Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Electrolux EWM2100

-

Page 1: Service Manual

SERVICE MANUAL WASHING Washing machines & © ELECTROLUX ITALIA S.p.A. Washer-dryers Publication no. Spares Operations Italy Corso Lino Zanussi, 30 Guide to diagnostics I - 33080 PORCIA /PN (ITALY) 599 70 56-70 ENV06 of electronic controls Fax +39 0434 394096 Edition: 03-2009 Rev. - Page 2 2/91 03-2009 SOI/DT-mdm FCPD-dp Quality-fz 599 70 56-70...

-

Page 3: Table Of Contents

Contents Purpose of this manual ........................5 Procedure ............................5 WM APPLIANCES CONTROL PANELS ....................6 WD APPLIANCES CONTROL PANELS ....................7 DIAGNOSTIC SYSTEM..........................8 ACCESS TO THE DIAGNOSTIC CYCLE ..................8 Exiting diagnostics mode ........................8 PHASES OF THE DIAGNOSTIC CYCLE ..................9 ALARMS .............................. - Page 4 BASIC CIRCUIT DIAGRAM WD WITH AQUA CONTROL..............87 11.1 Key to circuit diagram WD with aqua control ................88 CONNECTORS ON CIRCUIT BOARD WM/WD ................. 89 BURNING ON THE CIRCUIT BOARD EWM2100 WM/WD ..............90 APPENDIX ............................91 4/91 03-2009 SOI/DT-mdm FCPD-dp Quality-fz...

-

Page 5: Purpose Of This Manual

The purpose of this Service Manual is to provide a simple and clear description of the procedure to be followed by service engineers when confronted by problems identified by the various alarm codes generated by appliances with the EWM2100 electronic control system. -

Page 6: Wm Appliances Control Panels

2 WM APPLIANCES CONTROL PANELS ICON ICON AF3- A4.2 6/91 03-2009 SOI/DT-mdm FCPD-dp Quality-fz 599 70 56-70... -

Page 7: Wd Appliances Control Panels

Series 6 SPECIAL Series 6 3 WD APPLIANCES CONTROL PANELS PROPORTIONAL TIME MANAGER Series 6 Series 6 SPECIAL Series 7 These are the available stylings at the moment in this Service Manual, in future some others could be developped. 7/91 03-2009 SOI/DT-mdm FCPD-dp Quality-fz 599 70 56-70... -

Page 8: Diagnostic System

4 DIAGNOSTIC SYSTEM 4.1 ACCESS TO THE DIAGNOSTIC CYCLE All versions 1. Switch off the appliance. 2. Press and hold down the START/PAUSE button and the nearest OPTION button simultaneously (as represented in figure). 3. Holding down both buttons, switch the appliance on by turning the programme selector one position clockwise. -

Page 9: Phases Of The Diagnostic Cycle

4.3 PHASES OF THE DIAGNOSTIC CYCLE Irrespective of the type of PCB and the configuration of the programme selector it is possible, after entering diagnostic mode, turning the programme selector clockwise or pushing the buttons P1 or P2 (INPUT version), to perform diagnostics on the operation of the various components and to read the alarms. All the alarms are enabled during the diagnostic cycle. - Page 10 - Reading/Cancellation of the last ----- ---- alarm (*) In most cases, this time is sufficient to check the heating. However, the time can be increased by repeating the phase without draining the water: pass for a moment to a different phase of the diagnostic cycle and then back to the heating control phase (if the temperature is higher than 80°C, heating does not take place).

