Advertisement

Quick Links

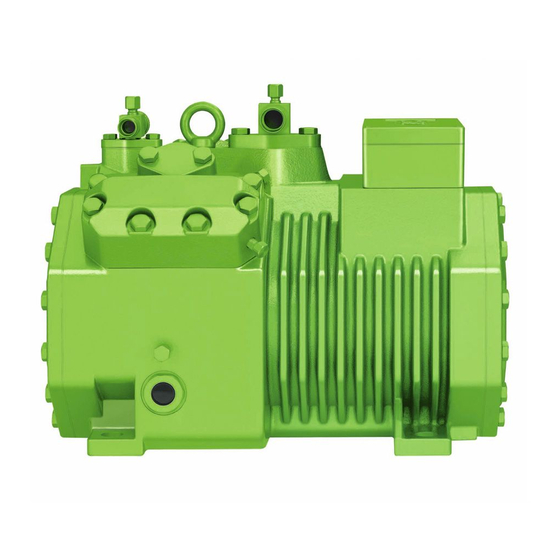

Halbhermetische

Hubkolbenverdichter

BITZER ECOLINE und

ECOLINE VARISPEED

• 2KES-05(Y) .. 2FES-3(Y)

• 2EES-2(Y) .. 2CES-4(Y)

• 22EES-4(Y) .. 22CES-8(Y)

• 4FES-3(Y) .. 4CES-9(Y)

• 44FES-6(Y) .. 44CES-18(Y)

• 4VE(S)-6Y .. 4NE(S)-20(Y)

• 44VE(S)-14(Y) .. 44NE(S)-40(Y)

• 4JE-13Y .. 4FE-35(Y)

• 44JE-30(Y) .. 44FE-70(Y)

• 6JE-22Y .. 6FE-50(Y)

• 66JE-50(Y) .. 66FE-100(Y)

• 8GE-50(Y) .. 8FE-70(Y)

• 4FDC-5Y .. 4CDC-9Y

• 4VDC-10Y .. 4NDC-20Y

• 2DES-3.F1Y

• 4FE-5.F1Y .. 4CE-9.F3Y

• 4VE-7.F3Y .. 4NE-20.F4Y

Inhalt

1 Sicherheit

2 Anwendungsbereiche

3 Montage

4 Elektrischer Anschluss

5 In Betrieb nehmen

6 Betrieb / Wartung

7 Außer Betrieb nehmen

Semi-hermetic

recipro cat ing

com pres sors

BITZER ECOLINE and

ECOLINE VARISPEED

• 2KES-05(Y) .. 2FES-3(Y)

• 2EES-2(Y) .. 2CES-4(Y)

• 22EES-4(Y) .. 22CES-8(Y)

• 4FES-3(Y) .. 4CES-9(Y)

• 44FES-6(Y) .. 44CES-18(Y)

• 4VE(S)-6Y .. 4NE(S)-20(Y)

• 44VE(S)-14(Y) .. 44NE(S)-40(Y)

• 4JE-13Y .. 4FE-35(Y)

• 44JE-30(Y) .. 44FE-70(Y)

• 6JE-22Y .. 6FE-50(Y)

• 66JE-50(Y) .. 66FE-100(Y)

• 8GE-50(Y) .. 8FE-70(Y)

• 4FDC-5Y .. 4CDC-9Y

• 4VDC-10Y .. 4NDC-20Y

• 2DES-3.F1Y

• 4FE-5.F1Y .. 4CE-9.F3Y

• 4VE-7.F3Y .. 4NE-20.F4Y

Content

Seite

2

1 Safety

2 Application ranges

4

7

3 Mounting

20

4 Electrical connection

25

5 Commissioning

6 Operation / Maintenance

31

34

7 De-commissioning

Compresseurs

hermétiques accessibles

à pis ton

BITZER ECOLINE et

ECOLINE VARISPEED

• 2KES-05(Y) .. 2FES-3(Y)

• 2EES-2(Y) .. 2CES-4(Y)

• 22EES-4(Y) .. 22CES-8(Y)

• 4FES-3(Y) .. 4CES-9(Y)

• 44FES-6(Y) .. 44CES-18(Y)

• 4VE(S)-6Y .. 4NE(S)-20(Y)

• 44VE(S)-14(Y) .. 44NE(S)-40(Y)

• 4JE-13Y .. 4FE-35(Y)

