Table of Contents

Advertisement

Quick Links

1.

GENERAL INTRODUCTION ................................................... 1

1.1. Document Purpose ............................................................... 1

1.2. Product Purpose ................................................................... 1

1.3. Product Mounting and Location ............................................ 1

2.

PRODUCT DESCRIPTION ....................................................... 2

3.

INSTALLATION ........................................................................ 4

3.1. Inspecting the Product .......................................................... 4

3.2. Following and Using Safety Precautions................................ 4

3.3. Obtaining Tools and Equipment ............................................ 4

3.4. Preparing the Installation Site ............................................... 4

3.5. Lifting the CUBE .................................................................. 5

3.6. Mounting the CUBE ............................................................. 5

3.8. CUBE Wiring and Equipment................................................ 7

3.9. Conduit Seals ..................................................................... 12

3.10. Verifying the Installation ..................................................... 12

4.

PERIODIC MAINTENANCE .................................................. 12

5.

TECHNICAL ASSISTANCE AND REPAIR SERVICE .......... 12

6.

WARRANTY & CUSTOMER SERVICE ................................. 12

7.

SPECIFICATIONS ................................................................... 13

7.1. Regulatory Specifications .................................................... 13

7.2. Product Specifications ........................................................ 13

1. GENERAL INTRODUCTION

1.1. Document Purpose

This document provides general information for the CUBE-SC21632xxx series of the Charles Industries' Universal Broadband Enclosure

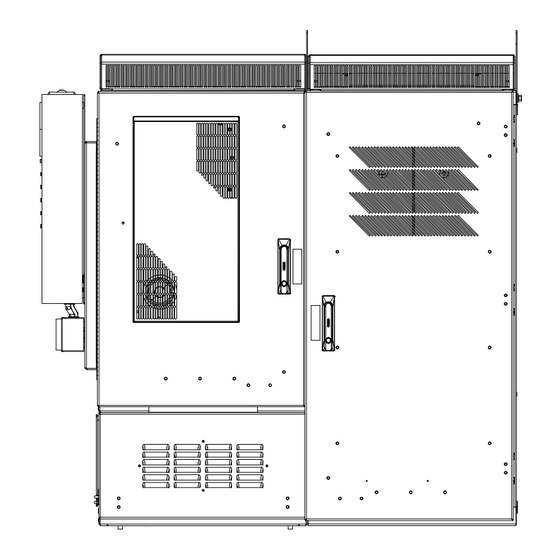

(CUBE) product line. Figure 1 shows a closed front view of the enclosure.

Hereafter, the Charles Universal Broadband Enclosure CUBE-SC21632xxx will be referred to by individual part number or as the "CUBE."

1.2. Product Purpose

This high power, small cell CUBE consists of a protective enclosure for an integrated system of electronic components and equipment.

1.3. Product Mounting and Location

This enclosure is suitable for outside plant-type (OSP) locations and those that may require NEC compliance. The outdoor, weather-

resistant CUBE is to be mounted on a pad. The installer connects the power, fiber, and copper connections. Detailed mounting and

installation information is covered in Section 3. Charles recommends the CPAD composite pad for pad mounting applications.

©Copyright 2024 Charles Industries LLC. All rights reserved.

Availability of features and technical specifications herein are subject to change without notice.

Charles is a registered trademark of Charles Industries.

Charles Universal Broadband Enclosure

CUBE-SC21632xxx Series

General Description and Installation

Figure 1

-NOTE-

LT-SC21632XXX

8

th

Printing, February 27, 2024

Front View of the CUBE

Page 1 of 13

Advertisement

Table of Contents

Summary of Contents for Amphenol Charles CUBE-SC21632 Series

-

Page 1: Table Of Contents

LT-SC21632XXX Printing, February 27, 2024 Charles Universal Broadband Enclosure CUBE-SC21632xxx Series General Description and Installation GENERAL INTRODUCTION ........... 1 1.1. Document Purpose ............... 1 1.2. Product Purpose ..............1 1.3. Product Mounting and Location ..........1 PRODUCT DESCRIPTION ............2 INSTALLATION ................ -

Page 2: Product Description

LT-SC21632XXX 2. PRODUCT DESCRIPTION The CUBE has radio, equipment, and battery compartments. The equipment compartment has 16RU of 19” horizontal rack spacing, a 14- position AC load center with a 50A generator inlet switch. The battery compartments in all CUBEs in the series support one string of customer supplied 48VDC NiCd batteries. - Page 3 LT-SC21632XXX DOOR ALARM SWITCH EQUIPMENT (2) LIFTING HOISTS COMPARTMENT 16RU, 19" HORIZONTAL RACK MOUNT WITH EIA HOLE SPACING RADIO COMPARTMENT GFCI OUTLET AC SURGE SUPPRESSOR 2X8 POSITION 3PT LATCH GROUND BAR 216 STYLE PADLOCKABLE WIND LATCH SWING HANDLE (BOTH DOORS) (BOTH DOORS) BATTERY RETAINING BRACKET REMO VABLE COVER PANEL...

