Table of Contents

Advertisement

Quick Links

JaNets JT Simple

User's Manual

(Random Inspection)

We appreciate your purchase of JUKI products.

In order to make the most of Ja Nets JT Simple ra ndom

Inspection, we kind ly ask you to read this ma nua l carefully

before using the product to e nsure a thorough understa nding.

Please store this manua l in a proper place where it

can b e

easily accessed and kept safe for future reference.

Version 07

June 2024

JUKI Corporation

Advertisement

Table of Contents

Summary of Contents for JUKI JT Simple

- Page 1 (Random Inspection) We appreciate your purchase of JUKI products. In order to make the most of Ja Nets JT Simple ra ndom Inspection, we kind ly ask you to read this ma nua l carefully before using the product to e nsure a thorough understa nding.

-

Page 2: Table Of Contents

Table of contents About this manual ....................... 5 I. Settings ........................8 I -1. Basic common settings ..................8 I-2. Random inspection function settings ..............9 I-2-1. System parameter settings ................10 I-2-1-2. Random inspection count setting ............10 I-2-2. Random inspectors’ operator registration ............10 I-2-3. - Page 3 I-2-9. Random Inspector list creation ..............33 I-2-9-1. Add Random inspectors and operators to be inspected ....... 33 I-2-9-2. Edit Random inspector ................37 I-2-9-3. Edit operators to be inspected ..............38 I-2-9-4. Delete Random inspector ............... 39 I-2-9-5. Enable / Disable Random inspector ............39 I-2-9-6.

- Page 4 II-3-3. Input inspection results ................68 II-3-2-1. In case of no defective products ............70 II-3-2-2. In case of any defective products (Cause of defect input) ......71 II-3-4. Delete inspection result ................74 II-3-4-1. Delete inspection result ................ 74 III.

-

Page 5: About This Manual

About this manual This manual describes the JaNets JT Simple’s Random Inspection. The structure of this manual is as follows. Chapter I: Settings. How to set up and use the Random Inspection function. Chapter II: Inspection. How to perform the inspection with a tablet PC. - Page 6 [ Random inspection flow ] In the random inspection, the person in charge of inspection goes around the sewing machines in order to conduct the inspection. 1.) Extract 7 pieces from the work in progress. (The number of pieces to be extracted varies depending on the operation.) 2.) Set up a flag of one color from among the three colors depending on the number of defective products.

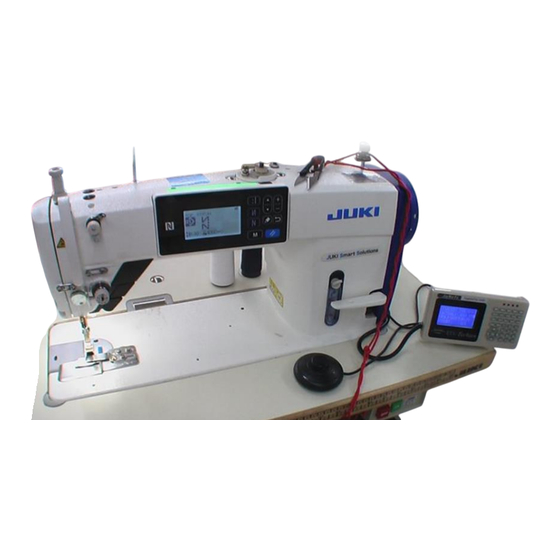

- Page 7 [ Devices required for random inspection function ] To use the random inspection function, the following devices are required: Please prepare the number of the equipment and RFID Card as necessary. device name explanation Tablet PC Used for inspection input. RFID Card with QR code RFID cards provided by Techzen.

