Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

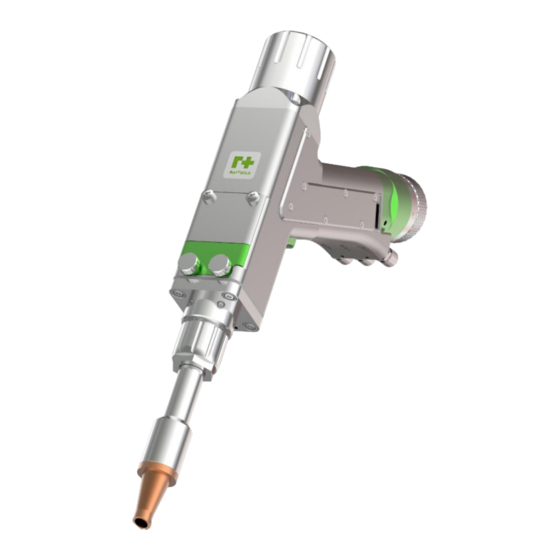

Summary of Contents for Raytools BW101-GS Series

- Page 1 BW101-GS SERIES (3kW) 4-in-One Handheld Laser Processing Head- User Manual...

- Page 2 For the benefit of our customers, we will constantly try to ensure that the products we develop comply with the latest technology. Raytools AG Email: sales@raytools.com Website: www.raytools.ch V2.0 Raytools AG © Copyright www.raytools.ch...

- Page 3 Read and understand basic safety instructions and operations. ▪ You must have studied the relevant regulations and safety instructions and understand the possible hazards. ▪ Comply with relevant regulations and implement corresponding protective measures. V2.0 Raytools AG © Copyright www.raytools.ch...

- Page 4 Storage and Transportation ▪ Observe the storage temperature range allowed by the technical data. ▪ Take reasonable measures to prevent fire, vibration or impact. ▪ Do not store in or near the magnetic field. V2.0 Raytools AG © Copyright www.raytools.ch...

-

Page 5: Table Of Contents

Table 2: Optional Material Bill ......................50 Table 3: Nozzle Selection ........................51 Table 4: Troubleshooting ........................52 Table 5: Process Parameter ......................... 53 Table 6: Wiring of Controller and Fiber Laser ..................55 V2.0 Raytools AG © Copyright www.raytools.ch... -

Page 6: Safety Instructions & Precaution

If the laser radiation doesn’t deviate from the human body, eyes and skin may be exposed. Laser radiation will burn the skin, and direct and scattered laser beams will cause permanent eye damage. V2.0 Raytools AG © Copyright 1 |63 www.raytools.ch... -

Page 7: Damage Source

This section explains the possible danger caused by laser products and response measure including: How to reduce risks through measures Raytools provides; How to ensure the safety of users when operating laser equipment through effective measures. - Page 8 Noise will be produced when using handheld laser head. Noise may cause permanent hearing damage and other health problems, especially for a long-time exposure. Solution: Mount protective cover for effective noise reduction; Earmuff is available at high noise level. V2.0 Raytools AG © Copyright 3 |63 www.raytools.ch...

-

Page 9: User Guideline

Laser products can only be used in good condition. Any damage should be repaired timely, especially those affecting safety facilities. ■ Modify Don’t modify any parts without the permission of Raytools, to avoid unsafe usage of laser product. ■ Spare parts Spare parts must meet technical requirements of Raytools. - Page 10 We recommend that users of laser products should identify potential risks through assessment and then take corresponding measures, to minimize losses or give emergency treatment to the injured. Please prepare emergency signs in visible places where there are potential risks. V2.0 Raytools AG © Copyright 5 |63 www.raytools.ch...

-

Page 11: Laser Welding Head

Humidity < 70 ° C Wavelength 1064 ± 10 Max. Laser Power 3000W Optical Configuration 60: 150 Wobbling Width 0-5mm Specification of Cover Glass D 18 × 2 Weight About 0.9 kg V2.0 Raytools AG © Copyright 6 |63 www.raytools.ch... -

Page 12: Qbh Fiber Insertion

It is recommended to use textured tape to seal the connection of female and male fiber interface after the installation is finished in order to prevent from dust as much as possible in critical dusty environment. V2.0 Raytools AG © Copyright 7 |63 www.raytools.ch... -

Page 13: Mechanical Size

BW101 GS SERIES 4-in-One Handheld Laser Processing Head-User Manual 2.4 Mechanical Size 2.4.1 Mounting of Human Machine Interface 2.4.2 Mounting of Motion Control System V2.0 Raytools AG © Copyright 8 |63 www.raytools.ch... - Page 14 BW101 GS SERIES 4-in-One Handheld Laser Processing Head-User Manual 2.4.3 Mounting of Switch Mode Power Supply V2.0 Raytools AG © Copyright 9 |63 www.raytools.ch...

