Table of Contents

Advertisement

Quick Links

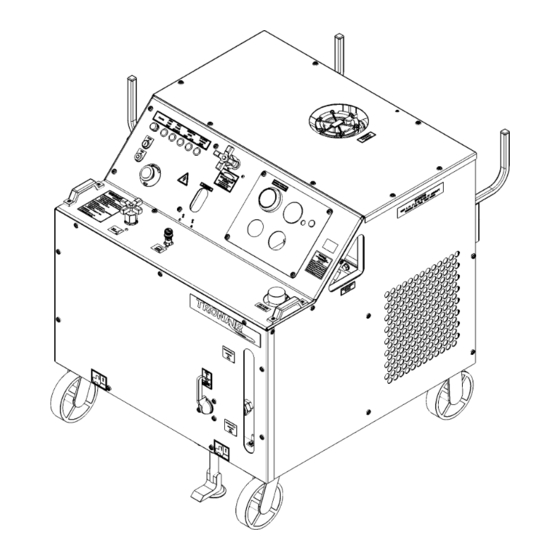

OPERATION & SERVICE MANUAL

54X1 Series

5411, 5421, 5431, 5441

Hydraulic Power Unit

07/2023 − Rev. 06

For Spare Parts, Operations & Service Manuals or Service Needs

Scan the QR code or visit Tronair.com/aftermarket

Tronair, Inc.

Phone: (419) 866-6301 | 800-426-6301

1 Air Cargo Pkwy East

Web: www.tronair.com

Swanton, OH 43558

Email: sales@tronair.com

Advertisement

Table of Contents

Summarization of Contents

1.0 PRODUCT INFORMATION

1.1 DESCRIPTION

Details about the Hydraulic Power Unit model numbers and fluid types.

1.2 MODEL & SERIAL NUMBER

Information on locating the model and serial number on the unit.

1.3 MANUFACTURER

Tronair, Inc. contact information.

1.4 FUNCTION

Explains the purpose and operation of the HPU.

1.5 REQUIREMENTS

Details the electrical power requirements for the HPU.

2.0 SAFETY INFORMATION

2.1 USAGE AND SAFETY INFORMATION

General safety guidelines and warning explanations for HPU operation.

2.2 EXPLANATION OF WARNING & DANGER SIGNS

Explains the meaning of hazard symbols used in the manual.

2.3 COMPONENT SAFETY FEATURES

Lists safety features integrated into the HPU components.

2.4 FUNCTIONAL SAFETY FEATURES

Describes built-in safety features related to HPU functionality.

2.5 PERSONAL PROTECTION EQUIPMENT

Specifies necessary personal protective equipment (PPE) for HPU operation.

2.6 SAFETY GUIDELINES

Provides essential safety rules for operating the HPU.

2.7 GENERAL COMMENTS

General remarks about HPU intended use and manual adherence.

3.0 PREPARATION PRIOR TO FIRST USE

3.1 GENERAL

Initial preparation steps before operating the HPU.

3.2 SERVICING RESERVOIR

Instructions for filling the HPU reservoir with hydraulic fluid.

3.3 CONNECTING ELECTRICAL LEADS

Guidelines for safely connecting electrical power to the HPU.

4.0 TRAINING

4.1 TRAINING REQUIREMENTS

Outlines employer responsibilities for operator training.

4.2 TRAINING PROGRAM

Details the content of the HPU operator training program.

4.3 OPERATOR TRAINING

Specifies the necessary training for safe HPU operation.

5.0 OPERATION

5.1 OPERATING PARAMETERS

Key parameters and requirements for HPU operation.

5.2 NUMERICAL VALUES

Lists numerical specifications for HPU components.

5.2.1 Fluid

Lists the fluid types for different HPU models.

5.2.2 Physical

Provides physical specifications (weight, dimensions) of the HPU.

5.2.3 Motor Driven Hydraulic Pump

Details specifications for the HPU's motor-driven hydraulic pump.

5.2.4 Electric Motor

Information about the HPU's 25 horsepower electric motor.

5.2.5 Filters

Describes the specifications of the various filters used in the HPU.

5.2.6 Hand Pump (Option M)

Specifications for the two-stage hand pump option.

5.3 LOCATION & LAYOUT OF CONTROLS

Identifies and describes controls on the HPU panels.

5.3.1 Front Panel Controls

Identifies and describes controls on the front panel of the HPU.

5.3.2 Electrical Control Panel

Details the functions of the switches, lights, and indicators on the electrical panel.

5.3.3 Hydraulic Control Panel

Explains the gauges and ports on the hydraulic control panel.

5.3.4 Rear Panel Controls

Identifies components and connections on the rear panel of the HPU.

