Summarization of Contents

Calibration Reference Sheet

Edit Mode

Explains how to enter and use Edit mode for programming numerical values.

Unit Definitions and Conversions

Unit of Measure Definitions

Lists abbreviations and their definitions for units of measure.

Unit of Measure Conversions

Provides conversion values for various units.

Important Safety Information

Safety Information

Provides general safety instructions and precautions for operating the console.

Hydraulic Safety

Details safety precautions when working with hydraulic systems.

Electrical Safety

Outlines safety measures for electrical connections and systems.

Introduction

Sprayer & Spreader Control Systems

Introduces the SCS 4000/5000 series control systems for agricultural applications.

System Components

Describes the various components of the SCS 4000/5000, SCS 4070, and SCS 4400/4600 control systems.

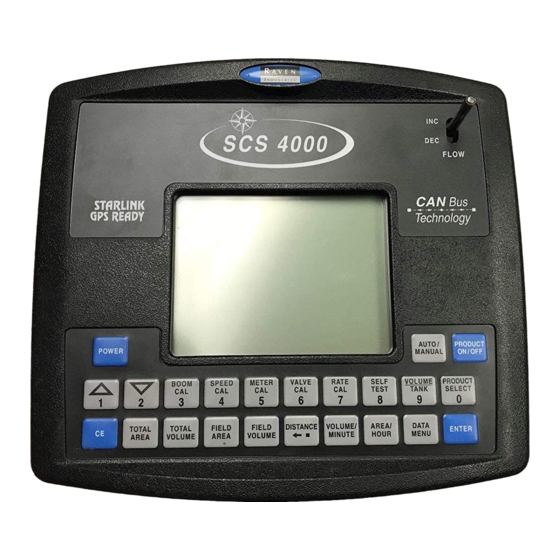

SCS 4000/5000 Series Console Feature Overview

Provides an overview of the console's display area and keypad features.

SCS Console Types

Describes SCS 4000/5000, SCS 4070, and SCS 4400/4600 console features.

Care and Use

Offers guidelines for proper care and maintenance of the SCS console.

Technical Specifications

Lists the technical specifications including dimensions, weight, and environmental ratings.

Updates

Provides information on obtaining manual and software updates from the Raven website.

CAN Networking and CAN Data Menu

Detecting CAN Nodes

Explains how the console communicates with CANbus system nodes.

CAN Node Management

Covers node version info, initialization, and readdressing procedures.

CANbus Node Programming and Troubleshooting

Details programming CAN nodes and troubleshooting common errors.

Installation

SCS Console Installation

Covers requirements for mounting location and console installation.

SCS Console Mounting and Connections

Details mounting the console and making cable/power connections.

Initial Startup & Console Programming

Reset Console Memory

Explains how to reset the console's internal memory to return to initial programming screens.

Initial Configuration Settings

Covers selecting units and product control types for initial setup.

Valve Type and Granular Setup

Details valve type selection and granular application setup.

Key Calibration Procedures

Covers Meter Cal, Fan Speed Cal, Valve Cal, Rate Cal, and Speed Sensor Type.

Speed and Boom Calibration

Guides on initial speed calibration and inputting boom section widths.

Reprogramming Initial Settings

Explains how to change initial console programming settings after initial setup.

Console Programming Overview

General programming concepts including Edit Mode and Calibration Keys.

Calibration Screen Navigation

Instructions for accessing Boom Cal, Speed Cal, and Meter Cal screens.

Calibration and Function Key Operations

Details Valve Cal, Rate Cal, Self Test, and Function Keys.

Display Information and Modes

Explains display info like Volume/Minute, Area/Hour, and modes like Self Test.

Decimal Shift Feature

Describes how to use decimal shift to increase system accuracy at low application rates.

Data Menu

Serial Submenu and Data Logging

Covers serial options, data logger, and field reference.

Serial Communication Settings

Details GPS Baud Rate, Serial Baud Rate, and alarms.

Product Submenu and Valve Control

Contains settings for product control, boom select, off rate, and PWM high offset.

