Jasic TIG Series Operator's Manual

Hide thumbs

Also See for TIG Series:

- Operator's manual (54 pages) ,

- Assembly instructions manual (8 pages) ,

- Operator's manual (20 pages)

Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Jasic TIG Series

-

Page 2: Your New Product

Please ensure that you carry out daily and periodic maintenance checks to ensure years of reliable and trouble free operation. Please call your Jasic distributor in the unlikely event of a problem occurring. Please record below the details from your product as these will be required for warranty purposes and to ensure you get the correct information should you require assistance or spare parts. -

Page 3: Table Of Contents

Guide to AC TIG Welding TIG Welding Torch TIG Welding Problems Maintenance Service Schedule Record Troubleshooting WEEE Disposal RoHS Compliance Declaration UKCA Declaration of Conformity EC Declaration of Conformity Statement of Warranty Options and Accessories Schematics Notes Jasic Contact Details... -

Page 4: Safety Instructions

SAFETY INSTRUCTIONS These general safety norms cover both arc welding machines and plasma cutting machines unless otherwise noted. It is important that users of this equipment protect themselves and others from harm or even death. The equipment must only be used for the purpose it was designed for. Using it in any other way could result in damage or injury and in breach of the safety rules. -

Page 5: Welding Processes Lens Shade Selector Guide

SAFETY INSTRUCTIONS Use of Personal Protective Equipment (PPE) Welding arc rays from all welding processes produce intense, visible and invisible (ultraviolet and infrared) rays that can burn eyes and skin. • Wear an approved welding helmet fitted with an appropriate shade of filter lens to protect your face and eyes when welding or watching. -

Page 6: Fume And Welding Gases

SAFETY INSTRUCTIONS Safety against fumes and welding gases The HSE have identified welders as being an ‘at risk’ group for occupational diseases arising from exposure to dusts, gases, vapours and welding fumes. The main identified health effects are pneumonia, asthma, chronic obstructive pulmonary disease (COPD), lung and kidney cancer, metal fume fever (MFF) and lung function changes. -

Page 7: The Working Environment

SAFETY INSTRUCTIONS The working environment Ensure the machine is mounted in a safe and stable position allowing for cooling air circulation. Do not operate equipment in an environment outside the laid down operating parameters. The welding power source is not suitable for use in rain or snow. Always store the machine in a clean, dry space. -

Page 8: Rf Declaration

SAFETY INSTRUCTIONS RF Declaration Equipment that complies with directive 2014/30/EU concerning electromagnetic compatibility (EMC) and the technical requirements of EN60974-10 is designed for use in industrial buildings and not those for domestic use where electricity is provided via the low voltage public distribution system. Difficulties may arise in assuring class A electromagnetic compatibility for systems installed in domestic locations due to conducted and radiated emissions. -

Page 9: Product Overview

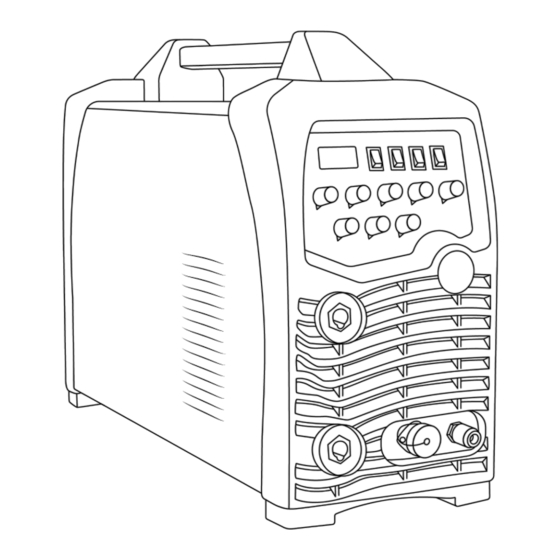

PRODUCT OVERVIEW The Jasic TIG inverter range of welding machines have been designed as integrated and portable welding power supply units incorporating the most advanced IGBT inverter technology in power electronics with easy operation and adjustment due to a friendly user interface. -

