Table of Contents

Advertisement

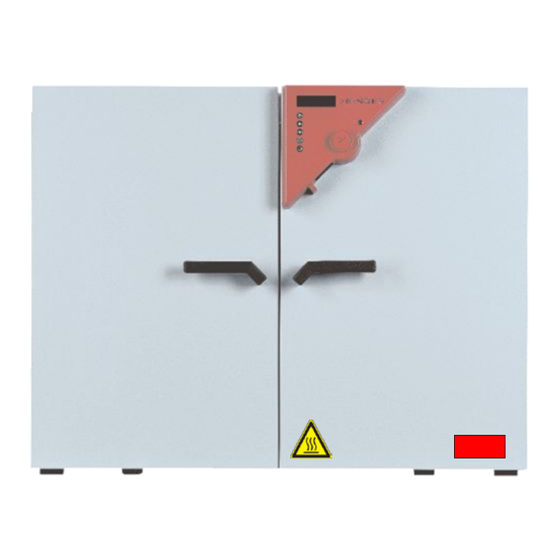

Operating Manual

Translation of the original operating manual

BD / BD-UL (E2) – Incubators with natural convection

ED / ED-UL (E2) – Drying and heating ovens with natural convection

FD / FD-UL (E2) – Drying and heating ovens with forced convection

with microprocessor temperature controller

Modell

Model version

BD023-230V

BD 23

BD023UL-120V

BD053-230V

BD 53

BD053UL-120V

BD115-230V

BD 115

BD115UL-120V

BD240-230V

BD 240

BD240UL-120V

BD400-230V

BD400

BD400UL-120V

BD720-230V

BD720

BD720UL-120V

ED023-230V

ED 23

ED023UL-120V

ED053-230V

ED 53

ED053UL-120V

ED115-230V

ED 115

ED115UL-120V

BINDER GmbH

Address: Post office box 102, 78502 Tuttlingen, Germany Phone: +49 7462 2005 0

Fax: +49 7462 2005 100 Internet: http://www.binder-world.com

E-mail: info@binder-world.com Service Hotline: +49 7462 2005 555

Service Fax: +49 7462 2005 93 555 Service E-Mail: service@binder-world.com

Service Hotline USA: +1 866 885 9794 or +1 631 224 4340 x3

Service Hotline Asia Pacific: +852 390 705 04 or +852 390 705 03

Service Hotline Russia and CIS: +7 495 988 15 16

Issue 03/2019

Art. No.

Modell

9010-0187

ED 240

9010-0189

9010-0081

ED400

9010-0179

9010-0088

ED720

9010-0181

9010-0095

FD 23

9010-0183

9010-0073

FD 53

9010-0176

9010-0074

FD 115

9010-0177

9010-0190/0191

FD 240

9010-0192/0193

9010-0078/0079

9010-0131/0132

9010-0096/0097

9010-0164/0165

Model version

Art. No.

ED240-230V

9010-0101

ED240UL-208V

9010-0167

ED400-230V

9010-0075

ED400UL-208V

9010-0168

ED720-230V

9010-0076

ED720UL-208V

9010-0169

FD023-230V

9010-0194

FD023UL-120V

9010-0196

FD053-230V

9010-0082

FD053UL-120V

9010-0128

FD115-230V

9010-0102

FD115UL-120V

9010-0129

FD240-230V

9010-0104

FD240UL-208V

9010-0130

Art. No. 7001-0026

Advertisement

Table of Contents

Summarization of Contents

Safety

1.1 Legal Considerations

Legal aspects and responsibilities related to the operation and use of the chamber.

1.2 Safety Instruction Structure

Explanation of safety symbols, signal words, and the structure of safety information within the manual.

1.3 Safety Label Locations

Details the positioning of safety labels on the chamber for user awareness.

1.4 Type Plate Information

Explains the details provided on the chamber's type plate for identification and specifications.

1.5 General Safety Instructions

Provides essential safety guidelines for installing and operating the chambers.

1.6 Intended Use

Defines the approved applications and limitations for the chamber's operation.

1.7 Operating Instructions

Guidelines for operators on how to use the chamber safely and effectively.

1.8 Accident Prevention Measures

Outlines measures taken by the manufacturer to prevent ignition, explosions, and other accidents.

Chamber Description

2.1 Chamber Overview

Provides a general description and overview of the chamber's features and components.

Delivery, Transportation, Storage, and Installation

3.1 Unpacking and Delivery Check

Instructions for unpacking the chamber and verifying its completeness and condition.

3.2 Safe Lifting and Transportation

Guidelines and precautions for safely lifting, moving, and transporting the chamber.

3.3 Chamber Storage

Recommendations for intermediate storage of the chamber under suitable environmental conditions.

3.4 Installation Location and Ambient Conditions

Specifies requirements for the installation site, including surface, ventilation, and ambient conditions.

