Table of Contents

Summarization of Contents

User Information

Purpose of the Document

Explains the manual's function, operation, and maintenance information.

Locations in the Operating Manual

Defines directions and conventions used within the manual.

Diagrams Used

Explains how diagrams and their elements are presented.

General Safety Instructions

Obligations and Liability

Outlines responsibilities of operator and user for safe machine operation.

Representation of Safety Symbols

Explains the meaning and significance of safety symbols and signal words.

Organisational Measures

Covers PPE, manual accessibility, and general accident prevention.

Safety and Protection Equipment

Details requirements for machine's safety and protection equipment.

User Training

Details requirements for personnel working with the machine.

Safety Measures in Normal Operation

Provides safety guidelines for routine machine operation.

Dangers from Residual Energy

Warns about hazards from stored energy in machine systems.

Maintenance and Repair Work, Fault Elimination

Outlines safety precautions for maintenance, repair, and fault elimination.

Constructive Changes

Prohibits unauthorized modifications to the machine.

Spare and Wear Parts and Aids

Emphasizes using genuine AMAZONE spare parts for safety and operation.

Cleaning and Disposal

Provides guidance on proper cleaning and disposal of materials.

User Workstation

Defines the allowed operator position during machine operation.

Warning Pictograms and Other Signs on the Machine

Explains the structure and purpose of warning pictograms on the machine.

Positioning of Warning Pictograms and Other Labels

Shows the location of warning pictograms and labels on the machine.

Hazards if Safety Information is Not Observed

Details consequences of non-compliance with safety information.

Safety-Conscious Working

Emphasizes adherence to safety rules and regulations during work.

Safety Information for Users

Provides comprehensive safety guidelines for machine connection, transport, and use.

General Safety and Accident Prevention Information

General safety rules for operation, connection, and transport.

Use of the Machine

Safety guidelines for operating the machine including clothing and general precautions.

Machine Transportation

Safety checks and procedures for transporting the machine on public roads.

Hydraulic System Safety

Safety measures for working with the machine's hydraulic system.

Electrical System Safety

Safety precautions related to the machine's electrical system.

Attached Machines Safety

Guidelines for combining the machine with tractors and other equipment.

Brake System

General safety instructions for the brake system.

Compressed Air Brake System

Safety procedures for the compressed air brake system.

Hydraulic Braking System for Export Machines

Safety notes for the hydraulic braking system on export models.

Tyres

Safety instructions for tyre maintenance and repair.

Operation of the Seed Drill

Safety precautions during the operation of the seed drill.

Cleaning, Maintenance, and Repairs

Safety guidelines for performing cleaning, maintenance, and repair work.

Loading and unloading

Loading and Unloading with a Tractor

Describes procedures for safely loading and unloading the machine using a tractor.

Product Description

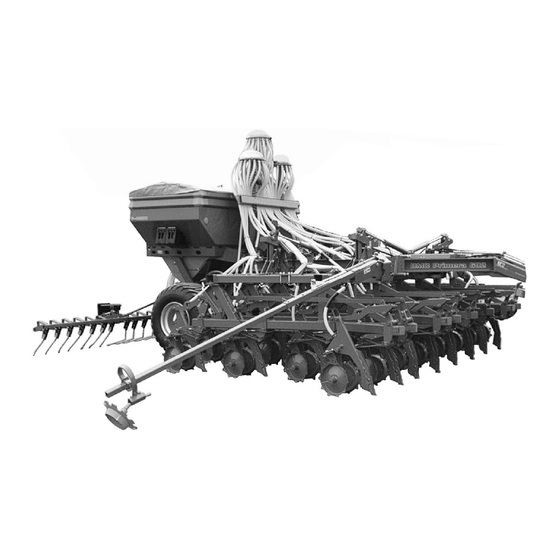

Overview of Subassemblies

Identifies and illustrates the main components of the machine.

Safety and Protection Equipment

Details safety features and equipment on the machine.

Overview – Supply Lines between the Tractor and the Machine

Describes hydraulic and electric connections between tractor and machine.

Transportation Equipment

Lists safety equipment required for road transport.

Intended Use

Defines the machine's proper application and forbidden uses.

Danger Area and Hazard Points

Identifies areas around the machine where hazards exist.

Rating Plate and CE Marking

Explains the information provided on the machine's rating plate.

Technical Data

Provides detailed specifications for different machine models.

Necessary Tractor Equipment

Lists engine, electrical, hydraulic, and PTO requirements for the tractor.

