Table of Contents

Advertisement

Quick Links

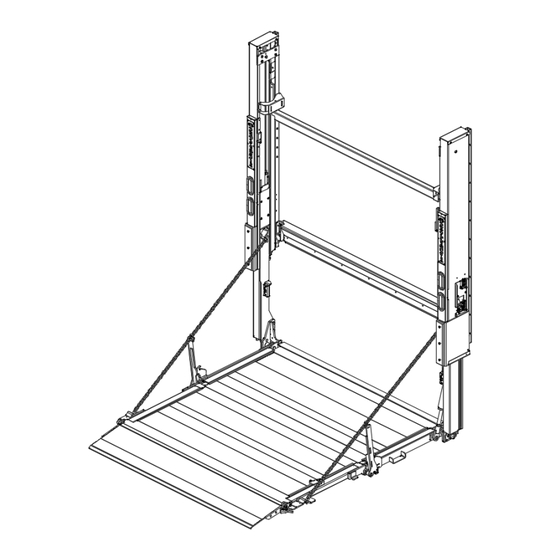

DH-VHT*

TECHNICAL GUIDE

Manufacturer:

DHOLLANDIA US, L.L.C.

E-mail : Technical.US@dhollandia.com

270 Southridge Parkway

Bessemer City North Carolina, 28016

website :

www.dhollandia.com

phone: 980-443-4446

Read the manual in its entirety before operating the liftgate

Keep this manual in the vehicle cab, as reference for the driver and liftgate operator

Ph

Order ref: xxx Doc: TECH_US technical guide DHVHT_US EN_2023 Rev: 0 Date: JUNE 2, 2023

Advertisement

Table of Contents

Summary of Contents for Dhollandia DH-VHT Series

- Page 1 DH-VHT* TECHNICAL GUIDE Manufacturer: DHOLLANDIA US, L.L.C. E-mail : Technical.US@dhollandia.com 270 Southridge Parkway Bessemer City North Carolina, 28016 website : www.dhollandia.com phone: 980-443-4446 Read the manual in its entirety before operating the liftgate Keep this manual in the vehicle cab, as reference for the driver and liftgate operator...

-

Page 2: Table Of Contents

Platform is not level ................................. 38 8.11 Platform moves abnormally ..............................39 APPENDIX ....................................... 40 Meaning of the safety and warning signs ..........................40 Prescribed torque values for bolts and nuts ..........................42 Electric and hydraulic requirements ............................43 End note ....................................45 DHOLLANDIA... -

Page 3: Understanding Safety And Warning Signs

Many safety signs and symbols used in this manual are based on international standards, others refer to specific situations or actions. • Consult appendix 9.1 on page 40 for an overview of signs and symbols used in DHOLLANDIA manuals, and their meaning. Make sure you understand these signs and symbols prior to starting the installation. -

Page 4: Introduction Contact Info And Disclaimers

NOTICE • Please confirm you have reviewed the most up-to-date version of this manual prior to operation of the associated DHOLLANDIA liftgate. See below for instructions to download the latest version of the manual. -

Page 5: Safety Precautions For Operation

• In case of doubt, ALWAYS contact your national DHOLLANDIA distributor for further advice, prior to continuing. DHOLLANDIA... -

Page 6: Identification

On the lift frame / columns On the platform • Use this serial number to order replacement parts, or to obtain technical advice from DHOLLANDIA or your local DHOLLANDIA distributor regarding maintenance, troubleshooting and repair. • The following information must be confirmed when ordering replacement parts: o Type, year of construction &... -

Page 7: Liftgate Terminology

22 Main controls: mounted in a fixed position on the sides of the passenger side lift column. 22a: externally mounted controls for LIFT / LOWER / OPEN / CLOSE 22b: internally mounted control for LIFT / LOWER 23 Extra controls: auxiliary controls besides the main controls that allow full or partial functions. DHOLLANDIA... - Page 8 DHOLLANDIA...

-

Page 9: Power Pack

14 Pressure gauge: measures system hydraulic pressure 15 Pump unit control panel: enables selection of MOTOR 1 or MOTOR 2 and the selection of Gravity Down or Power Down. 16 Emergency control: controller inside pump unit to operate liftgate during maintenance / repair. DHOLLANDIA... - Page 10 DHOLLANDIA...

