Summary of Contents for Westerbeke 3.5KW SBCG-60Hz

- Page 1 OPERATORS MANUAL 3.5KW SBCG 60Hz and 50Hz Single Phase GASOLINE RATOH ow Ca,bon Monoxide Emissions...

- Page 2 Gasoline with an ETHANOL content higher than 10% (E10) is not allowed and may void warranty. Engines & Generators...

- Page 3 Shut down the unit and do not restart until it has been inspected and repaired. This WARNING DECAL is provided by WESTERBEKE and should be fixed to bulkhead near your engine or generator. WESTERBEKE also recommends Installing CARBON MONOXIDE DETECTORS in the IIvlng/sleeplng quarters of your vessel.

- Page 4 SAFETY INSTRUCTIONS INTRODUCTION PREVENT BURNS - FIRE Read this safety manual carefully. Most accidents are WARNING: caused by failure to follow fundamental rules and precau- Fire can cause injury death! tions. Know when dangerous conditions exist and take the necessary precautions to protect yourself, your personnel, •...

- Page 5 SAFETY INSTRUCTIONS ACCIDENTAL STARTING WARNING: Carbon monoxide (CO) is deadly gas! WARNING: Accidental starting can cause injury or death! • Ensure that the exhaust system is adequate to expel gases discharged from the engine. Check the exhaust system • To prevent accidental starting when servicing the regularly for leaks and make sure the exhaust manifolds generator, remove the 8 amp fuse from the control panel.

- Page 6 SAFETY INSTRUCTIONS • Do not wear loose clothing or jewelry when servicing ABYC, NFPA AND USCG PUBLICATIONS FOR equipment; tie back long hair and avoid wearing loose INSTALLING DIESEL ENGINES jackets, shirts, sleeves, rings, necklaces or bracelets that Read the following ABYC, NFPA and USCG publications could be caught in moving parts.

- Page 7 It is a exhaust to provide a margin of safety. threat that must not be underestimated. . Westerbeke Low-CO generators achieve reduction of typical Westerbeke Low-CO generators are designed to dramatically_ CO by precise control of the engine's air/fuel ratio coupled reduce normal levels of CO in the engine exhaust.

- Page 8 California users of this genset should be aware that maintenance or service of your genset is authorized, you unauthorized modifications or replacement of fuel, exhaust, should seek assistance from an approved WESTERBEKE air 'intake, or speed control system components that affect dealer.

- Page 9 Zellwgwer Analytics, Industrial Scientific Corp, GFG, TPI, The other location is the boat's exhaust outlet, which . Teledyne and others. Westerbeke recommends analyzers with contains entrained cooling water (except dry stack exhaust a probe connected to the' analyzer by a length of transparent systems).

- Page 10 INSTALLATION When installing WESTERBEKE engines and generators it is important that strict attention be paid to the following information: CODES AND REGULATIONS Strict federal regulations, ABYC guidelines, and safety codes must be complied with when installing engines and generators in a marine environment.

-

Page 11: Table Of Contents

TABLE OF CONTENTS Parts Identification ............ Shore Power Transfer Switch ........Introduction ..............Engine Components ..........Spark Plugs ............20 Installation ..............5 Cam Sensor ............20 Rigging and Lifting ..........5 Air Screen .............. 20 Location and Mounting ........... 5 ECU ............... -