-

Page 8: Settings

This section explains the basic common settings. The basic common settings required are shown in the table below. If you are already using the report system, followings settings are not necessary. For details, refer to the JaNets JT Simple User's Manual. -

Page 9: I-2. Random Inspection Function Settings

I-2. Random inspection function settings This section describes the settings required to use the random inspection function. The setting flow is as follows. < Setting Flow > System parameter setting Random Inspector registration User registration with Random inspection function authority Operator’s Face Photo registration Style Image Picture registration Random Inspection Level creation... -

Page 10: I-2-1. System Parameter Settings

I-2-1. System parameter settings I-2-1-1. Style usage settings The random inspection function requires the use of style, so make sure the system parameter #13: "Style usage settings" is set to "1: Use only Style" or "2: Use Style and interdivisional WIP." The initial value is "1: Use only Style."... -

Page 11: I-2-3. Users' Registration With Random Inspection Authority

Select the person in charge of random inspection and the administrator, and add the authority to be granted. For details on adding permission types, refer to "III-1-4. Adding permission types" in the JaNets JT Simple User's Manual. [ Example of the permission for random inspection tablet only ] 11/84... -

Page 12: I-2-4. Operators' Face Photo Registration

Next, register the required number of users and grant permissions. For details on user registration, refer to " III- 1-2 . User Registration" in the JaNets JT Simple User's Manual. [Registration example] I-2-4. Operators’ face photo registration Register the face photo of the operator into the Operator Master to be displayed on the random inspection result input screen. -

Page 13: I-2-5. Style Images Registration

I-2-5. Style images registration Register the image into the Style Master to be displayed in the random inspection defective information input and random inspection analysis graph. [ Defective information input screen ] [ Random inspection analysis graph Two images can be registered for one style. *Aspect ratio 1:1, image file format : png , jpg 13/84... - Page 14 [How to register images] On the Style Master screen, select Main image 1 or Main image 2...① or ②. Select the image file to be registered...③ and click Open...④ to register the image. [ Image registration example ] 14/84...

-

Page 15: I-2-6. Random Inspection Level Creation

I-2-6. Random inspection level creation Set the inspection contents for random inspection. The content of inspections performed during the random inspection varies depending on the factory. "Random inspection level" refers to the cause of failure that is set according to the inspection content. - Page 16 Add Random Inspection screen shows up. ② ③ ④ Enter the Level name...②. Note 1: Maximum of 50 characters (no distinction between full-width and half-width characters), there are no restrictions on input characters. Note 2: Up to 30 levels can be registered. Next, select Random inspection level...③...

-

Page 17: I-2-6-3. Inspection Level Selection

I-2-6-3. Inspection level selection Set the inspection level to use for random inspections. Press the enable button for the inspection level you want to use...①. ① Press the confirmation "OK" button to enable the inspection level. Only one inspection level can be "enabled". 17/84... -

Page 18: I-2-6-4. Edit Inspection Level

I-2-6-4. Edit inspection level Press the enable button for the inspection level you want to edit...①. ① Change as necessary and press the Save button...③. ③ I-2-6-5. Delete inspection level Press the Delete button for the inspection level you want to delete...①. ①... -

Page 19: I-2-6-6. Export / Import

I-2-6-6. Export / Import You can save or load the settings into an Excel file. Please use it to back up your settings. [ Export ] Click the Export button... ①. ① The settings will be saved. 19/84... - Page 20 [ Import ] Click the Import button...②. ② Select the file to import...③, and click Open...④. ③ ④ The settings will be loaded. 20/84...

-

Page 21: I-2-7. Defect Cause List Creation

I-2-7. Defect cause list creation In the random inspection function, the inspectors enter the information about defective products by selecting display items on the tablet PC, and data will be aggregated. The “Defect cause list” is a list of defect causes displayed on the inspection tablet PC. Up to 300 items can be registered. - Page 22 Add Causes of defects screen shows up. Enter information into Causes of defects...②. Note 1: Maximum of 50 characters (no distinction between full-width and half-width characters), there are no restrictions on input characters. Next, select whether it is due to the equipment such as a sewing machine and/or due to human error from the Issue Relation…③, set the color for each cause (initial value is red)...④, and click the Save button...⑤.

