Advertisement

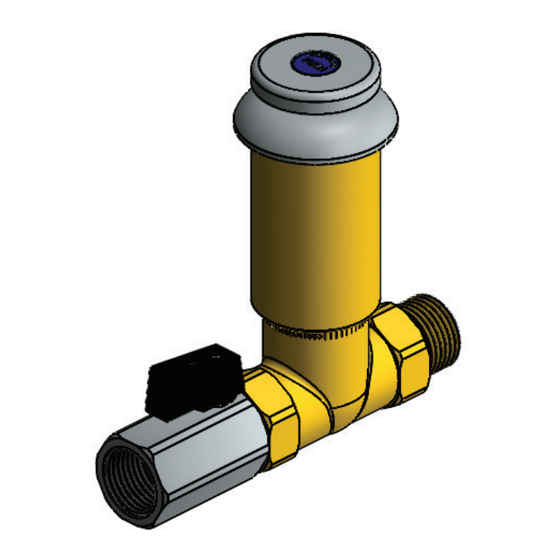

Detention Disabled Push Button Assembly

Spring Action Self Closing Straight Valve

Installation and Maintenance Instructions

DET701

technical data

Inlet Connection

Recommended Working Pressure

Recommended Temperature Range

Operating Temperature Range

Enware products are to be installed in accordance with the Plumbing Code of Australia (PCA) and AS/NZS3500.

Installations not complying with PCA and AS/NZS 3500 may void the product and performance warranty provisions.

Reference should also be made to the Australasian Health Facility Guidelines (AHFG), ABCB and Local Government

regulations when considering the choice of, and the installation of these products.

This product must be installed and commissioned by a qualified plumber.

For use with potable water only.

NOTE: Enware Australia advises:

1. Due to ongoing Research and Development, specifications may change without notice.

2. Component specifications may change on some export models.

I00612_20 Jan 2024

1300 369 273 | info@enware.com.au | enware.com.au

1/2" BSP (15mm)

100 - 500 kPa

5 - 30 °C

0 - 50 °C

Advertisement

Table of Contents

Summary of Contents for Watts ENWARE DET701

- Page 1 Detention Disabled Push Button Assembly Spring Action Self Closing Straight Valve Installation and Maintenance Instructions DET701 technical data Inlet Connection 1/2” BSP (15mm) Recommended Working Pressure 100 - 500 kPa Recommended Temperature Range 5 - 30 °C Operating Temperature Range 0 - 50 °C Enware products are to be installed in accordance with the Plumbing Code of Australia (PCA) and AS/NZS3500.

- Page 2 Indicator button Push button Base Push button spindle Circlip Connector Grub screw -socket 10- 24UNCx3/16 SS304 Tail 1/2" BSP 10 Stop tap body 1/2" 11 Mini ball valve 1/2" MF www.enware.com.au Page 2 © Enware Pty Ltd...

-

Page 3: Installation

installation • All supply lines must be flushed thoroughly to remove debris prior to the installation of this product, as per AS/NZS 3500.1. Strainers (40 mesh) are recommended if debris is an ongoing problem. • A pressure reduction valve may be required to comply with the recommended maximum supply pressure and/or balanced pressure requirements. - Page 4 8. Complete the inlet water connection to the valve (11) including the installation of an isolation valve prior to the valve assembly. Consider the ease of removal of the valve and for example use a connector nut rather than standard threaded fittings.

-

Page 5: Maintenance

maintenance CLEANING Enware products should be cleaned with a soft damp cloth using only mild liquid detergent or soap and water. Do not use cleaning agents containing a corrosive acid, scouring agent or solvent chemicals. Do not use cream cleaners, as they are abrasive. Use of unsuitable cleaning agents may damage the surface. - Page 6 SERVICING THE SBA WITH SERVICE KIT 1. Pull the piston assembly out from the SBA and remove the 2 piston o-rings. SBA SPRING 2. Use a spanner to unscrew bottom inlet port, STAINLESS STEEL BALL remove spring and stainless steel ball in the BALL SEATING WASHER port.

-

Page 7: Troubleshooting

troubleshooting PROBLEM CAUSE RECTIFICATION Water leaking from outlet Push button assembly Re-Adjust connector as per top screwed too tightly into assembly installation instructions Water dripping and does connector. not shut off SBA spindle has debris Remove SBA and inspect. caught in the mechanism. Remove debris and/or replace Water runs constantly from SBA if damaged. -

Page 8: Product Warranty Statement

- WATTS AUSTRALIA Effective 27 October 2023 3. Our responsibilities This Warranty Statement applies to products supplied by Australian Valve (a) In the event that the Supplier is reasonably satisfied that there is a Group Pty Ltd (ACN 068 227 270) (AVG) or Enware Pty Ltd (ACN 662...

Need help?

Do you have a question about the ENWARE DET701 and is the answer not in the manual?

Questions and answers