Page 12: Parts Identification

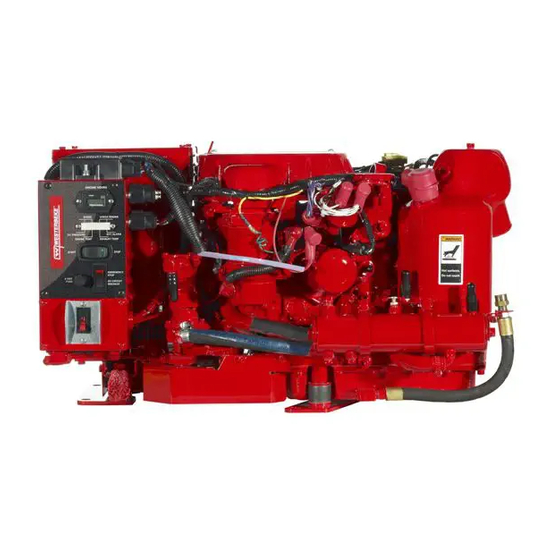

PARTS IDENTIFICATION 3.5 SBCG GENERATOR STEPPER MOTOR under this cover REGUL,A'~;l:::';;~~~ DC VOLTAGE K1-K2-K3-RELAYSfTIMER MODULE EXTERNAL CONNECTION TERMINAL STRIP LEFT SIDE REAR MODULE ~'W'-f-. HOURMETER FAULT LED'S VOLTAGE REGULATOR ,e:;~!J..o.I.stARTISTOP SWITCH CIRCUIT BREAKER ,ExtIAUl)T TEMP. SWITCH C MAlNJlREAKER rrII.~'--~"L DRAIN HOSE HEAT EXCHANGER IGNITION MODUL,E OIL PRESSURE SWITCH... -

Page 13: Introduction

WESTERBEKE dealer for assistance. This is your operators manual. A parts catalog is also provided and a technical manual is available from your ENGINE WESTERBEKE dealer. If you are planning to install this 0 " SERIAL LOCATED BEHIND... - Page 14 A carbon monoxide warning decal has been provided ways similar to a gasoline automobile engine. The cylinders by WESTERBEKE. Affix this decal in a visible location in the are in-line, and the engine's cylinder head has an overhead engine room.

-

Page 15: Installation

Locate the generator away from living quarters, and away from bilge splash and vapors. BOTTOM VIEW Refer to WESTERBEKE'S installation manual for detailed information on installing a Marine Generator in a boat. 1/2" ·FDUR... -

Page 16: Raw Water Discharge

INSTALLATION/EXHAUST SYSTEM RAW WATER DISCHARGE When the generators location is above the loaded water line of the vessel during all attitudes of vessel operation, it is still The fresh water that flows thru the engine is cooled by a advisable to loop the raw water discharge hose at least 6 •... -

Page 17: Fuel, Engine Oil And Engine Coolant

An oil viscosity of SAE 15W-40 is recommended for this engine in all conditions and all seasons. Westerbeke Corporation does not approve or disapprove the COOLANT RECOVERY TANK use of synthetic oils. If synthetic oils are use, engine break-in must be performed using conventional oil. -

Page 18: Control Panels - Starting/Stopping Procedure

CONTROL PANEL • START/STOP PANEL DESCRIPTION FAILURE TO START To Start: Press the rocker switch to the start position and The start cycle will automatically terminate if the engine fails release. (The switch will revert to its center position). The to start after 8 seconds of cranking. -

Page 19: Preparations For Initial Start-Up

PREPARATIONS FOR INITIAL START-UP PRESTART INSPECTION Before starting your generator set for the first time or after a prolonged layoff, check the following items: • Make certain the cooling water thru-hull petcock is open. • Check the engine oil level. Add oil to maintain the level at the full mark on the dipstick. -

Page 20: Initial Priming The Fuel System

MING OF THE FUEL SYSTEM SCHRADER VALVE FUEL . MODULE DIS_CONNECT TO HARNESS INLET FILTER FUEL DETACH FUEL LINE . , ANDFITriNG FROM SHIPS INTERNAL FUEL SUPPLY NOTE: The generators fuel system must be primed with fuel ·~SCHRADER before its initial start. ~ VALVE CAP INSTRUCTIONS 1. -

Page 21: Safety Shutdown Switches

SAFETY SHUTDOWN SENSORS AND SWITCHES SAFETY SHUTDOWN SWITCH/SENSORS Fuses The engine is protected by four automatic shutdown circuits. A FL-8A fuse located on the control panel protects the elec- do not attempt to restart without trical wiring. If an amperage overload occurs, the fuse will Should a shutdown occur, finding and correcting the cause. -

Page 22: Maintenance Schedule

" be monitored at least once an operating season. This is to "-' help ensure that the system is operating properly. Free system diagnostic software is available for use with a laptop by contacting your area Westerbeke Distributor. Engines & Generators... - Page 23 This is to ensure that the system is operating properly. Free system diagnostic software is available for use with a laptop by contacting your area Westerbeke Distributor. Em:zines & Generators...

-

Page 24: Engine Lubricating 0I1

An oil viscosity of SAE-15W-40 is recommended for this in all conditions, and all seasons. engine Westerbeke Corporation does not approve or disapprove the use of synthetic oils. If synthetic oils are used, engine break-in must be performed using conventional oil. Oil...

Need help?

Do you have a question about the 3.5KW SBCG-60Hz and is the answer not in the manual?

Questions and answers