Page 10: Technical Specifications

TECHNICAL SPECIFICATIONS Technical Parameter Unit TIG 202A Analog AC/DC Rated input voltage 1ph 230V AC 50/60Hz Input current Ieff TIG Input current Ieff MMA I Max TIG I Max MMA Input power Welding current range - TIG (AC / DC) DC 5 ~ 200 / AC 5 ~ 200 Welding current range - MMA (AC / DC) DC 10 ~ 160 / AC 10 ~ 160... -

Page 11: Description Of Controls

CONTROLS Front view Jasic TIG 202A AC/DC Pulse 1. Digital control panel: See page 12 for an enhanced detailed explanation of the controls 2. "+" Output terminal: To connect the work clamp in TIG mode or the electrode holder in MMA mode 3. - Page 12 CONTROLS Control panel view Jasic TIG 202A AC/DC Analog 1. Welding voltage output selection: Using this switch will select either DC or AC output voltage when in MMA or TIG welding mode depending on your requirements. 2. Remote control selection: Pressing this switch will set current control from the panel or to a remote device such as a foot pedal.

- Page 13 CONTROLS Control panel view Jasic TIG 202A AC/DC Analog—continued 9. Welding current adjustment (peak current when in pulse mode). Adjustment range is 10 ~ 200. 10. AC Frequency control: Allows the user to adjust the AC frequency setting by rotating this control dial.

-

Page 14: Installation

INSTALLATION Unpacking Check the packaging for any signs of damage. Carefully remove the machine and retain the packaging until the installation is complete. Location The machine should be located in a suitable position and environment. Care should be taken to avoid moisture, dust, steam, oil or corrosive gases. - Page 15 INSTALLATION MMA welding Insert the cable plug for the electrode holder into the “+” socket on the front panel of the welding machine and tighten it clockwise. Insert the cable plug for the work return lead into the “-” socket on the front panel of the welding machine and tighten it clockwise.

- Page 16 Please Note: This kit is used for other machine packages, you may note that extra screws are supplied and as a result there may be some screws left over once you have fully assembled the trolley package. For the following instructions we have used the Jasic JT-315 ACDC Multi Wave TIG power source and cooler as shown below.

- Page 17 INSTALLATION WATER COOLED TIG TROLLEY PACKAGE CONTENTS The below shows the main contents of the TIG trolley assembly kit. Various sundry items (required for assembly) Base unit (item 1) including assembled wheels Upright Cylinder Support (item 3) Side fixing brackets (item 4) Top shelf (item 2) also showing circled top shelf brackets...

- Page 18 INSTALLATION WATER COOLED TIG TROLLEY PACKAGE ASSEMBLY 1 Place the base unit on a flat surface, locate the Locate the cooler base brackets (circled cylinder support (Item 3) and use M10 screws (A) yellow) which secures the water cooler to to fix the cylinder support to the base unit (item1).

- Page 19 INSTALLATION WATER COOLED TIG TROLLEY PACKAGE ASSEMBLY 5 Fit the two side brackets (item 4) to the water Fit the TIG wire ‘cup’ (item 5) to the base cooler as shown below. using the supplied 3 screws (C) 7 Remove the bottom side front and rear screws either side of the power source (the middle screw may not be required to be removed) and mount the power source on top of the water cooler lining up the holes of the bracket.

- Page 20 INSTALLATION WATER COOLED TIG TROLLEY PACKAGE ASSEMBLY 8 Remove the top brackets shown with item 2 9 Mount the top shelf (item 2) on top of the and fit to the top of the power source as shown fitted brackets and use the screws removed below.

-

Page 21: Operation Mma

OPERATION - MMA Before starting any welding activity ensure that you have suitable eye protection and protective clothing. Also take the necessary steps to protect any persons within the welding area. The Process MMA (Manual Metal Arc), SMAW (Shielded Metal Arc Welding) or just Stick Welding. The manual metal arc process was first developed in Russia in 1888 and comprised a bare metal welding rod. - Page 22 OPERATION - MMA Before starting any welding activity ensure that you have suitable eye protection and protective clothing. Also take the necessary steps to protect any persons within the welding area. The Process The shape of the characteristic allowed the operator to control heat input and weld bead shape by electrode manipulation.

