Summary of Contents for Pressure Systems 9046

- Page 1 Model 9046 Ethernet Intelligent Temperature Scanner User’s Manual Edition August 2008 NetScanner™ System www.PressureSystems.com...

- Page 2 © This User’s Manual is a copyright product of Pressure Systems, Inc., 2008 Permission is hereby granted to make copies and distribute verbatim copies of this manual, provided the copyright notice and this permission notice are preserved on all copies.

-

Page 3: Table Of Contents

Pressure Systems, Inc. Model 9046 User’s Manual Table of Contents Introduction ......................1 General ........................1 1.1.1 Introduction....................1 1.1.2 Physical Description ..................2 1.1.3 Theory of Operation ..................3 1.1.3.1 Thermocouple Cold Junction Compensation........3 1.1.3.2 Open Circuit Detection ..............4 Setup Instructions .................... -

Page 4: Technical Support

E-mail assistance is available by contacting Applications@PressureSystems.com. Merchandise Return Procedures If your scanner needs to be returned to Pressure Systems, obtain a Returned Merchandise Authorization (RMA) from the Customer Service Department. Be prepared to supply the following information when requesting the RMA: •... - Page 5 Pressure Systems, Inc. Model 9046 User’s Manual PSI will return warranty items prepaid via UPS GROUND. If the customer desires another method of return shipment, PSI will prepay and add the shipping charges to the repair bill. Incoming freight charges are the customer’s responsibility. The customer is also responsible for paying shipping charges to and from PSI for any equipment not under warranty.

- Page 6 Pressure Systems, Inc. Model 9046 User’s Manual This page left intentionally blank. Page iv www.PressureSystems.com...

-

Page 7: Introduction

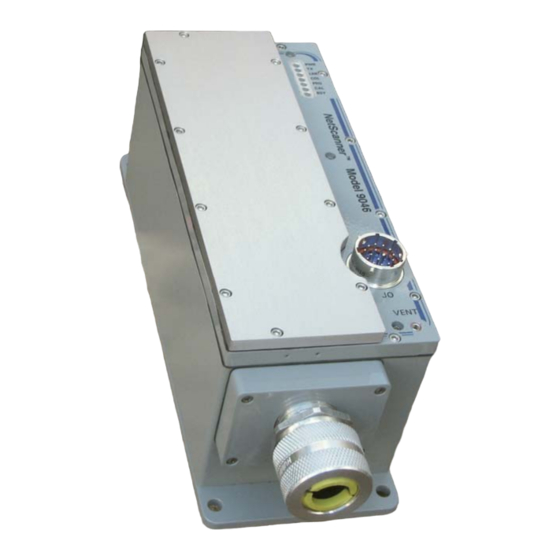

1.1 General 1.1.1 Introduction The Model 9046 Intelligent Temperature Scanner is a 16 channel modular scanning system designed to operate in harsh environments, such as turbine engine test cells. It uses an Ethernet TCP/IP or UDP interface and has the same mechanical footprint, power and interface connector, and front panel LED indicators as the Model 9116 Intelligent Pressure Scanner. -

Page 8: Physical Description

The direct wire connection is the most economical, and the most accurate, as it eliminates one thermocouple junction and its attendant potential for errors. The Model 9046 has the same mounting footprint as the PSI NetScanner family of pressure scanners. It is approved for operation in an ambient temperature environment from –30 to +70 degrees Centigrade. -

Page 9: Theory Of Operation

Pressure Systems, Inc. Model 9046 User’s Manual For operation, the Model 9046 only requires 18 to 36 VDC (i=200mA), and the appropriate Ethernet interface. 1.1.3 Theory of Operation The Model 9046 is a 32 channel analog multiplexer, controlled by a microprocessor. It communicates over an Ethernet TCP/IP or UDP interface. -

Page 10: Open Circuit Detection

This unit will handle thermocouples only and has no jumper. 2.0 Setup Instructions Use the procedures in this section to set up a Model 9046 module. Page 4 www.PressureSystems.com... -

Page 11: Equipment Required

PSI powered network solution such as 90DB, 90DC, 98RK or 9FC. 9IFC will be used as the example. • PSI 9080 cable for the connection between the 9IFC and the Model 9046 module. See Cable Connections. • Ethernet compatible AAUI transceiver and Ethernet cables •... -

Page 12: Computer Preparation

Pressure Systems, Inc. Model 9046 User’s Manual 2.2 Computer Preparation The PC must have its IP address and subnet mask set to be compatible with the addressing existing in the module. For a new module this will be the factory default. The IP address of the host PC must be set to: 200.200.1.1. - Page 13 Pressure Systems, Inc. Model 9046 User’s Manual Figure 2-2: TCP/IP Properties Dialog Box Be sure to record the subnet mask addressing settings prior to changing them to the values shown to facilitate restoring the Note computer to its previous network configuration.