-

Page 23: I-2-7-2. Edit Causes Of Defects List

I-2-7-2. Edit Causes of defects list Click the Edit button…① you want to edit. ① Edit the item as necessary, and click the Save button ...② to save. ② 23/84... -

Page 24: I-2-7-3. Delete Defective Cause List

I-2-7-3. Delete Defective cause list Press the delete button ① you want to delete. ① Click the “OK” button to delete. I-2-7-4. Enable / Disable Defect cause list It is available to configure whether or not to display the defective cause list on the inspection tablet PC. -

Page 25: I-2-7-5. Change Defect Cause List Display Order

I-2-7-5. Change Defect cause list display order It is available to change the Issue List display order. To change, select the Radio button…① for the desired Defect cause list to change, and then click the Move Up button…② or the Move Down button…③ to change the order. ②... - Page 26 [ Import ] Click the Import button...②. ② Select the file to import…③, and press Open...④. ③ ④ The settings will be loaded. 26/84...

-

Page 27: I-2-8. Defect Part List Creation

I-2-8. Defect part list creation With the random inspection function, inspectors select defective parts using inspection tablets, input information on defective products, and aggregate information. The defective parts list is a list of defective parts displayed on the inspection tablet device. Maximum 100 items can be registered. - Page 28 Enter the name of the defective part into the Input field...① Note 1: Maximum of 50 characters (no distinction between full-width and half-width characters), there are no restrictions on input characters. Next, click the Save button...② to save. ① ② The defective part will be registered.

-

Page 29: I-2-8-2. Edit Defective Part List

I-2-8-2. Edit defective part list Click the Edit button...① of the defective part to be edited. ① Edit the Defective part list…① and click the Save button…② to save. ① ② 29/84... -

Page 30: I-2-8-3.Delete Defective Part List

I-2-8-3.Delete defective part list Click the “Delete button…① you want to delete. ① Click the “OK” button to delete. I-2-8-4. Enable/disable defective part list It is possible to configure whether or not to display the defective part list on the inspection tablet PC. -

Page 31: I-2-8-5. Change Defective Part List Display Order

I-2-8-5. Change Defective part list display order It is possible to change the Defective part list display order. To change, select the Radio button…① for the desired Defective part list item to change, and then click the Move Up button…② or the Move Down button…③ to change the order. ③... - Page 32 [ Import ] Click the Import button...② ② Select the file to import...③, and click Open...④. ③ ④ The settings will be imported. 32/84...

-

Page 33: I-2-9. Random Inspector List Creation

I-2-9. Random Inspector list creation Create a list of Random Inspectors and Operators to be inspected. When starting an inspection on the inspection tablet, select an inspector from the list of inspectors created here. When you select an inspector, a list of operators to be inspected will be automatically displayed. - Page 34 Add inspector screen shows up. Enter the Inspector selection button ...②. ② The Operator Master list screen shows up. Click the Radio button...③ to select the inspector’s operator, and press the OK button...④. ③ ④ 34/84...

- Page 35 The selected operator name will be displayed to the inspector. Click the Save button...⑤ to save. ⑤ Information about the selected inspector will be displayed in the list. ⑥ Next, register the operator who will be responsible for the added inspector. Click the Edit button...⑥...

- Page 36 The Operator Master list screen shows up. Click the Checkbox...⑧ to select the operator to be inspected. You can select multiple operators. When the selection is complete, click the OK button...⑨. ⑧ ⑨ Addition of inspector list is completed. Click the OK button...⑩. ⑩...

-

Page 37: I-2-9-2. Edit Random Inspector

A list of registered operators will be displayed. (If it cannot be displayed fully, it will be displayed as "...". Add as many inspectors as necessary depending on the situation. I-2-9-2. Edit Random inspector Click the Edit button...① you want to edit. ①... -

Page 38: I-2-9-3. Edit Operators To Be Inspected

I-2-9-3. Edit operators to be inspected Edit the list of operators to be inspected from the operator list screen. Click the Edit button…① in the operator list column to open the operator list screen. ① [ How to add an operator. ] Click the Add button...③, and select the operator. -

Page 39: I-2-9-4. Delete Random Inspector

I-2-9-4. Delete Random inspector Click the Delete button…① you want to delete. ① Click the “OK” button to delete. The list of operators to be inspected will also be deleted. I-2-9-5. Enable / Disable Random inspector You can temporarily hide inspectors from the inspector list displayed on the inspection tablet. Even if it is set to hide, it will be displayed on this screen. -

Page 40: I-2-9-6. Change Display Order

I-2-9-6. Change display order You can change the display order of the inspector list. When selecting on the inspection tablet, they will be displayed in this order. Select the radio button…① of the inspector whose order you to change, and click the Move up button…②... - Page 41 [ Import ] Click the Import button...② ② Select the file to import...③, and click Open...④. ③ ④ The settings will be imported. At this time, if there is registration in the operator list, it will be imported at the same time. 41/84...

