Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for GeKaMac Power ARC 200 Series

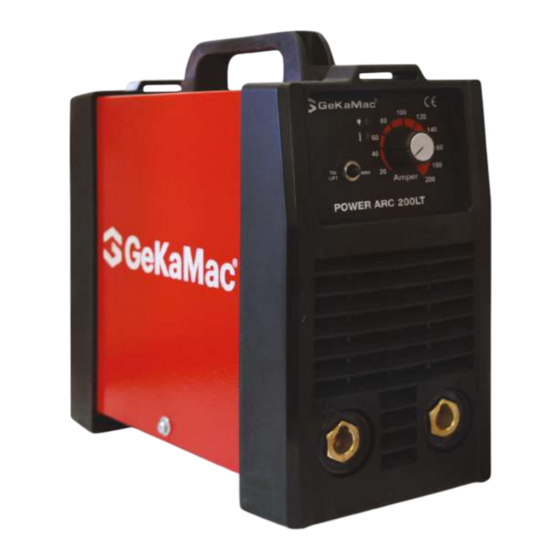

- Page 1 Power ARC 200 Series...

- Page 2 This machine is for internal use only. It complies with the WEEE Directive. This machine has been designed in accordance with the EN 60974-1 and EN 60974-10 standards. The machine is safe when installation, operation, and maintenance are performed in accordance with the user manual and regulations.

- Page 3 AT UYGUNLUK BEYANI EU DECLARATION OF CONFORMITY Bu uygunluk beyanı yalnızca /malatçının sorumluluğu altında düzenlen/r. Th#s declarat#on of conform#ty #s #ssued under the sole respons#b#l#ty of the manufacturer İstanbul, Turkey, 08.03.2024 İmalatçı / Manufacturer GEDİK KAYNAK SANAYİ ve TİCARET A.Ş. Ankara Cad.

- Page 4 AT UYGUNLUK BEYANI EU DECLARATION OF CONFORMITY Bu uygunluk beyanı yalnızca imalatçının sorumluluğu altında düzenlenir. This declaration of conformity is issued under the sole responsibility of the manufacturer İstanbul, Turkey, 08.03.2024 İmalatçı / Manufacturer GEDİK KAYNAK SANAYİ ve TİCARET A.Ş. Ankara Cad.

- Page 5 Attention! Our Valued Customer, We kindly request that you obey the warnings mentioned below: • Definitely have the “Warranty Document” approved when you get the machine. • Use the machine in a way that is in accordance with the fundamentals that are mentioned in the user’s guide of the machine.

- Page 6 CISPR 11:2009 in paragraph 10. In situ measurements can also be used to verify the efficiency of attenuation measurements. ® Thank you for prefering one of GeKaMac products. GEDİK KAYNAK SAN. VE TİC. A.Ş. Ankara Caddesi No:306 Şeyhli 34906 Pendik – İstanbul / TÜRKİYE...

- Page 7 1. INDEX Page 1. Index .............................. 3 2. Environment&Safety Rules ......................4 2.1. Electrical Shock ..........................4 2.2. Arc Rays ..........................4 2.3. Gases and Fumes ........................ 4 2.4. Welding Sparks ..........................4 2.5. Electricity and Magnetism ....................5 2.6. Accidents Originated From The Moving Parts ..............

-

Page 8: Electrical Shock

ENVIRONMENT&SAFETY RULES Protect yourself and others against possible serious injury or death risks. Keep children away. People who have pacemakers in their bodies should consult their doctors before operating the welding machine. Be careful when you are doing operations with your hands on the pieces. Use proper equipment that are necessarry to protect yourself from burns that can be caused by excessive heating of the piece during welding and / or cutting operation. - Page 9 2.5. ELECTRICITY AND MAGNETISM Electric flow that passes through a conductor causes Electric and Magnetic Fields (EMF) to be formed. Welding current creates EMF around welding cables and welding machines. — EMF can ruin the operation of some pacemakers. For this reason, welders who have pacamakers in their bodies should consult their doctors before welding.

