Bunn G9WD-RH Instructions Manual

Coffee grinder

Hide thumbs

Also See for G9WD-RH:

- Installation & operating manual (15 pages) ,

- Specifications (2 pages) ,

- Use & care instructions (2 pages)

Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Bunn G9WD-RH

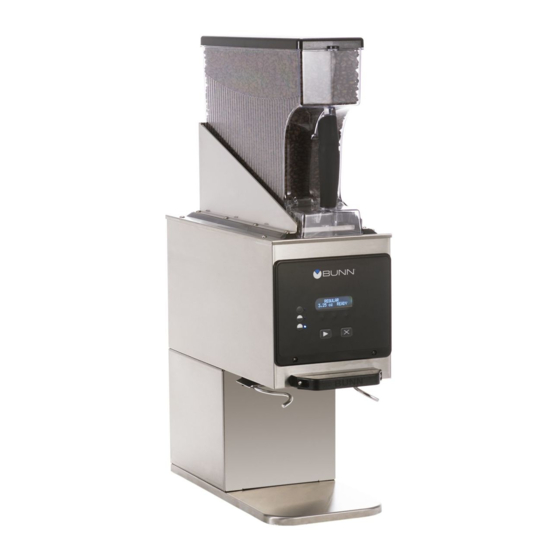

- Page 1 BUNN TECHNICAL TRAINING ® G9WD-RH...

-

Page 2: Table Of Contents

PM Steps ..........................20 Unit 5: Troubleshooting Service Tools ........................23 Test Outputs ......................... 24 Test Switches ....................... 24 Test Frequency ......................24 Error Messages ........................24 Transducer Replacement Special Instructions ..............25 © 2010 Bunn-O-Matic Corporation. All Rights Reserved Rev. A... -

Page 3: Unit 1: Installation

nstallation Unit Objectives Given a realistic scenario depicting a new site install, the learner will be able to install and setup the Weight Driven Grinder for customer turnover without error. Given a new machine, all the necessary tools and safety equipment, the learner will be able to install the Weight Driven Grinder without error. -

Page 4: Site Requirements

• G9WD-RH is only for indoor use on a sturdy counter or shelf • Adequate space must be available above the grinder to raise the lids when adding beans • G9WD-RH dimensions is 29.1”H x 9.0” W x 16.0” D (73.9cm H x 22.8cm W x 40.6cm D) • Weight 67 lbs Electrical • 120vac, 2 wire plus ground... -

Page 5: Hopper Install And Coffee Grinding

ING. THIS WILL CAUSE THE INCORRECT WEIGHT OF COFFEE TO BE GROUND. Step 7: Remove the funnel from the grinder and level the bed of grounds by gently shaking. Step 8: The loaded funnel is now ready for use in any commercial drip coffee brewer according to the manufac¬turer’s instructions. Bunn-O-Matic Corporation... -

Page 6: Unit 2: Setup

etup Unit Objectives Given a realistic scenario depicting a new site install, the learner will be able to install and setup the Weight Driven Grinder for customer turnover without error. Given an installed machine, all the necessary tools and safety equipment, the learner will be able to set the machine up for initial operation. -

Page 7: Setup And Programming

C. Hidden button used to navigate the programming menus. Operating Controls D. Used to select between small, medium and large batch size. E. Used to initiate or start a grind cycle. F. Used to stop the operation of the grinder. Bunn-O-Matic Corporation... -

Page 8: Programming Lockout

The items that can be checked vary from machine to machine. This is a feature that aides in troubleshooting and test individual input and out- puts. Selecting “Yes” will reset all of the previously entered settings and calibrations. Factory preset default values will replace all previous settings. G9WD-RH Training Manual... -

Page 9: Level 2 Programming

Smart funnels are used to transfer information between grinder and brewer. Two pieces of information writes to the transponder and is read from the brewer which is batch size and coffee name. Bunn-O-Matic Corporation... -

Page 10: Calibrating The Selected Coffee

“Review Recipe” menu will follow after the “3 Batches Done” menu. The purpose of the “Cali- brate Coffee” menu sets the “offset” weight for the coffee name selected, so that accurate weight grinding will be achieved. Step 1: Enter level 1 program and stop at “Select Coffee” menu and select yes. G9WD-RH Training Manual... -

Page 11: Calibrating Grinder Scale

Step 1: Enter level 1 program. “Select Coffee” menu will appear. Depress the right hidden switch one more time to scroll to “Enter Password” screen. Press and hold the right hidden switch for 3 seconds in “Enter Password” menu to enter level 2 programming. Level 2 programming will begin with “Machine Type” menu. Bunn-O-Matic Corporation... - Page 12 If precision weight is not available, proceed with a known object weight (ounces) for “Calibration Scale” menu. The transducer and CBA will be calibrated but a precision weight will still be needed for precise calibration of the two components together. G9WD-RH Training Manual...