-

Page 14: Module Connection

Pressure Systems, Inc. Model 9046 User’s Manual 2.3 Module Connection The module must now be connected to the PC via the 9IFC interface. Connect the cables as shown in Cable Connections. Figure 2-3: Cable Connections Page 8 www.PressureSystems.com... - Page 15 Pressure Systems, Inc. Model 9046 User’s Manual After supplying power to the module, observe the front panel for the following indications: • PWR LED should remain ON. If this LED is not ON, all other LED’s will also likely be OFF.

-

Page 16: Ip Address Assignment

Upon completion of addressing, change the Host computer IP address back to its previous value, and verify that the Host can connect to the Model 9046 module using NUSS. The module and PC are now ready to communicate. Follow this procedure to assign an IP address: From the start menu select NUSS. - Page 17 Pressure Systems, Inc. Model 9046 User’s Manual Connect to the module. (When a connection has been established, the top of the module icon will turn yellow.) Follow these steps: a. Left-Click on the module’s icon in the Node Map. b. Right-Click on the module’s icon (in either the Node Map or the Description Box).

- Page 18 Pressure Systems, Inc. Model 9046 User’s Manual Open the Network Options (Single Module) Dialog Box: a. Right-click on the module’s icon (in the Description Box). b. Click on “Configure”. c. Click on “Network Options”. Figure 2-6: Configure>Network Options Pulldown Menu...

- Page 19 Click the Exit button. Right-click on the module icon, and select Disconnect. Remove power from the Model 9046, wait 5 seconds and re-apply. The computer and the module now will have incompatible IP addresses. You will have to change the IP address to one that is Note compatible.

-

Page 20: Set Sensor Type

Pressure Systems, Inc. Model 9046 User’s Manual 2.5 Set Sensor Type Confirm that the correct SCM is installed and jumpered correctly: a. For Non-Universal SCMs: Confirm that each of the 16 hardware channels contains the correct SCM for the intended application. For isolated thermocouple applications, a SCM is required. - Page 21 Pressure Systems, Inc. Model 9046 User’s Manual Table 1: Sensor Type Values Page 15 www.PressureSystems.com...

-

Page 22: Read Sensor Type

Pressure Systems, Inc. Model 9046 User’s Manual 2.6 Read Sensor Type Each channel type can be read using a command of the form: uxxx51 . where xxx = the channel # in HEX . Example: • u00a51 will return 18, indicating the channel is configured for a type T thermocouple. - Page 23 Pressure Systems, Inc. Model 9046 User’s Manual Command: c05 0002 Enable thermocouple reference temperature Action: alarms in autonomous data stream. Page 17 www.PressureSystems.com...

-

Page 24: Set Temperature Units

Pressure Systems, Inc. Model 9046 User’s Manual 2.8 Set Temperature Units Set temperature units for all temperature channels. The ‘v’ command is used with array index aa = 11 (hex) and new coefficient index = 0b (hex). Command: v0110b dd dd = 00 for degrees C, dd = 01 for Fahrenheit. - Page 25 Pressure Systems, Inc. Model 9046 User’s Manual The following example sets channel 1 EU filter parameter to 10: Command: v00152 10 Normal Response: Error: Page 19 www.PressureSystems.com...

-

Page 26: Read Eu Filter Parameter

Pressure Systems, Inc. Model 9046 User’s Manual 2.11 Read EU Filter Parameter The EU filter parameter can be read for an individual channel using the ‘u’ command with coefficient index number 52 hex. The following example reads the EU filter parameter for channel 1. -

Page 27: Calibration

Pressure Systems, Inc. Model 9046 User’s Manual 3.0 Calibration Calibration consists of offset correction. Implement offset correction (automatically calculate and set offset coefficient) on a per channel basis using the ‘h’ command. Accurately measure the temperature of the select thermocouple sensor for use in the offset correction calibration. - Page 28 Pressure Systems, Inc. Model 9046 User’s Manual Examples: Correct the offset in channel 1 with channel 1 at 100 degree C : Command: h0001 100.0 0.294167 (offset coefficient returned) Response: Manually set channel 1offset coefficient to 0.4: Command: v00100 0.4...

