FPT NEF Series Use And Maintenance

Mechanical injection system industrial engines

Hide thumbs

Also See for NEF Series:

- Use and maintenance (72 pages) ,

- Use and maintenance (33 pages) ,

- Use and maintenance (60 pages)

Table of Contents

Advertisement

Advertisement

Table of Contents

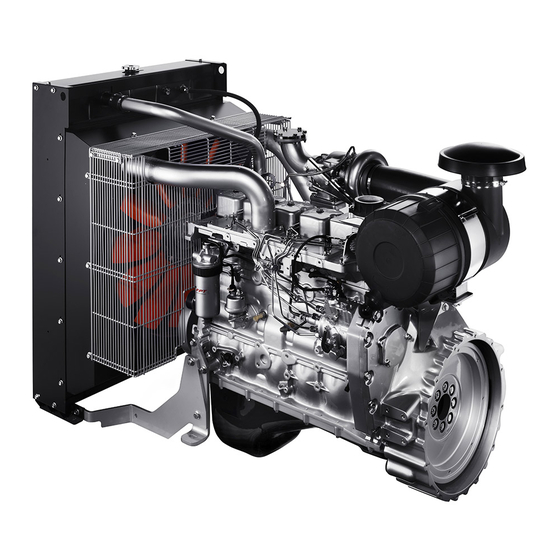

Summary of Contents for FPT NEF Series

- Page 2 NEF SERIES INTRODUCTION We would like to thank you for buying an IVECO MOTORS product, and compliment you on your choice of engine. MECHANICAL INJECTION Before you carry out any operation involving the engine or its fittings, please read the contents of this manual carefully; compliance...

-

Page 3: Table Of Contents

TABLE OF CONTENTS Page Page GENERAL INFORMATION ......3 LONG PERIODS OF INACTIVITY ..... . .35 Guarantee . -

Page 4: General Information

GENERAL INFORMATION The engines must only be used for the purposes indicated by the Manufacturer. Any tampering, modification and use of non-original spare parts GUARANTEE may compromise proper operation and safe use of the engine; In order to ensure that your engine gives the best possible never, under any circumstances make modifications to performance and to take advantage of the IVECO MOTORS the wiring and to the units equipping the engine, or connect them... -

Page 5: Engine Technical Data N45 Mna - N45 Msa

ENGINE TECHNICAL DATA N45 MNA - N45 MSA Performance: Maximum power (*) The technical code and serial number are indicated on a plate, which is located on different parts of the engine, according to the model: Maximum torque flywheel casing, tappet cover, other. N45 MNA / MSA 60 kW (81 CV) @ 2300 rpm 320 Nm (33 Kgm) @ 1400 rpm... - Page 6 05_591_N 05_592_N Engine N45 MNA - N45 MSA Engine N45 MNA - N45 MSA 1. Auxiliary member drive belt - 2. Fuel filter - 3. Oil filler cap - 4. 1. Exhaust manifold - 2. Oil vapour bleeder - 3. Exhaust outlet - Fuel outlet connector to tank - 5.

-

Page 7: Engine Technical Data N45 Mns/Mss/Mnt/Mst

ENGINE TECHNICAL DATA N45 MNS/MSS/MNT/MST Performance TIER2 Maximum power (*) The technical code and serial number are indicated on a plate, which Maximum torque is located on different parts of the engine, according to the model: N45 MNS / MSS 74 kW (100 CV) @ 2300 rpm flywheel casing, tappet cover, other. - Page 8 05_595_N 05_596_N Engine N45 MNS/MSS/MNT/MST EngineN45 MNS/MSS/MNT/MST 1. Auxiliary member drive belt - 2. Fuel filter - 3. Oil filler cap - 4. 1. Exhaust manifold - 2. Turbocharger air inlet - 3. Turbocharging air Fuel outlet connector to tank - 5. Oil vapour bleeder - 6. Lifting U- outlet ( only for N45 MNT / MST engines) - 4.

-

Page 9: Engine Technical Data N67 Mna/Msa/Mnt/Mst

ENGINE TECHNICAL DATA N67 MNA/MSA/MNT/MST The technical code and serial number are indicated on a plate, which Performance TIER2 Maximum power (*) is located on different parts of the engine, according to the model: Maximum torque flywheel casing, tappet cover, other. N67 MNA / MSA 81 kW (110 CV) @ 2500 rpm 440 Nm (45 Kgm) @ 1400 rpm... - Page 10 05_597_N 05_598_N Engine N67 MNA/MSA - N67 MNT/MST EngineN67 MNA/MSA - N67 MNT/MST 1. Auxiliary member drive belt - 2. Fuel filter - 3. Oil filler cap - 4. 1. Exhaust manifold - 2. Oil vapour bleeder - 3. Turbocharger air Engine intake manifold - 5.