5.3.5 Hydraulic Pump Controls

Describes the flow and pressure controls for the hydraulic pump.

5.3.6 Hand Pump Controls (Option M)

Details the controls and components related to the hand pump option.

5.3.7 Split System Controls (Option C)

Explains the valves and hoses for split system operation.

5.3.8 Split System Crossover Check Controls (Option D)

Describes controls for split system operation with crossover check functionality.

5.3.9 Return Back-Pressure with Sight Gauge (Option T)

Details the components for return back-pressure monitoring.

5.4 START UP PROCEDURES

Procedures for starting the HPU.

5.4.1 Procedure for First Time or Different Electrical Supply ONLY

Steps for initial HPU startup or after electrical supply changes.

5.4.2 Initial Start Up of the HPU

Standard procedures for starting the HPU.

5.5 PRELIMINARY ADJUSTMENTS FOR OPERATION

Adjustments to be made before HPU operation.

5.5.1 Flow Control Adjustment

Steps to adjust the HPU's flow control.

5.5.2 Pressure Control Adjustment

Steps to adjust the HPU's pressure control.

5.5.3 Reservoir Selector Valve Operation

How to operate the reservoir selector valve.

5.5.4 Bypass Valve Operation

Instructions for operating the bypass valve.

5.6 BLEEDING AIR FROM SYSTEM

Procedure for removing air from the hydraulic system.

5.6.1 To Easily Purge the Unit of Air

Procedure for removing air from the hydraulic system.

5.7 SPLIT SYSTEM OPERATION (Option C)

Steps for operating the split system.

5.7.1 To Operate the Split System

Steps for operating the split system.

5.8 SPLIT SYSTEM CROSSOVER CHECK (Option D)

Procedure for operating the split system with crossover check.

5.9 HAND PUMP OPERATION (Option M)

Instructions for using the hand pump.

5.9.1 To Operate the Hand Pump

Instructions for using the hand pump.

5.10 SAMPLE VALVE

Location and purpose of the sample valve.

5.11 EMERGENCY SHUT DOWN PROCEDURE

Steps for emergency shutdown of the HPU.

5.12 DESCRIPTION OF ALARM SYSTEMS

Description of HPU alarm systems and indicators.

5.12.1 High Fluid Temperature Indicator (Option S)

Explanation of the high fluid temperature indicator light.

5.12.2 Voltage/Phase Monitor Indicator (Options G − J)

Details the voltage/phase monitor indicator light.

5.12.3 High and Low Reservoir Level Indicator (Option L)

Description of reservoir level indicator lights.

5.12.4 Clogged Filter Indicator Light (Option R)

Information about the clogged filter indicator light.

5.13 INFREQUENT HPU USE

Guidelines for infrequent use of the HPU.

5.13.1 Infrequent HPU Use Start Up Procedure

Procedure for starting the HPU after periods of inactivity.

6.0 PACKAGING AND STORAGE

6.1 PACKAGING REQUIREMENTS

Guidelines for packaging the HPU.

6.2 HANDLING

Instructions for safely handling and lifting the HPU.

6.3 PACKAGING PROTECTION

Specifies packaging material requirements.

6.4 LABELING OF PACKAGING

Recommended labels for HPU packaging.

6.5 STORAGE COMPATIBILITY

Considerations for storing the HPU.

6.6 STORAGE ENVIRONMENT

Recommendations for the storage environment.

6.7 STORAGE SPACE AND HANDLING FACILITIES

Physical dimensions for storage.

8.0 TROUBLE SHOOTING

8.1 HPU WILL NOT START

Common causes and solutions for HPU startup failures.

8.2 NO FLOW

Troubleshooting steps for when the HPU has no fluid flow.

8.3 REDUCED FLOW

Identifies causes and solutions for reduced fluid flow.

8.4 NO PRESSURE or REDUCED PRESSURE

Troubleshooting steps for pressure-related issues.

8.5 FLUID OVERHEATS

Explains why the HPU fluid might overheat and solutions.

8.6 HAND PUMP (Option M) IS NOT PUMPING FLUID

Solutions for the hand pump not delivering fluid.

9.0 MAINTENANCE

9.1 GENERAL

General maintenance checks and recommendations.

9.2 ELECTRIC MOTOR

Maintenance information for the electric motor.

9.3 MOTOR DRIVEN HYDRAULIC PUMP

Information about the motor-driven hydraulic pump.

9.3.1 Motor Driven Hydraulic Pump Assembly

Lists parts for the hydraulic pump assembly.

9.3.2 Motor Driven Hydraulic Pump Replacement Kits List

Information on replacement kits for the hydraulic pump.

9.4 HYDRAULIC FLUID

Guidance on hydraulic fluid analysis and types.

9.5 FILTERS

Information about the HPU filters.

