Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Honda FG400

- Page 2 Keep this owner’s manual handy, so you can refer to it any time. This owner’s manual is considered a permanent part of the tiller and should remain with the tiller if resold. The information and specifications included in this publication were in effect at the time of approval for printing.

- Page 3 We want to help you get the best results from your new tiller and to operate it safely. This manual contains all the information on how to do that; please read it carefully.

- Page 4 INTRODUCTION A FEW WORDS ABOUT SAFETY Your safety and the safety of others are very important. And using this tiller safely is an important responsibility. To help you make informed decisions about safety, we have provided operating procedures and other information on labels and in this manual.

-

Page 5: Table Of Contents

Main Clutch Lever ... 11 Drag Bar Front Wheel Gearshift Lever BEFORE OPERATION ARE YOU READY TO GET STARTED? IS YOUR TILLER READY TO GO? Check the Engine Check the Tiller OPERATION SAFE OPERATING PRECAUTIONS STARTING THE ENGINE OPERATING THE CONTROLS FOR TILLING ... - Page 6 CONTENTS SERVICING YOUR HONDA TILLER (continued) CLUTCH CABLE ADJUSTMENT THROTTLE CABLE ADJUSTMENT DRIVE BELT ADJUSTMENT SPARK ARRESTER SERVICE STORAGE STORAGE PREPARATION Cleaning Fuel ... Engine Oil ... STORAGE PRECAUTIONS REMOVAL FROM STORAGE TRANSPORTING TAKING CARE OF UNEXPECTED PROBLEMS ENGINE PROBLEMS...

-

Page 7: Tiller Safety

Exhaust contains poisonous carbon monoxide, a colorless, odorless gas. Breathing exhaust can cause loss of consciousness and may lead to death. If you run the tiller in a confined or even partially enclosed area, the air you breathe could contain dangerous amounts of exhaust gas. To keep... - Page 8 Refuel With Care Gasoline is extremely flammable, and gasoline vapor can explode. engine to cool if the tiller has been in operation. Refuel only outdoors in a well- ventilated area with the engine OFF. Do not overfill the fuel tank. Never smoke near gasoline, and keep other flames and sparks away.

- Page 9 Sturdy shoes with aggressive soles provide better traction. Turn Engine Off When Not Operating the Tiller If you need to leave the tiller for any reason, even just to inspect the area ahead, always turn the engine off. Slope Operation When tilling on slopes, keep the fuel tank less than half full to minimize fuel spillage.

-

Page 10: Safety Label Locations

TILLER SAFETY SAFETY LABEL LOCATONS These labels warn you of potential hazards that can cause serious injury. Read them carefully. If a label comes off or becomes hard to read, contact your Honda servicing dealer for a replacement. -

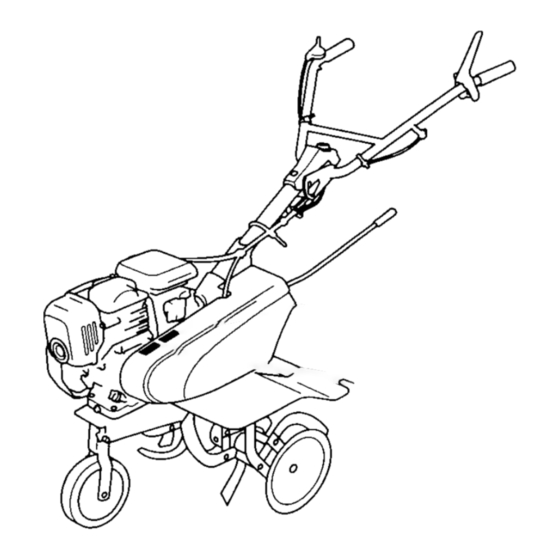

Page 11: Controls

CONTROLS COMPONENT & CONTROL LOCATIONS AIR CLEANER COVER SERIAL ENGINE FRONT WHEEL CLUTCHLEVER HANDLEBAR HEIGHT ADJUSTER FRAME SERIAL NUMBE THROTTLE LEVER ROTOR V-BELT COVER PARK PLUG CAP CHOKE ROD ECOIL STARTER TRANSMISSION OIL... -

Page 12: Controls

CONTROLS CONTROLS Choke Rod The choke rod opens and closes the choke valve in the carburetor. The CLOSED position enriches the fuel mixture for starting a cold engine. The OPEN position provides the correct fuel mixture for operation after starting and for restarting a warm engine. -

Page 13: Throttle Lever

Throttle Lever The throttle lever controls engine speed. Moving the throttle lever in the di- rections shown makes the engine run faster or slower. Tine speed iscontrolled by adjusting the throttle lever. At maximum throttle position, the tines at the highest speed. Moving the throttle lever toward the idle position will decrease the tine speed. -