-

Page 11: Engine Technical Data Nef 45 Sm1/Sm2 - Tm1/Tm2

ENGINE TECHNICAL DATA NEF 45 SM - TM Performance NEF 45 SM1 The technical code and serial number are indicated on a plate, which (50 Hz) Prime 53.5 kWm @ 1500 rpm is located on different parts of the engine, according to the model: Stand by 59 kWm @ 1500 rpm flywheel casing, tappet cover, other. - Page 12 05_611_N 05_612_N Engine NEF 45 SM - TM EngineNEF 45 SM - TM 1. Heat exchanger/s - 2. Coolant filler cap - 3. Oil filler cap - 4. 1. Exhaust manifold - 2. Turbocharger air intake - 3. Turbocharging Engine air inlet manifold - 5. Oil vapour bleeder - 6. Lifting U-bolt - air outlet - 4.

-

Page 13: Engine Technical Data Nef 67 Sm1 - Tm2/Tm3

ENGINE TECHNICAL DATA NEF 67 SM - TM The technical code and serial number are indicated on a plate, which Performance NEF 67 SM1 is located on different parts of the engine, according to the model: (50 Hz) Prime 110 kWm @ 1500 rpm flywheel casing, tappet cover, other. - Page 14 05_605_N 05_606_N Engine NEF 67 SM - TM EngineNEF 67 SM - TM 1. Coolant filler cap - 2. Heat exchanger - 3. Lubricant oil filler cap 1. Exhaust manifold - 2. Turbocharger air intake - 3. Turbocharging air - 4. Engine air inlet manifold - 5. Waste-gate - 6. Oil vapour bleeder outlet - 4.

-

Page 15: Signs

SIGNS Certain warning signs are affixed to the engine by the Manufacturer, and their meanings are indicated below N.B. The signs with an exclamation mark on them underline a potential danger. Lifting point (engine only). Danger of burning: Expulsion of hot water under pressure. Fuel Cap Danger of burning: (on the fuel tank, if there is one). -

Page 16: Use

STARTING AND STOPPING THE ENGINE The start-up and shut-down operations described below apply to an on-board control panel manufactured by IVECO MOTORS; if the PRELIMINARY CHECKS Manufacturer of the vehicle or machine has fitted a customised Before starting the engine each time: instrument panel, these operations may vary according to the various choices made during construction. - Page 17 Starting the engine from the IVECO MOTORS control panel 1. Insert the key into the switch (1) and turn it to the right to position 1B. “Run”. Once the indicator lights have been tested and the beeper has stopped sounding, make sure that the analogue instruments are showing values that conform with the relevant physical parameters of temperature, battery voltage and oil pressure;...

- Page 18 Start-up of a power generator Stopping the engine from the IVECO MOTORS control panel The start-up method described above may vary, depending on the solutions used to create the electric panels and the system control Before stopping the engine it is recommended you run it for a few and running boards;...

-

Page 19: Recognising Alarms

RECOGNISING ALARMS Operation When the key is turned in the switch to position 1B an efficiency Indicator and alarm synoptics test is performed, for 5 seconds, on all the indicator lights, with the The IVECO MOTORS instrument panel contains the indicator lights exception of the “Pre-post heating”... -

Page 20: Engine Pre-Heating

ENGINE PRE-HEATING FOR PROPER USE OF THE ENGINE (optional) (220 V, single phase electrical device) (with the exception of power generator engines) The engines for which low temperature start-up and immediate Do not leave the key turned to the start position , when the delivery of power are required may be fitted with a 220 V single engine has started. -

Page 21: Special Warnings

SPECIAL WARNINGS Fuel circuit Avoid using the engine with only a small reserve of fuel in the fuel Coolant circuit tank; this encourages the formation of condensation and makes it When a state of “Coolant temperature high” and “Engine coolant more likely you will suck up dirt or air, resulting in engine stoppage. -

Page 22: Running In

RUNNING IN Thanks to modern engine construction technology, no particular CAUTION! running in procedure is required. However, it is recommended that, for the first 50 hours, you do not use the engine at high power for Visually check that the exhaust circuit is not blocked or long periods. -

Page 23: Refuelling

REFUELLING Oil consumption is considered acceptable when it reaches a maximum of 0.5% of fuel consumption Parts to be supplied N45 ... N67 ... (3)The amounts indicated refer to initial refuelling, and include filling NEF 45 ... NEF 67 ... the engine, sump and filter. -

Page 24: Controls And Maintenance

CONTROLS AND MAINTENANCE • replacing or topping up lubricant (hot engine oil may cause burns and scalds. Only carry out these operations when the oil has dropped to a temperature of below 50°C). MAINTENANCE PERSONNEL When working in the engine compartment, pay particular The engine control and maintenance operations described in the attention to how you move, to avoid contact with moving parts following chapter require training, experience and compliance with... -

Page 25: Frequency

CAUTION! Planned maintenance Frequency Do not carry out maintenance operations when the electric power supply is turned on: always check to ensure that the Check state and tension of belt 300 hours appliances are properly earthed. During diagnosis and (3) (4) Change oil 600 hours maintenance operations, make sure that your hands and feet... -

