Table of Contents

Advertisement

Quick Links

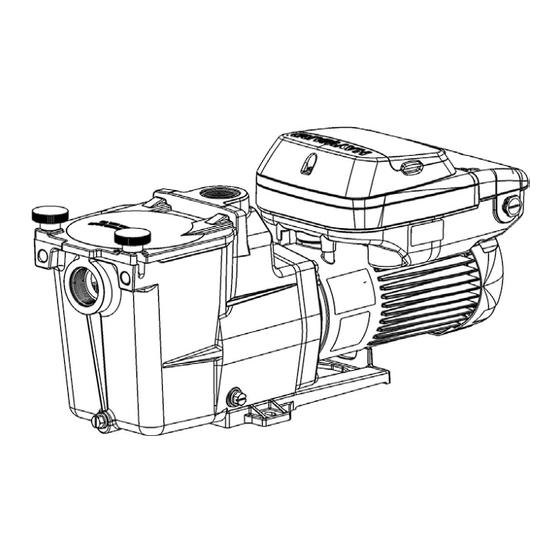

1.65 THP VS Pump Family

Owner's Manual

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

Contents

Safety Instructions.................1

Table of Contents...................5

Overview...............................6

Installation............................7

Operation.............................15

Maintenance........................22

Replacement Parts...............24

Troubleshooting...................25

HL2670020VSP

SPX2603Z1VSPE

SP2670020VSP

W3SP2603VSP

Hayward Industries

1415 Vantage Park Dr., Suite 400

Charlotte, NC 28203

Phone (908)-355-7995

www.hayward.com

1011784 RevA

Advertisement

Table of Contents

Summary of Contents for Hayward HL2670020VSP

-

Page 1: Table Of Contents

1.65 THP VS Pump Family Owner’s Manual Contents Safety Instructions....1 Table of Contents....5 Overview.......6 Installation......7 Operation......15 Maintenance......22 Replacement Parts....24 Troubleshooting....25 HL2670020VSP SPX2603Z1VSPE SP2670020VSP W3SP2603VSP Hayward Industries 1415 Vantage Park Dr., Suite 400 Charlotte, NC 28203 Phone (908)-355-7995 www.hayward.com USE ONLY HAYWARD GENUINE REPLACEMENT PARTS... -

Page 2: Safety Instructions

All electrical wiring MUST be in conformance with all applicable local codes, regulations, and the National Electric Code (NEC). USE OF NON-HAYWARD REPLACEMENT PARTS VOIDS WARRANTY. ATTENTION INSTALLER - THIS MANUAL CONTAINS IMPORTANT INFORMATION ABOUT THE INSTALLATION, OPERATION, AND SAFE USE OF THIS VARIABLE SPEED PUMP THAT MUST BE FURNISHED TO THE END USER OF THIS PRODUCT. - Page 3 Mechanical Entrapment - There is potential for jewelry, swimsuits, hair decorations, fingers, toes, or knuckles to be caught in an opening of a suction outlet cover resulting in mechanical entrapment. USE ONLY HAYWARD GENUINE REPLACEMENT PARTS...

- Page 4 It is also necessary to allow the motor to cool for at least 20 minutes prior to maintenance to minimize the risk for burns. WARNING – Failure to install according to defined instructions may result in severe personal injury or death. SAVE THESE INSTRUCTIONS USE ONLY HAYWARD GENUINE REPLACEMENT PARTS...

- Page 5 Hayward Industries 1415 Vantage Park Drive, Suite 400, Charlotte, NC 28203 Technical Service Phone: (908) 355-7995 Manufacture Location: Hayward Industries, One Hayward Industrial Drive, Clemmons, NC 27012 Date Manufactured: The serial number is a 17 digit number Example serial number: 21122305456789001 The 5th - 8th digits are the “year &...

-

Page 6: Table Of Contents

User Interface Summary........................16 Menu Outline............................16 Initial Startup............................17 Configuration Menu..........................17 Timers Menu............................19 Preset Speed Setup Menu........................20 Diagnostic Menu..........................21 Stop/Resume............................21 Quick Clean............................21 Remote Stop............................22 Maintenance............................22 Storage/Winterization..........................22 Shaft Seal Change Instructions......................23 Replacement Parts..........................24 Troubleshooting............................25 General Problems..........................25 Check System Messages........................26 USE ONLY HAYWARD GENUINE REPLACEMENT PARTS... -

Page 7: Overview

Hayward’s 1.65 THP variable speed pump family delivers incredible energy savings via its advanced hydraulic design combined with a totally enclosed, per- manent magnet motor. This pump is easily installed either as a programmable stand-alone pump or with a Hayward or third party controller and features an easy-to-use digital control interface that can be mounted in four different positions on the pump or removed and mounted on the wall for total user convenience. -

Page 8: Installation

NOTE: It is recommended that a minimum length of straight piping (shown as “L” in above diagram), equivalent to 5 pipe size diameters, be used between the pump suction inlet and any plumbing fittings (elbows, valves, etc.). USE ONLY HAYWARD GENUINE REPLACEMENT PARTS... -

Page 9: Plumbing

If the time clock is used in this manner, it should be set to power the equipment during a time cycle when the VS pump is operating at an appropriate flow rate to operate the other equipment, as defined by the timers set in the Timer Menu. USE ONLY HAYWARD GENUINE REPLACEMENT PARTS... -

Page 10: Digital Control Interface Orientation

See page 13 for more information regarding connecting this pump and third party/non-software compatible Hayward controls. They can communicate with and be controlled by Hayward pool and spa controls. See page 14 for more information regarding connecting this pump and Hayward pool and spa controls. - Page 11 11. Apply power to the system and resume normal operation. The following diagrams illustrate the interface wall mounting procedure: Figure A Remove the Digital Control Interface for Wall Mounting Figure B Attach the blank cover onto the pump. Figure C USE ONLY HAYWARD GENUINE REPLACEMENT PARTS...