-

Page 11: Alarms

5 ALARMS Displaying the alarms to the user The alarms displayed to the user are listed below: Door open Drain difficulty (dirty filter) Water fill difficulty (closet tap) AEG Version The alarms are represented through the flashing of the yellow LED, which is above the START-PAUSE button, and can be solved directly by the end user;... -

Page 12: Reading The Alarm Codes

5.2 Reading the alarm codes It is possible to display the last three memorised alarms in the FLASH memory of the electronic board: • Enter diagnostic mode (par. 4.1) • Irrespective of the type of PCB and configuration: turn the programme selector clockwise (version with knob) pushing button P1 (version INPUT) to the tenth position. -

Page 13: Examples Of Alarm Display

Notes: • The first letter of the alarm code “E” (Error) is not displayed, since this letter is common to all alarm codes. • The alarm code “families” are shown in hexadecimal; in other words: → A is represented by 10 flashes →... -

Page 14: Rapid Reading Of Alarm Codes

Rapid reading of alarm codes The last three alarm codes can be displayed even if the programme selector is not in the tenth position (diagnostics) or if the appliance is in normal operating mode (e.g. during the execution of the washing programme): →... -

Page 15: Table Of Alarms

5.5 TABLE OF ALARMS Alarm Possible fault Action/machine status Reset Alarm Pag. ---------------- ---------------- ---------------- ---------- No alarm Tap closed or water pressure too low; Drain tube improperly positioned; Water fill solenoid valve is faulty; Leaks from water circuit Cycle is paused with door locked. START/RESET Difficulties in water fill for washing on pressure switch;... - Page 16 Alarm Possible fault Action/machine status Reset Alarm Pag. Door interlock faulty; wiring faulty; PCB faulty. Cycle paused. START/RESET 40÷42 Problems of door closure Interlock power supply triac faulty Door interlock faulty; wiring faulty; PCB faulty. (Safety drain cycle) Cycle blocked. ON/OFF RESET 44÷45 Door interlock sensing circuit triac PCB faulty.

- Page 17 Alarm Possible fault Action/machine status Reset Alarm Pag. Wiring faulty; Control/display board faulty: Communication error between PCB ---------------- RESET PCB faulty. and display board Communication incongruence Wrong control/display board; Cycle interrupted. OFF/ON between main PCB- display board Wrong PCB (do not correspond to the model). (versions not compatible) Incorrect configuration of appliance PCB faulty;...

-

Page 18: Notes Concerning Certain Alarm Codes

Alarm Possible fault Action/machine status Reset Alarm Pag. Relay which commutates power Wiring faulty; WD board faulty; PCB faulty. Cycle blocked with door open. RESET between washing heating element and drying (in the WD board) Wiring faulty between PCB and programme display board; PCB No communication between PCB ---------------- OFF/ON... -

Page 19: The Diagnostic Programme Cannot Be Accessed

6 THE DIAGNOSTIC PROGRAMME CANNOT BE ACCESSED All LEDs on the circuit are board switched off 6.1.1 Replace or repair the power cable, check the No → Are the power cable and connection OK? connector. Yes ↓ No → Does the suppressor function correctly? Replace the suppressor. -

Page 20: Troubleshooting According To Alarm Codes

7 TROUBLESHOOTING ACCORDING TO ALARM CODES E11: Difficulty in filling water during washing phase Maximum water fill time for each pressure switch level (this time is reset to zero each time the level is reached) Tests to be performed: Access the diagnostic cycle and duct water through all the compartments (phases 2,3,4) Is water ducted through all the compartments? Is the drain hose positioned... - Page 21 Fig. 1 Fig.4 Fig.2 3500÷4500 Ω Circuit board 3500÷4500 Ω 3500÷4500 Ω 3500÷4500 Ω Fig.3 If there are traces of burning on the circuit board, refer to page 21/91 03-2009 SOI/DT-mdm FCPD-dp Quality-fz 599 70 56-70...

-

Page 22: E12: Difficulty In Filling Water During Drying Phase

E12: Difficulty in filling water during drying phase To check if the condensation valve is working, machine measures the increasing water level at the beginning of the drying phase. (Alarm appears after 10 min. of filling without reaching the level). Tests to be performed: Start the diagnostic cycle and perform the phase 9 drying. -

Page 23: E13: Water Leakage

E13: Water leakage Overall maximum water fill time exceeded (the sum of all the water fills between one drain phase and the next, to avoid exceeding the maximum volume) Tests to be performed: Access the diagnostic cycle and duct water through all the compartment (phases 2,3,4,5) Is water ducted through all the compartments? Is the drain hose positioned... - Page 24 Fig. 1 Fig.4 Fig.2 3500÷4500 Ω Circuit board 3500÷4500 Ω 3500÷4500 Ω 3500÷4500 Ω Fig.3 24/91 03-2009 SOI/DT-mdm FCPD-dp Quality-fz 599 70 56-70...

