Summarization of Contents

Important Safety Information

Safety Information

Read manual and safety instructions carefully before installing the SCS 4000/5000 Series console.

Hydraulic Safety

Recommendations for working on hydraulic systems, including precautions for hot fluid and maintenance.

Electrical Safety

Guidelines for safe electrical connections, including polarity and disconnecting for welding/jump-starting.

Introduction

Sprayer & Spreader Control Systems

Overview of SCS 4000/5000 Series systems for application uniformity and product coverage.

System Components

Description of components for SCS 4000/5000, 4070, and 4400/4600 control systems.

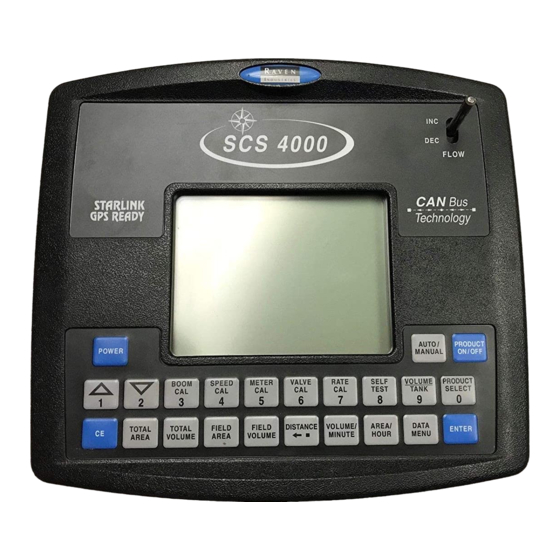

SCS 4000/5000 Series Console Feature Overview

Details on the display area and keypad features of the SCS 4000/5000 Series consoles.

Care and Use

Guidelines for proper mounting, cable routing, and environmental considerations for the SCS console.

Technical Specifications

Specifications including dimensions, weight, environmental limits, power, and ports for the SCS console.

Updates

Information on obtaining manual and software updates for Raven consoles from the website.

CAN Networking and CAN Data Menu

Detecting CAN Nodes

Ensuring the SCS console communicates with CANbus nodes for correct product application.

Readdressing the Nodes

Procedure to reconfigure product control node order if the SCS console cannot detect nodes.

Programming CANbus Nodes

Information on programming CAN product nodes using the SCS console in Edit mode.

CAN Troubleshooting

Troubleshooting techniques for CAN systems, applicable to flow/speed sensors and control/boom valves.

CAN Node Off-line Errors

Common causes for losing CAN communication between the console and nodes.

Installation

Install the SCS Console

Requirements for selecting a mounting location for the SCS console inside the machine cabin.

Mount the SCS Console

Instructions for mounting the SCS console using the provided plate and clamps.

Cable and Power Connections

Procedures for connecting the console cable and routing power connections.

Calibration Reference Sheet

Edit Mode

How to enter Edit mode to program numerical values into the SCS console.

Initial Startup & Console Programming

Reset Console Memory

Procedure to reset the SCS console's internal memory to return to initial programming screens.

Initial Calibration Sequence

Steps for initial console setup including contrast, units, and product control type.

Units

Setting the measurement units for the SCS console (US Acres, SI Hectares, etc.).

Product Control Type

Selecting the type of product control (Liquid, Granular, Spinner, NH3) for the SCS console.

Valve Type

Selecting the appropriate valve type for the SCS console's control system.

Spreader Constant (Granular Applications)

Inputting the spreader constant value for granular applications.

Product Density (Granular Applications)

Inputting the product density value for granular applications.

Meter Cal (Liquid Applications)

Inputting the meter calibration value for liquid product application.

Fan Speed Cal (Spinner Applications)

Inputting the fan speed calibration value for spinner applications.

Valve Cal

Programming the valve calibration value to adjust control valve response.

Rate Cal

Entering the target application rate for product application.

Speed Sensor Type

Selecting the type of speed sensor used (Wheel Speed or Radar).

Speed Cal

Initial speed calibration values and procedure for the SCS console.

Boom Cal

Inputting boom section widths for calibration in the SCS console.

Reprogramming Initial Settings

Procedure to change initial console programming settings after initial setup.

Console Programming

Overview of how to program the SCS console using calibration keys.

Edit Mode

How to enter Edit mode to program numerical values into the SCS console.

Calibration Keys

Using calibration keys to program and calibrate the SCS console.

Self Test

Performing a self-test to check or troubleshoot the product control system.

Function Keys

Using function keys to display application information and test the system.

Volume/Minute

Displays current volume per minute or flow rate.

Area/Hour

Estimates the area that could be covered based on current speed and boom operation.

Data Menu

Accessing the SCS Data Menu for console settings and features.

