Table of Contents

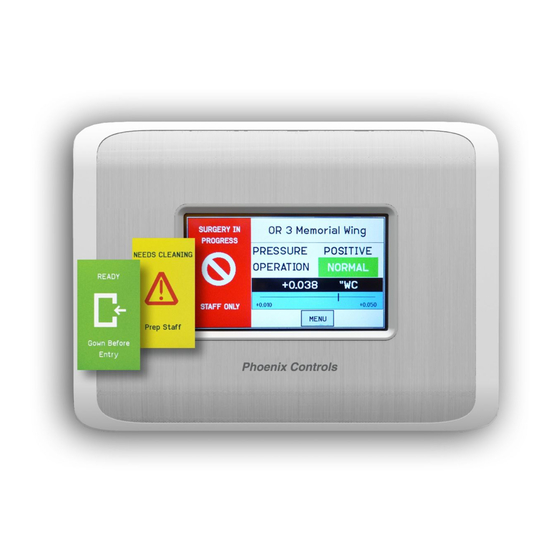

Advertisement

Advertisement

Table of Contents

Summary of Contents for Phoenix Advanced pressure monitor II

- Page 1 Advanced Pressure Monitor II and Central Display Rough-In Installation Guide...

- Page 2 Accel, Phoenix, Phoenix Controls, Usage Based Controls, UBC, Celeris, Theris, Traccel, Zone Presence Sensor and ZPS are registered trademarks, and LabPro, MacroServer, MicroServer and Neutralizer are trademarks of Honeywell International, Inc. Phoenix Controls products are covered by one or more of the following U.S. patents: 5,251,665 5,304,093...

-

Page 3: Table Of Contents

Table of Contents Section 1. Advanced Pressure Monitor II Rough-In Installation 1.1 Required Parts to be Supplied by the Installer ........1 1.2 Parts Included with Your Order . - Page 4 4.5 Phoenix Recommended Cables ........

-

Page 5: Section 1. Advanced Pressure Monitor Ii Rough-In Installation

Section 1. Advanced Pressure Monitor II Rough-In Installation For the Advanced Pressure Monitor II (APM2) to be installed correctly, the rough-in phase of the project must be completed properly. This section will outline the specific considerations the General Contractor must pay attention to so that the final wiring and commissioning will go smoothly. -

Page 6: Parts Included With Your Order

0.25" O.D. Tubes, Silicone, with integrated springs and attached brass barbed couplings, quantity 2 • Mounting screws, 6-32 x 1/2 Phillips head, quantity 5 • Mating Electrical Connectors, Phoenix contact MC plug kit, quantity 1 with 3 green and 2 black connec- tors 1.3 Installation Overview •... -

Page 7: Wiring Recommendations

Each pressurization zone should have either a dedicated single-phase primary circuit, or a secondary circuit disconnect. • Refer to Phoenix Recommended Cables on page 33 for approved cable manufacturers and wire types. • Use stranded wire for ease of installation. -

Page 8: Wiring Triple Gang Electrical Box

Advanced Pressure Monitor II Rough-In Installation Installation Overview • Strip 0.25" (6.4 mm) of insulation from each conductor, twist the strands, insert the conductor fully into the terminal block, and tighten the terminal. •Test the wire connection by pulling on each conductor. -

Page 9: Use Of External Transducers

(remote) transducer for the second room, or two external remote transducers may be used and wired to the analog inputs in the back of the unit. See Phoenix Recommended Cables on page 33 for approved cable manufacturers and wire types. NOTE: Layout the system in terms of wiring: •... -

Page 10: Remote Annunicator

Advanced Pressure Monitor II Rough-In Installation Plumbing (Finish) 1.3.5 Remote Annunicator If an remote annunciator will be used, then mount a single gang electrical box in the desired location and run wires to it. Green LED Audible Alarm Red LED... -

Page 11: Wiring

Advanced Pressure Monitor II Rough-In Installation Wiring Attach pressure tubing as follows: 1. Install the supplied silicone tube (with integrated spring) and attached barbed tube adaptor onto the end of the 0.25 field tubing. Thread the tubes, with installed adaptor, through the conduit opening at the bottom of the electrical box. -

