Summary of Contents for ESAB Aristo Edge 500R

- Page 1 Aristo Edge 500R Instruction manual Valid for: Serial number: OP321YY-XXXXXX 0448 134 001 GB 20240710...

-

Page 3: Table Of Contents

5.2.1 Connecting the FieldBus module ........................Flow guard ................. Turning the mains power on/off ......................ESAB Connect .................. 5.5.1 Setting up ESAB gateway .................. 5.5.2 Setting up ESAB Connect ...................... Setting up network ................5.6.1 Connecting to wired network ................ - Page 4 ........................ TROUBLESHOOTING ....................... ORDERING SPARE PARTS ..................... CALIBRATION AND VALIDATION ..............11.1 Measurement methods and tolerances ............11.2 Requirements, specifications and standards ..........................BLOCK DIAGRAM ......................... ORDERING NUMBERS ............................. ACCESSORIES 0448 134 001 - 4 - © ESAB AB 2024...

-

Page 5: Safety

Sheets (SDSs). Safety precautions Users of ESAB equipment have the ultimate responsibility for ensuring that anyone who works on or near the equipment observes all the relevant safety precautions. Safety precautions must meet the requirements that apply to this type of equipment. The following recommendations should be observed in addition to the standard regulations that apply to the workplace. - Page 6 If equipped with ESAB cooler Use ESAB approved coolant only. Non-approved coolant might damage the equipment and jeopardize product safety. In case of such damage, all warranty undertakings from ESAB cease to apply. For ordering information, see the "ACCESSORIES" chapter in the instruction manual.

- Page 7 For further information contact the nearest ESAB dealer. ESAB has an assortment of welding accessories and personal protection equipment for purchase. For ordering information contact your local ESAB dealer or visit us on our website. 0448 134 001 - 7 -...

-

Page 8: Introduction

For more information about the wire feed units, refer to the feeder instruction manual. ESAB accessories for the product can be found in the "ACCESSORIES" chapter of this manual. Equipment The power source is supplied with: •... -

Page 9: Technical Data

-40 to +80 °C temperature Constant sound <70 db (A) pressure when idling Dimensions l × w × h 700 × 325 × 680 mm Weight 85 kg (including cooler) 0448 134 001 - 9 - © ESAB AB 2024... - Page 10 3 TECHNICAL DATA Aristo Edge 500R Insulation class Enclosure class IP 23 Application class Coolant ESAB's coolant (0465 720 002) Cooling power 1.4 kW Cooling volume 4.7 l Maximum flow 2 l/min Maximum pressure 4.5 bar Mains supply, S sc min Minimum short circuit power on the network in accordance with IEC 61000-3-12.

-

Page 11: Installation

It is the user's responsibility to take adequate precautions. Location Position the power source so that cooling air inlets and outlets are not obstructed. A. Minimum 300 mm B. Minimum 300 mm C. Minimum 300 mm 0448 134 001 - 11 - © ESAB AB 2024... -

Page 12: Assemblying The Foot Brackets

4 INSTALLATION Assemblying the foot brackets 1) Remove M6 screw and foot with a 5mm allen key. 0448 134 001 - 12 - © ESAB AB 2024... - Page 13 4 INSTALLATION 2) Insert foot bracket between the power source and the foot. 3) Tighten the screw. 0448 134 001 - 13 - © ESAB AB 2024...

-

Page 14: Lifting Instructions

S . Refer to the technical data in the scmin TECHNICAL DATA chapter. 0448 134 001 - 14 - © ESAB AB 2024... -

Page 15: Recommended Fuse Sizes And Minimum Cable Area

Wait until the DC bus capacitors are discharged. The DC bus capacitor discharge time is at least two minutes! WARNING! This operation must be done by a person who has the appropriate electrical knowledge. 0448 134 001 - 15 - © ESAB AB 2024... - Page 16 2) If the mains cable needs to be changed, the earth connection to the bottom plate and the ferrites must be installed correctly. See the following image for the installation order of the ferrites, washers, nuts, and screws. 0448 134 001 - 16 - © ESAB AB 2024...

