Advertisement

Quick Links

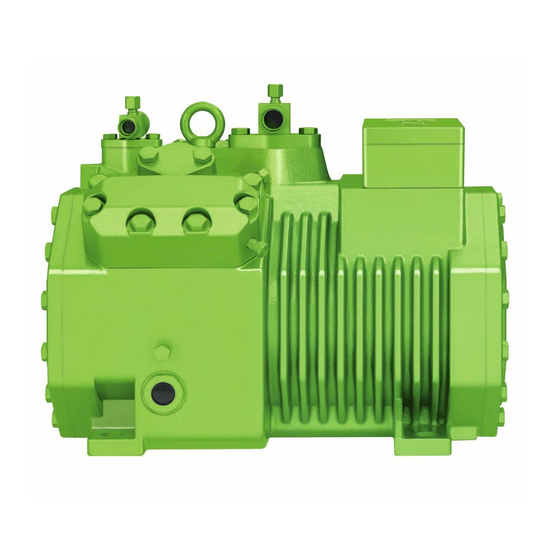

Halbhermetische

Hubkolbenverdichter

BITZER ECOLINE und

ECOLINE VARISPEED

• 2KES-05(Y) .. 2FES-3(Y)

• 2EES-2(Y) .. 2CES-4(Y)

• 22EES-4(Y) .. 22CES-8(Y)

• 4FES-3(Y) .. 4CES-9(Y)

• 44FES-6(Y) .. 44CES-18(Y)

• 4VE(S)-6Y .. 4NE(S)-20(Y)

• 44VE(S)-14(Y) .. 44NE(S)-40(Y)

• 4JE-13Y .. 4FE-35(Y)

• 44JE-30(Y) .. 44FE-70(Y)

• 6JE-22Y .. 6FE-50(Y)

• 66JE-50(Y) .. 66FE-100(Y)

• 8GE-50(Y) .. 8FE-70(Y)

• 4FDC-5Y .. 4CDC-9Y

• 4VDC-10Y .. 4NDC-20Y

• 2DES-3.F1Y

• 4FE-5.F1Y .. 4CE-9.F3Y

• 4VE-7.F3Y .. 4NE-20.F4Y

Inhalt

1 Sicherheit

2 Anwendungsbereiche

3 Montage

4 Elektrischer Anschluss

5 In Betrieb nehmen

6 Betrieb / Wartung

7 Außer Betrieb nehmen

Semi-hermetic

recipro cat ing

com pres sors

BITZER ECOLINE and

ECOLINE VARISPEED

• 2KES-05(Y) .. 2FES-3(Y)

• 2EES-2(Y) .. 2CES-4(Y)

• 22EES-4(Y) .. 22CES-8(Y)

• 4FES-3(Y) .. 4CES-9(Y)

• 44FES-6(Y) .. 44CES-18(Y)

• 4VE(S)-6Y .. 4NE(S)-20(Y)

• 44VE(S)-14(Y) .. 44NE(S)-40(Y)

• 4JE-13Y .. 4FE-35(Y)

• 44JE-30(Y) .. 44FE-70(Y)

• 6JE-22Y .. 6FE-50(Y)

• 66JE-50(Y) .. 66FE-100(Y)

• 8GE-50(Y) .. 8FE-70(Y)

• 4FDC-5Y .. 4CDC-9Y

• 4VDC-10Y .. 4NDC-20Y

• 2DES-3.F1Y

• 4FE-5.F1Y .. 4CE-9.F3Y

• 4VE-7.F3Y .. 4NE-20.F4Y

Content

Seite

2

1 Safety

2 Application ranges

4

7

3 Mounting

20

4 Electrical connection

25

5 Commissioning

6 Operation / Maintenance

31

34

7 De-commissioning

Compresseurs

hermétiques accessibles

à pis ton

BITZER ECOLINE et

ECOLINE VARISPEED

• 2KES-05(Y) .. 2FES-3(Y)

• 2EES-2(Y) .. 2CES-4(Y)

• 22EES-4(Y) .. 22CES-8(Y)

• 4FES-3(Y) .. 4CES-9(Y)

• 44FES-6(Y) .. 44CES-18(Y)

• 4VE(S)-6Y .. 4NE(S)-20(Y)

• 44VE(S)-14(Y) .. 44NE(S)-40(Y)

• 4JE-13Y .. 4FE-35(Y)

• 44JE-30(Y) .. 44FE-70(Y)

• 6JE-22Y .. 6FE-50(Y)

• 66JE-50(Y) .. 66FE-100(Y)

• 8GE-50(Y) .. 8FE-70(Y)

• 4FDC-5Y .. 4CDC-9Y

• 4VDC-10Y .. 4NDC-20Y

• 2DES-3.F1Y

• 4FE-5.F1Y .. 4CE-9.F3Y

• 4VE-7.F3Y .. 4NE-20.F4Y

Page

Sommaire

2

1 Sécurité

4

2 Champs d'application

7

3 Montage

20

4 Raccordement électrique

25

5 Mise en service

31

6 Service / Maintenance

34

7 Mise hors service

Page

2

4

7

20

25

31

34

Advertisement

Summarization of Contents

Safety and Hazard Awareness

Authorized Personnel Qualifications

Specifies requirements for trained and instructed refrigeration personnel for safe operation.

