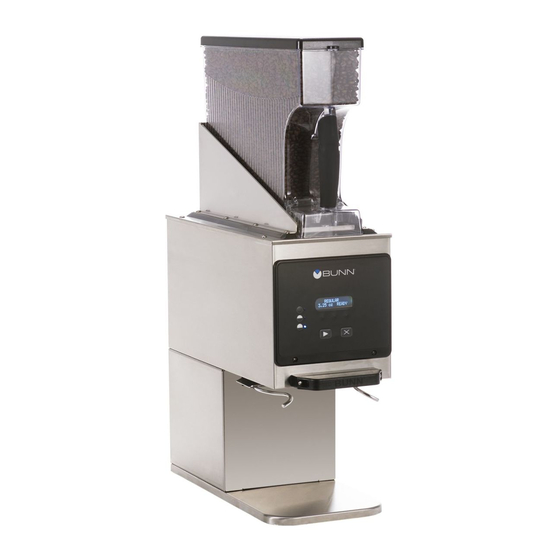

Bunn G9WD-RH Series Installation & Operating Manual

Weight-based, portion-control coffee grinder with 3 batch sizes

Hide thumbs

Also See for G9WD-RH Series:

- Instructions manual (26 pages) ,

- Installation & operating manual (15 pages) ,

- Specifications (2 pages)

Advertisement

Quick Links

G9WD-RH

Weight-based, portion-control coffee grinder with 3 batch sizes

INSTALLATION & OPERATING GUIDE

To ensure you have the latest revision of the Operating Manual, or to view the Illustrated Parts Catalog, Programming

Manual, or Service Manual, please visit the Bunn-O-Matic website, at www.bunn.com. For Technical Service, contact

Bunn-O-Matic Corporation at 1-800-286-6070.

Bunn-O-Matic Corporation

Post Office Box 3227, Springfield, Illinois 62708-3227

Phone (217) 529-6601 | Fax (217) 529-6644

www.bunn.com

41451.0001 K 05/19 © 2009 Bunn-O-Matic Corporation

Advertisement

Subscribe to Our Youtube Channel

Summary of Contents for Bunn G9WD-RH Series

- Page 1 INSTALLATION & OPERATING GUIDE To ensure you have the latest revision of the Operating Manual, or to view the Illustrated Parts Catalog, Programming Manual, or Service Manual, please visit the Bunn-O-Matic website, at www.bunn.com. For Technical Service, contact Bunn-O-Matic Corporation at 1-800-286-6070.

- Page 2 FIED HEREIN, TO REPAIR, REPLACEMENT OR REFUND. In no event shall BUNN be liable for any other damage or loss, including, but not limited to, lost profits, lost sales, loss of use of equipment, claims of Buyer’s customers, cost of capital, cost of down time, cost of substitute equip- ment, facilities or services, or any other special, incidental or consequential damages.

-

Page 3: Table Of Contents

CONTENTS Introduction ........................3 User Notices ........................3 Packaging & Shim Removal ...................4 Electrical Requirements ....................5 - 7 Operating Controls ......................7 Coffee Grinding ......................8 Adjustments ........................8 Cleaning .........................9 Preventive Maintenance ....................9 Troubleshooting ......................12 INTRODUCTION This equipment will store up-to six pounds of whole bean coffee in the hopper and grind it to a preset grind and amount into an awaiting funnel and filter from most commercial drip coffee brewers. -

Page 4: Packaging & Shim Removal

PACKAGING & SHIM REMOVAL WARNING THE FOLLOWING MUST BE COMPLETED BY A QUALIFIED SERVICE TECHNICIAN PRIOR TO OPERATING THE GRINDER. NOTE: DISCONNECT THE GRINDER FROM THE AC POWER! Step 1 - Remove & discard tape holding funnel arm in place. (Figure 1) Step 2 - Remove &... - Page 5 NORTH AMERICAN REQUIREMENTS • This appliance must be installed in locations where it can be overseen by trained personnel. • For proper operation, this appliance must be installed where the temperature is between 41°F to 95°F (5°C to 35°C). • Appliance shall not be tilted more than 10° for safe operation. •...

- Page 6 CE REQUIREMENTS • This appliance must be installed in locations where it can be overseen by trained personnel. • For proper operation, this appliance must be installed where the temperature is between 5°C to 35°C. • Appliance shall not be tilted more than 10° for safe operation. •...

-

Page 7: Electrical Requirements

ELECTRICAL REQUIREMENTS Refer to Data Plate on grinder, and local/national electrical codes to determine circuit requirements. This grinder has an attached cordset and requires 2-wire, grounded service rated: 120 volts ac, 15 amp, single phase, 60 Hz, for domestic grinders. 220-240 volts ac, 10 amp, single phase, 50 Hz, for most international grinders. -

Page 8: Coffee Grinding

COFFEE GRINDING 1. Visually inspect the hopper for an ample supply of whole bean coffee. 2. Place a paper filter into the brew funnel. The filter must not be folded-over or tilted to one side. 3. Insert the funnel into the funnel rails until it stops. 4. -

Page 9: Cleaning

15. Reinstall the cleaned hopper on the grinder. PREVENTIVE MAINTENANCE BUNN recommends that preventive maintenance be performed at regular intervals. Maintenance should be per- formed by a qualified service technician. For technical service, contact BUNN at 1-800-286-6070. NOTE: Replacement parts or service caused by failure to perform required maintenance is not covered by warranty. -

Page 10: Troubleshooting

A troubleshooting guide is provided to suggest probable causes and remedies for the most likely problems encountered. If the problem remains after exhausting the troubleshooting steps, contact the Bunn-O-Matic Technical Service Department. • Inspection, testing and repair of electrical equipment should be performed only by qualified service personnel. - Page 11 TROUBLESHOOTING (Continued) Problem Probable Cause Remedy Check that relay contacts close Grinder will not start 5. Relay when start switch is pressed. (continued) 6. Motor With a voltmeter, check that 120 volts AC is present across L1 and L2 on the rear of the motor when the Start switch is pressed.

Need help?

Do you have a question about the G9WD-RH Series and is the answer not in the manual?

Questions and answers