-

Page 42: I-2-10. Marker Settings

I-2-10. Marker settings In the marker settings, you can set the "size" of defect points to be displayed on the inspection tablet and graphs. [ Random inspection analysis graph [ Tablet input screen of defect cause ] (defective point analysis) ] I-2-10-1. -

Page 43: I-2-10-2. Changing The Size Of Defective Points

Current marker setting screen opens. Initial value: Point size "normal" I-2-10-2. Changing the size of defective points How to change the size of the points. Press the Modify button...①. ① Select the item to change, and click the Save button ... ②. ②... -

Page 44: I-2-11. Defective Process List Creation

(without JaNets JT Simple) or processes that do not use JaNets JT Simple terminal. Up to 100 items can be registered. Note 1) If no lines have been created in JaNets JT Simple "Line and Layout Settings", this function cannot be created. - Page 45 On the Defective Process List setting screen, press the +Add button...① ① Add screen shows up. ① Press the Process Selection button…①. The Process Master list screen will be displayed. ② ③ 45/84...

- Page 46 Click the Radio button...② to select the process, and press the OK button...③ ④ If you specify a line from the line list box…④, it will be displayed in the defective process list only when the specified line is inspected on the inspection tablet device. If you save without specifying a line (leaving it blank), it will be displayed in the defective process list for all inspections.

-

Page 47: I-2-11-2. Edit Defective Process List

I-2-11-2. Edit Defective Process List Press the Edit button…① you want to edit. ① Change as necessary and press the Save button...②. ② I-2-11-3. Delete Defective Process List Press the Delete button...① for the defective process you want to delete. ①... -

Page 48: I-2-11-4. Enable / Disable Defective Process List

Click "OK" to delete from the list. (It will not be deleted from the Process Master). I-2-11-4. Enable / Disable Defective Process List You can set whether to display the defective process list on the inspection tablet PC. Even if you set it to "Disable", it will be displayed on this screen. Press the “Enable”... -

Page 49: I-2-12. Defect Group Setting Creation

I-2-12. Defect group setting creation By using the defect group setting, the cause of defects and defective parts can be grouped by style and displayed on a tablet PC. Up to 100 defect group settings can be registered. When creating a list, select the necessary defect causes and defect parts from the "Defect Cause List"... - Page 50 The Add screen appears. Enter the Group name. . .② and press the OK button. . .③ . ② ③ The Group information is displayed in the list. Next, register the defect causes you want to group. Click the Edit button...④ in the “Cause of defects association” cell . ④...

- Page 51 The “Add cause of defect” screen appears. ⑥ ⑦ Click the Checkboxes...⑥ to select the “Cause of defects association“ you want to group. Multiple selections are available. Once you have completed your selections, click the Add button...⑦. The ”Cause of defects” have been added. Press the OK button…⑧. ⑧...

- Page 52 Return to the “Defect group settings.” The defect cause you added will not be displayed in the list. Add necessary defect causes according to your situation. Next, register the defective parts you want to group. Press the Edit button...⑨ in the “Defect Part association.” ⑨...

- Page 53 “Add Defect part” list screen appears. ⑪ ⑫ Press the Checkboxes...⑪ to select the defect causes you want to group. Multiple selections are available. Once you have completed your selections, click the Add button...⑫. The defect area has been added. Press the OK button...⑬. ⑬...