-

Page 15: Removal And Installation Of Cover Glass

Loose bolts to pull out drawer type holder of focus lens. Remove the pressing ring, seal ring and cover glass in the bottom of the holder. Replace or clean cover glass. V2.0 Raytools AG © Copyright 10 |63 www.raytools.ch... - Page 16 Install the cleaned or new cover glass (regardless of the front or back surface) into the holder of cover glass. Install the pressing ring. Insert the cover glass holder back to the laser head and tighten the bolts. V2.0 Raytools AG © Copyright 11 |63 www.raytools.ch...

-

Page 17: Maintenance

Check whether connecting cable contains water before daily use; If so, clean and check if there is water seepage. Ensure that water and gas interfaces are connected correctly (assist gas in middle, water in/out on both sides). Gas/water cooling interface: φ 6mm Water pipe Gas pipe Water pipe V2.0 Raytools AG © Copyright 12 |63 www.raytools.ch... -

Page 18: Controller

BW101 GS SERIES 4-in-One Handheld Laser Processing Head-User Manual 3 Controller Wiring V2.0 Raytools AG © Copyright 13 |63 www.raytools.ch... -

Page 19: Controller Power

24V and ±15V power supply are included in the standard kit and shall be connected to control box: Earthing 3.2 Connection of HMI Panel and Controller Power communication cable of HMI panel Controller Interface V2.0 Raytools AG © Copyright 14 |63 www.raytools.ch... -

Page 20: Connection Of Laser And Controller

DA -: analog input GND (control laser beaming power) Fault +: fault signal output + (Controller receives alarm signal from laser) Fault -: fault signal output - (Controller receives alarm signal from laser) V2.0 Raytools AG © Copyright 15 |63 www.raytools.ch... -

Page 21: Connection Of Laser Head And Controller

Gas valve ±: control switch of protective gas. Valve +: 24V + relay output, without additional relay to control; Valve -: 0V relay output, and customized solenoid valves have different inlet and outlet. Please connect correctly. V2.0 Raytools AG © Copyright 16 |63 www.raytools.ch... -

Page 22: Connection Of Alarm Signal

3.6 Connection of Alarm Signal Chiller Alarm ±: connect to chiller alarm interface, or short it if it’s unnecessary. Gas flow alarm ±: connect to gas alarm device, or short it if it’s unnecessary. V2.0 Raytools AG © Copyright 17 |63 www.raytools.ch... -

Page 23: Wire Feeder

Two 24V input cables of wire feeder shall be connected to the 24V power supply or switch mode power supply of CRT+ CRT- handheld laser head (power≥ 80W). And signal cables shall be connected to control box. V2.0 Raytools AG © Copyright 18 |63 www.raytools.ch... - Page 24 Connect the interface of wire tube; Press Manual Feeding in the panel to feed wire to the tube in the interface; Fix the wire feeding inlet onto the wire feeding mechanism; Tighten it by bolt. Wire tube bolt V2.0 Raytools AG © Copyright 19 |63 www.raytools.ch...

-

Page 25: Software Operation Of Wire Feeder

Internal structure of wire feeder Adjust the tension of tension regulator to enable stable wire feeding. Deliver the wire to wire feeding nozzle in manual feeding mode. 4.2 Software Operation of Wire Feeder V2.0 Raytools AG © Copyright 20 |63 www.raytools.ch... - Page 26 (display feeding speed in working status) V2.0 Raytools AG © Copyright 21 |63 www.raytools.ch...

- Page 27 Delay Filling 0-500 Filling Distance 0- 100 Technical Parameter Model RT-HWS-YB80A Voltage DC24V Power Motor PMDC motor Speed Adjusting PWM open-loop adjusting Wire Size 0.6/0.8/1.0/1.2/1.6/2.0(mm) Feeding Speed 5-100(mm/s) Size 580*310*460mm Weight 15kg V2.0 Raytools AG © Copyright 22 |63 www.raytools.ch...