-

Page 25: E21: Difficulty In Draining

E21: Difficulty in draining Maximum drain time exceeded (measured for each phase of the cycle) Tests to be performed: Clean the filter and restart the diagnostic cycle Is the drain filter clean? to check for further alarms. Is the drain system OK? (drain hose and Disconnect and check the drain system. - Page 26 Fig. 1 Fig.4 Circuit board fig. 5 155÷200Ω 155÷200Ω 26/91 03-2009 SOI/DT-mdm FCPD-dp Quality-fz 599 70 56-70...

-

Page 27: E22: Difficulty In Draining Water During Drying Phase

E22: Difficulty in draining water during drying phase Tests to be performed: Clean the condenser and Is the condenser clean? restart the diagnostic cycle to -(see fig.24)- check for further alarms. Clean the filter and restart the diagnostic cycle Is the drain filter clean? to check for further alarms. - Page 28 Fig. 1 Fig.4 fig. 5 Fig. 24 Condenser 28/91 03-2009 SOI/DT-mdm FCPD-dp Quality-fz 599 70 56-70...

-

Page 29: E23: Malfunction Of The Component (Triac) That Controls The Drain Pump

E23: Malfunction of the component (triac) that controls the drain pump Tests to be performed: Is the resistance of the pump Is the resistance of the pump Replace the pump and restart about 150-200 Ω? (Measure about 150-200 Ω? the diagnostic cycle to check across connectors J7-1 and (Measure directly on the for further alarms. -

Page 30: E24: «Sensing» Circuit Of The Component (Triac) That Controls The Drain Pump Faulty

E24: «Sensing» circuit of the component (triac) that controls the drain pump faulty Replace the circuit board and restart the diagnostic cycle to check for further alarms. If there are traces of burning on the circuit board, refer to page E31: The analogic pressure switch is giving to the main board a signal outside the range Tests to be performed:... - Page 31 E32: The analogic pressure switch is giving an error during the calibration phase (At the beginning of each cycle the appliance drain to empty the tub and create a 0 level to verify the calibration of the analogic pressure switch) Tests to be performed: Drain the water from the tub.

-

Page 32: E35: Water Level Too High

E35: Water level too high The electronic board measures a water level from analogic pressure switch higher then 300 mm for more then 15 seconds. Tests to be performed: Empty the machine. Clean/change the hoses and/or air trap Are pressure switch hose and air trap system and repeat completely the system free? (You can disconnect the diagnostic cycle to check for further... -

Page 33: E38: Pressure Chamber Blocked

E38: Pressure chamber blocked The analogic pressure switch is not able to measure any variation of the water level for at least 30-sec. during drum movement. Tests to be performed: Empty the machine. Clean the air trap Start the diagnostic Verify the air trap system and/or the cycle and set the... -

Page 34: E3A: Problems With "Sensing" Circuit Of The Heating Element Relay

E3A: Problems with “Sensing” circuit of the heating element relay Tests to be performed: Replace the circuit board and run the diagnostic cycle again to check for further alarms. 34/91 03-2009 SOI/DT-mdm FCPD-dp Quality-fz 599 70 56-70... -

Page 35: E41: Door Open (3-Contact Device)

E41: Door open (3-contact device) Maximum time exceeded (PTC = 15 seconds) Tests to be performed: Close the door correctly and restart the diagnostic cycle to fig. 9 Is the door check for further alarms. correctly closed? The door interlock is Continues at page 37. - Page 36 E41 (3-contact device) Fig.4 fig. 9 ∞ Ω Circuit board n Ω n Ω ∞ Ω If there are traces of burning on the circuit board, refer to page 36/91 03-2009 SOI/DT-mdm FCPD-dp Quality-fz 599 70 56-70...