Page 26: Requirements

6) The frequency with which operations are carried out will depend on the working conditions and efficiency/wear of the product. Special maintenance 7) Required by oil vapour recirculation. Frequency Clean the turbocharger 1200 hours REQUIREMENTS 1. Do not disconnect the batteries with the engine running. Check the efficiency of the pre-post 1200 hours heating system (if there is one) -

Page 27: How To Proceed

HOW TO PROCEED Check oil level in engine Only proceed with the engine stopped and at a low temperature, so as to avoid the risk of burning. Take all necessary action to ensure that the machine is “level”. Using the dipstick (1), check that the oil level is between the "Min"... - Page 28 Check coolant level Clean heat exchangers Only proceed with the engine stopped and at a low temperature, so Check that the radiator air inlets are free from dirt (dust, mud, as to avoid the risk of burning. straw, etc.). Clean them if necessary, using compressed air or steam. With the engine cold, make sure that the level of coolant in the expansion tank is above the minimum level.

- Page 29 Cleaning the air filter (Refers to IVECO MOTORS components) WARNING Only proceed with the engine stopped. Remove the filter cover (1) after first unscrewing the locking Take care to ensure that the parts are reassembled correctly. handle. Imperfect assembly might result in unfiltered air being sucked into the Remove the external cartridge (2), after unfastening the second engine, causing serious damage.

- Page 30 Drain water from the fuel pre-filter Visually check that the fluid level is between the “Min” and “Max” limits; in the absence of references, check that the fluid covers The high risk of refuelling with fuel that is polluted by foreign bodies the Lead plates inside the elements.

- Page 31 Restore the correct tension in the auxiliary member drive belt (Refers to engines with traditional tensioning devices) Loosen the screw fixing the alternator to the bracket (1). Loosen the bolt anchoring the alternator to its lower support. Proceed to tighten the tensioner (2), locking the counternut. On reaching the required tension, lock the fixing screws and bolt.

- Page 32 Change oil Change oil filter Only proceed with the engine stopped and at a low temperature, so Only proceed with the engine stopped and at a low temperature, so as to avoid the risk of burning. as to avoid the risk of burning. Only use filters with a filtration level equivalent to the ones you are Place a container under the drainage plug to collect the used oil replacing (see section FREQUENCY).

- Page 33 Change fuel filter/s WARNING Only proceed with the engine stopped and at a low temperature, so as to avoid the risk of burning. Do not fill up the new filter before it is fitted to the support, to avoid Only use filters with a filtration level equivalent to the ones you are inserting harmful impurities into the injection system and circuit.

- Page 34 Changing the fuel pre-filter Check the efficiency of the earthing connection of the filter support. Only proceed with the engine stopped. NOTE: should it be necessary to accelerate the bleeding phase, the Should the filter be fitted with a hand pump can be used during start-up. sensor to detect the presence of water, remove the whole sensor Check exhaust pipe/s for damage...

-

Page 35: Moving The Engine

MOVING THE ENGINE The operations necessary to disconnect and subsequently reconnect the engine must only be carried out by technicians from WARNING Authorised Service Centres. When lifting the engine only, use the U-bolts indicated in this manual in the section ENGINE TECHNICAL DATA and marked on the The operations listed below must only be carried out by qualified staff engine with special stickers. -

Page 36: Long Periods Of Inactivity

LONG PERIODS OF INACTIVITY 7. Drain the residual 30/M protective oil from the sump. This oil can be used again for a further 2 preparation operations. 8. Fit signs reading "ENGINE WITHOUT OIL" to the engine and to PREPARING THE ENGINE FOR A LONG the on-board control panel. -

Page 37: Restarting The Engine After A Long Period Of Inactivity

RESTARTING THE ENGINE AFTER A LONG PERIOD OF INACTIVITY 1. Drain the residual 30/M protective oil from the sump. 2. Fill the engine, as prescribed, with lubricant of the type and amount indicated in the table REFUELLING. 3. Drain the CFB protective fluid from the fuel circuit, carrying out this operation as indicated under point 3. -

Page 38: Behaviour In An Emergency

BEHAVIOUR IN AN EMERGENCY 2. Do not attempt to remove pieces of clothing that may have stuck to the skin; The user of a machine that has been constructed according to safety 3. In the case of scalding, immediately but carefully remove any regulations, when following the instructions provided in this manual clothing that may be soaked in the hot liquid;... - Page 39 Electrocution Injuries and fractures A. The engine's electrical 12 V or 24 V electrical system does not The vast number of possible circumstances and the specific nature of operations required means that the intervention of a medical involve the risk of electrocution, however, in the event of a team is necessary.

- Page 41 ELECTRONIC CONTROL PANEL USE REQUIREMENTS The data indicated below refer to IVECO MOTORS equipment in its original configuration. The requirements and technical characteristics of the customisations may differ from those indicated and must be dealt with in a specific document prepared by those who have performed any such customisations. IVECO MOTORS control panels With analogue instruments With digital instruments...

Need help?

Do you have a question about the NEF Series and is the answer not in the manual?

Questions and answers