- Page 17 4 INSTALLATION Connections Cable colour (CE) Brown Black Grey Yellow/Green 0448 134 001 - 17 - © ESAB AB 2024...

-

Page 18: Operation

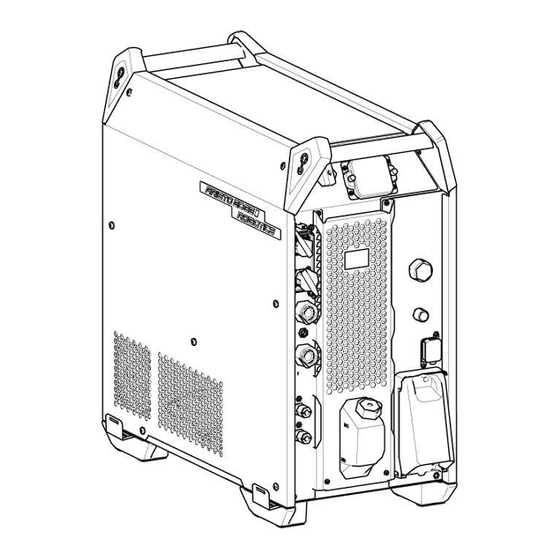

8. Connection BLUE for coolant from cooling unit 17. Mains cable 9. Coolant tank FieldBus module connector The FieldBus module provides communication between the power source and the robot controller. ESAB offers seven different FieldBus connectors: 0448 134 001 - 18 - © ESAB AB 2024... -

Page 19: Connecting The Fieldbus Module

Connecting the FieldBus module 1) Insert the FieldBus module into the slot until it goes freely. 2) When the module is obstructed, gently press. 3) Push the module further. 4) Tighten the screws. 0448 134 001 - 19 - © ESAB AB 2024... -

Page 20: Flow Guard

To achieve a proper restart, wait at least 30 seconds after turning off the main power supply switch. ESAB Connect ESAB Connect is a web-based welding user interface intended for automation and robotic application. ESAB Connect enables the following options: •... - Page 21 4) Enter a new password, at least 6 characters long, and then select on Save new password. NOTE! This password is applicable only for gateway page and not for the ESAB Connect. For instructions on how to set the ESAB Connect password, refer to "Setting up ESAB Connect"...

-

Page 22: Setting Up Esab Connect

5 OPERATION 5.5.2 Setting up ESAB Connect 1) Go to Settings » User settings. 2) Turn on the Enable ESAB Connect option. 3) Open the web browser and go to esab.local. 0448 134 001 - 22 - © ESAB AB 2024... - Page 23 5 OPERATION 4) Enter a password and select Save. 5) ESAB Connect displays the rename power source screen. 6) Confirm screen appears as the power source name is saved. Select PowerSourceName.local to login to ESAB Connect. 0448 134 001 - 23 - ©...

-

Page 24: Setting Up Network

2) Log in with your ESAB gateway credentials. 3) Setup the network in any of the following ways: • PC with Ethernet cable connection (see, Section 5.5.1 "Setting up ESAB gateway", page 20) • Wired network •... -

Page 25: Connecting To Wireless Network

3) Select Save changes 5.6.2 Connecting to wireless network Requirements • Wi-Fi dongle with ordering number 0349 313 618, or alternatives such as the ASUS AC51 or the TP-Link WN725N 0448 134 001 - 25 - © ESAB AB 2024... - Page 26 1) Open the USB cover on the front of the power source. 2) Connect the Wi-Fi dongle on the power source. 3) Go to Configuration » Network configuration » Wi-Fi. 4) Choose and enter your network's:Name (SSID) and Password. 0448 134 001 - 26 - © ESAB AB 2024...