-

Page 37: E41: Door Open (4-Contact Device)

E41: Door open (4-contact device) Maximum time exceeded (5 pulses for instantaneous) fig. 28 Instantaneous door interlock with 4 connections. - fig 28 - To check the wiring (with the door Detach the connectors and open), measure the following measure on the component: wiring connectors (fig.4): - across connectors 3 and 4 - between J1-1 and J1-3, the... - Page 38 E41 (4-contact device) Fig.4 fig. 28 ∞ Ω Circuit board n Ω n Ω n Ω n Ω ∞ Ω 38/91 03-2009 SOI/DT-mdm FCPD-dp Quality-fz 599 70 56-70...

-

Page 39: E42: Problems With Door Aperture (3-Contact Device)

E42: Problems with door aperture (3-contact device) Maximum time exceeded (255 seconds) Tests to be performed: Close the door correctly and restart the diagnostic cycle to fig. 9 Is the door check for further alarms. correctly closed? Continues at page 42. The door interlock is Instantaneous door interlock traditional with... - Page 40 E42 (3-contact device) Fig.4 fig. 9 ∞ Ω Circuit board n Ω n Ω ∞ Ω If there are traces of burning on the circuit board, refer to page 40/91 03-2009 SOI/DT-mdm FCPD-dp Quality-fz 599 70 56-70...

-

Page 41: E42: Problems With Door Aperture (4- Contact Device)

E42: Problems with door aperture (4- contact device) Maximum time exceeded (5 pulses for instantaneous) fig. 28 Instantaneous door interlock device with 4 Connections. - fig 28 - Detach the connectors of To check the wiring (with the door the door interlock and open), measure the following measure on the component: wiring connectors (fig. - Page 42 E42 (4-contact device) Fig.4 fig. 28 ∞ Ω Circuit board n Ω n Ω n Ω n Ω ∞ Ω 42/91 03-2009 SOI/DT-mdm FCPD-dp Quality-fz 599 70 56-70...

- Page 43 E43: Problems with the component (triac) which actions the door interlock (3-contact device) Tests to be performed: Replace the door Detach the connectors and To check the wiring, (with the door interlock and measure on the component open), measure the following restart the wiring connectors (fig.

- Page 44 E43: Problems with the component (triac) which actions the door interlock (4-contact device) Tests to be performed: Detach the connectors of the door interlock and measure Replace the door To check the wiring, (with the door on the component (fig. 28): interlock and open), measure the following - across connectors 3 and 4...

-

Page 45: E44: Door Closure «Sensing» Circuit Faulty

E44: Door closure «sensing» circuit faulty Tests to be performed: Replace the circuit board and restart the diagnostic cycle to check for further alarms. E45: Problems with the «sensing» circuit of the triac that actions the door interlock Tests to be performed: Replace the circuit board and restart the diagnostic cycle to check for further alarms. -

Page 46: E51: Motor Power Triac Short-Circuited

E51: Motor power triac short-circuited Intervention of the safety system for short-circuiting of the triac (after 5 attempts during the cycle, immediately if detected at the start or during diagnostics) Tests to be performed: Measure among all the E52 will probably be Reconnect the connector J7 to terminals of wiring connector displayed: replace the... -

Page 47: E52: No Signal From The Motor Tachometric Generator (First Part)

E52: No signal from the motor tachometric generator (first part) detected at the start or during Cycle blocked after 5 attempts during the cycle or immediately if diagnostics. Tests to be performed: Perform phase 7 of the diagnostic cycle (the drum rotates at Does the 55 rpm clockwise 55 motor rotate... - Page 48 E52a Fig.4 fig. 6 fig. 10 XXXΩ Circuit board XXXΩ fig. 12 fig. 11 48/91 03-2009 SOI/DT-mdm FCPD-dp Quality-fz 599 70 56-70...