9.5.1 Pressure Filter

Instructions for replacing the pressure filter element.

9.5.2 Return Filter

Instructions for replacing the return filter element.

9.5.3 Hand Pump (Option M) Filter

Guidance on replacing the hand pump filter element.

9.5.4 Desiccant Air Filter

When and how to replace the desiccant air filter.

9.6 HYDRAULIC HOSES

Information on inspecting and replacing hydraulic hoses.

9.7 INSTRUMENT PANEL

Details of the HPU instrument panels.

9.7.1 Electric Panel

Details the components of the electric control panel.

9.7.2 Hydraulic Panel

Lists and describes components on the hydraulic control panel.

9.7.3 Control Block/Flowmeter

Information on the control block and flowmeter.

9.7.3.a System Pressure Relief Valve

Details on the system pressure relief valve.

9.7.3.b Check Valve

Information about the check valve.

9.7.3.c Bypass Valve

Details on the bypass valve.

9.7.4 Flow Control

Information on the flow control valve.

9.7.5 Pressure Control

Details on the pressure control valve.

9.8 RESERVOIR ASSEMBLY

Information about the reservoir assembly and its components.

9.9 RETURN MANIFOLD ASSEMBLY

Details on the return manifold assembly.

9.9.1 Return System Pressure Relief Valve

Information on the return system pressure relief valve.

9.10 PRESSURE FILTER ASSEMBLY (Single System)

Details the pressure filter assembly.

9.11 ELECTRICAL COMPONENTS

Lists and describes electrical components.

9.11.1 Electrical Components With 100 ft. Input Cord Option

Lists electrical components for units with a 100 ft cord.

9.12 HEAT EXCHANGER ASSEMBLY

Information on the heat exchanger assembly.

9.13 EXTERNAL COMPONENTS

Lists and describes the external components of the HPU.

9.14 ADDITIONAL FEATURES

Details on optional features for the HPU.

9.14.1 50 ft (15.2 m) Hoses (Option B)

Details for the 50 ft hose option.

9.14.2 Split System (Option C)

Information on the split system option.

9.14.3 Crossover Check (Option D)

Details on the crossover check option.

9.14.4 Hour Meter (Options E and F)

Information on the hour meter.

9.14.5 Voltage/Phase Monitor (Options G − J)

Details on the voltage/phase monitor.

9.14.6 Pyrometer (Option K)

Information about the pyrometer.

9.14.7 Electric Reservoir Level (Option L)

Details on the electric reservoir level switch.

9.14.8 Hand Pump (Option M)

Information on the hand pump option.

9.14.9 Hand Pump (Option M-7)

Details on the Hand Pump (Option M-7).

9.14.10 Towing Trailer (Option N)

Information about the towing trailer option.

9.14.11 Calibration Port (Option Q)

Details on the calibration port option.

9.14.12 Electric Filter Clogging Indicator (Option R)

Information on the electric filter clogging indicator.

9.14.13 Electric Over-Temperature (Option S)

Details on the electric over-temperature switch.

9.14.14 Return Back-Pressure with Sight Gauge (Option T)

Information on the return back-pressure option.

9.14.14.a Item 16 Sight Glass Assembly Exploded View

Exploded view of the sight glass assembly.

9.14.15 Return Sight Gauge (Option U)

Details on the return sight gauge option.

9.14.16 Return Back Pressure (Option V)

Information on the return back pressure option.

9.14.17 Drip Pan (Option 4)

Details on the drip pan option.

9.15 REPLACEMENT LABELS PARTS LISTS

Lists of replacement labels for various HPU parts.

9.15.1 Base Unit

Lists replacement labels for the base unit.

9.15.2 Fluid Labels

Lists labels for different fluid types.

9.15.3 Filter Element Kit Labels

Lists labels for filter element kits.

9.15.4 Split System (Option C) and Crossover Check (Option D) Labels

Labels for split system and crossover check options.

9.15.5 Pyrometer (Option K) Label

Label for the pyrometer option.

9.15.6 Hand Pump (Option M) Labels

Labels for the hand pump option.

9.15.7 Calibration Port (Option Q) Labels

Labels for the calibration port option.

9.15.8 Back-Pressure Valve with Sight Glass (Option T) Label

Label for the back-pressure valve with sight glass option.

10.0 PROVISION OF SPARES

10.1 SOURCE OF SPARE PARTS

Information on where to obtain spare parts.

10.2 RECOMMENDED SPARE PARTS LISTS

Lists recommended spare parts for maintenance.

11.0 CALIBRATION OF INSTRUMENTATION

11.1 SOURCE OF CALIBRATION

Information on calibration sources for HPU gauges.

Need help?

Do you have a question about the 5431 and is the answer not in the manual?

Questions and answers