PWM Valve Settings

Covers PWM Low Offset, Frequency, Preset Offset, Standby Pressure, and Rate Bump Delta.

Flow Control and Limit Settings

Details Low Flow Limit, Low Tank, Valve Delay, and Spreader Constant.

Advanced Valve and Pump Settings

Covers Valve Cal 2 and Pump Cal/Fan Cal for enhanced control.

System Alarms and Valve Adjustments

Covers Dual Sensor Alarm, Vacuum/Bin alarms, Valve Advance, and Pressure Calibrations.

Advanced PWM Control Features

Details Standby Pressure, Low Pressure Limit, Dual Loop Control, and Auto Calibration.

Smart Control Feature

Provides quicker control responses for granular applications.

Console Submenu Settings

Covers contrast, alarms, time, data lock, and software updates.

Ratio Rate and Zero Speed Shutoff

Enables ratio rate mode and zero speed shutoff feature.

CAN Submenu and Node Status

Indicates status of CAN nodes, sensors, and AutoBoom.

Node Management and Data Logging Setup

Covers readdressing nodes, calibration summary, and data logger setup.

SCS Alarm Definitions

Brief descriptions of visual and audible alarms for the SCS console.

Console Calibration

Speed Calibration Procedures

Covers initial speed calibration and wheel/speedometer sensor calibration.

Speed Sensor Adjustments

Details adjusting speed calibration for additional magnets and speedometer sensors.

Liquid Application Calibration

Covers boom width, band spraying adjustment, and meter calibration for liquid sprayers.

Valve Calibration

Explains programming calibration numbers for control valve response.

Rate Calibration and Multi-Tier Features

Covers rate calibration, flow rate limits, and multi-tier features.

Advanced Control Mode Settings

Details dual loop control, flow calibration, and tier volume settings.

System Gain and Granular Calibration

Covers system gain adjustment and granular application calibration.

Spreader Constant Verification and Density

Details metric rate display, spreader constant verification, and product density input.

Rate, RPM, and Tank Calibration

Covers rate calibration, spinner RPM, and tank volume settings.

Job Setup & Field Testing

Liquid Application Setup and Testing

Procedures for initial job setup, field testing, and maintenance for liquid applications.

Granular Application Setup and Testing

Procedures for initial job setup, field testing, and maintenance for granular applications.

Testing Extension Cables

Speed Sensor Cable Testing

Details how to disconnect and test speed sensor extension cables.

Flow Meter/Encoder Cable Testing

Details how to disconnect and test flow meter/encoder extension cables.

Connecting an SCS Console to a Raven Field Computer

Firmware Requirements and Operation Guidelines

Specifies firmware and operational guidelines for multi-console CANbus systems.

Field Computer Setup

Instructions for setting up Viper Pro and Envizio Pro consoles for CAN product control.

Flow Meter Maintenance & Adjustment Procedure

Flow Meter Recalibration Procedure

Step-by-step guide to clean, reassemble, and recalibrate the flow meter.

Ratio Rate Feature

Handgun Operation with Ratio Rate

Covers handgun installation and operation steps within the ratio rate feature.

Remote Switch Option

Remote Switch Installation and Diagram

Provides a diagram and explanation of the remote switch option.

SCS 4000/5000 Series Firmware Update Procedure

Firmware Update Preparation

Covers using a USB to Serial Adapter and its preparation for firmware updates.

Serial Console Updater Utility

Information on the serial console updater utility for firmware updates.

Hyperterminal Firmware Update

Instructions for using HyperTerminal for firmware updates.

Serial Interface & Data String Formats

Remote Computer to SCS Console Communication

Details data strings for remote computer requests and rate change requests.

Console to Remote Computer Data Strings (4000/4070/5000)

Covers output strings and calibration strings for SCS 4000/4070/5000 consoles.

Console to Remote Computer Data Strings (4400/4600)

Covers output strings and calibration strings for SCS 4400/4600 consoles.

Need help?

Do you have a question about the SCS 4000 Series and is the answer not in the manual?

Questions and answers