Page 14: Drag Bar

In general, the drag bar should be adjusted so that the tiller is tilted slightly backward. Front Wheel The front wheel is used to help... -

Page 15: Before Operation

Read and understand this manual. Know what the controls do and how to operate them. Familiarize yourself with the tiller and its operation before you begin using it. Know how to quickly shut off the tiller in case of an emergency. -

Page 16: Check The Engine

BEFORE OPERATION Do not place flammable objects close to the engine. Before beginning your preoperation checks, be sure the tiller is on a level surface and the engine switch is in the OFF position. Check the Engine Check the oil level (see page 29). -

Page 17: Operation

Before operating the tiller for the first time, please review both the TlLLER SAFETY chapter and the chapter titled BEFORE OPERATION. For your safety, avoid starting or operating the tiller in an enclosed area such as a garage. Your tiller's exhaust contains poisonous carbon monoxide gas which can collect rapidly in an enclosed area and cause illness or death. -

Page 18: Starting The Engine

OPERATION STARTING THE ENGINE Refer to Safe Operating Precautions on Page 15. Tines are sharp and spin fast. Spinning tines can cut you severely and can amputate body parts. Wear protective footwear. Keep your hands and feet away from the tines while the engine is running. - Page 19 2. Turn the engine switch to the position 3. Move the throttle lever away from the SLOW position, about 1/3 of the way toward the position. Pull the starter grip lightly until you feel resistance, then pull briskly. Do not allow the starter grip to snap back against the engine.

- Page 20 OPERATION 5. If the choke rod was pulled to the CLOSED position to start the engine, gradually move it OPEN position as the to the engine warms up. CHOKE ROD /-t-...

-

Page 21: Operating The Controls For Tilling

If the tines dig in but the machine will not move forward, move the handlebars from side-to-side. When turning, push down on the handlebars to bring the tiller's weight to the rear; this will make turning easier. Handlebar Height Adjustment... - Page 22 2. Release the clutch lever 3. Move the shift lever to the desired gear position. If the shift lever will not engage the desired gear, squeeze the clutch lever and move the tiller slightly to reposition the gears. to disengage the clutch. NEUTRAL...

- Page 23 Reverse Gear Operation (A2 Type) Use the reverse gear only when it is necessary to move the tiller away from an obstacle. The tiller tines propel the tiller toward the operator when operated in reverse. Contact with rotating tines will cause serious injury.

- Page 24 Tiling Depth Adjustment The drag bar is used to control the tilling depth, which can be adjusted by removing the pin and retainer and sliding the drag bar up and down as necessary. During operation, if the machine jerks forward while tilling, press down on the handlebars.

-

Page 25: Stopping The Engine

STOPPING THE ENGINE To stop the engine in an emergency, simply turn the engine switch to the OFF position. Under normal conditions, use the following procedure. 1. Release the main clutch lever to the DISENGAGED position, and move the shift lever to the neutral position (A2 type). -

Page 26: Servicing Your Honda Tiller

Good maintenance isessential for safe, economical, and It will also help reduce air pollution. To help you properly care for your tiller, the following pages include a maintenanceschedule, routine inspection procedures, and simple maintenan procedures using basic hand tools. Other service tasks that are more difficult, or require special tools, are best handled by professionals and are normally performed by a Honda technician or other qualified mechanic. -

Page 27: Maintenance Safety

Use only a nonflammable solvent, not gasoline, to clean parts. Keep cigarettes, sparks, and flames away from all fuelrelated parts. Disconnect the spark plug cap and wear heavy gloves when working near the tine blades. SERVICING YOUR HONDA TILLER... -

Page 28: Maintenance Schedule

SERVICING YOUR HONDA TILLER MAINTENANCE SCHEDULE Fuel tank and filter Valve clearance Combustion chamber Fuel tube Emission related items. Service more frequently when used in dusty areas. (2) Change engine oil every 25 hours when used under heavy load or in high ambient temperatures. -

Page 29: Refueling

REFUELING Fuel tank capacity: FG400 FG500 With the engine stopped, remove the fuel tank cap and check the fuel level. Refill the tank if the fuel level is low. Do not fill above the fuel level mark. Gasoline is highly flammable and explosive. - Page 30 SERVICING YOUR HONDA TILLER Never use stale or contaminated gasoline or an oil/gasoline mixture. Avoid getting dirt or water in the fuel tank. Occasionally you may hear light “spark knock’ or “pinging” (metallic rapping noise) while operating under heavy loads. This is no cause for concern.