-

Page 28: Troubleshooting Of Wire Feeder

Replace or clean the wire tube The bending angle of wire tube is Put the wire feeding tube straight less than 30 degrees Deformation of wire tube after extrusion Replace wire tube V2.0 Raytools AG © Copyright 23 |63 www.raytools.ch... -

Page 29: Maintenance Of Wire Feeder

Close the right-side plate of wire reel when welding, otherwise electric shock or winding may occur caused by the rotation of rotating parts. ▪ Before welding, please ensure the real shaft end cover is tightened, otherwise the wire reel may fall off. V2.0 Raytools AG © Copyright 24 |63 www.raytools.ch... -

Page 30: Auto Feeding Speed Adjustment

Knob the two adjustable rotation sleeves of tension regulator until wire reel rotates uniformly (Ensure that the wire tube is smooth without bending). Real-time Adjust: Adjust feeding speed and other parameters manually according to actual processing effect. V2.0 Raytools AG © Copyright 25 |63 www.raytools.ch... -

Page 31: Connection Of Wire Feeding Mechanism And Laser Head

Fix the wire feeding assembly on the laser head. ▪ Adjust the wire feeding angle to align laser beam with wire. ▪ Tighten all bolts. Ensure wire reel is smooth without knots. V2.0 Raytools AG © Copyright 26 |63 www.raytools.ch... -

Page 32: Hmi Panel

SpotWeld or Line Wobble Weld. number of laser pulses emitted by the laser per second. range: 0-200Hz. ratio of pulse duration to pulse cycle (range: 0-100%). adjust wobble line length when welding. open/close laser V2.0 Raytools AG © Copyright 27 |63 www.raytools.ch... - Page 33 HMI in order to prevent other people from touching the screen by mistake when the operator is welding or debugging. It is used to secure the safety of the operator. Click it to switch locking and unlocking status. select different languages. V2.0 Raytools AG © Copyright 28 |63 www.raytools.ch...

-

Page 34: Setting

Beaming will stop if the non-contact duration is longer than this parameter. adjust beaming duration of scale welding according to the reality. beaming stopping interval of scale welding. V2.0 Raytools AG © Copyright 29 |63 www.raytools.ch... - Page 35 (range: 0-5mm). range: 0-200Hz. galvo center correction, finished before selling, but allowing fine adjustment in actual usage. finished before selling, but allowing fine adjustment in actual usage. V2.0 Raytools AG © Copyright 30 |63 www.raytools.ch...

-

Page 36: Process

BW101 GS SERIES 4-in-One Handheld Laser Processing Head-User Manual 6.4 Process switch parameters of feeding and no-feeding. current process No., valid after saving modified parameters. click to apply selected process No. click to edit parameters. click to restore defaulted parameters. V2.0 Raytools AG © Copyright 31 |63 www.raytools.ch... -

Page 37: Monitoring

Alarm status: green-normal, red-abnormal. green-normal, red-abnormal. green-normal, red-abnormal. green-normal, red-abnormal. green-normal, red-abnormal. V2.0 Raytools AG © Copyright 32 |63 www.raytools.ch... -

Page 38: Function Switch

Please contact the seller if it’s necessary. click to restore default factory setting. This operation will clean all modified parameters. display hardware version like HMI panel, laser control card. V2.0 Raytools AG © Copyright 33 |63 www.raytools.ch... -

Page 39: About

BW101 GS SERIES 4-in-One Handheld Laser Processing Head-User Manual 6.7 About Each version product match corresponding device, including HMI pane version and laser card version. For following version upgrade, please contact the manufacturer. V2.0 Raytools AG © Copyright 34 |63 www.raytools.ch... -

Page 40: Multi-Function

BW101 GS SERIES 4-in-One Handheld Laser Processing Head-User Manual 7 Multi-Function 7.1 Cut 7.1.1 Config. Nozzle base Nozzle BW101-GS SERIES supports cutting. ▪ Remove wire feeding assembly and nozzle. ▪ Install the nozzle base on the extending tube and install the nozzle on the base as above. ▪... - Page 41 Green: conductive; Red: non-conductive. support to modify parameters in basic setting and galvo setting interfaces. contain process reference parameters, which can be modified or selected to use. V2.0 Raytools AG © Copyright 36 |63 www.raytools.ch...