Page 12: Power, Labeled Power, L1, L2, Ground Symbol

Advanced Pressure Monitor II Rough-In Installation Wiring ANALOG (ANL) OUTPUT POWER Earth Ground Current Output (4-20 mA) Voltage Output (0-5 Vdc, 0-10 Vdc) 24 Vac 24 Vac INPUTS (wired to door N.O. contact) RELAY Door Digital Input +15 Vdc Analog Input2... -

Page 13: Analog Input, Labeled Door, Input2, Input1

APM2 Rough-In Installation Guide Advanced Pressure Monitor II Rough-In Installation Wiring 1.5.3 Analog Input, Labeled DOOR, INPUT2, INPUT1 There are two analog inputs available for remotely mounted transducer inputs. These are INPUT1 and INPUT2. A 15 Vdc (14.8 to 15.2) excitation is available to power up to two transducers. They can source 90 mA max. -

Page 14: Relay And Annunciator Output, Labeled Relay

Advanced Pressure Monitor II Rough-In Installation Wiring 1.5.5 Relay and Annunciator Output, Labeled RELAY There is an SPDT dry contact available. When an alarm occurs the Normally Open (NO) and the Common (COM) internal contacts will be closed. During no alarm conditions the Normally Closed (NC) and COM are shorted. -

Page 15: Third Party Remote Annunciator

APM2 Rough-In Installation Guide Advanced Pressure Monitor II Rough-In Installation Wiring 1.5.7 Third Party Remote Annunciator The APM2 can drive other annunciators that are powered by a 15V supply, 50 mA max current draw, and accept a 15V trigger. If purchased separately, the Remote Annunciator can also be driven as shown below. - Page 16 Advanced Pressure Monitor II Rough-In Installation Wiring Mounting APM2 in Triple Gang Electrical Box Figure 1-11. 4. Mount the front cover assembly. Installed APM2 Figure 1-12. MKT-0262 MPC-1748 Rev 02/13...

-

Page 17: Section 2. Fitting An Apm2 In An Apm100 Enclosure

Section 2. Fitting an APM2 in an APM100 Enclosure 2.1 Overview APM100 pressure monitors from Phoenix Controls can be replaced in the field using the newer APM2 units. However, it is important to order the Retrofit Kit version of the APM2 product for compatibility with the existing enclosure. -

Page 18: Instructions

Fitting an APM2 in an APM100 Enclosure Instructions 2.2 Instructions As part of the site preparation, any wiring or tubing coming into the APM100 unit may IMPORTANT: need to be moved to accomodate the depth of the APM2. APM100 Display Figure 2-1. -

Page 19: Ensure Existing Apm1 Enclosure Is Prepared For Apm2 Unit

APM2 Rough-In Installation Guide Fitting an APM2 in an APM100 Enclosure Instructions 2.2.2 Ensure Existing APM1 Enclosure Is Prepared For APM2 Unit 1. Make sure the wall surface around the existing enclosure is flat and clean with no wall damage or holes beyond the electrical box. -

Page 20: Wiring

The back of the APM2 has electrical connectors labeled with their function. The mating electrical connectors (supplied) are color coded and labeled with the matching function. Refer to the Advanced Pressure Monitor II User’s Guide (MKT-0263) for detailed wiring instructions. 2.2.5 Remotely Switching Alarm Setpoints... -

Page 21: Modified Pressure Taps

Figure 2-5. 2.2.7 Complete the Installation 1. Complete the installation following the instructions in the Advanced Pressure Monitor II User’s Guide (MKT-0263), which can be obtained from the Partner Login area of http://www.phoenixcontrols.com/. 2. Once wiring and pressure tubes are connected, verify functionality of the APM2 before sliding it into the wall enclosure. - Page 22 Fitting an APM2 in an APM100 Enclosure Instructions 4. Mount the front cover assembly. Installed APM2 Figure 2-7. MKT-0262 MPC-1748 Rev 02/13...

