Table of Contents

Summary of Contents for Giersch GU200

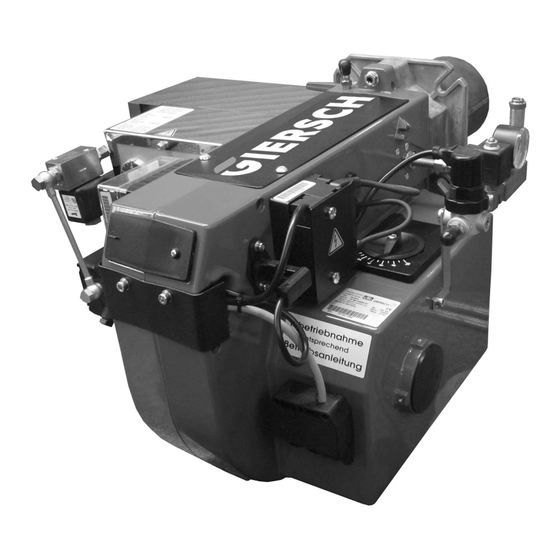

- Page 1 Technical Information • Installation Instructions Universal Oil Burner GU200 January 2024 edition In the interests of continuous product improvement, technical specifications are subject to change without prior notice.

-

Page 2: Table Of Contents

Contents General information ........................3 Checking scope of supply and electrical ratings ................ 3 Operating instructions ........................ 3 Instruction ..........................3 Maintenance and customer service ................... 3 Technical specifications ......................4 Functional description ........................ 4 Air/oil flow schematic........................4 Installing flange and burner......................5 Connecting to power supply....................... -

Page 3: General Information

2. Checking scope of supply and electrical ratings Before installing the GIERSCH universal oil burner please check the items supplied for completeness. Scope of supply: burner, mounting unit, separate operating instructions, technical information, flange seal. -

Page 4: Technical Specifications

Technical specifications 6. Technical specifications Burner type Technical specifications GU200 Output, fuel oil 148- 210 Oil throughput, fuel oil kg/h 12.5 - 17.7 Output, rapeseed oil 95 - 150 Oil throughput, rapeseed oil kg/h 9.4 - 14.9 Compressor output Primary air connection 0.5 - 1.4... -

Page 5: Installing Flange And Burner

Install flange and burner 9.Install flange and burner Attach the burner flange and the seal to the heat generator. 10.Connect to power supply • Connect the burner to the power supply using the supplied connector unit as indicated in the wiring diagram. -

Page 6: Oil Pump

Oil pump 12. Oil pump The oil pumps serve as delivery units, pumping oil into the burner tank. The atomisation of the oil is not dependent on the oil pressure. Suntec oil pump: = feed = return = pressure pipe connection ... -

Page 7: Control Unit Lmo

Function testing the control unit 15. Function testing the control unit Testing the control unit for proper functioning Danger of fatal injury from electric shocks! Disconnect electrical cable from power supply before carrying out any work on live parts! Troubleshooting may only be carried out by authorised and trained personnel! Unlocking may only be carried out by an authorised specialist. - Page 8 Function testing the control unit Diagnostics of the cause of fault After lockout, the red fault signal lamp remains steady on. In that condition, the visual diagnostics of the cause of fault according to the error code table can be activated by pressing the lockout reset button for more than 3 seconds.

-

Page 9: Table Of Settings

If the oil level is too high, the float switch will switch off the burner. If the oil level is too low, the heating cartridge will become encrusted or damaged. Adjustment table for rapeseed oil Burner type GU200 Output in kW Oil throughput in kg/h 9.42 10.5... -

Page 10: Settings For Primary Airflow

Settings for primary airflow 17. Settings for primary airflow The primary airflow should be set using the pressure regulator (1) according to the required burner output. The information given in the diagram can be used as guide values. Higher-viscosity fuels require higher air pressures. 18. -

Page 11: Flue Connection

Flue connection 19. Flue connection The prerequisite for perfect operation of the furnace is a correctly dimensioned flue. Dimensioning is effected in accordance with DIN 4705 in consideration of DIN 18160 and based on the boiler and burner outputs. For operation on a sliding basis, provide flues as per DIN 18160 part, group 1. The flue gas mass flow of the total rated heat output must be factored into the calculation. -

Page 12: Wiring Diagram

SP_1-1066.1 E.04.2000 • G. 05.01.24... -

Page 13: Possible Errors

Troubleshooting 23. Troubleshooting Observation Cause Remedy Open the water drain cock on the burner tank, Oil not combustible due to sludge and / or water drain off sludge and water or use a higher-grade heating oil Refill tank with oil Oil tank empty Oil level in burner tank too high Correct the oil level by draining off oil by means... -

Page 14: Exploded View Drawing / Parts List

Exploded view drawing / spare parts list 24. Exploded view drawing / spare parts list... - Page 15 Exploded view drawing / spare parts list Position Designation Pack qty. Art. No. Burner pipe, 177 mm long 47-90-27625 Burner pipe, 277 mm long (100 mm extension) 47-90-29229 Burner pipe, 377 mm long (200 mm extension) 47-90-29232 Diaphragm plate compl. with holder 41-90-20850 Nozzle assembly compl.

- Page 16 Exploded view drawing / spare parts list Position Designation Pack qty. Art. No. Electronic ignition unit Mod. 26/48 47-90-26930 Flame detector QRB 4 47-90-29994 Air distributor connecting tube 47-90-27628 Air distributor, compl. 47-90-24568 Safety valve 47-90-22344 Pressure gauge 0-2.5 bar 47-90-12121 Solenoid valve coil 59-90-50368...

- Page 17 Exploded view drawing / spare parts list...

-

Page 18: Burner Dimensions / Boiler Connecting Dimensions

Subject to change. Giersch GmbH • Brenner und Heizsysteme D-58675 Hemer • Adjutantenkamp 18 Telephone +49 (0)2372/965-0 • Telefax +49 (0)2372/61240...

Need help?

Do you have a question about the GU200 and is the answer not in the manual?

Questions and answers