- Page 42 (power range:0- 3000W). select PNP/NPN active (24V - PNP active). beaming duration when the nozzle temporarily separates from workpiece. Beaming will stop if the non-contact duration is longer than this parameter. V2.0 Raytools AG © Copyright 37 |63 www.raytools.ch...

- Page 43 BW101 GS SERIES 4-in-One Handheld Laser Processing Head-User Manual Galvo Setting: galvo center correction, finished before selling, but allowing fine adjustment in actual usage. finished before selling, but allowing fine adjustment in actual usage. V2.0 Raytools AG © Copyright 38 |63 www.raytools.ch...

-

Page 44: Weldseam Clean

BW101 GS SERIES 4-in-One Handheld Laser Processing Head-User Manual 7.2 WeldSeam Clean 7.2.1 Config。 Weldseam cleaning tube BW101-GS SERIES supports weld seam cleaning. ▪ Remove extending tube and wire feeding assembly. ▪ Install weldseam cleaning tube and tighten it as above. - Page 45 16 types (1-16) with relevant parameters. Process No. can be selected on Process Interface. show status of safety lock. Green: conductive; Red: non-conductive. V2.0 Raytools AG © Copyright 40 |63 www.raytools.ch...

- Page 46 (power range:0- 3000W). select PNP/NPN active (24V - PNP active). beaming duration when the nozzle temporarily separates from workpiece. Beaming will stop if the non-contact duration is longer than this parameter. V2.0 Raytools AG © Copyright 41 |63 www.raytools.ch...

- Page 47 (range: 0-5mm). range: 0-200Hz. galvo center correction, finished before selling, but allowing fine adjustment in actual usage. finished before selling, but allowing fine adjustment in actual usage. V2.0 Raytools AG © Copyright 42 |63 www.raytools.ch...

-

Page 48: Remote Clean (Optional

BW101 GS SERIES 4-in-One Handheld Laser Processing Head-User Manual 7.3 Remote Clean (Optional) 7.3.1 Config. BW101-GS SERIES supports remote cleaning. ▪ Remove two circle head screws of drawer type holder of focus lens by hex wrench. ▪ Remove the holder and install a lens holder of remote clean. - Page 49 16 types (1-16) with relevant parameters. Process No. can be selected on Process Interface. support to modify parameters in basic setting and galvo setting interfaces. V2.0 Raytools AG © Copyright 44 |63 www.raytools.ch...

- Page 50 (power range:0- 3000W). select PNP/NPN active (24V - PNP active). beaming duration when the nozzle temporarily separates from workpiece. Beaming will stop if the non-contact duration is longer than this parameter. V2.0 Raytools AG © Copyright 45 |63 www.raytools.ch...

- Page 51 0-5mm. range: 0-200Hz. galvo center correction, finished before selling, but allowing fine adjustment in actual usage. finished before selling, but allowing fine adjustment in actual usage. V2.0 Raytools AG © Copyright 46 |63 www.raytools.ch...

- Page 52 Panel 1pcs HMI panel kit-standard HMI panel kit version Power 1pcs communication cable 24V-100W 1pcs Power supply ±15V-55W 1pcs 1pcs Motor cable 10m (cable: Motor cable(8m) (select 1 of 2) 8m+head: 2m) V2.0 Raytools AG © Copyright 47 |63 www.raytools.ch...

- Page 53 BW101 GS SERIES 4-in-One Handheld Laser Processing Head-User Manual (cable:13m+head: Motor cable(13m) Nozzle box kit 1pcs Cover glass 5pcs D18*2 alligator clamp & 1pcs Accessories package- Accessories cable standard version package Open end wrench 1pcs Open end wrench 1pcs V2.0 Raytools AG © Copyright 48 |63 www.raytools.ch...

- Page 54 BW101 GS SERIES 4-in-One Handheld Laser Processing Head-User Manual Consumables: Item Specification Image for reference Cover glass D18*2-1064nm-3kW Seal ring For cover glass V2.0 Raytools AG © Copyright 49 |63 www.raytools.ch...

- Page 55 Laser protective glass 1pcs OD4+,1064nm Including 220V power input cable*2, ± Power supply cable kit 1pcs 15V power output cable*1 and 24V power output cable*1 V2.0 Raytools AG © Copyright 50 |63 www.raytools.ch...