Noise Production Data

Specifies the workplace-related emission value (noise level).

Structure and Function

Mode of Operation

Explains the basic working principle of the direct seed drill.

Hydraulic Joints

Details hydraulic couplings, their function, and markings.

Coupling the Hydraulic Hose Lines

Step-by-step guide for connecting hydraulic hose lines safely.

Uncoupling the Hydraulic Hose Lines

Step-by-step guide for disconnecting hydraulic hose lines safely.

Dual-Circuit Service Brake System

Describes the dual-circuit pneumatic braking system.

Automatic Load-Dependent Braking Force Regulator – Adjustment

Details adjustment of the automatic load-dependent braking force regulator.

Brake Axles

Identifies components of the brake axles.

Coupling the Brake and Supply Lines

Step-by-step guide for safely connecting brake and supply lines.

Uncoupling the Brake and Supply Lines

Step-by-step guide for safely disconnecting brake and supply lines.

Parking Brake

Explains the operation and adjustment of the parking brake.

Hydraulic Operating Brake System

General information on the hydraulic operating brake system.

Coupling the Hydraulic Operating Brake System

Instructions for connecting the hydraulic operating brake system.

Uncoupling the Hydraulic Service Brake System

Instructions for disconnecting the hydraulic operating brake system.

Emergency Brake

Describes the function and activation of the emergency brake system.

Safety Chain for Implements without Brake System (Option)

Mandates a safety chain for implements without or with single-line brake systems.

Vario Gearbox

Describes the Vario gearbox and its function in adjusting spread rate.

Dosing Unit

Explains the function of dosing units for seed and fertiliser.

Metering Rollers

Details the selection and function of metering rollers.

Dosing Roller Diagram Table

Illustrates different dosing rollers and their capacities.

Drive Wheel

Explains the drive wheel's role in powering dosing units and its lifting mechanism.

Calibration Trough

Describes the use of the calibration trough for seed and fertiliser calibration.

Spreading Fertiliser (Option)

Explains how to spread fertiliser simultaneously with seed.

Seeding Maize (Option)

Describes the process of seeding maize and simultaneous fertiliser spreading.

Distributor

Explains how to adjust distributors based on row spacing.

Tramline Control

Details the tramline control system and hose replacement for row spacing.

Coulters

Explains how to lift and lock unused coulters for transport.

DMC 3000: Overview of Closed Outlets in Distributor

Shows configurations for closed outlets and switched-off coulters for DMC 3000.

DMC 3000: Row Spacing 75 cm

Details locking plates, hose replacement, and coulter switching for 75cm spacing.

DMC 3000: Row Spacing 75/37.5 cm

Details locking plates, sealing plugs, hose replacement for mixed spacing.

DMC 3000: Row Spacing 37.5 cm

Details sealing plugs, hose replacement for 37.5cm spacing.

DMC 3000: Row Spacing 75/18.75 cm

Details locking plates, sealing plugs, hose replacement for mixed spacing.

DMC 3000: Row Spacing 37.5/18.75 cm

Details sealing plugs, hose replacement for mixed spacing.

DMC 4500: Overview of Closed Outlets in Distributor

Shows configurations for closed outlets and switched-off coulters for DMC 4500.

DMC 4500: Row Spacing 75 cm

Details locking plates, hose replacement, and coulter switching for 75cm spacing.

DMC 4500: Row Spacing 75/37.5 cm

Details locking plates, sealing plugs, hose replacement for mixed spacing.

DMC 4500: Row Spacing 37.5 cm

Details sealing plugs, hose replacement for 37.5cm spacing.

DMC 4500: Row Spacing 37.5/18.75 cm

Details sealing plugs, hose replacement for mixed spacing.

DMC 4500: Row Spacing 75/18.75 cm

Details locking plates, sealing plugs, hose replacement for mixed spacing.

DMC 602: Overview of Closed Outlets in Distributor

Shows configurations for closed outlets and switched-off coulters for DMC 602.

DMC 602: Row Spacing 75 cm

Details locking plates, hose replacement, and coulter switching for 75cm spacing.

DMC 602: Row Spacing 75/37.5 cm

Details locking plates, sealing plugs, hose replacement for mixed spacing.

DMC 602: Row Spacing 37.5 cm

Details sealing plugs, hose replacement for 37.5cm spacing.

DMC 602: Row Spacing 37.5/18.75 cm

Details sealing plugs, hose replacement for mixed spacing.

