Summarization of Contents

Introduction to REDUREX Gear Units

General Information for Operating Instructions

Provides general information about the operating instructions and required knowledge.

Lubricant Recommendations for Gear Units

Details on the type, viscosity, and quantity of lubricants required for the gear unit.

Safety Instructions for Gear Unit Operation

Industrial Security Notes

Information on industrial security functions and protection against cyber threats.

Five Essential Safety Rules

Essential safety rules to follow when working on electrical components.

Gear Unit Symbols and Markings

Explains symbols used on the gear unit and their meanings.

General Warning Symbols and Hazards

Details common warning symbols and their associated hazards.

Specific Dangers and Personal Protective Equipment

Identifies specific dangers and lists required personal protective equipment (PPE).

Intended Use of the Gear Unit

Defines the proper and improper uses of the gear unit.

Description of REDUREX Gear Units

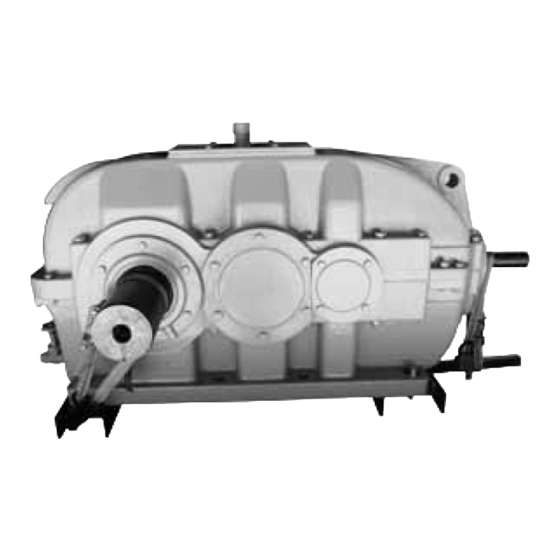

General Description of REDUREX Gear Units

Overview of the FLENDER gear unit's development and basic configuration.

REDUREX Gear Unit Housing

Describes the construction and features of the gear unit housing.

Gear Unit Oil Supply Systems

Explains the different methods for supplying oil to the gear unit.

Shaft Seal Types

Describes various types of shaft seals to prevent oil escape or dirt ingress.

Gear Unit Cooling Systems

Covers different cooling equipment options for the gear unit.

Bearing Monitoring Systems

Covers bearing monitoring using Pt 100 thermometers and acceleration sensors.

Application Planning for Gear Units

Scope of Gear Unit Delivery

Lists the items included in the gearbox delivery and how to check them.

Safe Transport of Gear Units

Provides instructions for safely transporting the gear unit to avoid damage.

Gear Unit Attachment Points

Details the correct attachment points for lifting and moving the gear unit.

Gear Unit Lubrication Features

Explains oil filling and draining procedures for different gear unit types.

Mounting Procedures for REDUREX Gear Units

General Assembly Instructions

Covers general precautions and requirements for assembly work.

Unpacking the Gear Unit

Provides instructions for safely unpacking the gear unit upon receipt.

Gear Unit Mounting Procedures

Details the requirements and procedures for mounting the gear unit.

Shaft-Mounted Gear Unit with Hollow Shaft

Details mounting procedures for gear units with hollow shaft and parallel keyway.

Shaft-Mounted Gear Unit with Shrink Disk

Describes mounting and dismantling for units with hollow shaft and shrink disk.

Coupling Installation and Alignment

Details on coupling misalignment and alignment procedures.

Connecting System Components

Instructions for connecting various components like cooling coils and coolers.

Bolt Tightening Procedures

Details bolt properties and connection classes for proper tightening.

Final Work After Mounting

Final checks and tasks after assembly is completed.

Commissioning Procedures for REDUREX Gear Units

Pre-Commissioning Measures

Lists essential checks and preparations before commissioning the gear unit.

Measures During Commissioning

Actions to perform during the commissioning process of the gear unit.

Operation of REDUREX Gear Units

Operating Data and Conditions

Presents valid operating data and conditions for the gear unit and oil.

Irregularities During Operation

Lists common irregular behaviours during operation and immediate actions.

Taking the Unit Out of Service

Procedures for taking the gear unit out of service for prolonged periods.

Maintenance and Servicing of REDUREX Gear Units

General Maintenance Activities

Overview of general maintenance requirements and time limits.

Maintenance Schedule and Activities

Table detailing maintenance and servicing activities at regular intervals.

Maintenance and Service Work Procedures

Detailed procedures for specific maintenance tasks.

Troubleshooting Possible Faults

Lists possible faults and provides a troubleshooting guide.

Service and Support Information

Contact Information for Flender GmbH

Contact information for Flender GmbH for spare parts and technical queries.

Further Service and Support Information

Information on finding further service and support on the Internet.

Disposal of Gear Units and Environmental Protection

Disposal of the Gear Unit

Measures for disposing of the gear unit and its parts after its useful life.

Environmental Protection Measures for Disposal

Environmental protection measures for disposal of oil and packaging materials.

Spare Parts Information

Note on Unsuitable Spare Parts

Warning regarding the use of unsuitable or non-original spare parts.

Information for Ordering Spare Parts

Details on the information needed to order spare parts from Flender.

Quality Documents

Declaration of Incorporation

Formal declaration of incorporation for the gear unit as a partially completed machinery.

Technical Data for REDUREX Gear Units

General Technical Data and Rating Plate

Explains the information found on the gear unit rating plate.

Ambient Temperature Specifications

Specifies the permissible ambient temperature range for the gear unit.

Available Gear Unit Types

Illustrates the different types of gear units available.

Gear Unit Weights

Tables providing approximate weights for various gear unit types and sizes.

Enveloping Surface Sound Pressure Level

Information on the gear unit's sound power level and emission characteristics.

Need help?

Do you have a question about the S.A Series and is the answer not in the manual?

Questions and answers