-

Page 31: Engine Oil Level Check

ENGINE OIL LEVEL CHECK Check the engine oil level with the tiller on a level surface and the engine stopped. 1. Remove the oil filler cap/dipstick and wipe it clean. 2. Insert and remove the dipstick without screwing it into the filler neck. -

Page 32: Engine Oil Change

3. With the tiller in a level position, fill to the outer edge of the oil filler hole with the recommended oil (see page 29). Oil Capacity: 0.61... -

Page 33: Engine Oil Recommendations

The SAE oil viscosit! and service classification are in the API label on the oil container. Honda recommends that you use API SERVICE category SJ oil. SERVICING YOUR HONDA TILLER SAE VISCOSITY GRADES AMBIENTTEMPERATURE 100 ‘F ‘C... -

Page 34: Transmission Oil Level Check

SERVICING YOUR HONDA TILLER TRANSMISSION OIL LEVEL CHECK Check the transmission oil level with the tiller stopped. Remove the transmission oil filler cap. The oil should be level with the lower edge of the oil filler hole. 2. Add the same oil as recommended for the engine (see page 31), is low. -

Page 35: Air Filter Inspection

Operating the engine without an air filter, dirt to enter the engine, causing rapid engine wear. This type covered by the Distributor's Limited Warranty. TABS FILTER SERVICING YOUR HONDA TILLER or with a damaged air filter, will all of damage is not CLEANER COVER LATCH TABS... -

Page 36: Air Filter Cleaning

SERVICING YOUR HONDATILLER AIR FILTER CLEANING A dirty air filter will restrict air flow to the carburetor, reducing engine performance. If you operate the engine in very dusty areas, clean the air filter more frequently than specified in the Maintenance Schedule. 1. -

Page 37: Spark Plug Service

5. Install thesparkplug carefully, by hand, to avoid cross-threading. After the spark plug seats, tighten with a 13/16 - inch spark plug wrench to compress the washer. SERVICING YOUR HONDA TILLER I ' \ - 0.80 mm). PULG WRENCH (0.70... - Page 38 SERVICING YOUR HONDA TILLER If reinstalling a used spark plug, tighten 1/8 1/4 turn after the spark plug seats. If installing a new spark plug, tighten turn after the spark plug seats. A loose spark plug can overheat and damage the engine.

-

Page 39: Clutch Cable Adjustment

Free play : 1 -3/16 - 1 -9/16 in (30 - 40 rnm) If the free play is incorrect, turn the adjusting nut in or out as required. 1-3/16 1-9/16 40 mm) SERVICING YOUR HONDA TILLER 3/8 inches - 10 rnm) of free play at the lever end. LOCK NUT... -

Page 40: Drive Belt Adjustment

SERVICING YOUR HONDA TILLER DRIVE BELT ADJUSTMENT 1. Adjust the clutch cable (page 37). Belt tension is correct when the form distance to the top of the tension roller is 1-3/4 - 1-15/16 when the clutch is engaged. 2. T O adjust, loosen the four engine... -

Page 41: Spark Arrester Service

Remove the three muffler protector. 2. Remove the two special screws from the spark arrester, and remove the spark arrester from the muffler. MUFFLER PROTECTOR SERVICING YOUR HONDA TILLER mm bolts from the muffler protector, and remove the BOLTS... - Page 42 SERVICING YOUR HONDA TILLER 3. Use a brush to remove carbon deposits from the spark arrester screen. Be careful to avoid damaging the screen. The spark arrester must be free of breaks and holes. Replace the spark arrester if it is damaged.

-

Page 43: Storage

Tiller If using a garden hose or pressure washing equipment to clean the tiller, be careful to avoid getting water on the belts. Spraying water on hot tine shaft bearings can cause them to be dama from cooling too quickly. - Page 44 5. Stop the engine and allow it to cool. 6. After the tiller is clean and dry, touch up any damaged paint and coat other areas with a light film of oil. Lubricate the throttle cable core with a silicone...

-

Page 45: Fuel

Gasoline will oxidize and deteriorate in storage. Old gasoline will cause hard starting, and it leaves gum deposits that clog the fuel system. If the gasoline in your tiller deteriorates during storage, you may need to have the carburetor and other fuel system components serviced or replaced. - Page 46 STORAGE Draining the Fuel Tank and Carburetor 1. Remove the fuel filler cap, and empty the fuel tank into an approved gasoline container using a commercially available hand siphon. Reinstall the fuel filler cap. 2. Place an approved gasoline container below the carburetor, and use a funnel to avoid spilling fuel.