DMC 602: Row Spacing 75/18.75 cm

Details locking plates, sealing plugs, hose replacement for mixed spacing.

Blower

Explains the function of the blower fan and its speed regulation.

Chisels

Describes the chisel coulters, their arrangement, and depth control.

Exact Harrow

Explains the function of the exact harrow and optional roller harrows.

Stony Ground Rollers (Optional)

Notes the suitability of stony ground rollers for stony terrain.

Markers

Details the track marker system for creating field tracks.

Transport Position of the Track Marker (DMC 3000 / 4500)

Instructions for securing track markers in transport position.

AMALOG+ On-board Computer

Describes the functions of the AMALOG+ on-board computer.

Distributor Head and Tramline Circuit

Explains uniform seed distribution and tramline creation.

Tramline Rhythm

Details how to set tramline spacing using tramline rhythms.

Examples for Creating Tramlines

Provides examples for setting up tramlines based on working widths.

Tramline Rhythm 4, 6 and 8

Shows examples of creating tramlines with specific rhythms.

Tramline Rhythm 2 and 6plus

Demonstrates tramline creation using rhythms 2 and 6plus.

Hydraulic Slide-on Pump

Explains connection and operation of the hydraulic slide-on pump.

Tensioned Crosspiece

Describes the tensioned crosspiece for securing the machine to the tractor.

Stand

Details raising and lowering the machine's stand.

Hopper with Swivelable Cover

Describes the seed and fertiliser hopper capacity and features.

Working Platform

Notes safety for the working platform and securing the ladder.

Level Sensor

Explains the function and adjustment of the seed level sensor.

Filling Auger (Optional)

Describes the optional filling auger for loading seed/fertiliser.

Commissioning

Checking the Suitability of the Tractor

Guides on verifying tractor compatibility for safe operation.

Calculating the Actual Values for Total Tractor Weight

Explains how to calculate tractor weight, axle loads, and minimum ballast.

Data Required for the Calculation

Lists necessary data for tractor suitability calculations.

Calculation of Required Minimum Ballasting

Details formula for calculating minimum front ballast for steering capability.

Calculation of Actual Axle Loads

Provides formulas for calculating actual front/rear axle loads and total weight.

Tyre Load Capacity

Instructions for determining tyre load capacity.

Table

Presents a table for entering calculation results and approved values.

Requirements for Tractor Operation with Attached Machines

Lists requirements for tractors coupled with attached machines.

Machines Without Their Own Brake System

Safety notes for machines lacking an integrated brake system.

Securing the Tractor / Machine Against Unintentional Start-up and Rolling

Details procedures to prevent accidental movement during interventions.

Coupling and Uncoupling the Machine

Coupling the Machine

Step-by-step guide for safely attaching the machine to the tractor.

Uncoupling the Machine

Step-by-step guide for safely detaching the machine from the tractor.

Uncoupling the Machine

Step-by-step guide for safely detaching the machine from the tractor.

Manoeuvring the Uncoupled Machine

Procedures for moving the machine using a separate vehicle.

Settings

Selecting the Dosing Roller

Guides on choosing and fitting appropriate dosing rollers based on seed type.

Table - Metering Rollers, Seed

Provides a table mapping seed types to suitable metering rollers.

Table - Metering Rollers, Fertiliser

Provides a table mapping fertiliser types to suitable metering rollers.

Replacing the Dosing Roller

Step-by-step instructions for replacing dosing rollers in the unit.

Setting the Level Sensor

Explains how to adjust the height of the seed level sensor.

Adjusting the Spread Rate on the Gearbox

Guides on adjusting the spread rate using the gearbox.

Calibration Test

Explains how to perform calibration tests for seed and fertiliser rates.

Determining the Gearbox Setting Using the Calculating Disc Rule

Guides on using the calculating disc rule to set the gearbox.

Adjusting Blower Fan Speed

Explains how to adjust blower fan speed for optimal air volume.

Blower Speed Table

Provides a table of fan speeds based on working width and seed type.

Adjusting the Placement Depth of the Seed

Details how to adjust seed placement depth using the crank.

Adjusting the Double Rollers

Explains how to adjust double rollers for different sowing conditions.

Adjusting the Track Marker

General instructions for adjusting the track marker system.

Setting the Track Marker Length (on the Field)

Instructions for adjusting the length of the track marker discs.

Adjusting the Working Intensity of the Track Markers (DMC 602)

Guides on adjusting track marker intensity for soil conditions.