-

Page 49: E52: No Signal From The Motor Tachometric Generator (Second Part)

E52: No signal from the motor tachometric generator (second part) detected at the start or during Cycle blocked after 5 attempts during the cycle or immediately if diagnostics. Tests to be performed: The motor does not rotate at all. To check the wiring, measure (Ω) across the following terminals of the circuit board connector (fig.4) and compare with the correct values... -

Page 50: Procedure For Checking The Commutator Motors

Procedure for checking the commutator motors P = motor protector 1) Check the connector blocks (wiring) R = rotor S = stator and check for detached or bent T = tachometric generator terminals. 2) Check for traces, residue or deposits of water or detergent on the motor and identify the source. -

Page 51: E53: Problems With The "Sensing" Circuit Of The Triac Which Powers The Motor

E53: Problems with the "Sensing" circuit of the triac which powers the motor Tests to be performed: Replace the circuit board and restart the diagnostic cycle to check for further alarms. If there are traces of burning on the circuit board, refer to page 51/91 03-2009 SOI/DT-mdm FCPD-dp Quality-fz 599 70 56-70... -

Page 52: E54: Motor Relay Contacts Sticking

E54: Motor relay contacts sticking Voltage in the motor circuit even when the motor should be inoperative Tests to be performed Measure between all terminals of wiring connector J7-2 ÷ J7-8 and the structure of the appliance Replace the circuit board and restart the see page 50, point 3 diagnostic cycle to check for further Is there any current leakage? -

Page 53: E61: Insufficient Heating During Washing

E61: Insufficient heating during washing Maximum heating time exceeded SOMETIMES THE ALARM CAN BE CAUSED BY THE POWER VOLTAGE TOO LOW! Tests to be performed: Measure the value of the Detach the connector and NTC sensor across contacts Replace the NTC measure the value directly J9-9 and J9-8 of the circuit temperature sensor and... -

Page 54: E62: Overheating During Washing (Version Wm)

E62: Overheating during washing (version WM) The temperature of the NTC sensor exceeds 88°C for more than 5 minutes. Tests to be performed: Start the diagnostic cycle Detach the connector and Replace the heating and fill with water up to the measure across the heating element and restart the level of the door to ensure... -

Page 55: E62: Overheating During Washing (Version Wd)

E62: Overheating during washing (version WD) The temperature of the NTC sensor exceeds 88°C for more than 5 minutes. Tests to be performed: Start the diagnostic cycle and Detach the connector and Replace the heating fill with water up to the level of measure across the heating element and restart the the door to ensure that the... -

Page 56: E66: The Contacts Of The Heating Element Power Relay Are Always Closed (Version Wm)

E66: The contacts of the heating element power relay are always closed (version WM) Tests to be performed: Replace the circuit board and restart the Measure across connector J2-1/J2-2 on the diagnostic cycle to check for further circuit board and the structure of the appliance. alarms. -

Page 57: E66: The Contacts Of The Heating Element Power Relay Are Always Closed (Version Wd)

E66: The contacts of the heating element power relay are always closed (version WD) Tests to be performed: Replace the WD board and restart the Measure across connector J6-1/J62-2 on the circuit board and the structure of the appliance. diagnostic cycle to check for further alarms. -

Page 58: E68: Washing Heating Element Leaks Current (Version Wm)

E68: Washing heating element leaks current (version WM) Tests to be performed: Detach the connector and Start the diagnostic cycle Start phase 8 of the measure across the heating and fill with water up to the diagnostic cycle, drain water element and the ground level of the door to ensure from tub. -

Page 59: E68: Washing Heating Element Interrupted (Version Wd)

E68: Washing heating element interrupted (version WD) Tests to be performed: Start phase 8 of the Detach the connector and Start the diagnostic cycle diagnostic cycle, drain water measure across the heating and fill with water up to the from tub. Replace the element and the ground level of the door to ensure heating element and restart... -

Page 60: E69: Washing Heating Element Interrupted (Version Wm)