- Page 29 Pressure Systems, Inc. Model 9046 User’s Manual Page 23 www.PressureSystems.com...

-

Page 30: Firmware

Pressure Systems, Inc. Model 9046 User’s Manual 4.0 Firmware 4.1 Description of Operation Table 1 shows the different sensor types available along with the gain settings and engineering units for each type. Setting channel sensor type automatically causes the gain for that channel to be set according to Table1. - Page 31 Pressure Systems, Inc. Model 9046 User’s Manual Voltage If a channel is configured for straight voltage then no additional EU conversion is needed. Va is returned as transducer voltage. Vb is returned as cold junction temperature. Thermocouple Va is the thermocouple voltage. Vb is the cold junction reference voltage and is saved to be used in cold junction compensation calculations.

-

Page 32: Updating The Firmware

Special precautions must be taken when updating NetScanner™ firmware. If care is not taken, the module program memory can be corrupted rendering the module inoperative until the program memory chip is physically replaced. Never download firmware not made specifically for the Model 9046. Page 26 www.PressureSystems.com... - Page 33 Pressure Systems, Inc. Model 9046 User’s Manual This page intentionally blank. Page 27 www.PressureSystems.com...

-

Page 34: Command Set

Pressure Systems, Inc. Model 9046 User’s Manual 5.0 Command Set Command Quick Reference Type Operation Command Function Code TCP/IP No Operation Commands Reset Read Primary Transducer Volts Read Primary Transducer A/D Counts Read Primary Transducer E. U. Data at High Speed... - Page 35 Change Specified Module’s IP Address Resolution Method & Reboot The commands in this section are quite detailed and involved to anyone wishing to only use the 9046 module. The commands need Note be understood fully only by persons wishing to program software that talks to the module.

-

Page 36: Summary Information About All Commands

Model 9046 module before such commands can be sent to the module. Finally, there are a few special UDP/IP commands listed that can be sent to a Model 9046 module without a valid TCP "connection" having to be established. These commands can be sent even if the module currently has no TCP address assigned to it. - Page 37 A few commands have a fixed format for sending or returning data, which is stated explicitly in its command description. The Model 9046 has several special datum values it returns when a particular E. U. datum is out of range, or was calculated incorrectly. Such values vary with the Sensor type of any channel.

- Page 38 Pressure Systems, Inc. Model 9046 User’s Manual The individual description of each command follows immediately. Each command has a functional title (and operation code), followed by a short text description. Next, there is a formal definition of the command format and its response, followed by a more detailed text discussion.

-

Page 39: No Operation (Command 'A')

Model 9046 User’s Manual 5.2 No Operation (Command ’A’) Purpose : This command has no internal module effect. It is used as a simple method to verify proper communications to the Model 9046 module. Command "A" ’A’ is the operation code. -

Page 40: Reset (Command 'B')

Pressure Systems, Inc. Model 9046 User’s Manual 5.3 Reset (Command ’B’) Purpose : Instructs the module to reset internal operating parameters, and to set all internal control variables to their default "reset" state (see description below). The current TCP/IP socket connection will remain open. -

Page 41: Read Primary Transducer Volts (Command 'V')

Pressure Systems, Inc. Model 9046 User’s Manual 5.4 Read Primary Transducer Volts (Command ’V’) Purpose : Returns the most recently acquired primary transducer (i.e., temperature/ resistance) raw data for the specified channels. These data are averaged signed A/D counts (in the range -32768 to +32767). - Page 42 Pressure Systems, Inc. Model 9046 User’s Manual single binary float to single binary float (little endian: lsb first) Example : Command module to return decimal voltage data for Primary Transducer channels 1, 5, 9, and " V11110 " Response contains data for channels 13, 9, 5, and 1 (left to right): "...

-

Page 43: Read Primary Transducer A/D Counts (Command 'A')

Pressure Systems, Inc. Model 9046 User’s Manual 5.5 Read Primary Transducer A/D Counts (Command ’a’) Purpose : Returns the most recently acquired primary transducer (i.e., temperature/ resistance) raw data for the specified channels. These data are averaged signed A/D counts (in the range -32768 to +32767). - Page 44 Pressure Systems, Inc. Model 9046 User’s Manual single binary float to single binary float (big endian: msb first) single binary float to single binary float (little endian: lsb first) Example : Command module to return decimal raw "Temperature/Resistance" A/D counts data for Primary Transducer channels 1, 5, 9, and 13: "...