- Page 23 OPERATION - MMA Before starting any welding activity ensure that you have suitable eye protection and protective clothing. Also take the necessary steps to protect any persons within the welding area. MMA operation steps After connecting the MMA welding leads as detailed on page 15 you will need to turn the power switch of the machine to the “ON”...

- Page 24 OPERATION - MMA Before starting any welding activity ensure that you have suitable eye protection and protective clothing. Also take the necessary steps to protect any persons within the welding area. MMA welding Current and Voltage Changes in DC MMA Current and Voltage Changes in AC MMA Note: t0 - Standby section, no welding current, output no-load voltage...

- Page 25 OPERATION - MMA Before starting any welding activity ensure that you have suitable eye protection and protective clothing. Also take the necessary steps to protect any persons within the welding area. MMA welding Arc force Arc force refers to the slope of the current rise during a short circuit and it is set to increase the current every millisecond on this machine.

-

Page 26: Guide To Mma Welding

GUIDE TO MMA WELDING Before starting any welding activity ensure that you have suitable eye protection and protective clothing. Also take the necessary steps to protect any persons within the welding area. Notes for the welding beginner This section is designed to give the beginner who has not yet done any welding some information to get them going. - Page 27 GUIDE TO MMA WELDING Before starting any welding activity ensure that you have suitable eye protection and protective clothing. Also take the necessary steps to protect any persons within the welding area. MMA process tips and guides Typical welder set up 1.

- Page 28 GUIDE TO MMA WELDING Before starting any welding activity ensure that you have suitable eye protection and protective clothing. Also take the necessary steps to protect any persons within the welding area. MMA arc striking Tap technique - Lift the electrode upright and bring it down to strike the work piece. After forming a short circuit, quickly lift up about 2~4mm and arc will be ignited.

- Page 29 GUIDE TO MMA WELDING Before starting any welding activity ensure that you have suitable eye protection and protective clothing. Also take the necessary steps to protect any persons within the welding area. Fillet welding The electrode should be positioned to split the angle i.e. 45°. Again, the electrode should be inclined in the direction of travel at around 10°-30°.

-

Page 30: Mma Welding Problems

MMA WELDING PROBLEMS Before starting any welding activity ensure that you have suitable eye protection and protective clothing. Also take the necessary steps to protect any persons within the welding area. Arc welding defects and prevention methods Defect Possible cause Action Excessive spatter (beads of metal Amperage too high for the... -

Page 31: Operation Dc Tig

OPERATION - DC TIG Before starting any welding activity ensure that you have suitable eye protection and protective clothing. Also take the necessary steps to protect any persons within the welding area. TIG welding Terms used: TIG – Tungsten Inert Gas, GTAW – Gas Tungsten Arc Welding. TIG welding is an arc welding process that uses a non-consumable tungsten electrode to produce the heat for welding. - Page 32 OPERATION - DC TIG Before starting any welding activity ensure that you have suitable eye protection and protective clothing. Also take the necessary steps to protect any persons within the welding area. TIG DC operation steps • Select TIG by pressing the TIG/MMA switch •...

- Page 33 OPERATION - DC TIG Before starting any welding activity ensure that you have suitable eye protection and protective clothing. Also take the necessary steps to protect any persons within the welding area. TIG DC pulse operation steps • Select TIG by pressing the TIG/MMA switch •...

- Page 34 OPERATION - DC TIG Before starting any welding activity ensure that you have suitable eye protection and protective clothing. Also take the necessary steps to protect any persons within the welding area. TIG DC pulse operation steps After the parameters are set appropriately, open the gas valve of the cylinder and adjust the gas regulator to the desired flow rate.

-

Page 35: Operation Ac Tig

OPERATION - AC TIG Before starting any welding activity ensure that you have suitable eye protection and protective clothing. Also take the necessary steps to protect any persons within the welding area. TIG AC operation steps • Select TIG by pressing the TIG/MMA switch •... - Page 36 OPERATION - AC TIG Before starting any welding activity ensure that you have suitable eye protection and protective clothing. Also take the necessary steps to protect any persons within the welding area. TIG AC pulse operation steps • Select TIG by pressing the TIG/MMA switch •...

