Table of Contents

Advertisement

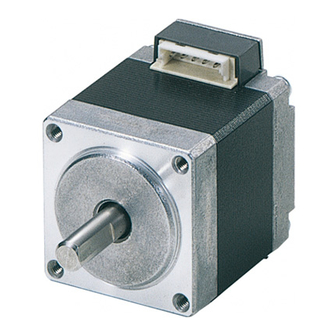

5-Phase Stepping Motor Unit

CRK

OPERATING MANUAL

Thank you for purchasing an Oriental Motor product.

This Operating Manual describes product handling procedures and safety precautions.

Please read it thoroughly to ensure safe operation.

•

•

Always keep the manual where it is readily available.

Table of contents

1 Introduction .................................. 2

2 Safety precautions ....................... 4

3 Precautions for use ...................... 7

4 Preparation................................. 10

4.1

Checking the product ................ 10

4.2

drivers ....................................... 10

4.3

Names and functions of parts ... 13

5 Installation .................................. 15

5.1

Location for installation ............. 15

5.2

Installing the motor.................... 15

5.3

Installing a load ......................... 17

5.4

permissible thrust load .............. 17

5.5

Installing the driver.................... 19

5.6

with EMC Directive.................... 21

Series

6 Connection..................................24

6.1

Connection example................. 24

6.2

connector housings .................. 27

6.3

Connecting the power supply ... 29

6.4

Explanation of I/O signals......... 29

6.5

Timing chart.............................. 33

7 Setting.........................................34

7.1

Step angle ................................ 34

7.2

Pulse input modes.................... 36

7.3

Smooth drive function............... 36

7.4

Motor current ............................ 37

8 Inspection....................................42

actions ........................................43

10 Options (Sold separately)............46

HP-4189-2

Advertisement

Table of Contents

Summarization of Contents

Introduction to CRK Series Motor Units

Before Using the Motor Unit

Guidance for initial use and important warnings before operating the motor unit.

Overview of the CRK Series Product

Details the CRK series product features, including smooth drive function and low vibration.

Standards and CE Marking

Information on product recognition by UL, certification by CSA, and CE Marking compliance.

Low Voltage Directive Considerations

Advises on installation and connection for 24 VDC products not subject to EC Low Voltage Directive.

EMC Directive Compliance

Details CE marking conditions and refers to EMC Directive compliance measures.

Hazardous Substances Compliance

States the product's compliance with RoHS Directive concerning hazardous substances.

Safety Precautions for CRK Series

General Safety Guidelines

Covers general warnings regarding environment, personnel, and elevator applications.

Installation Safety

Precautions for safe installation, emphasizing enclosures to prevent injury.

Connection Safety

Guidelines for safe electrical connection, including power supply and wiring.

Operational Safety

Instructions for safe motor and driver operation, including power failure and stopping.

Repair and Modification Safety

Warnings against unauthorized repair, disassembly, or modification of the motor or driver.

Transportation Safety

Safety advice for transporting the motor, focusing on handling cables and shafts.

Disposal Procedures

Guidance on proper disassembly and disposal of the motor and driver as industrial waste.

Precautions for Use

Operational Limitations and Requirements

Covers insulation testing, load limits, temperature, static torque, and electrical noise.

Geared Type Motor Specifics

Details backlash, maximum torque, gear ratio effects, and grease leakage for geared motors.

Regeneration Energy Management

Advises on managing regenerative energy to prevent driver damage from voltage increases.

Preparation and Product Checking

Product Verification and Contents

Instructions for checking the product package contents upon receipt.

Motor and Driver Combinations

Lists compatible combinations of CRK series motors and drivers across different types.

Motor and Driver Component Identification

Illustrates and names the key parts of the motor and driver units.

Installation Guide for CRK Series

Installation Site Selection Criteria

Specifies environmental conditions and location requirements for motor and driver installation.

Motor Mounting Procedures

Describes methods for installing the motor onto a mounting plate and its orientation.

Load Installation Guidelines

Explains how to connect loads to the motor using couplings, belt drives, or gear drives.

Permissible Load Specifications

Details the maximum permissible overhung and thrust loads for the motor's output shaft.

Driver Mounting Procedures

Instructions for mounting the driver unit, including horizontal and vertical orientations.

EMC Directive Installation and Wiring

Provides methods for installing and wiring to ensure compliance with EMC Directive requirements.

Connection and Wiring

NPN and PNP Connection Examples

Illustrates typical wiring diagrams for NPN and PNP input signals.

Driver Connector Pin Assignments

Details the pin configurations for the driver's power supply, I/O signals, and motor connectors.

Motor Connector Pin Assignments

Specifies the pin assignments for connector-type motors, including wire colors.

Contacts and Connector Housings

Lists suitable Molex connector housings, contacts, and crimping tools for driver and motor connections.

Power Supply Connection

Guidance on selecting and connecting the appropriate DC power supply for the driver.

Explanation of I/O Signals

Describes the function and usage of various input and output signals for motor control.

Timing Chart

Presents timing charts illustrating signal sequences for motor operation and control inputs.

Setting Motor Parameters

Step Angle Configuration

Explains how to set the motor's step angle using dials and switches.

Pulse Input Mode Selection

Describes how to select between 1-pulse and 2-pulse input modes for controller compatibility.

Smooth Drive Function Activation

Details how to enable the smooth drive function for low-vibration, low-noise operation.

Motor Current Adjustment

Guides on setting operating and standstill motor currents for optimal performance and temperature.

Inspection and Maintenance

Periodic Motor and Driver Inspection Items

Lists key items to check during periodic inspections for motor and driver maintenance.

Troubleshooting and Remedial Actions

Common Operating Issues and Solutions

Provides a table of phenomena, causes, and remedial actions for motor operation problems.

Advanced Troubleshooting Scenarios

Addresses issues like vibration, overheating, and output signal errors with corrective steps.

Optional Accessories

Motor Cables and Connectors

Lists available motor cables and connector sets for different motor models.

Driver Cable Sets

Describes the available driver cable sets for power, I/O, and motor connections.

Motor Connector Sets (Molex)

Details Molex connector sets, including housings, contacts, and applicable cables for motors.

Need help?

Do you have a question about the CRD5107P and is the answer not in the manual?

Questions and answers