-

Page 45: Read Primary Transducer E.u. Data At High Speed (Command 'B')

Pressure Systems, Inc. Model 9046 User’s Manual 5.6 Read Primary Transducer E. U. Data at High Speed (Command ’b’) Purpose : Returns the most recent Primary Transducer E. U. data from all channels of the module as fast as possible. Data is returned directly in its native internal (IEEE single-precision float) binary form (i.e., as for format code 7 in other commands). - Page 46 Pressure Systems, Inc. Model 9046 User’s Manual NUSS does not use this command normally. You may execute it manually via the ’Execute Commands’ or ’Execute Script’ functions Note of NUSS - though this should be avoided if NUSS is currently operating the module via other NUSS functions.

-

Page 47: Define/Control Autonomous Host Streams (Command 'C')

If data streams are defined to occur at high scan rates, then each data scan received by the host must be processed and disposed of Note in a timely manner. Model 9046 modules are capable of generating autonomous data streams faster than some "slow" hosts (or limited software, including NUSS) can absorb. - Page 48 ’c 00’ sub-command below for the default contents of each stream that NUSS configures automatically for each Model 9046 module. When you use the NUSS ’Run’ function, you unleash these streams, which are then processed by (and displayed on) the Run form’s data fields.

- Page 49 200Hz even if the requested output is 100Hz or less. Because the default Scans-Per-Average option is set to 64 (default) in a Model 9046, only a 10Hz scan rate is normally achievable, however, unless the Scans- Per-Average option is reduced.

- Page 50 Pressure Systems, Inc. Model 9046 User’s Manual 5.7.1 Command ’c’- Sub-command Index 00: Configure a Host Delivery Stream This sub-command is used to configure the principle parameters of each of the three possible concurrent host delivery streams, one at a time. Following this configuration phase, the particular stream (1, 2, or 3) or all streams (0) may be started, stopped, altered, or undefined, with other sub-commands.

- Page 51 Pressure Systems, Inc. Model 9046 User’s Manual When the hardware trigger is used to synchronize stream scans ( sync = 0), it is assumed that the user would prefer to also synchronize internal data acquisition cycle. For this reason, when a stream utilizing hardware trigger is started, the module firmware switches out of the free- running continuous data acquisition mode described earlier.

- Page 52 Pressure Systems, Inc. Model 9046 User’s Manual The ‘ f ’ parameter identifies the format of each selected acquired datum in each data group of the stream scan, and is a single numeric digit. Valid format codes are listed in the following...

- Page 53 Pressure Systems, Inc. Model 9046 User’s Manual " A " " A " " A " Example 2: To similarly acquire data at "relative" rates (1, 2, and 4) using a periodic hardware trigger (assumed to also cycle periodically at some practical (adjustable) rate), enter the commands: "c 00 1 000F 0 1 7 0"...

- Page 54 Pressure Systems, Inc. Model 9046 User’s Manual NUSS automatically creates a default Run State 0 for every module that uses its Run function. This run state uses the above sub- Note command to configure three (3) "unbounded" autonomous data streams that the module will deliver concurrently at various rates to the host: •...

-

Page 55: Sub-Command Index 01: Start Stream(S)

Pressure Systems, Inc. Model 9046 User’s Manual 5.7.2 Command ’c’- Sub-command Index 01: Start Stream(s) This sub-command is used to start the delivery of any previously configured host stream in a module. If the stream started is "unbounded", then it will be necessary to use the Stop Stream sub-command to stop it. - Page 56 Pressure Systems, Inc. Model 9046 User’s Manual module. Each of the three possible host streams will report its own unique sequence number. Note that if a previously stopped data stream is restarted, the returned sequence numbers will resume with the next number at the point of the stream’s termination. The sequence numbers will restart at one (1) only if the streams are reconfigured (with ‘...

-

Page 57: Sub-Command Index 02: Stop Stream(S)

Pressure Systems, Inc. Model 9046 User’s Manual 5.7.3 Command ’c’- Sub-command Index 02: Stop Stream(s) This sub-command is used to stop (or temporarily suspend) the delivery of any previously started host stream in a module, one at a time or all together, whether the stream was unbounded or bounded. - Page 58 Pressure Systems, Inc. Model 9046 User’s Manual Example: Stop all the streams configured in the previous example: " c 02 0 " Read response: " A " NUSS uses this sub-command to stop the acquisition of data on each Run form when that form exits, or when the [Acquire] button Note on the form is clicked once.