- Page 56 Table 3: Nozzle Selection Product ID Type Image In-corner Out-corner Butt Wire Dia. 120W50513E In-corner 120W50514E Wire 0.8-1.2 1.2mm 120W50515E Wire 1.2-1.6 1.6mm 120W50524B Out-corner 120W50517E Out-corner 0.8-1.2 wire 1.2mm 120W50518E Out-corner 1.2-1.6 wire 1.6mm V2.0 Raytools AG © Copyright 51 |63 www.raytools.ch...

- Page 57 Wiring Check wiring as chapter 5. Independent power supply is suggested. Wire feeder not working Check installation from wire feeder to wire feeding mechanism. (refer Installation to user manual or installation video) V2.0 Raytools AG © Copyright 52 |63 www.raytools.ch...

- Page 58 100% 2.5MM 60HZ 2.5MM 1.2mm 10mm/s 1000 4.0MM 2000W 100% 3.0MM 50HZ 3.0MM 1.6mm 8mm/s 1000 5.0MM 2500W 100% 3.0MM 50HZ 3.5MM 2.0mm 8mm/s 1000 6.0MM 3000W 100% 3.0MM 50HZ 4.0MM 2.0mm V2.0 Raytools AG © Copyright 53 |63 www.raytools.ch...

- Page 59 1000HZ 3.0MM 50HZ 8mm/s 4.0MM Note: Above parameters are only for reference (Lasers of different brands have different energy density), for detailed parameters, please set according to actual laser and customer requirements. V2.0 Raytools AG © Copyright 54 |63 www.raytools.ch...

- Page 60 Control laser modulation beaming, 10- 24V, PNP active. PWM- External modulation input signal GND BWT Laser DB25 Handheld Controller Enable+ Enable+ Enable- Enable- PWM+ PWM+ PWM- PWM- Fault signal+ Fault input+ Fault signal- Fault input- V2.0 Raytools AG © Copyright 55 |63 www.raytools.ch...

- Page 61 5V, 12V and 24V) EX_ALARM_OUT- Fault signal output - Reci Laser 2PIN (AD interface) Handheld Controller Reci Laser 16-core aviation plug CTRL Enable+ LASER_EN+ Enable- LASER_EN- PWM+ MOD_SW+ PWM- MOD_SW- Fault input+ Fault input- V2.0 Raytools AG © Copyright 56 |63 www.raytools.ch...

- Page 62 Enable input + Enable input - Modulation input + PWM+ Modulation input - PWM- Fault output 2 Fault input+ Fault input- Handheld Fault output 1 controller Fault light Preparation light Running light V2.0 Raytools AG © Copyright 57 |63 www.raytools.ch...

- Page 63 PIN8 & PIN24 output) Analog Input External power gives <10mA analog <20mA Laser Output Laser power sign power <100mA Alarm Output Laser abnormity Abnormal Normal AGND 22 & 23 reference GND Other No connection V2.0 Raytools AG © Copyright 58 |63 www.raytools.ch...

- Page 64 BW101 GS SERIES 4-in-One Handheld Laser Processing Head-User Manual V2.0 Raytools AG © Copyright 59 |63 www.raytools.ch...

- Page 65 18、19 com. GND Earth cable Earthing Handheld Controller JPT Laser 24PIN 0-10V + 0-10V +, analog input ground 18、19 com. GND PWM+ Modulation + PWM- Modulation - Fault input+ Alarm output Fault input- V2.0 Raytools AG © Copyright 60 |63 www.raytools.ch...

- Page 66 Main power Digital output 24V DC 100 mA (source) 120 ms PNP = Main power starts starting Laser emitted Digital output 24V DC 100 mA (source) 120 ms PNP = laser EN V2.0 Raytools AG © Copyright 61 |63 www.raytools.ch...

- Page 67 24V: YES / 0V: NO Power on sign output signal 24V: Normal / 0V: Abnormal EN_ON EN sign output signal 24V: YES / 0V: NO EN_ON Beaming sign output signal 24V: YES / 0V: NO V2.0 Raytools AG © Copyright 62 |63 www.raytools.ch...

- Page 68 BW101 GS SERIES 4-in-One Handheld Laser Processing Head-User Manual Handheld Controller Feibo Laser DB25 IFWD_SET CASE EX_EN GND_IO PWM+ GATE PWM- GND_IO Fault input+ FAULT Fault input- V2.0 Raytools AG © Copyright 63 |63 www.raytools.ch...

Need help?

Do you have a question about the BW101-GS Series and is the answer not in the manual?

Questions and answers

WHY WIRE AND GAS NOT FEEDING AT HEAD