E69: Washing heating element interrupted (version WM) Tests to be performed: Measure the heating Measure the ohmic value Replace the heating directly on the terminals of element and restart the element value (Ω) across the heating element (detach terminals J2-2 ÷ J2-1of the diagnostic cycle to check the connectors) for further alarms. -

Page 61: E69: Washing Heating Element Interrupted (Version Wd)

E69: Washing heating element interrupted (version WD) Tests to be performed: Measure the heating Measure the ohmic value Replace the heating directly on the terminals of element and restart the element value (Ω) across the heating element (detach terminals J6-2 ÷ J6-1 of the diagnostic cycle to check the connectors) wiring connector. -

Page 62: E71: Ntc Washing Sensor Faulty

E71: NTC washing sensor faulty Voltage not within limits (short-circuited or open) Tests to be performed: Detach the connector Perform phase 6 of the diagnostic Start phase 8 of the and measure the NTC cycle and wait until the fill ends. Switch diagnostic cycle, sensor directly. -

Page 63: E72: Drying Ntc Sensor On Condenser Faulty

E72: Drying NTC sensor on condenser faulty Ohm value of the NTC out of limits Tests to be performed: Measure the value of the NTC Detach the connector Replace the NTC sensor across contacts J7-3 and and measure the NTC sensor and restart the J7-4 of the WD board connector. -

Page 64: E73: Ntc Sensor On Drying Duct Faulty

E73: NTC sensor on drying duct faulty Ohm value of the NTC out of limits Tests to be performed: Measure the value of the NTC Detach the connector Replace the NTC sensor across contacts J7-1 and and measure the NTC sensor and restart the J7-2 of the WD board sensor directly. -

Page 65: E74: Ntc Sensor Wrongly Positioned

E74: NTC sensor wrongly positioned Tests to be performed: Position the sensor again into its seat Is the sensor correctly positioned? and restart the diagnostic cycle to check -see fig.17- for further alarms. Measure the value of the NTC sensor Replace the sensor and restart the diagnostic cycle to check for further (5.7÷6.3KΩ... -

Page 66: E82: Error In Reading The Reset/Off Position Of The Programme Selector

E82: Error in reading the RESET/OFF position of the programme selector Reading of position “0” of the selector when the appliance is switched on, or configuration error Tests to be performed: Restart the diagnostic Switch the appliance on and Switch the appliance OFF cycle to check for turn the programme selector (in (selector position “0”). -

Page 67: E83: Error In Reading The Programme Selector Code

E83: Error in reading the programme selector code Code for the position of the selector not included in configuration data or configuration error Tests to be performed: Restart the diagnostic Switch the appliance on and cycle to check for further turn the programme selector alarms. -

Page 68: E91: Communication Error Between User Interface And Main Board

E91: Communication error between user interface and main board Incongruence of configuration values at the switching on of the appliance Tests to be performed: Possible configuration error Replace the circuit board and restart the diagnostic cycle to check for further alarms. E92: Protocol incongruence Incongruence of configuration values at the switching on of the appliance Tests to be performed:... -

Page 69: Ea1: Drum Positioning System (Dsp) Faulty (Top-Loaders)

EA1: Drum positioning system (DSP) faulty (top-loaders) No signal or discontinuous signal from the sensor for more than 10 seconds during actioning of the motor to position the drum Tests to be performed: Replace the belt/pulley and restart Is the drive belt OK? Is the pulley OK? Is the ferrite plate the diagnostic cycle to check for positioned correctly? further alarms. -

Page 70: Ea6: Drum Flap Faulty (Top-Loaders)

EA6: Drum flap faulty (top-loaders) Cycle immediately blocked if a not correct tachometric signal is identified for at least 3 seconds Tests to be performed: Detach the connector Measure across the Open the door and Replace the from the motor and terminals of the wiring manually check if motor or the... -

Page 71: Eh1: Incorrect Mains Frequency

EH1: Incorrect mains frequency The power supply frequency is not within the configured limits Tests to be performed: Important! The appliance remains in alarm mode until the frequency returns to the correct value or the appliance is switched off (programme selector on “0”). Only the family of the alarm is displayed, and the diagnostic cycle cannot be started. -

