FPT NEF Series Use And Maintenance

G-drive engines

Hide thumbs

Also See for NEF Series:

- Use and maintenance (60 pages) ,

- Use and maintenance (52 pages) ,

- Use and maintenance (33 pages)

Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for FPT NEF Series

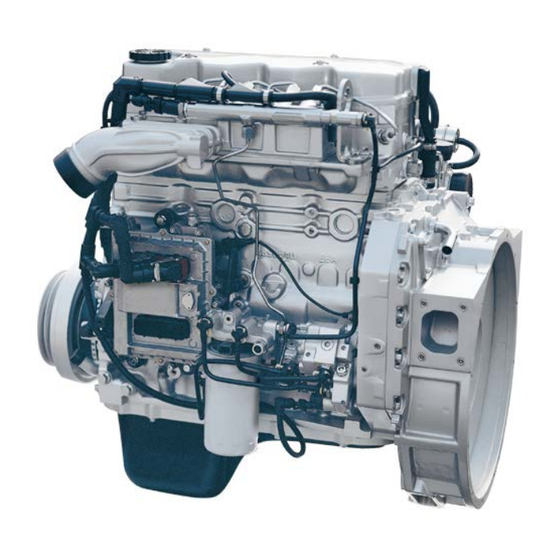

- Page 1 USE AND MAINTENANCE USO E MANUTENZIONE UTILISATION ET ENTRETIEN BETRIEB UND WARTUNG USO Y MANTENIMIENTO SERIES G-DRIVE ENGINES Publication edited by: FPT Industrial S.p.A Via Puglia 15, 10156 Torino, Italia www.fptindustrial.com Print L31901182 - 11/23...

- Page 2 NEF SERIES INTRODUCTION We would like to thank you for buying an FPT product, and compliment you on your choice of engine. Before you carry out any operation involving the engine or its fittings, please read the contents of this manual carefully; compliance with the...

-

Page 3: Table Of Contents

TABLE OF CONTENTS Page Page GENERAL INFORMATION ..... 3 CHECKS AND MAINTENANCE ....29 Guarantee . -

Page 4: General Information

FPT will not be considered liable in any It is therefore essential to observe the following safety instructions. way during the whole working life of the engine. - Page 5 Risk of intoxication or poisoning. Risk of injury. Make sure that no combustible vapours or gasses are Avoid contact with liquids and fluids when the engine is present in the area in which the engine is to operate. hot: risk of burns. Provide adequate ventilation and a suitable exhaust gas Failure to observe these instructions could cause serious extraction system in enclosed environments.

- Page 6 Fire hazard. Risk of injury. Pay the utmost attention to parts glowing with heat and Due to the high pressure in the pipes which go from the guards with warning pictograms. high pressure pump to the rail and from the rail to the Failure to observe these instructions could cause serious electro-injectors, do not under any circumstances: health risks.

- Page 7 All the technical instructions are For correct engine operation, only use recommended oils provided in the FPT repair and technical manuals. or oils with the required characteristics. In the case of Partial or total non-compliance with these instructions refilling, do not mix oils with different characteristics.

- Page 8 General instructions. General instructions. Always keep the work area clean during workshop Do not use fast screw tightening tools. operations; immediately clean the surfaces of the work Failure to observe these instructions could cause damage area from any liquids, fluids or oils which may have leaked. to the engine.

- Page 9 Replace the auxiliary device belt if it shows signs of If the installation of mechanical or electromechanical abrasions, cracks or tears or if it is soiled with oil or fuel. optionals is required, always refer to the "FPT Installation Partial or total non-compliance with these instructions Guide" documents.

- Page 10 General danger, general precautions. General danger, general precautions. The engines must only be used for the purposes declared Maintenance checks and interventions must be carried by the Manufacturer. out with the engine switched off, unless specifically Failure to observe this indication (fully or in part) can cause indicated due to the type of check or intervention.

- Page 11 General instructions. General instructions. Before proceeding with any work on the engine, operation Use the specific and general tools according to the or maintenance, carefully read the technical service instructions in the respective user and maintenance documentation, owner's manual and repair manual of manuals.

- Page 12 General instructions (handling of components «>25kg»). General instructions. When lifting using a crane or hoist, pay careful attention Use only the specific equipment listed in the repair to the affixing points. The items attached must be manual and standard equipment that complies with cantilevered.

- Page 13 Risk of injury. General instructions. Make sure that the guards of moving parts are correctly Maintenance procedures requiring engine start-up, for positioned and pay attention to the warning pictograms example during the forced regeneration procedure of ATS on the engine. systems.