-

Page 54: I-2-12-2. Link Defect Group To A Style

Screen returns to the defect group setting. The added defect location will not be displayed on the list. Add any necessary defective parts according to your situation. I-2-12-2. Link defect group to a style To link the defective group, you have created to a style, set up the defect group in the Style Master. -

Page 55: I-2-12-3. Edit Group Names

I-2-12-3. Edit group names Press the Edit button...① for the group you want to edit. ① After editing the Group...②, press the Save button...③ ② ③ I-2-12-4. Edit the cause of defects Cause of defects can be edited from the “Cause of defects association” edit screen. Press the Edit button...①... -

Page 56: I-2-12-5. Edit The Defect Parts

If you do not use a defect group, the defect causes will be sorted in the order they are displayed in the defect causes list. After changing the defect cause group, press the OK button...⑦. ⑥ ② ⑤ ③ ④... -

Page 57: I-2-12-6. Delete A Group

If you do not use a defect group, the defect parts will be sorted in the order they are displayed in the defect parts list. After changing the defect part group, press the OK button...⑦. ⑥ ② ⑤ ③ ④... -

Page 58: I-2-12-7. Export / Import

However, if you have set it as a defect group in the Style Master, you cannot delete it. In that case, unset the defect group in Style Master before deleting it. I-2-12-7. Export / Import The settings can be saved to and loaded from an Excel file . Use it to back up your settings, etc. -

Page 59: I-2-13. Auto Switch Dashboard Settings

I-2-13. Auto Switch Dashboard Settings You can set up Random inspection analysis graphs on the Auto Switch Dashboard. For details on the settings, refer to "III-2-15. Auto Switch Dashboard Settings" in the JaNets JT Simple User's Manual. 59/84... -

Page 60: Ii. Inspection

II. Inspection This section explains how to conduct Random Inspection using a tablet device. II-1. How to access the random inspection screen Turn on the tablet's Wi-Fi and connect it to the same network as the JaNets Server. Start Google Chrome and enter "https:// ( JaNets Server 's IP address )" ( e.g. https://192.168.1. -

Page 61: Ii-2. Random Inspection Login

Additionally, for users who have authority for functions other than random inspection input, the JaNets JT Simple report system screen will be displayed. "Number of connected devices/Number of tablets contracted" is displayed on the right side of the title. - Page 62 The number of connected devices will decrease in the following cases: 1.) Logging out using the "Exit" button. 2.) Closing with X in your browser. 3.) Disconnecting the Internet (if the tablet is in sleep mode and the Wi-Fi connection is set to OFF), 4.) Timing out after 60 minutes of inactivity, etc.

-

Page 63: Ii-3. Random Inspection Input

II-3. Random inspection input This section explains the random inspection input screen. Inspection input screen. II-3-1. Inspection target selection Before starting the inspection, select the inspector who will conduct the inspection and call up the list of operators to be inspected. Select the inspector from the inspector pull-down list on the inspection input screen ...①. - Page 64 The list of operators created in the inspector list will be automatically displayed. 64/84...

-

Page 65: Ii-3-2. How To Start The Inspection

II-3-2. How to start the inspection Below are instructions on how to start the inspection. There are two ways to start the inspection: a.) Selecting the operator from the list. b.) Reading the operator's QR code. II-3-2-1. Select the operator from the list Find the operator from the Random inspection input screen, and touch the target inspection count column cell. -

Page 66: Ii-3-2-2. Read The Operator's Qr Code

Random inspection result input screen shows up. II-3-2-2. Read the operator's QR code Touch the QR code reading button...① to activate the tablet camera and read the QR code on the operator's RFID card. ① 66/84... - Page 67 Random inspection result input screen shows up. 67/84...

-

Page 68: Ii-3-3. Input Inspection Results

II-3-3. Input inspection results Enter the inspection results on the Random inspection result input screen. This screen displays information about the number of inspections and the operator being inspected. ① ③ ② ④ ⑤ ⑥ ⑦ ① Number of inspections Displays the number of inspections performed this time. - Page 69 First, select the order No. (style) being inspected. ⑥ ⑦ Touch the Line...⑥ and select the line where the operator is working on. Select the Order No. ( Style) from the pull-down list...⑦. (When you enter for the first time, nothing is selected.) If there is no change in the order number (style) from the second time onwards, there is no need to select it.