Adjusting the Working Depth of the Track Markers (DMC 602)

Instructions for setting the working depth of track markers.

Adjusting the Exact Harrow

Details how to adjust the exact harrow using the turnbuckle.

Adjusting the Air Flow Distributor

Guides on adjusting air flow for individual dosing units.

Transportation

Safety Instructions for Operator

Refers to safety guidelines for machine transport.

Placing the Machine in the Transport Position

Details steps to secure the machine for transport.

Use of the Machine

General Use Precautions

Provides general safety warnings for machine operation.

Filling the Seed Hopper

Provides instructions for safely filling the seed hopper.

Placing the Machine in the Working Position

Details steps to transition the machine from transport to working position.

Sowing Operation

Covers operational steps during sowing, including obstacle avoidance.

Headland

Explains operations when turning at the end of a field.

Emptying the Dosing Unit or Hopper and Dosing Unit

Instructions for emptying and cleaning dosing units and hoppers.

Faults

Errors in the Dosing System

Describes troubleshooting steps for dosing system blockages.

Cleaning, Maintenance, and Repairs

General Safety for Maintenance

General safety warnings for carrying out maintenance work.

General Cleaning Procedures

Outlines general cleaning guidelines and prohibited actions.

Cleaning the Distributor Head (Workshop)

Specific instructions for cleaning the distributor head.

Lubrication Specifications (Workshop Work)

Lists required lubricants and lubrication points for the machine.

Lubrication Point Overview

Provides a table of lubrication points with intervals and quantities.

Sowing Shaft Bearings

Instructions for lubricating sowing shaft bearings.

Lubricating Axles

Details procedures for renewing wheel hub bearing grease.

Service Plan – Overview

Details maintenance tasks and their recommended intervals.

Axle and Brake

Covers general visual inspection of the brake system.

Checking the Brake Drum for Dirt

Instructions for checking and cleaning the brake drum.

Check Wheel Hub Bearing Play

Guides on checking and adjusting wheel hub bearing play.

Check the Brake Shoes

Instructions for checking the thickness of brake shoes.

Brake Adjustment

Notes the need for continuous brake checking and readjustment.

Air Reservoir

Procedures for draining and cleaning the air reservoir.

Inspection Instructions for the Dual Circuit Service Brake System

Details checks for leak tightness, pressure, and brake cylinder condition.

Parking Brake

Instructions for readjusting the parking brake cable.

Tyres / Wheels

Required tyre pressure and wheel nut torque specifications.

Tyre Pressures

Factors affecting tyre pressure and checks to perform.

Fitting Tyres

Guidelines for fitting new tyres and valves.

Hydraulic System

Safety and maintenance guidelines for the hydraulic system.

Labelling Hydraulic Hose Lines

Explains information on hydraulic hose line assembly labelling.

Maintenance Intervals

Specifies intervals for checking hydraulic system components.

Inspection Criteria for Hydraulic Hose Lines

Lists criteria for replacing hydraulic hoses to ensure safety.

Installation and Removal of Hydraulic Hose Lines

Guides on proper installation and removal of hydraulic hoses.

Electrical Lighting System

Instructions for replacing light bulbs.

On-board Hydraulics

Details changing oil and replacing the filter for the on-board hydraulics.

Checking the Hydraulic Fluid Filter

Explains how to check and replace the hydraulic fluid filter.

Upper and Lower Link Pins

Safety warning regarding damage to link pins.

Checking the Oil Level in the Vario Gearbox

Instructions for checking the oil level in the Vario gearbox.

Setting the Tramline to Tractor's Track Spacing (Specialist Workshop)

Guides on setting tramlines to match tractor wheel gauge.

Adjusting the Track (Activate or Deactivate the Sliders)

Explains how to activate or deactivate sliders for tramline creation.

Activating or Deactivating Sliders

Detailed steps for activating or deactivating sliders in the distributor head.

Hydraulics Diagram

Provides hydraulic circuit diagrams for different machine models.

Obstacle Avoidance Control

Shows the hydraulic diagram for obstacle avoidance control.

Hydraulic Brake (Only DMC 3000)

Shows the hydraulic diagram for the hydraulic brake system.

Blower

Shows the hydraulic diagram for the blower system.

Filling Auger

Shows the hydraulic diagram for the filling auger system.

Notes

Bolt Tightening Torques

Lists torque specifications for various bolt sizes and grades.

Need help?

Do you have a question about the DMC Primera 602 and is the answer not in the manual?

Questions and answers