-

Page 4: Installation

LT-SC21632XXX 3. INSTALLATION 3.1. Inspecting the Product The CUBE is shipped mounted upright on a skid. Remove the bolts, unpack the unit, and dispose of the packaging material. -INSPECTION NOTE- Visually inspect the unit for damages prior to installation. If the equipment was damaged in transit, immediately report the extent of the damage to the transportation company. -

Page 5: Lifting The Cube

LT-SC21632XXX 3.5. Lifting the CUBE See Table 1 for CUBE weight. Charles recommends the following procedure for lifting the CUBE. SPREADER BAR 3.5.1. Required Equipment SHORT SLINGS/CHAINS One derrick (crane) capable of lifting the CUBE • Spreader bar • Two lifting slings or chains with each having a 2,500 lbs. capacity •... - Page 6 LT-SC21632XXX 3.6.2. Constructing a New Pad 7.75 8.00 10.00 20.25 Use only concrete for new pad construction. Do not use substitute materials • since they lack the rigidity for CUBE placement. • Observe local building practices for pad construction. Charles recommends that the pad should extend a minimum of 8”...

-

Page 7: Cube Wiring And Equipment

LT-SC21632XXX 3.8. CUBE Wiring and Equipment After the CUBE is properly mounted in the desired location, apply No-Ox where bus bar and other 2-hole lug connections will be made. Install ground and power connections. Always ground the equipment first, before making any other connections. WARNING Perform all bonding and grounding connections prior to any electrical and communications connections. - Page 8 LT-SC21632XXX CO Reference Use only GE approved Ground (BK) circuit breakers Bulk -48VDC Distribution Output Door (Power System) Switch Lights Anderson Connector Battery Alarm Door switches Block Cables Chass is Surge All alarms are normally closed and open upon alarm W/GN -48VDC Overheat...

- Page 9 LT-SC21632XXX CO Reference Use only GE approved Ground (BK) circuit breakers Bulk -48VDC Distribution Output Door (Power System) Switch Lights Anderson Connector Battery Alarm Door switches Block Cables Chass is Surge All alarms are normally closed and open upon alarm W/GN -48VDC Overheat...

-

Page 10: Ground Connection

LT-SC21632XXX 3.8.1. Ground Connection Use the 2x8 position ground bars provided in the equipment and radio compartments for NUTS all grounding of internal equipment. Stack hardware as shown in Figure 10. External BELLEVILLE WASHERS ground lugs are available on the sides of the battery compartment for connecting a site FLAT WASHERS ground wire. -

Page 11: Radio Mounting

LT-SC21632XXX 3.8.5. HVAC Operation (JP1/JP2 Only) The 4000BTU AC powered HVAC is driven by a built-in controller and temperature sensor. The factory cooling cycle turns on at 30 C and ° off at 27 C. The heating cycle turns on at 10 C and turns off at 15 C. -

Page 12: Conduit Seals

LT-SC21632XXX • Three 1/2” plugged conduit holes Equipment to radio compartment • One 1” cord grip fitting Two 1/2” cord grip fittings • Two 1” plugs • Four 1/2” plugs between equipment and radio compartment • 3.9. Conduit Seals All internal and external conduit openings on the CUBE must be completely sealed with a duct seal compound to prevent moisture from entering the equipment compartment. -

Page 13: Specifications

LT-SC21632XXX 7. SPECIFICATIONS 7.1. Regulatory Specifications • Designed to meet GR-487 GFCI: UL-943 Listed • If CUBEs are field-modified, a customer provided ETL field evaluation of the modified components may be required to re-establish ETL certification to UL standards. Consult local jurisdictions for guidance on a site-by-site basis. 7.2.

Need help?

Do you have a question about the Charles CUBE-SC21632 Series and is the answer not in the manual?

Questions and answers