- Page 37 OPERATION - AC TIG Before starting any welding activity ensure that you have suitable eye protection and protective clothing. Also take the necessary steps to protect any persons within the welding area. TIG AC pulse operation steps After the parameters are set appropriately, open the gas valve of the cylinder and adjust the gas regulator to the desired flow rate.

-

Page 38: Tig Torch Trigger Modes

TIG TORCH TRIGGER MODES Before starting any welding activity ensure that you have suitable eye protection and protective clothing. Also take the necessary steps to protect any persons within the welding area. Torch trigger operation modes Torch trigger mode options is easily accessed by pressing the 2T/4T selection switch as shown right . To access either 2T or 4T trigger modes, you need to switch between MMA and TIG which will engage the 2T trigger mode, by switching again to MMA then back to TIG you will be in 4T trigger mode, this is noted by either 2T or 4T being shown in the... -

Page 39: Remote Control Socket

REMOTE CONTROL SOCKET Before starting any welding activity ensure that you have suitable eye protection and protective clothing. Also take the necessary steps to protect any persons within the welding area. Remote control socket • The 9 pin remote control socket located on the front panel is used to connect a TIG torch trigger switch and/or torch mounted current adjustment dial •... -

Page 40: Guide To Tig Welding

GUIDE TO TIG WELDING Before starting any welding activity ensure that you have suitable eye protection and protective clothing. Also take the necessary steps to protect any persons within the welding area. TIG torch body and components The torch body holds the various welding consumables in place as shown and is covered by either a rigid phenolic or rubberised covering. - Page 41 GUIDE TO TIG WELDING Before starting any welding activity ensure that you have suitable eye protection and protective clothing. Also take the necessary steps to protect any persons within the welding area. TIG welding electrodes TIG welding electrodes are a ‘non consumable’ as it is not melted into the weld pool and great care should be taken not to let the electrode contact the welding pool to avoid weld contamination.

- Page 42 The TIG process can use both non contact and contact methods to provide arc starting. Depending on the Jasic model, the options are indicated on a selector switch on the front control panel of the power source. The most common method of arc starting is ‘HF’ start. This term is often used for a variety of starting methods and covers many different types of start.

- Page 43 GUIDE TO TIG WELDING Before starting any welding activity ensure that you have suitable eye protection and protective clothing. Also take the necessary steps to protect any persons within the welding area. Arc starting - lift TIG (lift arc) Not to be confused with scratch start, this arc starting method allows the tungsten to be in direct contact with the work piece first but with minimal current so as not to leave a tungsten deposit when the tungsten is lifted and an arc is established.

-

Page 44: Guide To Dc Tig Welding

The Jasic TIG series polarity should generally be set up for Direct Current - Electrode Negative (DCEN) as this method of welding can be used for a wide range of materials. - Page 45 GUIDE TO DC TIG WELDING Before starting any welding activity ensure that you have suitable eye protection and protective clothing. Also take the necessary steps to protect any persons within the welding area. Manual DC TIG Welding Amperage Guide- Mild Steel and Stainless Steel Base Metal Base Metal Tungsten...

-

Page 46: Guide To Ac Tig Welding

DC welding when the current flows in one direction only. The Jasic TIG series polarity should generally be set up like Direct Current - Electrode Negative (DCEN) as this method of welding can be used for a wide range of materials. - Page 47 GUIDE TO AC TIG WELDING Before starting any welding activity ensure that you have suitable eye protection and protective clothing. Also take the necessary steps to protect any persons within the welding area. Manual AC TIG Welding Amperage Guide - Aluminium Material Base Metal Base Metal Tungsten...

- Page 48 GUIDE TO AC TIG WELDING Before starting any welding activity ensure that you have suitable eye protection and protective clothing. Also take the necessary steps to protect any persons within the welding area. AC TIG welding square wave With the electronic development of inverter power sources, the square wave machine was developed. Due to these electronic controls the cross over from positive to negative and vice versa can be made almost in an instant which leads to more effective current in each half cycle due to a longer period at maximum.

