Advertisement

Table of Contents

- 1 Table of Contents

- 2 Safety Instructions

- 3 General Information

- 4 Installation

- 5 Specifications

- 6 Initial Startup

- 7 Filter Disassembly/Assembly

- 8 Filter Cleaning Procedure

- 9 System Inspection/Winterizing

- 10 Troubleshooting Guide

- 11 Pressure Drop Curve

- 12 Repair Parts List

- Download this manual

See also:

Owner's Manual

Pentair Water Pool and Spa, Inc.

© 2007 Pentair Water Pool and Spa, Inc. All rights reserved. This document is subject to change without notice.

1620 Hawkins Ave., Sanford, NC 27330 • (919) 566-8000

10951 West Los Angeles Ave., Moorpark, CA 93021 • (805) 553-5000

Trademarks and Disclaimers:

®

System 3

and Pentair Water Pool and Spa

ated companies in the United States and/or other counties. Unless noted, names and brands of others that may be used in

this document are not used to indicate an affiliation or endorsement between the proprietors of these names and brands and

Pentair Water Pool and Spa, Inc. Those names and brands may be the trademarks or registered trademarks of those parties

or others. Printed in U.S.A.

November 1, 2007

SYSTEM 3

MODULAR MEDIA FILTER

O

W

N

E

U.S. Patent No. 3988244, 4537681, 5190651; other patents pending.

INSTALLATION, OPERATION & PARTS

S7M120

S7M400

®

are registered trademarks of Pentair Water Pool and Spa, Inc. and/or its affili-

®

R ' S

M

A N

MODELS

S8M150

S8M500

U

A L

Furnish this manual to the end user

of this filter; its use will reduce ser-

vice calls and chance of injury and

will lengthen filter life.

S293 (Rev. A)

Advertisement

Table of Contents

Summary of Contents for STA-RITE System 3

- Page 1 ® SYSTEM 3 MODULAR MEDIA FILTER R ’ S U.S. Patent No. 3988244, 4537681, 5190651; other patents pending. INSTALLATION, OPERATION & PARTS MODELS S7M120 S8M150 Furnish this manual to the end user of this filter; its use will reduce ser-...

-

Page 2: Table Of Contents

2. Make sure there is no air entrapped in system. Release all air in system before testing. READ AND FOLLOW 3. When using a Sta-Rite pump and trap, tighten pump SAFETY INSTRUCTIONS! trap lid to 30 ft. lbs. (4.1 kg-m.) torque before testing. -

Page 3: General Information

NOTICE: Some pool disinfectants may clog filter media. GENERAL To maximize media-life and filter cycle time, closely fol- INFORMATION low disinfectant manufacturers instructions when clean- Hazardous pressure. Can cause severe ing pool or filter. injury or major property damage from tank blow up. If filter is improperly disassembled or as- Release all pressure and read instructions before work- sembled, it may explode under pressure! To avoid dan-... -

Page 4: Specifications

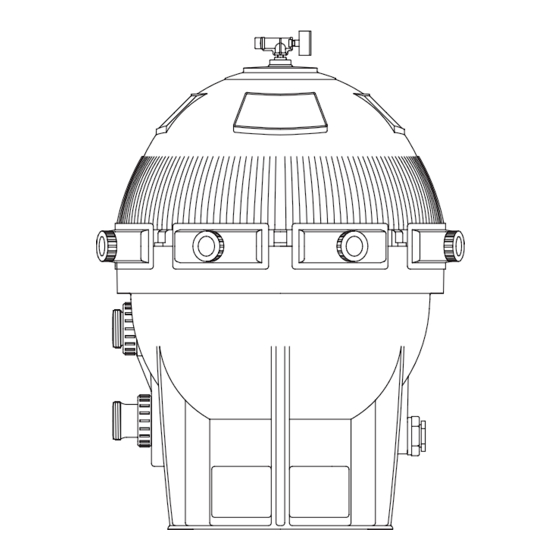

130 GPM (492 l/min.) Max Operating Pressure 50 PSI (345 kPa) 50 PSI (345 kPa) 50 PSI (345 kPa) 50 PSI (345 kPa) INLET 7.812" (19.85 cm) OUTLET 9.19" (23.3 cm) 2" (51mm) Sta-Rite Union Connectors Figure 1 - Dimensions in inches (mm) -

Page 5: Initial Startup

INITIAL START-UP Assembly: 1. Remove Cord Ring slowly to avoid stretching or tearing Turn pump OFF before starting procedure. Properly seat filter clamps and securely tighten clamp knobs before proceeding. 2. Inspect Cord Ring (Key No. 23, Page 10) for cuts, nicks, etc. -

Page 6: Filter Cleaning Procedure

B. Special Cleaning Instructions: FILTER CLEANING PROCEDURE Use this procedure to clean scale or oils which are not NOTICE: When sanitizing your pool using PHMB (poly- removed by simply hosing down and scrubbing ele- hexamethylene biquanide based) cleaners, use only ment. -

Page 7: System Inspection/Winterizing

1. Clean filter elements first according to cleaning SYSTEM INSPECTION procedure above. General 2. Use one of the commercial filter cleaners listed Wash outside of filter with a mild detergent and water. (see Table III) Rinse off with hose. TABLE III - Specialty Filter Cleaners NOTICE: DO NOT use solvents to clean filter;... -

Page 8: Troubleshooting Guide

C. Pool Water Not Clear: TROUBLESHOOTING GUIDE 1. Chlorine dosage too low; maintain adequate chlorine residual (consult pool professional for A. Short Cycle: recommendation). Time between cleanings will vary with each installa- 2. Element cloth torn or punctured; replace element. tion and between different areas of the country. -

Page 9: Pressure Drop Curve

PRESSURE DROP CURVE Max Flow Rate S7M400 S8M150 S7M120 S8M500 (41.4) (20.7) (13.8) (76) (154) (530) (227) (303) (379) (454) Flow Rate in GPM (LPM) 3102 1097... -

Page 10: Repair Parts List

2860 0597 REPAIR PARTS LIST Model No. S7M120 S7M400 S8M150 S8M500 Part Description Qty. 300 Ft Filters 400 Ft Filters 450 Ft Filters 500 Ft Filters 2 Inch Gauge 33600-0023T 33600-0023T 33600-0023T 33600-0023T Air Release Valve WC212-120P WC212-120P WC212-120P WC212-120P Close Nipple 1/4 In. - Page 11 Blank Page...

- Page 12 S293 (Rev. A)

Need help?

Do you have a question about the System 3 and is the answer not in the manual?

Questions and answers

I have a drip at the bottom bulkhead retaining nut, is there a gasket that I can purchase that will stop the drip?