-

Page 47: Engine Oil

Engine Oil 1. Change the engine oil (page 30). Remove the spark plug (page 35). 3. Pour a tablespoon (5 4. Pull the starter rope several times to distribute the oil in the cylinder. 5. Reinstall the spark plug. 6. Pull the starter rope slowly until resistance is felt. This will close the valves, so moisture cannot enter the engine cylinder. -

Page 48: Storage Precautions

STORAGE STORAGE PRECAUTIONS If your tiller will be stored with gasoline in the fuel tank and carburetor, it is important to reduce the hazard of gasoline vapor ignition. Select a well ventilated storage area away from any appliance that operates with a flame, such as a furnace, water heater, or clothes dryer. -

Page 49: Before Loading

Position the tiller so it sits flat on the bed of the transport vehicle. Tie the tiller down with rope or straps. Keep the tie-down rope or straps away from the... -

Page 50: Engine Problems

Engine Will Not Check control positions. 2. Check fuel. 3. Checkengineoil level. 4. Remove and inspect spark plug. 5. Take tiller to an autho- rized Honda servicing dealer, or refer to the Possible Cause Choke OPEN. Engine switch OFF Out of fuel. -

Page 51: Taking Care Of Unexpected Problems

1. Check air filter. Check fuel. rized Honda servicing dealer, or refer to the shop manual. Possible Cause Air filter clogged. Bad fuel; tiller stored without treating or drain- ing gasoline, or refueled with bad gasoline. Fuel filter clogged, carburetor malfunction, ignition malfunction, valves stuck, etc. -

Page 52: Tilling Problems

3. Check drag bar depth setting. Check tines. Possible Cause Engine speed is too slow to till well. Tiller is movingtoo fast for soil conditions. Drag bar adjustment set to high. Tines dull, worn, dam- aged. Wrong tines installed. -

Page 53: Technical & Consumer Information

TECHNICAL & CONSUMER INFORMATION TECHNICAL INFORMATION Serial Number Loc FRAME Record the engine and frame serial numbers in the spaces below. You will need this serial number when ordering parts, and when making technical or warranty inquires. (see page 59.) Engine serial number: Frame serial number:... -

Page 54: Carburetor Modification For High Altitude Operation

High altitude performance can be improved by a specific modifications to the carburetor. If you always operate your tiller at altitudes above 5,000feet (1,500 meters) have your servicing dealer perform this carburetor modification. This engine, when operated at high altitude with the carburetor modifications for high altitude use, will meet each emission standard throughout its useful life. -

Page 55: Oxygenated Fuels

TECHNICAL & CONSUMER INFORMATION Oxygenated Fuels Some conventional gasolines are being blended with alcohol or an ether compound. These gasolines are collectively referred to as oxygenated fuels. To meet clean air standards, some areas of the United States and Canada use oxygenated fuels to help reduce emissions. -

Page 56: Emission Control System Information

TECHNICAL & CONSUMER INFORMATION Emission Control System Information Source of Emissions The combustion process produces carbon monoxide, oxides of nitrogen, and hydrocarbons. Control of hydrocarbons and oxides of nitrogen is very impor- tant because, under certain conditions, they react to form photochemical smog when subjected to sunlight. - Page 57 TECHNICAL & CONSUMER INFORMATION Problems That May Affect Emissions If you are aware of any of the following symptoms, have your engine inspected and repaired by your authorized Honda servicing dealer. Hard starting or stalling after starting. Rough idle. Misfiring or backfiring under load. Afterburning (backfiring).

-

Page 58: Air Index

Applicable to Emissions Durability Period Moderate 125 hours Intermediate 300 hours (0 Extended The Air Index Information hang tag must remain on the tiller until it is sold. Remove the hang tag before operating the tiller. hours (greater than hours hours (greater... -

Page 59: Specifications

IN: 0.1 1 0.19 mm cold 0.24 mm cold other adjustments needed. FG500-A2 FG500-A1 FG400-A1 FZCY 106 Ibs (48 kg) Ibs (49 kg) 42.9 in (1,090mm) 42.1 GC160 9.8 cu-in (1 60 cm3) 2.5 X 2.0 in (64 X 50 mm) 2.5X1.7 in US gal (2.0... -

Page 60: Consumer Information

CONSUMER INFORMATION Honda Publications These publications will give you additional information for maintaining and repairing your tiller. You may order them from your Honda tiller dealer. Shop Manual This manual covers complete maintenance and overhaul procedures. It is intended to be used by a skilled technician. -

Page 61: Customer Service Information

When you write or call, please give us this information: Model and serial numbers (see page 51) Name of the dealer who sold the tiller to you Name and address of the dealer who services your tiller Date of purchase... - Page 63 First 5 hours Subsequent Unleaded gasoline with a pump octane rating of 86 or higher (page 27) FG400 : 0.45 US gal (1.71) FG500 : 0.53 US gal (2.01) SAE 10 W - 30, API SJ, for general use (page 31) 0.51 US qt (0.581)

Need help?

Do you have a question about the FG400 and is the answer not in the manual?

Questions and answers