- Page 14 The machine assembly may have auxiliary devices such as emergency personnel with proven experience using instruments switches / emergency push button; these are to be used in the event considered appropriate by FPT. of an emergency. Failure to comply with these instructions can result in serious health risks and damage to the engine.

- Page 15 Always pay careful attention to example: filters, fluids and any rags - paper rags soaked the safety instructions indicated by the Manufacturer of in liquids and fluids. FPT Technical Service Network the unit and the generator Bodybuilder to ensure workshops are equipped for this.

-

Page 16: Safety Warning Symbols

SAFETY WARNING SYMBOLS You will find these symbols on the following pages; follow the instructions to which they refer, for your own safety and that of your engine. Risk of injury: failure to comply with these instructions General risk: combines the risks of both the signs can result in the risk of serious injury. -

Page 17: Engine Technical Data

ENGINE TECHNICAL DATA Electrical system 12 - 24 V The technical code and serial number are indicated on a plate, which is located on different parts of the engine, according to the model: (**) Reccomanded Battery - capacity Min: 130 Ah - Max: 500 flywheel casing, tappet cover, other. - Page 18 500 hours/year with a mean load factor of 90% of the declared stand-by power. No kind of overload is permissible for this use. Any alteration of the above mentioned characteristics is strictly prohibited, penalty invalidation of the guarantee and absence of all liability on the part of FPT.

- Page 19 18_248_N 18_249_N N45 ENT Z W N45 ENT Z W 1. Lubricant oil filler cap - 2. Common rail - 3. Fuel discharge pipe - 1. Turbocharger exhaust gas outlet from motorized throttle valve (Exhaust flap) - 2. Water degassing pipe - 3. Lifting eyelet - 4. Coolant 4.

- Page 20 18_250_N 18_251_N N45 ENT Z W N45 ENT Z W 1. Turbocharger comburent air outlet to intercooler - 2. Engine cable - 1. Lifting eyelet - 2. Motorized throttle valve (Exhaust flap) - 3. Exhaust 3. Fan control pulley - 4. Idler pulley - 5. Crankshaft pulley with manifold - 4.

-

Page 21: Exhaust Gas After-Treatment System (Ats)

EXHAUST GAS AFTER-TREATMENT SYSTEM (ATS) 18_252_N 1. DOC upstream NOx sensor - 2. Engine coolant 3 way valve - 3. Dosing module DeNOx 2.2 - 4. Intake air humidity and temperature sensor - 5. Supply module DeNOx 2.2 - 6. AdBlue tank - 7. AdBlue tank level sensor - 8. Urea quality sensor (UQS) - 9. Selective catalyst reduction (SCR) - 10. -

Page 22: Nameplates

This plate highlights the fact that the engine must be installed with the corresponding ATS system by the bodybuilder. When installation has 17_575_C been completed, it must be removed. A. Commercial code B. Engine serial number TYPE-APPROVAL PLATE FPT Industrial S.p.A. 18_145_N... -

Page 23: Use

USE General instructions. Make sure there are no vapours of fuel or gas in the PRELIMINARY CHECKS engine area. Ensure that closed areas are adequately ventilated and fitted with a suitable exhaust extraction system. General danger, general precautions. Failure to observe the indications provided could cause Before proceeding with the operation, please refer to the serious personal injury and damage to the vehicle. -

Page 24: For Proper Engine Use

FOR PROPER ENGINE USE Prescriptions Do not disconnect the batteries with the engine running. Before starting the engine each time, check that the tank contains a sufficient amount of fuel. Do not perform arc welding near the engine without first removing its electrical wiring. -

Page 25: Special Warnings

SPECIAL WARNINGS Fuel circuit Avoid using the engine with small reserve of fuel in the fuel tank. Thus Coolant circuit the vapour condensation is encouraged and makes the engine more When the engine is running, regularly check that the engine coolant likely to suck up dirt or air, resulting in engine stoppage. -

Page 26: Run-In

CAUTION! The batteries contain an acid solution that will burn the skin and corrode clothing; when checking them, always Visually check that the exhaust circuit is not obstructed wear protective clothing, gloves and goggles, do not or damaged to prevent the formation of noxious and smoke or use live flames in the vicinity, and make sure harmful fumes inside the ducts. -

Page 27: Refilling

(3) The quantities indicated relate to the first refill only and are relative to the engine, oil sump and filter filling. (4) Fuel tank not supplied by FPT. Consult supplier / generator set manufacturers data. Only use fuels which comply with ASTM D975 or EN 590 international standards. - Page 28 Premium 10W-40 Semi - Synthetic < 15 ppm ACEA E6/E9 API CJ-4 Cold climate 5W-30 Synthetic < 15 ppm ACEA E6/E9 Not permitted Single-grade (*)To identify the product recommended by FPT refer to the Oil configurator using the QR-Code indicated:...