-

Page 13: Unit 3: Machine Composition

achine oMposition Unit Objectives Given a realistic scenario in which the learner has access to the machine’s internal components the learner will understand the composition and functions of the Weight Driven Grinder. Given a realistic scenario requiring the learner to access the internal components of the machine the learner will be able to remove the top cover, front /rear access covers and access the corresponding internal components. -

Page 14: Exterior Overview

Machine Composition Exterior Overview The majority of service work done to the G9WD-RH grinder will require the service technician to access the inside of the unit. The grinder has four removable panels to facilitate access- the control panel, front/rear panel and top panel. -

Page 15: Component Bracket Assembly

You are now ready to remove the rotor auger off the motor shaft by pulling the rotor auger toward you. If the rotor auger will not move on the motor shaft a tool is available for purchase called a Burr Rotor Puller Kit (BUNN P/N:27680.000) to pull the rotor auger from the motor shaft. You now have ac- cess to posterior and anterior burrs and motor shaft extension. Bunn-O-Matic Corporation... -

Page 16: Machine Function And Operations

The hopper holds 6 lbs of coffee beans. The hopper has a transponder located in the rear for the acceptance of read/write of coffee flavor name for the hopper. Not all weight driven grinders will have the read/write capabil- ity and will be model specific. G9WD-RH Training Manual... -

Page 17: Grind System

The CBA reads the recipe and will in return activate an output to the relay to turn on the motor. The recipe sequence will run the amount of weight or time in the recipe. The weigh scale Bunn-O-Matic Corporation... - Page 18 “weight” mode, it will always tare the funnel when you depress the grind switch and then start the grind recipe process. J1 Stepdown Transformer 120/12 VAC and K1-Relay Coil J7 Load Cell 12-14 VDC J12 Funnel Sensor J13 Switch Membrane G9WD-RH Training Manual...

-

Page 19: Unit 4: Preventive Maintenance

reventive aintenance Unit Objectives Given a realistic scenario depicting a machine requiring a preventive maintenance, the learner will be able to identify which elements of a component need to be serviced without error. Given a machine, all the necessary tools and safety equipment, the learner will be able to identify the components that need to be serviced for the PM. -

Page 20: Preventive Maintenance

□ Clean the dechaffer plate with cloth or replace the dechaffer plate if it is broken or missing from the bracket. □ Re-installation is opposite from removal. □ If replacing the dechaffer, make sure it has clearance and does not rub. G9WD-RH Training Manual... - Page 21 Note: The adjustment range for “Calibration Oz” menu is 3 to 16 ounces. A precision weight between the parameter ranges can be used but is recommended to use a precision weight matched with the typical weight recipe volume being used. Bunn-O-Matic Corporation...

-

Page 22: Unit 5: Troubleshooting

roubleshooting Unit Objectives Given a realistic scenario depicting a broken machine, the learner will be able to effectively troubleshoot, diagnosis, and repair the problem returning the machine to normal operation. Given a machine displaying an error message, all the necessary tools and safety equipment, the learner will be able to diagnosis the problem. -

Page 23: Service Tools

Service Tools The G9WD-RH grinder features on-board troubleshooting menus. Since all of the machine’s components are con- trolled or activated by the control board you can activate and test load components individually from the user inter- face switch/display board and test the outputs, switches, frequency and weigh scale. -

Page 24: Test Outputs

The “Scale Unstable Please Try Again” error message appears when you depress the grind button and the CBA can- not tare the funnel within the allowable time frame of 20 seconds. The message will display for 5 seconds and return back to the home screen “Ready To Grind”. G9WD-RH Training Manual... -

Page 25: Transducer Replacement Special Instructions

Loctite should be used on the screws. It is very important to use a precision weight to calibrate the new replacement transducer to the main control board. Bunn-O-Matic Corporation...

Need help?

Do you have a question about the G9WD-RH and is the answer not in the manual?

Questions and answers