-

Page 59: Sub-Command Index 03: Clear Stream(S)

Pressure Systems, Inc. Model 9046 User’s Manual 5.7.4 Command ’c’- Sub-command Index 03: Clear Stream(s) This sub-command is used to "undefine" any previously configured host stream in a module, one at a time, or all together. The sub-command’s format is: “c 03 st”... - Page 60 Pressure Systems, Inc. Model 9046 User’s Manual NUSS uses this sub-command to undefined data specific streams when its Run State Editor form is used to define "custom" stream configurations Note (called Run States 1-9) and all three streams are not to be generated concurrently.

-

Page 61: Sub-Command Index 04: Return Stream Information

Pressure Systems, Inc. Model 9046 User’s Manual 5.7.5 Command ’c’ - Sub-command Index 04: Return Stream Information This sub-command returns current stream configuration information in its response. Its format Command “c 04 st” ‘c’ is the operation code ‘04’ is the sub-command index (‘ ii ’) for configuration ‘... - Page 62 Pressure Systems, Inc. Model 9046 User’s Manual Description : This sub-command returns the current configuration information for a particular stream. Returned values are defined the same as the “contributing” parameters of the separate sub- commands: Configure a Host Delivery Stream (“ 00 ”), Select Protocol (“ 06 ”), and Select Data in a Stream (“...

-

Page 63: Sub-Command Index 05: Select Prefix/Data Groups In A Stream

Pressure Systems, Inc. Model 9046 User’s Manual 5.7.6 Command ’c’ - Sub-command Index 05: Select Prefix/Data Groups in a Stream This sub-command sets additional options that cause an already defined stream to deliver a specific prefix and/or other groups of data to the host. By default, only the Primary Transducer (i.e., Temperature/ Resistance) E. - Page 64 Selecting too many data groups will reduce module performance. Note bbbb (hex) data selected for inclusion in each stream packet 0001 (reserved for Valve Status Prefix (9046 does not use) 0002 Enable UTR Alarm Status Prefix (see alarm bit map below) 0010 Enable Primary Transducer (Temperature/Resistance) EU Data (default if "05"...

- Page 65 Transducer E. U. Data group only. There is such a sub-command in the definition file for each Run State ’r’ (recorded in a file with the name: "9046-<serial#>rs<r>.ini" in the ‘Ini’ subfolder of NUSS). A similar file with the name: "9046-<serial#>rs<r>.0" in the same subfolder defines the Data Set of Run State ‘r’.

-

Page 66: Sub-Command Index 06: Select Protocol For Stream Delivery

Pressure Systems, Inc. Model 9046 User’s Manual 5.7.7 Command ’c’ - Sub-command Index 06: Select Protocol For Stream Delivery Command “ c 06 st pro [ remport [ ipaddr ]] ” ‘c’ is the operation code. ‘ 06’ is the sub-command index ( ii ) for Select Protocol . - Page 67 Pressure Systems, Inc. Model 9046 User’s Manual The optional remport parameter may be any value in the range 1024 to 65535. However, remport = 7001 should be avoided, since NetScanner modules emit responses to that port, and most host programs (like NUSS) should have a UDP socket already bound to that port for receiving these special responses.

- Page 68 Pressure Systems, Inc. Model 9046 User’s Manual NUSS does not normally use this command since it generates and processes TCP/IP streams exclusively with a unique Socket Note allocated for each "connected" module. Also, you may NOT execute it manually via the ’Execute Script’ or ’Execute Commands’...

- Page 69 Pressure Systems, Inc. Model 9046 User’s Manual This page intentionally left blank. Page 63 www.PressureSystems.com...

-

Page 70: Appendix A

Pressure Systems, Inc. Model 9046 User’s Manual Appendix A Cable Diagrams Model 9046 Ethernet Interface Cable P/N 9080 Page 64 www.PressureSystems.com... - Page 71 Pressure Systems, Inc. Model 9046 User’s Manual Model 9046 Ethernet Interface Cable P/N 9080 Page 65 www.PressureSystems.com...

- Page 72 Headquarters/Factory: European Office: Pressure Systems, Inc. PSI, Ltd. 34 Research Drive 124, Victoria Road Hamtpton, VA 23666 Farnborough, Hants GU14 7PW Phone: (757) 865-1243 United Kingdom Toll Free: (800) 328-3665 Phone: +44 1252 510000 Fax: (757) 865-8744 Fax: +44 1252 510099 E-mail: sales@PressureSystems.com...

Need help?

Do you have a question about the 9046 and is the answer not in the manual?

Questions and answers