XX_A) XX_I CR LF Command understood but not accessible at this moment XX _ ^ CR LF... - Page 158 Tare the balance Format: T CR LF Accessible responses: T_A CR LF - command understood and in progress T_D CR LF - command carried out T_A CR LF - command understood and in progress T_v CR LF - command understood but taring range exceeded T_A CR LF - command understood and in progress T_E CR LF...

- Page 159 Send stable measurement result in basic measuring unit Format: S CR LF Accessible responses: S_A CR LF - command understood and in progress S_E CR LF - time limit exceeded while waiting for stable measurement result S_I CR LF - command understood but not accessible at this moment S_A CR LF - command understood and in progress MASS FRAME...

- Page 160 Send stable measurement result in current weighing unit Format: SU CR LF Accessible responses: SU_A CR LF - command understood and in progress SU_E CR LF - time limit exceeded while waiting for stable measurement result SU_I CR LF - command understood but not accessible at this moment SU_A CR LF - command understood and in progress MASS FRAME...

- Page 161 Switch on continuous transmission in basic measuring unit Format: C1 CR LF Accessible answers: C1_I CR LF - command understood but not accessible at this moment C1_A CR LF - command understood and in progress MASS FRAME - response is mass value in basic measuring unit Frame format 7-15 stability...

-

Page 162: Error Messages

Send all the implemented commands Format: PC CR LF Response: PC_A_”Z,T,S,SI, SU,SUI,C1,C0,CU1,CU0,PC" - command carried out, the indicator sent all the implemented commands 22. ERROR MESSAGES Value beyond zero range, Err2- Value beyond tare range, -Err3- Tarring / Zeroing operation time exceeded, -Err8- Zero value from converter, -NULL-... -

Page 163: Under Hook Weighing

In standard analytical and precision balances loads can be weighed under the weighing pan. Such means of operation requires placing a balance on an uplifted position. RADWAG offers a rack for under hook weighing. The rack is optional equipment offered for balances PS series. -

Page 164: Additional Equipment

24. ADDITIONAL EQUIPMENT 24.1. Anti-vibration table It is a very stable basis which eliminates all kinds of vibrations and ground shakes. The inner part of the table holds a marble plate, which is a foundation for balance positioning. 24.2. Rack for under hook weighing The rack is used if under hook weighing option has to be applied. - Page 165 O F E L E C T R O N I C W E I G H I N G I N S T R U M E N T S RADWAG Balances & Scales 26 – 600 Radom 28 Bracka Street POLAND phone.

Need help?

Do you have a question about the AS 220.R and is the answer not in the manual?

Questions and answers