• 44JE-30(Y) .. 44FE-70(Y)

• 6JE-22Y .. 6FE-50(Y)

• 66JE-50(Y) .. 66FE-100(Y)

• 8GE-50(Y) .. 8FE-70(Y)

• 4FDC-5Y .. 4CDC-9Y

• 4VDC-10Y .. 4NDC-20Y

• 2DES-3.F1Y

• 4FE-5.F1Y .. 4CE-9.F3Y

• 4VE-7.F3Y .. 4NE-20.F4Y

Page

Sommaire

2

1 Sécurité

4

2 Champs d'application

7

3 Montage

20

4 Raccordement électrique

25

5 Mise en service

31

6 Service / Maintenance

34

7 Mise hors service

Page

2

4

7

20

25

31

34

Advertisement

Summarization of Contents

1 Sicherheit

Autorisiertes Fachpersonal

Work on compressors and refrigeration systems must be performed by trained personnel.

Restgefahren

Unavoidable residual hazards exist. All personnel must read these instructions carefully.

Sicherheitshinweise

Allgemeine Sicherheitshinweise

General warnings and precautions for handling compressors, including pressure and temperature hazards.

2.1 Einsatz von Kältemitteln der Sicherheitsgruppen A2 bzw. A2L

Anforderungen an den Verdichter und die Kälteanlage

Specifications and requirements for compressors and refrigeration systems using specific refrigerant groups.

3 Montage

3.1 Verdichter transportieren

Instructions for safely transporting the compressor, including lifting and pallet handling.

3.2 Verdichter aufstellen

Guidelines for placing the compressor horizontally and considering environmental conditions.

Schwingungsdämpfer

Montage von Saug- und Druckleitung

Connecting suction and discharge lines to the compressor, ensuring they are stress-free.

Transportsicherungen bei Verflüssigungssätzen

Schwingungsdämpfer Typ I

Procedure for removing transport locks for Type I anti-vibration mountings after installation.

Schwingungsdämpfer Typ II

Procedure for removing transport locks for Type II anti-vibration mountings after installation.

3.3 Rohrleitungen anschliessen

Rohranschlüsse

Details on pipe connections, including standard dimensions and solder connections.

Absperrventile

Guidelines for operating shut-off valves, including removal of protective caps and spindle operation.

4 Elektrischer Anschluss

Elektrischer Anschluss der ECOLINE VARISPEED Verdichter

Details on wiring ECOLINE VARISPEED compressors, referencing technical information.

Allgemeine Hinweise

General guidelines for electrical connections, including safety standards and compliance.

4.1 Netzanschlüsse

Guidelines for dimensioning motor contactors, cables, and fuses for mains connections.

Motorausführung

Stern oder Dreieck-Motor

Description of direct-on-line start motors designed for dual voltages, with star/delta operation.

Teilwicklungsmotor

Details on part-winding motors, including winding partition, contactor selection, and wiring.

Stern-Dreieck-Motor

Specific options for star-delta motors, including part-winding options and configuration.

4.2 Schutzgeräte

SE-B1 (Standard)

Information on SE-B1 protection devices installed in the terminal box for specific compressor models.

SE-B2 (Standard)

Information on SE-B2 protection devices installed in the terminal box for specific compressor models.

5 In Betrieb nehmen

5.1 Druckfestigkeit prüfen

Procedures for testing the pressure resistance of the refrigeration circuit and compressor.

5.6 Startvorgang

Schmierung / Ölkontrolle

Immediate post-start checks for compressor lubrication, oil level, and oil pressure.

Öldrucküberwachung (Option)

Details on optional oil pressure monitoring systems like Delta-PII and OLC-K1.

Schwingungen und Frequenzen

Schalthäufigkeit

Guidelines on the maximum number of starts per hour and minimum running times for compressors.

6 Betrieb / Wartung

6.1 Regelmäßige Kontrollen

Regular checks to be performed on the plant according to national regulations, including operating data and oil supply.

7 Außer Betrieb nehmen

7.1 Stillstand

Procedure to follow when the compressor is shut down, including keeping the oil heater on.

7.2 Demontage des Verdichters

Steps for safely removing the compressor, including closing valves and extracting refrigerant.

Verdichter entsorgen

Instructions for properly draining and disposing of used compressors and oil.

Need help?

Do you have a question about the 4NE-20 F4Y Series and is the answer not in the manual?

Questions and answers