-

Page 27: Configuring Hotspot Network

Recommended maximum current values for connection set cables At an ambient temperature of +25 °C and normal 10 minutes cycle: Duty cycle Cable area Voltage loss / 10 m 100% 0448 134 001 - 27 - © ESAB AB 2024... -

Page 28: Symbols

When liquid cooled torch is connected, if the coolant temperature exceeds 45 °C, the cooler fan and pump will start even if there is no welding operation. NOTE! For the Non ESAB torches cooling unit operations, select Forced mode in the ESAB Connect. 5.11 Operation of cooling unit after welding If the coolant temperature is below 55 °C, the cooler fan and pump will continue to run for three... -

Page 29: Cooling Unit Connection

1. IoT Gateway USB port 1 3. USB port 3, enables the user to upgrade the software and to export the error log and export jobs. 2. IoT Gateway USB port 2 0448 134 001 - 29 - © ESAB AB 2024... -

Page 30: Control Panel

2. Display, shows set or measured current 5. Application selection knob 3. Display, shows set or measured voltage/dynamics NOTE! The knobs will not have any selection function if FieldBus module is inserted. 0448 134 001 - 30 - © ESAB AB 2024... -

Page 31: Led Indicators Description

To achieve a good welding result, the arc voltage is a crucial factor. In MIG/MAG welding, the power source is prepared to sense the arc voltage in the wire feeder. Prerequisite for this functionality is that an ESAB wire feeder and an ESAB interconnection cable is used. -

Page 32: Setting Range For Manual And Synergic

Crater fill wire feed speed % 0–100 End method SCT/Burnback SCT (Burnback for core wires) Burnback time 0.01 0.00–0.50 0.06 Burnback pinch-off pulse % 1–200 Job limits ON/OFF Depends on the selected synergic line. 0448 134 001 - 32 - © ESAB AB 2024... -

Page 33: Setting Range For Pulse

31–1378 Estimated amperage Dependent on WFS value l/min 5.0–35.0 Gas flow 11–74 Arc dynamics -9 – +9 Hot start ON/OFF Hot start time 0.0–10 Hot start V -9.9 – +9.9 0448 134 001 - 33 - © ESAB AB 2024... -

Page 34: Setting Range For Root - Pipe And Thin

-9.9 – +9.9 Crater fill wire feed speed % 0–100 Crater fill arc length offset -9.9 – +9.9 End method SCT/Burnback SCT (Burnback for core wires) Burnback time 0.01 0.00–0.50 0.06 0448 134 001 - 34 - © ESAB AB 2024... -

Page 35: Function Explanations For Settings

MIG/MAG manual, voltage offset for Synergy, and arc length offset for Pulse respectively. Post-flow This controls the time during which shielding gas flows after the arc is extinguished. 0448 134 001 - 35 - © ESAB AB 2024... - Page 36 Too long a burnback time results in a shorter stick out, with increased risk of the arc striking back to the contact tip. 0448 134 001 - 36 - © ESAB AB 2024...

-

Page 37: Maintenance

Clean weld terminals. Check the cables. unreadable labels. Every 12 months or depending on environmental conditions (by authorised service Clean inside technician) equipment. Use dry compressed air with maximum 4 bar pressure. 0448 134 001 - 37 - © ESAB AB 2024... -

Page 38: Cleaning The Power Source

4) Remove the plastic cover between the heat sink and fan. 5) Clean the power source with dry compressed air (maximum 4 bar) as follows: • The upper rear part • From the rear panel through the secondary heat sink 0448 134 001 - 38 - © ESAB AB 2024... -

Page 39: Cooling Unit

Flushing can only be performed via red coolant connection. Then drain the tank manually, i.e. empty via the tank's filling hole. 7.4.1 Filling the coolant Use only ESAB's ready mixed coolant. See chapter "ACCESSORIES". CAUTION! The coolant must be handled as chemical waste. CAUTION! Make sure that the FieldBus module is covered while filling the coolant. - Page 40 7 MAINTENANCE 1) Fill with coolant. The fluid level must not exceed the upper marking, but neither must it be below lower marking. 0448 134 001 - 40 - © ESAB AB 2024...