-

Page 11: Electrical Basics And Controls

6 ELECTRICAL BASICS AND CONTROLS • This chapter explains the electrical basics of DHOLLANDIA DH-VHT* series liftgates. E2051 CONNECTION BLOCK • The orange connection block acts as a junction between the controls and the components of the liftgate. • In the image above, “MC” and “EC” stand for Main Controls and Extra Controls, respectively. This is where the source leads for your controls can be connected to power the various liftgate functions. -

Page 12: Vht- Electrical Cheat Sheet

VHT- Electrical Cheat Sheet Function Activates the motor solenoid, which in turn powers the electric motor Energizes the solenoid valves located on / near the lift cylinder(s) Main 12V source from vehicle batteries to power controls and components Ground DHOLLANDIA... -

Page 13: Schematics

SCHEMATICS • The primary controls for the DH-VHT* series liftgates are shown wired in default configuration below: DHOLLANDIA... - Page 14 DHOLLANDIA...

-

Page 15: Extra Controls

EXTRA CONTROLS • Some of the popular extra controls for the DH-VHT* series liftgates are shown wired in the configuration below: 6.3.1 2 Button Wander Controls - OAE001 – E0787.2.H DHOLLANDIA... -

Page 16: Toggle 4 Function - Oae017.Pr - E0834

6.3.2 Toggle 4 Function - OAE017.PR – E0834 DHOLLANDIA... -

Page 17: Toggle Switch Control 2+1 - Oae017.Pr - E0837

6.3.3 Toggle switch control 2+1 – OAE017.PR – E0837… DHOLLANDIA... -

Page 18: Cabin Switch - Oae510.15 - E0393.S.15

CABIN SWITCH - OAE510.15 – E0393.S.15 • The cabin switch controls for the DH-VHT* series liftgates is shown wired in the configuration below: DHOLLANDIA... -

Page 19: Flow Diagrams

7 FLOW DIAGRAMS • This chapter outlines flow diagrams for DHOLLANDIA DH-VHT* series liftgates. • Only the primary controls are shown. • To troubleshoot other configurations, please refer to the previous chapters, or see contact information on page 3. Remainder of page left intentionally blank... - Page 20 • LIFT function activated: DHOLLANDIA...

- Page 21 DHOLLANDIA...

- Page 22 • LOWER function activated: DHOLLANDIA...

- Page 23 DHOLLANDIA...

- Page 24 • OPEN function activated: DHOLLANDIA...

- Page 25 DHOLLANDIA...

- Page 26 • CLOSE function activated: DHOLLANDIA...

- Page 27 DHOLLANDIA...

-

Page 28: Troubleshooting

8 TROUBLESHOOTING • This chapter outlines the most common issues encountered with DHOLLANDIA DH-VHT* series liftgates. CHECKING BATTERIES • Before moving on to any other section of this chapter, measure the voltages throughout the system. • Do this with the vehicle powered off, so normal use case scenarios can be assessed. -

Page 29: Checking Oil

1” below the maximum level. • Please see appendix 9.3 on page 43 for the main types of oil used by DHOLLANDIA. • NEVER allow the hydraulic pump to run dry or without a proper supply of hydraulic fluid in the reservoir. -

Page 30: Testing Solenoid Valves

If no magnetic field is present, and proper voltage is verified to be going to the proper row on the connection block, the valve coil or valve coil harness needs to be replaced. • DHOLLANIDA provides a solenoid tester as part number E0247. Please email Parts.US@dhollandia.com to place an order or to find a local distributor. DHOLLANDIA... - Page 31 This will manually actuate the pin within the valve and temporarily allow hydraulic fluid to bypass the valve. • See the following chapters for how these manual activation methods can be used for troubleshooting. DHOLLANDIA...