- Page 29 Coolant refilling Refuelling For the initial engine start-up and in the cases in which the refilling of Use only diesel oil in accordance with ASTM D975 or EN 590 the cooling circuit is required with a considerable quantity of coolant, standard normally commercially available.

-

Page 30: Checks And Maintenance

Do not leave external objects on the engine. The most qualified Assistance Centres are those which make up the Use suitable, safe containers for used oil. FPT Technical Assistance Network. Once the repair activities are completed, take the necessary steps ACCIDENT PREVENTION to stop engine air suction in case of uncontrolled increase in engine speed after start-up. -

Page 31: Maintenance Schedule

6 months Engine coolant replacement 3,000 hours (*) Indicated frequencies are valid only if the component (s) supplied by FPT. Periodic maintenance Frequency (1) Maximum period relative to the use of high quality fuel, (specification ASTM D975 or EN 590); this is reduced based on... - Page 32 2) To be performed every year even if the specified interval of devices. The procedure and modality for carrying out operating hours has not been reached. these operations are illustrated in the FPT Technical 3) To be performed every two years even if the specified number of and Repair Manual.

- Page 33 ATS System filter location 14_169_C 1. Dosing module filter (36 μm) - 2. Dosing module - 3. Supply module main-filter - 4. Supply module backflow-filter (100 μm) - 5. Supply module pre-filter (100 or 70 μm) - 6. AdBlue tank - 7. Tank neck filter (300 or 100 μm) - 8.

-

Page 34: Checks (In Period Of Use) - How To Proceed

CHECKS (IN PERIOD OF USE) – HOW TO PROCEED Risk of injury. Use suitable clothing, preferably tight-fitting; do not wear chains, rings, etc. Failure to observe these instructions could cause serious Safety notes - Check engine lubricant oil level health risks. General danger, general precautions. - Page 35 Engine lubricant oil level check The check must be executed when the engine is disconnected and possibly cool. Only proceed with the engine stopped and at low temperature, in order to avoid the risk of burning. Make sure the machine is on a flat surface. ...

- Page 36 Engine coolant level check Safety notes - Check engine coolant level Only proceed with the engine stopped and at low temperature, in General danger, general precautions. order to avoid the risk of burning. Before proceeding with the operation, please refer to the section 'Warnings and safety instructions".

- Page 37 Engine visual inspection It is a good habit to execute, before engine start, a series of simple General instructions. checks that might represent a valid warranty to avoid inconveniences, If the refill operations occur frequently a diagnosis of the cooling circuit is necessary. even serious, during engine running.

- Page 38 Safety notes - Air filter cleaning Air filter and housing cleanness check Only proceed with the engine stopped. Remove the filter cover (1) after first unscrewing the locking General danger, general precautions. handle. Before proceeding with the operation, please refer to the section 'Warnings and safety instructions".

- Page 39 Safety notes - Check condition of auxiliary belts General danger, general precautions. Before proceeding with the operation, please refer to the section 'Warnings and safety instructions". Failure to comply with these instructions can result in serious health risks and damage to the engine. 05_590_N Risk of injury.

- Page 40 Tension and condition check of auxiliary members’ belt Risk of injury. Only proceed when the engine is not turning and is at low Use suitable PPE (gloves, safety shoes, goggles, etc.). temperature so as not to run the risk of burns. Failure to observe these instructions could cause serious health risks.

- Page 41 Safety notes - Air filter cleaning Exhaust duct(s) condition check Visually check that the exhaust gas system is not blocked, corroded or damaged. General danger, general precautions. In the event of any problems, perform the operations necessary to Before proceeding with the operation, please refer to the restore the exhaust duct.

-

Page 42: Periodic Maintenance - How To Proceed

PERIODIC MAINTENANCE - HOW TO PROCEED Risk of burns. Safety notes - Drain water from fuel pre-filter Only carry out the following operation when the engine parts have cooled down. Failure to comply with these indications could result in General danger, general precautions. death or serious injury. - Page 43 Water drainage from the fuel pre-filter (if present) Safety notes - Draining condensate from fuel tank The high risk of refuelling with fuel that is polluted by foreign bodies General danger, general precautions. and water makes it advisable to carry out this control every time you Before proceeding with the operation, please refer to the refuel.