-

Page 23: Section 3. Apm2 Central Display Rough-In Installation

Triple gang-double deep electrical box (RACO 697 or Appleton M3-350), quantity 1 • Green grounding screw, quantity 1 • Power (18 AWG recommended) and signal wiring (22 AWG recommended), as needed. Refer to Phoenix Recommended Cables on page 33. • EMT conduit (if required by local code) •... -

Page 24: Wiring Recommendations

Each pressurization zone should have either a dedicated single-phase primary circuit, or a secondary circuit disconnect. • See Phoenix Recommended Cables on page 33 for approved cable manufacturers and wire types. • Use stranded wire for ease of installation. •... -

Page 25: Wiring Triple Gang Electrical Box

APM2 Rough-In Installation Guide APM2 Central Display Rough-In Installation Installation Overview • Strip 0.25" (6.4 mm) of insulation from each conductor, twist the strands, insert the conductor fully into the terminal block, and tighten the terminal. •Test the wire connection by pulling on each conductor. WARNING: Wiring must be performed by a licensed electrician according to local and state codes. -

Page 26: Wiring

APM2 Central Display Rough-In Installation Wiring 3.4 Wiring POWER Earth Ground 24 Vac 24 Vac COMM BACnet Communications (See Detail A) B (+) A (-) COMM B (+) DATA + A (-) DATA - DETAIL "A" GROUND SHIELD - ONE END ONLY REAR VIEW Rear View of the APM2 Central Display Showing Wiring Connections Figure 3-3. -

Page 27: Completing The Finish Wiring

APM2 Rough-In Installation Guide APM2 Central Display Rough-In Installation Wiring 3.4.2 Completing the Finish Wiring 1. Connect all the electrical connectors matching the wiring connector with the mates on the back of the unit. Connectors are color coded and keyed. 2. - Page 28 APM2 Central Display Rough-In Installation Wiring THIS PAGE INTENTIONALLY LEFT BLANK. MKT-0262 MPC-1748 Rev 02/13...

-

Page 29: Section 4. Ancillary Product Specifications

APM2 Rough-In Installation Guide Ancillary Product Specifications Model 264 Pressure Transducer Section 4. Ancillary Product Specifications The following specifications are subject to changes without notice. NOTE: 4.1 Model 264 Pressure Transducer Table 1. Model 264 Pressure Transducer (Remote Transducer 0-5 V Output) Model 264 Pressure Transducer Performance Data Standard... - Page 30 Ancillary Product Specifications Model 264 Pressure Transducer Pressure Fittings 3/16" OD barbed brass pressure fitting for 1/4" push-on tubing Zero and Span Adjustments Accessible on top of case Weight (approximate) 10 ounces Pressure Media Typically air or similar non-conducting gases Electrical Data—Voltage Circuit 3-wire (Com, Exc, Out)

- Page 31 APM2 Rough-In Installation Guide Ancillary Product Specifications Model 264 Pressure Transducer #6 SCREW R0.078 in. TYP . WIRE CLAMP (R1.98 mm) TOP VIEW 3 PLACES 0.312 in. TYP . (7.92 mm) 2.750 in. (69.85 mm) 1.662 in. TYP . 0.385 in. (42.21 mm) TYP .

-

Page 32: Model 267 Pressure Transducer

Ancillary Product Specifications Model 267 Pressure Transducer 4.2 Model 267 Pressure Transducer Table 2. Model 267 Pressure Transducer Performance Data Standard Optional ± 1.0 % FS ± 0.4 % FS ± 0.25 % FS Accuracy RSS (at constant temperature) Non-linearity (BFSL) ±... - Page 33 APM2 Rough-In Installation Guide Ancillary Product Specifications Model 267 Pressure Transducer Electrical Data—Voltage Circuit 3-wire (Exc, Gnd, Sig) Excitation/Output (0-5 Vdc output) 9 - 30 Vac / 12 - 40 Vdc 11 - 30 Vac / 13 - 40 Vdc Excitation/Output (0-10 Vdc output) Bi-directional output at zero pressure Mid-range of specified output...

