Table of Contents

Advertisement

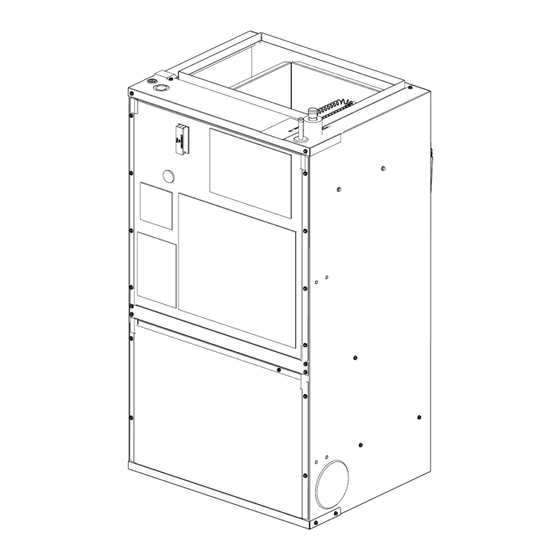

WALL MOUNT AIR HANDLERS

INSTALLATION INSTRUCTIONS & OPERATING INSTRUCTIONS

AWSF/AWST 18-24

ONLY PERSONNEL THAT HAVE BEEN TRAINED TO INSTALL,

ADJUST, SERVICE, MAINTENANCE OR REPAIR

(HEREINAFTER, "SERVICE") THE EQUIPMENT SPECIFIED IN

THIS MANUAL SHOULD

SERVICE THE EQUIPMENT. THE MANUFACTURER WILL

NOT BE RESPONSIBLE FOR ANY INJURY OR PROPERTY

DAMAGE ARISING FROM IMPROPER SERVICE OR SERVICE

PROCEDURES. IF YOU SERVICE THIS UNIT, YOU ASSUME

RESPONSIBILITY FOR ANY INJURY OR PROPERTY

DAMAGE WHICH MAY RESULT. IN ADDITION, IN

JURISDICTIONS THAT REQUIRE ONE OR MORE LICENSES

TO SERVICE THE EQUIPMENT SPECIFIED IN THIS

MANUAL, ONLY LICENSED PERSONNEL SHOULD SERVICE

THE EQUIPMENT.

IMPROPER INSTALLATION, ADJUSTMENT, SERVICING,

MAINTENANCE OR REPAIR OF THE EQUIPMENT SPECIFIED

IN THIS MANUAL, OR ATTEMPTING TO INSTALL, ADJUST,

SERVICE OR REPAIR THE EQUIPMENT SPECIFIED IN THIS

MANUAL WITHOUT PROPER TRAINING MAY RESULT IN

PRODUCT DAMAGE, PROPERTY DAMAGE, PERSONAL

INJURY OR DEATH.

WARNING

© 2023-2024

19001 Kermier Rd., Waller, TX 77484

www.daikinac.com

P/N: IO-4010A

Date: June 2024

AWSF/AWST 30-36

DO NOT BYPASS SAFETY DEVICES

RECOGNIZE THIS SYMBOL AS A SAFETY

PRECAUTION.

NOTE: SPECIFICATIONS AND PERFORMANCE

DATA LISTED HEREIN ARE SUBJECT TO CHANGE

WITHOUT NOTICE.

NOTE: NEVER OPERATE THE UNIT WITHOUT THE

RECOMMENDED FILTER OR THE OUTER PANEL

INSTALLED.

NOTE: THIS EQUIPMENT IS APPROVED TO USE

ONLY WITH R-32 REFRIGERANT

WARNING

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Daikin AWSF 18 Series

- Page 1 WALL MOUNT AIR HANDLERS © 2023-2024 INSTALLATION INSTRUCTIONS & OPERATING INSTRUCTIONS 19001 Kermier Rd., Waller, TX 77484 www.daikinac.com P/N: IO-4010A Date: June 2024 AWSF/AWST 18-24 AWSF/AWST 30-36 WARNING WARNING DO NOT BYPASS SAFETY DEVICES ONLY PERSONNEL THAT HAVE BEEN TRAINED TO INSTALL, ADJUST, SERVICE, MAINTENANCE OR REPAIR (HEREINAFTER, “SERVICE”) THE EQUIPMENT SPECIFIED IN RECOGNIZE THIS SYMBOL AS A SAFETY...