-

Page 70: Ii-3-2-1. In Case Of No Defective Products

II-3-2-1. In case of no defective products This section explains how to input inspection results in case of no defective products. Perform the inspection of the specified number of pieces, and if there are no defective products, touch the Finish button...⑩. ⑩... -

Page 71: Ii-3-2-2. In Case Of Any Defective Products (Cause Of Defect Input)

II-3-2-2. In case of any defective products (Cause of defect input) This section explains how to input inspection results in case of any defective products. Enter the cause of the defect for each defective product. Touch the Reject button...① to display the Defective information input screen. ①... - Page 72 Select the Cause of the defects...①, the Defective parts...②, and the Defective process...③. Next, touch the defective area on the image and draw a dot…④. If you want to correct a mistake, you can use the Return button...⑤ to delete the previous input (Cause of the defects, Defective parts, Defective process, and point).

- Page 73 The defect cause input is completed and the screen returns to the random inspection input screen. The number will be incremented by 1 on the Reject button・・① ⑩ ⑪ If you wish to subtract the number of defective items due to a mistake, etc., touch the Subtract defective products button・・・⑪.

-

Page 74: Ii-3-4. Delete Inspection Result

II-3-4. Delete inspection result Deleting an input result is available on the inspection result input screen. This deletion will also be reflected in the analysis graph. II-3-4-1. Delete inspection result Press and hold the cell of the inspection result you want to delete. The delete menu will appear. -

Page 75: Iii. Analysis

III. Analysis This section describes the random inspection analysis graph. III-1. Random inspection analysis graph The random inspection analysis graph allows you to analyze information on defective products entered during random inspection. Six types of graphs can be switched and displayed by part, cause, process, operator, time series, and defect point. - Page 76 Click the Submenu...④ of the random inspection analysis screen to display each graph. ④ 76/84...

-

Page 77: Iii-1-1. Analysis Target Selection

III-1-1. Analysis target selection First, select the period and equipment to analyze. This selection is common to all 6 types of graphs. III-1-1-1. Period selection Select the period you want to analyze. Click the Date display...①, select either Current shift, Today, Yesterday, Last 7 days, Last 31 days, Any...②, and click the OK button...③. -

Page 78: Iii-1-1-2. Equipment Selection

III-1-1-2. Equipment selection Select the equipment to analyze. Please select Factory...①, Floor...②, Line...③, Order No. ( Style)...④, and Inspector...⑤. If you want to target all, select "All". ⑤ ② ③ ④ ① 78/84... -

Page 79: Iii-1-2. Data Narrow Down

III-1-2. Data narrow down You can narrow down the defect information displayed in each graph. Select from the Defective parts pull-down list...①, Causes of defects pull-down list...②, Defective process pull-down list...③, and Operator in charge pull-down list...④. At first, everything is selected. Uncheck the items you want to exclude and click the update button. -

Page 80: Iii-1-3. Defect Quantity Pie Chart By Part

III-1-3. Defect quantity Pie chart by part The defect quantity is categorized by part and displayed in a pie chart. The pie chart is displayed clockwise from the 12 o'clock direction in descending order of composition ratio . Also, the total quantity and ratio of each part is displayed in a list. III-1-4. -

Page 81: Iii-1-5. Defect Quantity Graph By Process

III-1-5. Defect quantity Graph by process The defect quantity is categorized by process and displayed in a bar graph. The horizontal axis is the process, and the vertical axis is the defect quantity. Bar graphs for each process are displayed stacked by cause. If you set a color for each cause in the causes of defects list, they will be displayed in different colors. -

Page 82: Iii-1-7. Defect Quantity Graph By Time Series

III-1-7. Defect quantity Graph by time series The defect quantity is categorized in chronological order and displayed in a bar graph. The horizontal axis is the date (unit time if the period is one day), and the vertical axis is the number of defects. -

Page 83: Change History

Change history Edition Date Target Contents number version Aug 2023 1.8.4 First edition Oct 2023 1.8.5 Added 1-2-10 Automatic switching dashboard settings. Jan 2024 1.9.1 I-2. Setting the Random Inspection function: Added automatic switching dashboard settings and creation of defective process list. I-2-6-2. - Page 84 Newly added. 5.) I-2-10. Marker settings. Newly added. 6.) I-2-11. Defective process list creation. Added "Note 1) If JaNets JT Simple "Line and Layout Settings" has not been created, this function cannot be created." 7.) I-2-12. Add a Defect group.

Need help?

Do you have a question about the JT Simple and is the answer not in the manual?

Questions and answers