Residual Hazards Identification

Highlights unavoidable residual hazards from compressors that necessitate careful handling.

General Safety References and Warnings

Provides general instructions to prevent hazards, including specific warnings and cautions.

Application Ranges and Refrigerant Guidelines

Compressor Types and Permitted Refrigerants

Details compressor models, permitted refrigerants, oil charge, and application limits.

Refrigerant Handling Safety Warnings

Crucial warnings regarding counterfeit refrigerants and safe operation in vacuum conditions.

Safety Groups A2/A2L Refrigerant Requirements

Regulations and system requirements for using refrigerants from safety groups A2 and A2L.

Mounting and Installation Procedures

Compressor Transport and Installation

Guidelines for safely transporting and horizontally installing compressors.

Anti-Vibration Mounting Details

Instructions for fitting, removing, and specifying anti-vibration mountings to prevent damage.

Transport Securing Devices

Guidance on removing transport locks from units after installation.

Pipeline Connections and Valve Operation

Pipe Connection and Valve Operation

Guides on pipe compatibility, valve operation, and safety.

Pipeline Safety and Component Protection

Measures for long pipelines and protecting components from damage.

Start Unloading (SU) and Capacity Control

Start Unloading (SU) Functionality

Details on SU as an accessory, retrofitting, and specific compressor model considerations.

Capacity Control (CRII System)

Information on the CRII system, its applications, and tandem compressor setup.

Compressor Connections and Diagrams

Single Compressor Connection Diagrams

Visual guides showing port layouts for various single compressor series.

Tandem Compressor Connection Diagrams

Visual guides for tandem compressor configurations and their connections.

Connection Position Legend

Key to understand the numbered connection points shown in diagrams.

Electrical Connection Procedures

ECOLINE VARISPEED Wiring and General Guidelines

Wiring info for specific models and general electrical safety compliance.

Mains Connection and Motor Configurations

Guidance on mains connections, motor types, and contactor selection.

Protection Devices and Electrical Safety

SE-B1 and SE-B2 Protection Devices

Information on SE-B1 and SE-B2 devices and their application for specific compressor series.

Protection Device Relocation for A2/A2L Refrigerants

Safety instructions for relocating protection devices when using A2/A2L refrigerants.

System Accessories and Monitoring Options

Differential Oil Pressure Switch Delta-PII

Technical details and connection for the Delta-PII oil pressure monitoring switch.

Opto-electronical Oil Level Monitor OLC-K1

Information on the OLC-K1 for monitoring oil levels in specific compressors.

Discharge Gas Temperature Sensor Installation

Installation and function of the discharge gas temperature sensor.

Pressure Limiting Safety Devices

CIC System for Low-Temperature Applications

Explanation of the CIC system's role in ensuring thermal limits for low-temp cooling.

Commissioning Procedures

Pressure Testing and Evacuation

Procedures for strength testing, tightness testing, and system evacuation.

Refrigerant Charging and Pre-Start Checks

Guidelines for refrigerant charging, safety checks, and oil level verification.

Start-up Lubrication and Optional Monitoring

Procedures for checking lubrication, oil pressure, and optional monitoring systems post start-up.

Operating Conditions and Monitoring

Preventing Wet Operation

Critical temperature guidelines to avoid wet operation and potential damage.

Vibration and Frequency Management

Instructions for identifying and mitigating abnormal vibrations and resonant frequencies.

Compressor Cycling Rate Limits

Recommended limits for compressor start-ups per hour and minimum run times.

Operation and Maintenance Tasks

Regular Plant Checks and Safety Verification

Routine inspections, safety device checks, and connection verification.

Condensation Water and Oil Management

Procedures for condensation water and guidelines for oil changing/handling.

De-commissioning Procedures

Compressor Standstill Procedures

Steps to take when the compressor is stopped, including oil heater operation.

Compressor Dismantling and Disposal

Safe procedures for dismantling the compressor and disposing of refrigerant and oil.

Need help?

Do you have a question about the 4CE-9 F3Y Series and is the answer not in the manual?

Questions and answers