-

Page 12: Installation Procedure

See Input Power Wiring section below for diagram. If the pump will be controlled using a Hayward pool control, connect the provided three-conductor cable as shown in the Hayward Automation Control Wir- ing diagram. See Hayward Automation Control Wiring section below. - Page 13 When communicating with the Omni family of controls, the HUA (Hayward Unique Address) is used for communication. For all other Hayward controls, the pump address must be set using the DIP switches on the drive PCB. To determine which address should be used, consult the appropriate Hayward pool control instal- lation manual, or visit our website at www.haywardpool.com.

-

Page 14: External Relay Speed Control Wiring

DIP switch #1 must be “ON”. This pump can be controlled from third party pool controls as well as Hayward controls that are not software compatible using relay contacts to select the speeds set in the Timer Menu (see page 19). -

Page 15: Wall Mounted Digital Control Interface Wiring

, so care must be taken when connecting to these terminals to ensure proper operation of user interface. If the “+12V” and “COM” terminals are used, DIP switch #1 must be “ON”. USE ONLY HAYWARD GENUINE REPLACEMENT PARTS... -

Page 16: Operation

Have a professional perform this test. Ensure all Hayward pump and system components are removed from system prior to performing test. WARNING – If circulation equipment must remain in the plumbing system during water pressure test, do not apply more than 10 psi pressure to the system. -

Page 17: User Interface Summary

Rename Timer “X” (where “X” equals 1 through 8) Pump Speed for Timer “X” (where “X” equals 1 through 8) Start/Stop Time for Timer “X” (where “X” equals 1 through 8) Choose Days for Timer “X” (where “X” equals 1 through 8) USE ONLY HAYWARD GENUINE REPLACEMENT PARTS... -

Page 18: Initial Startup

Select language for all displayed messages. < > Move to next menu item. English Time: Th 1:27PM Use + button to change clock setting. < > + change or > skip Use > if clock is correct. USE ONLY HAYWARD GENUINE REPLACEMENT PARTS... - Page 19 NOTE: This sets the amount of time from the last button activation after the system has been unlocked to the point where the system becomes locked again. System Password Use to set password timeout. < > + change or > skip Move to next menu item. USE ONLY HAYWARD GENUINE REPLACEMENT PARTS...

-

Page 20: Timers Menu

Speed 4 buttons at the same time while powering on the drive, or by resetting all parameters in the Configuration Menu. If a mistake is made when entering the password, pressing Stop/Resume will cancel the action. If the pump is being controlled by a Hayward or third party pool control, the pump display can be locked by the password, however, the pump will respond to any and all commands being sent from the pool control. -

Page 21: Preset Speed Setup Menu

NOTE: Preset Speed settings can also be quickly updated without entering the Speeds Menu using the + and - arrow buttons to change the speed and then pressing the > button to save the new speed setting. USE ONLY HAYWARD GENUINE REPLACEMENT PARTS... -

Page 22: Diagnostic Menu

Stop/Resume is pressed a second time, at which point the pump will resume normal operation. Quick Clean Screen Quick Clean Quick Clean running Quick Clean 3450 rpm for 60 min; USE ONLY HAYWARD GENUINE REPLACEMENT PARTS... -

Page 23: Maintenance

Keep motor clean. Keep motor air vents free of obstructions to avoid damage. Do NOT use water to hose off motor. • Occasionally, shaft seals must be replaced, due to wear or damage. Replace with genuine Hayward seal assembly kit. See “Shaft Seal Change Instructions” in this manual. -

Page 24: Shaft Seal Change Instructions

Disconnect all electrical power service to pump before beginning shaft seal replacement. • Only qualified personnel should attempt rotary seal replacement. Contact your local authorized Hayward Dealer or service center if you have any questions. • Refer to page 24 for pump component locations. -

Page 25: Replacement Parts

SPXHKIT3 Quick Fix Kit (Includes #3, 7, 10A, 11 & Jack’s Lube) POWER END SPX1600Z2VIT Shaft Seal Assembly (Viton) SPX1600T Housing Gasket SPX2603Z1VSPE Power End Assembly (Includes #7-14, Motor & Drive) SPX2600E5 Seal Plate USE ONLY HAYWARD GENUINE REPLACEMENT PARTS... -

Page 26: Troubleshooting

Motor bearings noisy from normal wear, rust, overheating, or concentration of chemicals causing seal damage, which will allow chlorinated water to seep into bearings wiping out the grease causing bearing to whine. All seal leaks should be replaced at once. USE ONLY HAYWARD GENUINE REPLACEMENT PARTS... -

Page 27: Check System Messages

Under certain circumstances, the “Drive overload” error can only be reset by cycling power applied to the pump. If the troubleshooting steps listed above do not help to resolve the error condition, then the problem may be internal to the motor/drive. Contact Hayward Technical Service at (908) 355-7995 for additional assistance. - Page 28 Hayward Industries, Inc. © 2024 Hayward Industries, Inc. All other trademarks not owned by Hayward are the property of their respective owners. Hayward is not in any way affiliated with or endorsed by those third parties. For patent information, refer to www.hayward.com/patents.

Need help?

Do you have a question about the HL2670020VSP and is the answer not in the manual?

Questions and answers