-

Page 41: Event Codes

This event code is displayed due to one of the following: • 205 - Mains over/under voltage or phase error. Make sure that the supply voltage is stable. Restart the system. 0448 134 001 - 41 - © ESAB AB 2024... -

Page 42: Temperature Fault

Contact authorised person to check the main inputs. Wire feed speed fault This event code is displayed due to one of the following: • 311 - Wire saturation warning/error. • 311 - Wire motor start/work current error. 0448 134 001 - 42 - © ESAB AB 2024... -

Page 43: Communication Fault

In case of voltage sensor lost, contact service technician. Otherwise restart the system. Lost contact with another unit This event code is displayed due to one of the following: • 017 - Mandatory node missing. 0448 134 001 - 43 - © ESAB AB 2024... -

Page 44: Internal Memory Fault

025 - System communication version mismatch warning/error. • 025 - Power converter control module version not valid. • 025 - Power converter control module power capacity unknown. Contact service technician. 0448 134 001 - 44 - © ESAB AB 2024... -

Page 45: Timing Fault

Contact service technician. Gas flow fault This event code is displayed due to one of the following: • 632 - Gas saturation warning/error. • 632 - No gas out error. 0448 134 001 - 45 - © ESAB AB 2024... -

Page 46: Usb Fault

035 - Message allocation error. • 035 - Driver message allocation error. • 035 - Event queue overflow. • 035 - Failed to start microservices. Restart the system. Contact service technician. 0448 134 001 - 46 - © ESAB AB 2024... -

Page 47: Troubleshooting

Poor cooling effect Clean the cooling element using compressed air. Check the coolant level. Check that the ambient temperature is not above the one for the rated duty cycle 40 °C/104 °F. 0448 134 001 - 47 - © ESAB AB 2024... -

Page 48: Ordering Spare Parts

Spare parts and wear parts can be ordered through your nearest ESAB dealer, see esab.com. When ordering, please state product type, serial number, designation and spare part number in accordance with the spare parts list. -

Page 49: Calibration And Validation

The ESAB Aristo Edge 500R welding power source presents the measured value in rectified arithmetic mean and should therefore not show any significant differences compared to other ESAB welding equipment, due to the measurement method. 11.2... -

Page 50: Block Diagram

APPENDIX APPENDIX BLOCK DIAGRAM 0448 134 001 - 50 - © ESAB AB 2024... -

Page 51: Ordering Numbers

* here. Make sure to use a manual with a serial number or software version that corresponds with the product, see the front page of the manual. Technical documentation is available on the Internet at: www.esab.com 0448 134 001 - 51 - © ESAB AB 2024... -

Page 52: Accessories

0447 533 007 Profinet for FieldBus module 0465 720 002 ESAB ready mixed coolant (10 l / 2.64 gal) Use of any other cooling liquid than the prescribed one might damage the equipment. In case of such damage, all warranty undertakings from ESAB cease to apply. - Page 53 I/O connector kit For assembly instruction, refer to document – 0447 635 001 0349 313 450 Trolley, compatible with RobustFeed Edge and Aristo Edge 500R 0446 600 880 RobustFeed Edge BX with EURO connector, torch cooling system and NFC 0446 600 881...

- Page 54 3.6 m (12 ft) 0446 504 881 5 m (16 ft) Intermediate cable, liquid cooled, 120 mm 0446 504 890 3.6 m (12 ft) 0446 504 891 5 m (16 ft) 0448 134 001 - 54 - © ESAB AB 2024...

- Page 55 APPENDIX 0448 134 001 - 55 - © ESAB AB 2024...

- Page 56 For contact information visit http://esab.com ESAB AB, Lindholmsallén 9, Box 8004, 402 77 Gothenburg, Sweden, Phone +46 (0) 31 50 90 00 manuals.esab.com...

Need help?

Do you have a question about the Aristo Edge 500R and is the answer not in the manual?

Questions and answers