-

Page 10: Electromagnetic Compatibility (Emc)

3. ELECTROMAGNETIC COMPATIBILITY (EMC) This machine has been designed in accordance with all related regulations and norms. Additionally, it can still generate electromagnetic forces that affect other systems such as communications (telephone, radio, television). These affects can cause security problems in the exposed systems. Read carefully and understand this section in order to reduce or get rid of the affects that can be created by this machine. - Page 11 4. GENERAL INFORMATIONS AND WARNINGS Do not set up, operate or repair before reading the user’s guide and the security measures that are found in it. Hide this user’s guide and always have it on hand. • Cut off the electrical connection between the welding machine and the network when the work is finished or when you are going to take a long break.

-

Page 12: Technical Informations

6. TECHNICAL INFORMATIONS Models ARC 160LT ARC 180LT ARC 200LT Power Supply Voltage(V) 1~220/230/240±10% 1~220/230/240±10% 1~220/230/240±10% Frequency (Hz) 50/60 50/60 50/60 Rated Input Power(kW) 5 MMA/ 3.5 TIG 5.8 MMA/ 4 TIG 6.8 MMA/ 4.3 TIG Rated Input Current(A) 37 MMA/ 27 TIG 41 MMA/ 31 TIG 46 MMA/ 31 TIG 40% 160A... -

Page 13: Operational Warnings

8. OPERATIONAL WARNINGS 8.1 Installation (1)Welding environmental temperature should be between -10℃ to 40℃. (2)Welding should be done in relatively dry environments, the air humidity of not more than90%. (3)to avoid areas containing dust or corrosive gas welding operation environment. (4)to avoid sunlight or rain, welding, do not le water or rain water infiltrated the welding machine. -

Page 14: Layout For Front&Rear Panel

9. LAYOUT FOR FRONT&REAR PANEL 1. Positive (+) Welding Cable Connection: Positive output connection for welding current. 2. Negative (-) Welding Cable Connection: Negative output connection for welding current. 3. Welding Current Control Button: Set welding current (20 ~200A). 4. Power Indicator Lamp: This lamp is activated when the machine is turned on. 5. -

Page 15: Maintenance

10. MAINTENANCE In order to guarantee that arc welding machine works high-efficiently and in safety, it must be maintained regularly. Let customers understand the maintenance methods and means of arc welding machine more , enable customers to carry on simple examination and safeguarding by oneself, try one's best to reduce the fault rate and repair times of arc welding machine, so as to lengthen service life of arc welding machine .Maintenance items in detail are in the following table. -

Page 16: Warranty Conditions

7. Ministry of Science Industry and Technology, The Protection of the Consumer and Competition General Directorate can be refered to whenever a problem concerning the warranty document comes up. 8. Earth clamp and electrode holder kits are not under warranty. ® GeKaMac... - Page 17 Gedik Welding Machines Warranty Document MACHINE INFORMATION ® Brand : GeKaMac Model : …………………………………………………………..........Serial Number : ………………………………………………..........CUSTOMER INFORMATION Company Name : ……………………………………………….......... Authorized Person : …………………………………………….......... Telephone : ……………………………………………………..........Company Address : …………………………………………..........City/Country…………………………..………………………........E-Mail :……………… @………………………..............

-

Page 18: Warranty Document

Gedik Welding Machines Warranty Document MACHINE INFORMATION ® Brand : GeKaMac Model : …………………………………………………………..........Serial Number : ………………………………………………..........CUSTOMER INFORMATION Company Name : ……………………………………………….......... Authorized Person : …………………………………………….......... Telephone : ……………………………………………………..........Company Address : …………………………………………..........City/Country…………………………..………………………........E-Mail :……………… @………………………..............

Need help?

Do you have a question about the Power ARC 200 Series and is the answer not in the manual?

Questions and answers