- Page 44 Safety notes - Replace engine lubricant oil Risk of burns. General danger, general precautions. Only carry out the following operation when the engine Before proceeding with the operation, please refer to the parts have cooled down. section 'Warnings and safety instructions". Failure to comply with these indications could result in Failure to comply with these instructions can result in death or serious injury.

- Page 45 Dispose of consumable materials and the parts in contact with them (for example filters) in accordance with the law. Retighten the lubricant oil cap (1). FPT Technical Service Network workshops are equipped Together with the replacement of the engine lubricant oil it is for this.

- Page 46 Safety notes - Replace engine lubricant oil filter General danger, general precautions. Before proceeding with the operation, please refer to the section 'Warnings and safety instructions". Failure to comply with these instructions can result in serious health risks and damage to the engine. General instructions.

- Page 47 (for example filters) in accordance with the law. using the dipstick. If necessary, top up to compensate for the FPT Technical Service Network workshops are equipped quantity of oil used to fill up the filtering cartridge. for this.

- Page 48 Safety notes - Fuel pre-filter replacement General danger, general precautions. Before proceeding with the operation, please refer to the section 'Warnings and safety instructions". Failure to comply with these instructions can result in serious health risks and damage to the engine. General danger, general precautions.

- Page 49 Fuel pre-filter replacement (if present) Only proceed with the engine stopped. Risk of burns. Only carry out the following operation when the engine Should the filter be fitted with a sensor to detect the presence of parts have cooled down. water (3), remove the whole sensor from its seat.

- Page 50 Safety notes - Replace fuel filter(s) General danger, general precautions. Before proceeding with the operation, please refer to the section 'Warnings and safety instructions". Failure to comply with these instructions can result in serious health risks and damage to the engine. General danger, general precautions.

- Page 51 Electric shock hazard. Risk of injury. Pay attention to the electrical fuel pre-heater (if installed) Do not smoke or use open flames during this operation. and its electrical connections. Do not inhale the vapours that exit the filter. Failure to observe the indications provided could cause Failure to observe these instructions could cause serious serious personal injury and damage to the vehicle.

- Page 52 Fuel filter replacement Start the engine and allow it to run at minimum for a few minutes to expel any remaining air. Only proceed with the engine stopped and at low temperature, in order to avoid the risk of burning. Only use filters with the following specifications (see the FREQUENCY chapter): - degree of filtering <...

- Page 53 Safety notes - Air filter replacement Air filter replacement (Demonstrative) Only proceed when the engine is not running. Remove the cover (4) of the air filter after having undone the two General danger, general precautions. quick release clips (3). Before proceeding with the operation, please refer to the section 'Warnings and safety instructions".

- Page 54 Safety notes - Replace auxiliary components belt General danger, general precautions. Before proceeding with the operation, please refer to the section 'Warnings and safety instructions". Failure to comply with these instructions can result in serious health risks and damage to the engine. General danger, general precautions.

- Page 55 Auxiliary members’ belt replacement Pull the automatic belt tensioner (1) by using appropriate tool and Risk of burns. remove the auxiliary members' belt (3) from alternator (8), water Only carry out the following operation when the engine pump (6), fan control pulley (2), crankshaft pulley with damper (5) parts have cooled down.

- Page 56 Safety notes - Clean the heat exchanger (radiator) General danger, general precautions. Before proceeding with the operation, please refer to the section 'Warnings and safety instructions". Failure to comply with these instructions can result in serious health risks and damage to the engine. Risk of injury.

- Page 57 Heat exchanger cleaning (radiator) (Supplied on demand) Risk of injury. When the engine is hot, the pressure inside cooling circuits Check that the air intake surfaces of the radiators are free of impurities is such that it may expel the hot liquid in an extremely (dust, mud, straw etc.).

- Page 58 Safety notes - Blow-by filter replacement Blow-by filter replacement The blow-by filter has been developed and equipped for the General danger, general precautions. collection, filtering and condense of the lubricating oil vapours. Before proceeding with the operation, please refer to the Only proceed with the engine stopped and at low temperature, in section 'Warnings and safety instructions".