Page 72: Ef1: Drain Hose Blocked/Throttled/Too High; Drain Filter Dirty/Blocked

EF1: Drain hose blocked/throttled/too high; drain filter dirty/blocked It is a warning that appears only at the end of the cycle. The machine has detected long draining phases during the cycle (Es. More then 20 seconds during draining after rinsing phase). Check/clean the drain filter. -

Page 73: Ec1: Water Fill Solenoids Blocked

EC1: Water fill solenoids blocked The flowmeter detects water filling even if the solenoid is not controlled Tests to be performed: Does the Replace the main circuit As soon as the appliance fill in appliance is switched board and restart the water when the diagnostic cycle to check for on does the solenoid... -

Page 74: Ed1: Communication Problems Betweeen Main Circuit Board And Wd Board

ED1: Communication problems betweeen main circuit board and WD board Tests to be performed: Measure the continuity Replace the wiring and between connector J16 restart the diagnostic (main circuit board) and cycle to check for J1 (WD board). further alarms. Is the wiring OK? Replace the WD board and restart the... -

Page 75: Ed2: Drying Heating Element 1 Faulty

ED2: Drying heating element 1 faulty Tests to be performed: Check if the belt of the motor Fit the belt and reset the manually reset thermostat. To reset fan is correctly fitted (fig. 21)- the thermostat push the red button (see fig. 23). Restart the Is the bel OK? diagnostic cycle to check for further alarms. - Page 76 Follows page 75 Detach the connectors and measure the value of Replace the Measure if the automatically 0Ω directly across the automatically reset reset thermostat is off (0Ω) terminals of the thermostat and restart across terminals J5-2 ÷ J5-3 of automatically reset the diagnostic cycle to the wiring connector.

- Page 77 Fig. 23 Fig. 21 Push the red button to reset the thermostat. Belt well tense and inserted correctly inside the pulleys. Fig. 24 Fig. 22 Condenser If there are traces of burning on the circuit board, refer to page board 77/91 03-2009 SOI/DT-mdm FCPD-dp Quality-fz 599 70 56-70...

-

Page 78: Ed3: Drying Heating Element 2 Faulty

ED3: Drying heating element 2 faulty Tests to be performed: Detach the connectors Replace the drying Check across terminals and measure the value of heating element and J5-1 ÷ J8-3 and J5-1 ÷ J8-4 the two branches of the restart the diagnostic of the connector wiring drying heating element. -

Page 79: Ed4: Drying Relays Faulty

ED4: Drying relays faulty Tests to be performed: Measure across terminals J8-3, J8- Replace the WD board and restart the 4 of the connector and the structure diagnostic cycle to check for further of the appliance- see fig.6 - alarms. Is there any leakage? Replace the wiring and restart the fig. -

Page 80: Ed6: Communication Failure Between Main Circuit Board And Satellite Board (Input Styling)

ED6: Communication failure between main circuit board and Satellite board (INPUT styling) Tests to be performed: Measure the continuity between Fit / replace the wiring and restart connector J16 (main circuit board) the diagnostic cycle to check for and J1 (Satellite board further alarms. -

Page 81: Basic Circuit Diagram Wm

8 BASIC CIRCUIT DIAGRAM WM 81/91 03-2009 SOI/DT-mdm FCPD-dp Quality-fz 599 70 56-70 599 70 56-70... -

Page 82: Key To Circuit Diagram Wm

8.1 Key to circuit diagram WM Electrical components on appliance Components on main board 1. Analogue pressure switch DOOR_TY Door interlock Triac 2. NTC temperature sensor DRAIN_TY Drain pump Triac 3. Solenoid valve for prewash REC_TY Triac circulation pump 4. Solenoid valve for wash Heating element relay 5. -