- Page 49 GUIDE TO AC TIG WELDING Before starting any welding activity ensure that you have suitable eye protection and protective clothing. Also take the necessary steps to protect any persons within the welding area. AC pulsed TIG welding Tc - Cathode current time Tp - AC period Tp - Pulsed peak current time T - Pulse period...

- Page 50 GUIDE TO AC TIG WELDING Before starting any welding activity ensure that you have suitable eye protection and protective clothing. Also take the necessary steps to protect any persons within the welding area. AC Wave balance or cleaning control When welding materials with a refractory oxide surface such as aluminium this oxide needs to be removed to allow welding of the base material.

-

Page 51: Tig Welding Torch

TIG TORCH SPARE PARTS LIST TIG Welding Torch Air Cooled - Model TIG-79ERGO Rating 200A DC, 150A AC @ 60% Duty Cycle EN60974-7 • 0.5mm to 4.0mm Electrodes 9 PIN Torch plug Pt No - JSG-PLUG-9PIN PLEASE NOTE: Check the torch supplied with your package to ensure it matches the above details... -

Page 52: Tig Welding Problems

TIG WELDING PROBLEMS Before starting any welding activity ensure that you have suitable eye protection and protective clothing. Also take the necessary steps to protect any persons within the welding area. TIG welding defects and prevention methods Defect Possible cause Action Excessive tungsten use Set up for DCEP... - Page 53 TIG WELDING PROBLEMS Before starting any welding activity ensure that you have suitable eye protection and protective clothing. Also take the necessary steps to protect any persons within the welding area. TIG welding defects and prevention methods Defect Possible cause Action Excessive bead build up, poor Weld current too low...

-

Page 54: Maintenance

MAINTENANCE The following operation requires sufficient professional knowledge on electric aspects and comprehensive safety knowledge. Make sure the input cable of the machine is disconnected from the electricity supply and wait for 5 minutes before removing the machine covers. In order to guarantee that the arc welding machine works efficiently and in safety, it must be maintained regularly. -

Page 55: Troubleshooting

TROUBLESHOOTING The following operation requires sufficient professional knowledge on electric aspects and comprehensive safety knowledge. Make sure the input cable of the machine is disconnected from the electricity supply and wait for 5 minutes before removing the machine covers. Before arc welding machines are dispatched from the factory, they have already been checked thoroughly. -

Page 56: Weee Disposal

Jasic has a relevant recycling system which is compliant and registered in the UK with the environment agency. Our registration reference is WEEMM3813AA. -

Page 57: Ec Declaration Of Conformity

EC Declaration of Conformity... -

Page 58: Statement Of Warranty

This should be carried out by a suitably qualified competent person. In the unlikely event of a problem, this should be reported to Jasic technical support team to review the claim. -

Page 59: Options And Accessories

WP26 TIG Torch 25ft c/w Dinse Adaptor + Jasic Plug TIG-79ERGO-8MFLEXI WP26F TIG Torch 12.5ft c/w Dinse Adaptor + Jasic Plug TIG-83-8MERGO10K Titanium 18 TIG Torch 25ft c/w Swivel Dinse with 10K Potentiometer + Jasic Plug - - - TIG torch options for JT-202A water cooled package TIG-83ERGO Titanium 18 TIG Torch 12.5ft c/w Adaptor + Jasic Plug... -

Page 60: Schematics

SCHEMATIC... -

Page 61: Notes

NOTES _______________________________________________ _______________________________________________ _______________________________________________ _______________________________________________ _______________________________________________ _______________________________________________ _______________________________________________ _______________________________________________ _______________________________________________ _______________________________________________ _______________________________________________ _______________________________________________ _______________________________________________ _______________________________________________ _______________________________________________ _______________________________________________ _______________________________________________ _______________________________________________ _______________________________________________ _______________________________________________ _______________________________________________ _______________________________________________ _______________________________________________ _______________________________________________ _______________________________________________ _______________________________________________ _______________________________________________... -

Page 62: Jasic Contact Details

November 2021 - Issue 7...

Need help?

Do you have a question about the TIG Series and is the answer not in the manual?

Questions and answers