-

Page 59: Extraordinary Maintenance - How To Proceed

EXTRAORDINARY MAINTENANCE - HOW TO Safety notes - Valves/rocker arm clearance PROCEED adjustment Turbocharger visual inspection General danger, general precautions. Before proceeding with the operation, please refer to the Only proceed when the engine is not turning over. Visually check that section 'Warnings and safety instructions". - Page 60 Valves/rocker arm clearance adjustment Safety notes - Change engine coolant The adjustment of the clearance between the rocker arms and the General danger, general precautions. intake and exhaust valve control rods must be strictly carried out using Before proceeding with the operation, please refer to the an Allen wrench (1), box-end wrench (3) and a feeler gauge (2).

- Page 61 Engine coolant replacement Only proceed when the engine is not turning, and is at low Risk of burns. temperature, so as not to run the risk of burns. When the engine is hot, the pressure inside cooling circuits is such that it may expel the hot liquid in an extremely ...

- Page 62 the coolant does not overfill the internal volume of the exchanger in order to allow the expansion of coolant volume during increases in temperature.

-

Page 63: Engine Handling

ENGINE HANDLING DISPOSAL OF WASTE The engine must only be removed and installed by authorised Service The engine consists of parts and elements that can cause ecological Centre personnel. damage if disposed of in the environment. For lifting only the engine use the eyelets indicated in this manual in The materials listed below must be delivered to authorised collection the chapter ENGINE TECHNICAL DATA and marked on the engine centres:... -

Page 64: Scheduled Maintenance For The Ats System - How To Proceed

SCHEDULED MAINTENANCE FOR THE ATS Filter disassembly SYSTEM - HOW TO PROCEED Unscrew and remove the filter cover (1). Remove the equalizing element (2). Change Supply Module main-filter To prevent damage to the pump and dosing module, the supply module contains a filter which removes any impurities from the AdBlue. - Page 65 Filter assembly Insert the appropriate tool (1) in the correct direction in the filter, based on the colour of the filter supplied. Carefully clean with water the contact surface (1). Insert the appropriate tool (1) until a click is felt which indicates the ...

- Page 66 Assembly a new equalizing element (2). Carefully clean the filter cover (1). Tighten the filter cover (1) to a torque of 20 ± 5 Nm. 14_188_C Check that the filter cover and the contact surface of the supply module are not cracked or damaged. If necessary, replace any damaged components.

-

Page 67: Long Periods Of Inactivity

LONG PERIODS OF INACTIVITY 7. Drain the residual protective oil from the sump. This oil can be used again for a further 2 preparation operations. PREPARING THE ENGINE FOR A LONG 8. Fit signs reading "ENGINE WITHOUT OIL" to the engine and to PERIOD OF INACTIVITY the on-board control panel. -

Page 68: Restarting The Engine After A Long Period Of Inactivity

RESTARTING THE ENGINE AFTER A LONG PERIOD OF INACTIVITY 1. Drain the residual protective oil from the sump. 2. Fill the engine, as prescribed, with lubricant of the type and amount indicated in the REFILLING table. 3. Drain the CFB protective fluid from the fuel circuit, carrying out this operation as indicated under point 3 of PREPARING THE ENGINE FOR A LONG PERIOD OF INACTIVITY. -

Page 69: Engine Malfunctions

ENGINE MALFUNCTIONS The electronic unit overseeing management and control of all operation of the engine is capable of recognising any malfunctions that may occur, and of adopting strategies that will allow you to proceed in full safety. The event, signalled by light-up of the EDC MALFUNCTION indicator on the on-board control panels, results in programmed limitation of power within certain thresholds, set according to the severity of the case. -

Page 70: Behaviour In Emergency

BEHAVIOUR IN EMERGENCY Cover the burn with a special burn dressing or sterile bandage. Carbon monoxide intoxication (CO) The user of a machine that has been constructed according to safety regulations, when following the instructions provided in this manual Carbon monoxide from the engine exhaust is without smell, and is and the indications given on the engine labels, will be working in safe dangerous both because it causes intoxication, and because when... - Page 71 Electrocution Caustic burns The engine 12 V electrical system does not involve the risk of Caustic skin burns are caused by contact with extremely acid or electrocution, however, in the event of a short-circuit caused, for alkaline substances. example, by a metal tool, there is a risk of burning due to overheating For electric maintenance technicians these are typically caused by acid of the object through which the electrical current runs.

- Page 72 RECOMMENDED OPERATING TEMPERATURE RANGE The use of viscosity grade to be used depends on the ambient temperature, as shown in the figure below 15W - 40 10W - 40 5W - 30 Temperature -30°C -20°C -10°C 0°C 10°C 20°C 30°C 40°C 50°C 17_076_N...

Need help?

Do you have a question about the NEF Series and is the answer not in the manual?

Questions and answers