Page 83: Basic Circuit Diagram Wm With Aqua Control

9 BASIC CIRCUIT DIAGRAM WM WITH AQUA CONTROL 83/91 03-2009 SOI/DT-mdm FCPD-dp Quality-fz 599 70 56-70 599 70 56-70... -

Page 84: Key To Circuit Diagram Wm With Aqua Control

9.1 Key to circuit diagram WM with Aqua Control Electrical components on appliance Components on main board Analogue pressure switch DOOR_TY Door interlock Triac NTC temperature sensor DRAIN_TY Drain pump Triac Solenoid valve for prewash REC_TY Triac circulation pump Solenoid valve for wash Heating element relay Solenoid valve for bleach Motor relay: clockwise rotation... -

Page 85: Basic Circuit Diagram Wd

10 BASIC CIRCUIT DIAGRAM WD 85/91 03-2009 SOI/DT-mdm FCPD-dp Quality-fz 599 70 56-70 599 70 56-70... -

Page 86: Key To Circuit Diagram Wd

10.1 Key to circuit diagram WD Electrical components on appliance Components on main board 1. Analogue pressure switch DOOR_TY Door interlock Triac 2. NTC temperature sensor DRAIN_TY Drain pump Triac 3. Solenoid valve for prewash REC_TY Triac circulation pump 4. Solenoid valve for wash Heating element relay 5. -

Page 87: Basic Circuit Diagram Wd With Aqua Control

11 BASIC CIRCUIT DIAGRAM WD WITH AQUA CONTROL 87/91 03-2009 SOI/DT-mdm FCPD-dp Quality-fz 599 70 56-70 599 70 56-70... -

Page 88: Key To Circuit Diagram Wd With Aqua Control

11.1 Key to circuit diagram WD with aqua control Electrical components on appliance Components on main board Analogue pressure switch DOOR_TY Door interlock Triac NTC temperature sensor DRAIN_TY Drain pump Triac 3. Solenoid valve for prewash REC_TY Triac circulation pump 4. -

Page 89: Connectors On Circuit Board Wm/Wd

12 CONNECTORS ON CIRCUIT BOARD WM/WD J15/J15B Serial interface: Communication with J11-3 Flowmeter (GND) J9-1 Washing solenoid (triac) J7-1 Drain pump (line) J1-1 Door safety interlock WD external board: J11-4 Flowmeter (signal) J9-3 Solenoids (line) J7-2 Motor (stator - ½ field) (triac) J15-1 ASY_IN J9-4 Solenoids (line) -

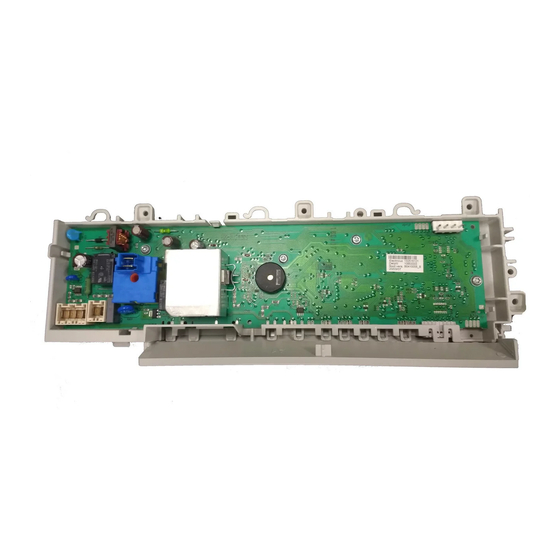

Page 90: Burning On The Circuit Board Ewm2100 Wm/Wd

13 BURNING ON THE CIRCUIT BOARD EWM2100 WM/WD In case of burning on the main circuit board, check that the problem is not caused by another electrical component (short-circuits, poor insulation, water leakage). Refer to the figures below in order to identify the component that might have caused the burning according to the position of the burned area. -

Page 91: Appendix

14 APPENDIX Revision Date Description 06/03/2009 Modified Alarms E21-E22 page 15 / Alarm EF3 page 73 91/91 03-2009 SOI/DT-mdm FCPD-dp Quality-fz 599 70 56-70...

Need help?

Do you have a question about the EWM2100 and is the answer not in the manual?

Questions and answers