-

Page 32: Motor Fails To Run

(where the yellow thermal contact wire used to be). NOTICE • If this step has resolved your issue, please contact your local DHOLLANDIA dealer for more information about repairing the thermal contact. See contact info on page 3. •... - Page 33 Check the primary controls harness for shorts, sharp bends / crimps, or other signs of damage / wear. If any damage exists, consider contacting your local DHOLLANDIA dealer to acquire new controls. Damage to the controls can be verified by following the flow diagrams in section 7 on page 18.

-

Page 34: Platform Does Not Lift

After maintenance, the seal for the pump can become dislodged. This causes hydraulic fluid to only circulate in the reservoir and not build pressure. o If aeration of the fluid in the reservoir occurs, please contact your local DHOLLANDIA dealer. See page 3. •... -

Page 35: Liftgate Does Not Lift The Rated Capacity

Using a small implement, verify the valve plunger can be depressed and that it moves freely back and forth. HYDRAULIC • Check the operating pressures of the liftgate. o If you are not outfitted with DHOLLANDIA’s pressure gauge (part K0106). Please email Parts.US@dhollandia.com to place an order or to find a local distributor o The maximum pressure the liftgate is set at from the factory is listed on your order paperwork. -

Page 36: Platform Does Not Lower

WARNING • Removing or testing the solenoid valves causes the platform to fall and / or open rapidly. • Ensure the platform is either on the ground, or properly secured from falling before proceeding with removing the solenoid valves. DHOLLANDIA... -

Page 37: Platform Drifts Down

Using a small implement, verify the valve plungers can be depressed and that it moves freely back and forth, o Contamination in these valves may allow fluid to bypass and cause the platform to drift down. • If the liftgate continues to drift down, please contact your local DHOLLANDIA dealer. See contact information on page 3. DHOLLANDIA... -

Page 38: Platform Does Not Open / Close

Removing or testing the solenoid valves causes the platform to fall and / or open rapidly. • Ensure the platform is either on the ground, or properly secured from falling before proceeding with testing or removing the solenoid valves. DHOLLANDIA... -

Page 39: Platform Is Not Level

Check platform for alignment with the ground. NOTE: If the platform pitch needs to be changed ensure both chains are platform may be pitched upwards 1-2 degrees to adjusted equally by modifying the position of the U-Bolts. accommodate deflection from loading. DHOLLANDIA... -

Page 40: Platform Moves Abnormally

Removing or testing the solenoid valves causes the platform to fall and / or open rapidly. • Ensure the platform is either on the ground, or properly secured from falling before proceeding with testing or removing the solenoid valves. DHOLLANDIA... -

Page 41: Appendix

WARNING signs MANDATORY ACTION signs Overview and keep visual control over the working Contact your regional DHOLLANDIA distributor. area of the hydraulic ramp at all times. General warning sign used to alert the user to potential hazards. All messages that follow Consult the DHOLLANDIA website. - Page 42 / or cabin Switch between external and internal controls. switch. This is an operation to be executed manually (as opposed to an electrical function controlled by means of one of the control units). DHOLLANDIA...

-

Page 43: Prescribed Torque Values For Bolts And Nuts

A fall of the liftgate off the chassis can damage the liftgate and / or vehicle chassis and can cause serious bodily injury or death to the operator and any bystanders. • Therefore, it is essential that the mounting plates are installed following the instructions of this manual. DHOLLANDIA... -

Page 44: Electric And Hydraulic Requirements

• The applicable wiring diagrams are saved at the inside of the main external control box, and can be found there for reference. • A copy of the wiring diagrams can also be obtained from the national DHOLLANDIA distributor [see contact info on page 3];... - Page 45 It is important to follow these guidelines with due care. A lot of oils or fluids used in automotive industry, such as transmission fluids and ATF oils, are not suitable for liftgate use. DHOLLANDIA has not tested the potential consequences of oils and fluids with deviating specifications and cannot be held responsible or legally liable for any damage to the liftgate caused by the replenishment with non-compatible oils or fluids;...

-

Page 46: End Note

END NOTE • DHOLLANDIA would like to thank you for using our products and leave you with this final notice and warning. • Additional information about this liftgate and many other DHOLLANDIA products is available at the following link: http://www.dhollandia.com/ NOTICE •...

Need help?

Do you have a question about the DH-VHT Series and is the answer not in the manual?

Questions and answers