Product On/Off

Toggles product control on or off.

Tank Volume

Displays current volume remaining in the tank or bin.

Product Select

Toggles product selection on the controller for viewing data or changing settings.

Self Test Mode

Simulates speed for testing the system while the vehicle is not moving.

Decimal Shift

Feature to increase system accuracy at low application rates by shifting decimal places.

Data Menu

Serial Submenu

Options for serial communication, data logging, and field reference.

Data Logger (4400 and 4600 Only)

Enabling/disabling data logging and saving information to a compact flash card.

Field Reference

Entering a reference number to represent a job for data logging.

GPS Baud Rate

Setting the baud rate for communication with a connected GPS receiver.

Serial Baud Rate

Selecting baud rate for serial port communication.

Variable Rate Change Alarm

Enabling or disabling alarms for variable rate changes.

Trigger Value

Determining how often data is sent to the serial port for data logging.

Trigger Units

Selecting trigger units (feet, meters, or seconds) for data logging.

Additional Serial Options

Options for print field data or data direction for SCS 4400/4600.

Product Submenu

Settings related to product control, including boom selection and PWM offsets.

Boom Select

Assigning products to individual boom sections for application.

Off Rate %

Acceptable percentage deviation of actual rate from target rate.

PWM High Offset

Setting the maximum desired RPM or hydraulic output for a PWM control valve.

PWM Low Offset

Setting the minimum RPM or hydraulic output for a PWM control valve.

PWM Frequency

Setting the coil frequency for PWM valves.

Preset PWM Offset (PWM Valves Only)

Setting an initial pulse width for PWM-Close mode valves.

Standby Pressure (PWM Valves Only)

Setting target pressure for liquid systems in standby condition.

Rate Bump Delta

Setting the increment for rate adjustments using the INC/DEC switch.

Low Flow Limit

Setting a limit for volume/minute to activate low flow limit and alarm.

Low Tank

Setting a level for tank volume to activate the low level alarm.

Valve Delay

Setting the delay between console controlling flow rate after booms are turned on.

Spreader Constant

Setting the spreader constant, should be zero for liquid products.

Valve Cal 2

Fine-tuning control valve response and application rate oscillations in PWM mode.

Pump Cal/Fan Cal

Setting pulses per revolution for pump/fan RPM readout.

Dual Sensor Alarm %

Tolerance setting for flow switch monitor and flow readings.

Vacuum or Bin Level Alarm

Enabling or disabling vacuum or bin level alarms.

Flow Switch Alarm (Chemical Injection Unit)

Enabling or disabling flow switch alarm for chemical injection.

Valve Advance (Standard or Fast Valve)

Setting time for valve opening when booms are turned off in automatic mode.

Pressure

Displays current PSI, kPa, or BAR.

Pressure 1 Cal

Calibrating pressure transducer #1.

Pressure 2 Cal

Calibrating pressure transducer #2.

Agitator

Enabling or disabling the agitator output.

PWM Output

Indicating the output status of a PWM valve.

VLV STATUS (when not programmed in PWM mode)

Displays current status of the control valve.

Standby (Pressure) Enable (PWM Valves Only)

Enabling standby pressure setting for liquid application systems.

Low Pressure Limit

Setting a minimum pressure for liquid application systems.

Dual Loop Control (PWM Valves Only)

Feature for low application rates using flow meter and pressure transducer.

Auto Calibration (PWM Valves Only)

Automatically calibrating high and low offset values for PWM control valves.

Console Submenu

Settings for console contrast, alarms, display smoothing, and data lock.

Contrast

Adjusting screen contrast for readability.

Audible Alarm

Toggling the audible alarm on or off.

Display Smoothing

Smoothing the rate displayed during product applications.

Time, Month, Day, and Year

Setting the current date and time for the console.

Days Wait

Setting days before console enters low power mode and loses time settings.

Data Lock

Prohibiting calibration value entry without a data lock code.

PGM REV Update

Displaying SCS console software program and revision level.

Ratio Rate

Enabling or disabling ratio rate application mode for multiple products.

CAN Submenu

Status indicators for CAN nodes like boom sense, AutoBoom, and product control nodes.

Boom Sense and Speed Node

Indicates status of boom sense/speed node.

Speed Signal Source (SCS 4070 Only)

Toggling speed signal source between Console and Speed/AccuBoom node.

AutoBoom Control Node

Indicates status of AutoBoom control node.

Product Control Node 1

Indicates status of CAN product control node #1.

Product Control Node 2

Indicates status of CAN product control node #2.

Product Control Node 3

Indicates status of CAN product control node #3.

Product Control Node 4

Indicates status of CAN product control node #4.