-

Page 2: Table Of Contents

CONTENTS WARNING 1 Important Safety Instructions ........3 A REFRIGERANT LEAK DETECTION SYSTEM IS INSTALLED. 2 Codes & Regulations ............ 3 THE UNIT MUST BE POWERED ON AT ALL TIMES EXCEPT 3 Clearances ..............3 FOR SERVICE. 4 Wiring Diagrams ............5 5 Air Flow Data &... -

Page 3: Important Safety Instructions

WARNING AUXILIARY DEVICES WHICH MAY BE A POTENTIAL IGNITION SOURCE SHALL NOT BE INSTALLED IN THE DUCT WORK. EXAMPLES OF SUCH POTENTIAL IGNITION SOURCES ARE HOT SURFACES WITH A TEMPERATURE EXCEEDING 700 °C AND ELECTRIC SWITCHING DEVICES. 1 IMPORTANT SAFETY INSTRUCTIONS The following symbols and labels are used throughout this manual to indicate immediate or potential safety hazards. - Page 4 WARNING THE ONLY AUXILIARY DEVICES APPROVED BY THE APPLIANCE MANUFACTURER OR DECLARED SUITABLE WITH THE REFRIGERANT SHALL BE INSTALLED IN CONNECTING DUCTWORK. The unit clearance from a combustible surface may be 0”. However, service clearance must take precedence. A minimum of 24” in front of the unit for service clearance is required.

-

Page 5: Wiring Diagrams

4 WIRING DIAGRAM AWSF18SU13**, AWST18SU13** Wiring is subject to change. Always refer to the Wiring Diagram on the unit for the most up-to-date wiring. - Page 6 WIRING DIAGRAM AWSF24SU13**, AWST24SU13** Wiring is subject to change. Always refer to the Wiring Diagram on the unit for the most up-to-date wiring.

- Page 7 WIRING DIAGRAM AWSF30LU13**, AWST30LU13** Wiring is subject to change. Always refer to the Wiring Diagram on the unit for the most up-to-date wiring.

- Page 8 WIRING DIAGRAM AWSF36LU13**, AWST36LU13** Wiring is subject to change. Always refer to the Wiring Diagram on the unit for the most up-to-date wiring.

-

Page 9: Air Flow Data & Wiring Diagrams

5 AIR FLOW DATA & WIRING DIAGRAMS Figure 1 NOTE: SPECIFICATIONS & PERFORMANCE DATA LISTED HEREIN ARE SUBJECT TO CHANGE WITHOUT NOTICE. AWSF/AWST 18, 24, 30, 36 Model COLOR Thermostat GREEN AWSF18SU13** PURPLE AWST18SU13** PINK AWSF24SU13** AWST24SU13** WHITE #18 Gauge Table 1 24 VAC *NOTE: For units using 3KW and 5KW heaters, White... -

Page 10: Low Voltage Connections

5.1 Low Voltage Connections Several combinations of low voltage schemes are possible, WARNING depending on the presence of a heat kit and whether the HIGH VOLTAGE heat kit is single-stage or multi-stage, whether the outdoor TO AVOID THE RISK OF FIRE OR EQUIPMENT section is an air conditioner or heat pump, and whether DAMAGE, USE ONLY COPPER CONDUCTORS. -

Page 11: Maximum Overcurrent Protection (Mop)

drop from the building breaker/fuse panel to the unit. • Wires with different insulation temperature rating have varying ampacities - be sure to check the temperature Top of Cabinet rating used. Refer to the latest edition of the National Electric Code or in Canada the Canadian Electric Code when determining the correct wire size. -

Page 12: Charging Procedure

8. Attached the red and black wire to the heater kit removed in Step 3. 9. Install the upper access panel removed in Step 2. 10. Install the disconnect switch back to the air handler to turn on the unit. 8 CHARGING PROCEDURE In addition to conventional charging procedures, the following requirements shall be followed:... - Page 13 SATURATED SUCTION PRESSURE- SATURATED LIQUID PRESSURE- TEMPERATURE CHART FOR R-32 TEMPERATURE CHART FOR R-32 SUCTION PRESSURE SATURATED SUCTION SUCTION PRESSURE SATURATED SUCTION (PSIG) TEMPERATURE (°F) (PSIG) TEMPERATURE (°F) Table 7 Table 6 NOTE: Specifications and Performance Data listed herein are subject to change without notice.