- Page 34 Ancillary Product Specifications Model 267 Pressure Transducer 6.10 in. (155 mm) 5.60 in. (142 mm) 0.18 in. (Ø4.5 mm) 2.68 in. 0.75 in. (68 mm) (19 mm) 1.34 in. (34 mm) 0.50 in. (13 mm) 3/16" O.D. PRESSURE FITTING FOR 1/4" PUSH-ON TUBING 0.80 in.

-

Page 35: Remote Annunciator

APM2 Rough-In Installation Guide Ancillary Product Specifications Remote Annunciator 4.3 Remote Annunciator Table 3. Remote Annunciator Enclosure 2.75" W x 4.5" H stainless steel wall cover plate External Supply 15 Vdc, 50 mA maximum Display Panel Green and red LED indicators and Acknowledge (ACK) switch Audible Alarm 0-85 dBA measured 4"... -

Page 36: Pressure Pickup Port

Ancillary Product Specifications Pressure Pickup Port 4.4 Pressure Pickup Port Table 4. Pressure Pickup Port Cover Stainless steel standard wall cover plate Mounting Standard single gang electrical box (2 screws included) Dimensions 2.77" (70.23 mm) W x 4.52" (114.78 mm) H x 1.02" (26.08 mm) D Pressure Fitting 1/4"... -

Page 37: Phoenix Recommended Cables

APM2 Rough-In Installation Guide Ancillary Product Specifications Phoenix Recommended Cables 4.5 Phoenix Recommended Cables Cable Plenum Wire Primary Alternate Function Color Code Notes Type Rated Gauge Vendor/Part # Vendor/Part # 24 Vac power to Belden 9409 1: Red Must be... - Page 38 Ancillary Product Specifications Phoenix Recommended Cables Cable Plenum Wire Primary Alternate Function Color Code Notes Type Rated Gauge Vendor/Part # Vendor/Part # Signal Belden 9421 Manhattan 1: White M13308 2: Orange substitutes 3: Black 4: Red 5: Green 6: Yellow...

-

Page 39: Ms/Tp Specifications For Alternate Cable Solutions

APM2 Rough-In Installation Guide Ancillary Product Specifications Phoenix Recommended Cables Cable Plenum Wire Primary Alternate Function Color Code Notes Type Rated Gauge Vendor/Part # Vendor/Part # Shielded Belden 82729 1: White with Blue Shield with MS/TP (100 ohm) specifications stripe... - Page 40 Ancillary Product Specifications Phoenix Recommended Cables THIS PAGE INTENTIONALLY LEFT BLANK. MKT-0262 MPC-1748 Rev 02/13...

- Page 41 Electrical Box 1, 19 3-gang Double-deep 13 5-gang Single deep 13 Cables Appleton M3-350 1, 2, 19 Phoenix Recommended 33 RACO 697 1, 2, 19 Calibration Certificate Electrical Connectors (supplied) 8, 16, 22 APM2 13 EMT Conduit 1, 2, 19...

- Page 42 Model 267 Electrical Data Included Parts 2, 19 Current 29 0.25" O.D. Tubes 2 Voltage 29 Advanced Pressure Monitor II 2, 19 Model 267 Environmental Data 28 APM2 2, 19 Model 267 Performance Data 28 Barbed Couplings 2 Model 267 Physical Description 28...

- Page 43 APM2 Rough-In Installation Guide Pressure Pickup Port 1, 4, 32 Room Side 14 Turn Off Power 14 Pressure Pickup Port Installation 5 Pressure Signals 5, 11 Pressure Taps 17 Pressure Transducer Use of External Transducers 5 Model 264 25 Model 267 28 Pressure Tubing 14 Voltage Model 264 Electrical Data 26...

- Page 44 THIS PAGE INTENTIONALLY LEFT BLANK. IX-4 MKT-0262 MPC-1748 Rev 02/13...

- Page 46 For additional information and a listing of our global offi ces, please visit our Web site at www.phoenixcontrols.com or call (800) 340-0007. Phoenix Controls is a business of Honeywell International, Inc. © 2010 Phoenix Controls 2/13 Printed in U.S.A. MKT-0262 MPC-1748...

Need help?

Do you have a question about the Advanced pressure monitor II and is the answer not in the manual?

Questions and answers