Product Control Node 5

Indicates status of CAN product control node #5.

Row Sense Node

Indicates status of a row sense node.

Readdress Control Nodes

Reconfigure product control node order.

AccuBoom Control Node

Indicates status of AccuBoom control node.

Calibration Summary

Review current values and settings for each configured product control channel.

Data Logger (4400 and 4600 Only)

Saves on-the-go application info to flash card for PC transfer.

Setup

Setup procedures for data logging system, including trigger value and GPS baud rate.

Console Calibration

Speed Cal

Recommended initial speed calibration values and procedure.

Wheel Drive Speed Sensor

Procedure for calibrating the wheel drive speed sensor.

Adjusting for Additional Magnets

Adjusting speed calibration for additional magnets on the wheel drive sensor.

Speedometer Drive Speed Sensor

Procedure for calibrating the speedometer drive speed sensor.

Liquid Applications

Calibration procedures for liquid sprayers.

Boom Cal

Inputting boom section widths for calibration.

Band Spraying Adjustment

Calculating the Adjusted Applied Rate for band spraying.

Meter Cal

Flow meter calibration number found on the flow meter tag.

Valve Cal

Programming valve calibration number to adjust control valve response time.

Rate Cal

Programming the target application rate.

SCS Multi-Tier Features

Accessing features for multi-tier plumbing systems.

Tier 1 High Volume per Minute

Sets maximum allowed volume per minute before the second tier is enabled.

Tier 2 High Volume per Minute

Selects max allowed volume per minute before tiers 1 and 2 are enabled.

Percent Tier Disable

Percentage factor to disable the higher tier based on volume settings.

Dual Loop Control Mode Settings

Settings for dual loop control feature using flow meter and pressure transducer.

Flow Cal

Sets system response to rate control inputs while product is flowing.

System (Pressure) Gain

Adjusting system aggressiveness for pressure response.

Granular Applications

Calibration procedures for granular applications.

Spreader Constant

Calculating and verifying the spreader constant for granular applications.

Standard Rate display

Formula to calculate spreader constant for rates in 1 pound increments.

Metric Rate Display

Formula to calculate spreader constant for rates in 1 kg increments.

Verification of Spreader Constant

Procedure to verify and refine the spreader constant.

Product Density

Entering product density for spreader constant calculations.

Spinner RPM

Calibrating spinner speed control using a CAN control node.

Additional Calibration Data

Programming data through the VOLUME/TANK key.

Entering Tank Volume

Entering an estimated volume of product in the tank or bin.

Low Tank Alarm

Setting an alarm for low calculated volume of product remaining in the tank.

“Zero Out” Display Information

Resetting display values like total area, volume, field area, field volume, and distance.

Job Setup & Field Testing

Liquid Applications

Procedures for initial job setup and field testing for liquid applications.

Initial Job Setup

Steps for initial setup and verification of programmed values for liquid applications.

Field Test

Testing the SCS console speed display and automatic rate correction.

Preventive Maintenance

Regular maintenance procedures to ensure long life of the system.

Granular Applications

Procedures for initial job setup and field testing for granular applications.

Testing Extension Cables

Speed Sensor Cables

Testing the speed sensor extension cable for proper voltage and signal.

Flow Meter/Encoder Cables

Testing the flow meter extension cable for proper volume readings.

Connecting an SCS Console to a Raven Field Computer

Firmware Requirements

Required firmware versions for SCS consoles to operate on a Raven CANbus.

Operation Guidelines

Recommended guidelines for operating multi-console CANbus systems.

Field Computer Set Up

Setting up Viper Pro and Envizio Pro consoles for CAN product control.

Viper Pro

Steps to set up the Viper Pro console for CAN product control.

Envizio Pro or Envizio Pro II

Steps to set up Envizio Pro consoles for CAN product control.

Cruizer or Cruizer II

Connection diagrams for Cruizer/Cruizer II with SCS 4400 console.

SCS 4000/5000 Series Firmware Update Procedure

Using a USB to Serial Adapter

Using a USB to Serial Adapter to update Raven SCS 4000/5000 Series consoles.

USB to Serial Adapter Preparation

Steps for preparing the USB to Serial Adapter on a PC.

Serial Console Updater Utility

Using the serial console updater utility to update SCS console firmware.

Hyperterminal

Using HyperTerminal to update SCS console firmware.

Serial Interface & Data String Formats

Remote Computer to SCS Console

Data string format for rate change requests from a remote computer.

SCS 4000/4070/5000 Console to Remote Computer

Output data string formats from SCS 4000/4070/5000 consoles to a remote computer.

Need help?

Do you have a question about the SCS 4000 and is the answer not in the manual?

Questions and answers