-

Page 14: Shipping Inspection

If the unit is located in an unconditioned area with high HOMEOWNER SUPPORT ambient temperature and/or high humidity, the air handler DAIKIN COMFORT TECHNOLOGIES may be subject to nuisance sweating of the casing. On MANUFACTURING, L.P. these installations, a wrap of 2” fiberglass insulation with 19001 KERMIER ROAD a vapor barrier is recommended. -

Page 15: Achieving Low Air Leakage Rate

The air handler also has a bottom and front return. Large • Low voltage wiring is properly connected. chassis installations should be installed as front return • Unit is protected from vehicular or other physical only. If the small chassis air handler is to be installed in damage. -

Page 16: Refrigerant Recovery

2. Remove the pin connecting the sensor cable on the be used. However, for flammable refrigerants it is important that best practice be followed, since flammability is a PCB as shown in figures 6 and 7. Remove the filter consideration. The following procedure shall be adhered to from the air handler based on the following: A. -

Page 17: A2L Pcb Servicing Instructions

15.5. A2L PCB Servicing Instructions: LEAK DETECTION SYSTEM INSTALLED. UNIT MUST BE Take off the front side of the access panel, Disconnect the POWERED EXCEPT FOR SERVICE. PCB harness and R32 sensor wire connected to the PCB, RED LED'S STATUS (REFER I/O FOR RECOMMENDED ACTION) detach the defective PCB from the four plastic standoffs, MODE... - Page 18 RED LED'S STATUS MODE Definition LED Flashing Pattern Recommended actions Notes: Normal Slow LED flashing pattern No faults to report No action - life is good Operation (2 seconds on and 2 seconds off) In terms of the controls, no action is needed. The controls and sensor are working fine.

- Page 19 Figure 6 Figure 7...

-

Page 20: Awst-Factory Installed Txv Models

16 AWST-FACTORY INSTALLED TXV Superheat adjustments should not be made until indoor MODELS ambient conditions have stabilized. This could take up to 24 hours depending on the indoor temperature and AWST air handlers come equipped with a factory installed humidity. Before checking superheat run the unit in cooling fully adjustable TXV, follow instruction below for installation for 10 minutes or until refrigerant pressures stabilize. -

Page 21: Awsf Fixed Orifice Adjustment

Superheat Adjustments (Only if necessary) 1. Bulb location: Must be tightly secured to the suction 1. Attach a pipe clamp thermometer near the suction line line upstream of the equalizer connection. service valve at the outdoor unit. 2. Insulation: Bulb must be properly insulated. A. - Page 22 SPLIT SYSTEMS AIR CONDITIONING AND HEAT PUMP HOMEOWNER’S ROUTINE MAINTENANCE RECOMMENDATIONS We strongly recommend a biannual maintenance checkup be performed before the heating and cooling seasons begin by a qualified servicer. Replace or Clean Filter IMPORTANT NOTE: Never operate unit without a filter installed as dust and lint will build up on internal parts resulting in loss of efficiency, equipment damage and possible fire.

-

Page 23: Start-Up Checklist

20 START-UP CHECKLIST Air Handler / Coil Model Number Serial Number ELECTRICAL Line Voltage (Measure L1 and L2 Voltage) L1 - L2 Secondary Voltage (Measure Transformer Output Voltage) R - C Blower Amps Heat Strip 1 - Amps Heat Strip 2 - Amps BLOWER EXTERNAL STATIC PRESSURE Return Air Static Pressure IN. - Page 24 Contractor Programs and Training • Customer Services • Financing Options Daikin Comfort Technologies Manufacturing, L.P. 19001 Kermier Rd., Waller, TX 77484 © 2023-2024 is a registered trademark of Maytag Corporation or its related companies and is used under license. All rights reserved.

Need help?

Do you have a question about the AWSF 18 Series and is the answer not in the manual?

Questions and answers