Equipment Installation

4.1 Electrical Connection

Detailed instructions on how to connect the chamber to the power supply, including plug types and voltage.

4.2 Suction Plant Connection (Optional)

Guidance on connecting a suction plant to the chamber's exhaust duct, including potential influences.

Start Up

5.1 Chamber Startup

Step-by-step procedure for turning on the chamber and initial operation.

5.2 Heating Operation Display

Explanation of the indicators and displays related to the heating operation status.

5.3 Air Change Adjustment

How to adjust the air change rate using the air flap in the exhaust duct.

Operating the Controller

6.1 Temperature Set-Point Entry (No Ramp)

Procedure for setting and displaying the desired temperature without using a ramp function.

6.2 Temperature Set-Point Entry (With Ramp)

Instructions for setting temperature set-points when a temperature ramp function is active.

6.3 Time Functions: Continuous & Timer Operation

Details on setting and using continuous operation and timer functions for chamber control.

6.4 User Level Settings

Accessing and modifying user-configurable settings such as temperature units and chamber address.

6.5 General Controller Notes

Important general information and notes regarding controller operation and settings.

Temperature Safety Devices

7.1 Safety Device Class 2 (ED, FD)

Description, function, and setting of the Class 2 temperature safety device for ED and FD models.

7.2 Safety Device Class 3.1 (BD)

Description, function, and setting of the Class 3.1 temperature safety device for BD models.

Options

8.1 Audible Over-Temperature Alarm

Details on activating and using the optional audible alarm for over-temperature conditions.

8.2 APT-COM 4 Software

Information on the optional APT-COM 4 software for chamber management and data logging.

8.3 Data Logger Kit

Description of the optional data logger kit for temperature measurement and recording.

8.4 Additional Pt100 Temperature Sensor

Information on the optional Pt100 sensor for enhanced temperature measurement capabilities.

8.5 Analog Temperature Output

Details of the optional analog output for transmitting temperature data to external systems.

8.6 Water-Protected Internal Socket

Features and usage of the optional water-protected internal socket for powering devices inside the chamber.

Maintenance, Cleaning, and Service

9.1 Maintenance Intervals and Service

Guidelines for regular maintenance, service requirements, and warranty considerations.

9.2 Cleaning and Decontamination

Procedures and recommendations for cleaning and decontaminating the chamber after use.

9.3 Returning Chamber to BINDER

Instructions and requirements for sending the chamber back to BINDER GmbH for repair or other reasons.

Disposal

10.1 Transport Packing Disposal

Guidance on the proper disposal and recycling of transport packing materials.

10.2 Chamber Decommissioning

Steps for safely decommissioning the chamber before final disposal.

10.3 Disposal in Germany

Specific regulations and procedures for disposing of the chamber in Germany according to WEEE.

10.4 Disposal in EU Member States (Excl. Germany)

Disposal procedures for EU member states, excluding Germany, adhering to WEEE directives.

10.5 Disposal in Non-EU States

Guidelines for the disposal of the chamber in countries outside the European Union.

Technical Description

12.1 Factory Calibration and Adjustment

Information on the factory calibration and adjustment procedures performed on the chambers.

12.2 Usable Volume Definition

Explains how the usable volume of the chamber is calculated and defined for optimal use.

12.3 Over Current Protection

Description of the over-current protection mechanisms, including fuses, for the chamber.

12.4 BD Technical Data

Detailed technical specifications, dimensions, and performance data for BD model series.

12.5 ED Technical Data

Detailed technical specifications, dimensions, and performance data for ED model series.

12.6 FD Technical Data

Detailed technical specifications, dimensions, and performance data for FD model series.

12.7 BD Equipment and Options

List of standard equipment and available optional accessories for BD chambers.

12.8 ED Equipment and Options

List of standard equipment and available optional accessories for ED chambers.

12.9 FD Equipment and Options

List of standard equipment and available optional accessories for FD chambers.

12.10 Accessories and Spare Parts

Catalog of accessories and spare parts available for the chambers, including article numbers.

Certificates and Declarations of Conformity

13.1 EU Declaration of Conformity for BD

Official EU declaration confirming the BD series chambers comply with relevant directives.

13.2 EU Declaration of Conformity for ED

Official EU declaration confirming the ED series chambers comply with relevant directives.

13.3 EU Declaration of Conformity for FD

Official EU declaration confirming the FD series chambers comply with relevant directives.

13.4 GS Mark of Conformity Certificate

Certificate verifying compliance with German safety standards (GS mark) from DGUV.

Contamination Clearance Certificate

15.1 For Chambers Outside USA & Canada

Form and instructions for declaring the chamber is free from hazardous substances for return.

15.2 For Chambers in USA & Canada

Form for product return authorization and decontamination declaration for US and Canadian customers.

Need help?

Do you have a question about the ED 53 and is the answer not in the manual?

Questions and answers