Summary of Contents for Amazone AMATRON+ ZA-M

- Page 1 Operating Manual On-board computer AMATRON ZA-M Please read this operating manual before first MG3685 commissioning. BAG0063.1 03.10 Keep it in a safe place for Printed in Germany future use.

- Page 2 Reading the instruction Manual and following it should seem to be in- convenient and superfluous as it is not enough to hear from others and to realize that a machine is good, to buy it and to believe that now everything should work by itself.

- Page 3 + 49 (0)5405 501-234 E-mail: amazone@amazone.de Spare part orders Spare parts lists are freely accessible in the spare parts portal at www.amazone.de. Please send orders to your AMAZONE dealer. Formalities of the operating manual Document number: MG3685 Compilation date: 03.10 ...

- Page 4 Send us your suggestions by fax. AMAZONEN-WERKE H. DREYER GmbH & Co. KG Postfach 51 D-49202 Hasbergen Tel.: + 49 (0)5405 501-0 Fax: + 49 (0)5405 501-234 E-mail: amazone@amazone.de Amatron+ BAG0063.1 03.10...

-

Page 5: Table Of Contents

Table of Contents User Information ..................7 Purpose of the document......................7 Locations in the operating manual...................7 Diagrams used .........................7 General safety instructions.................8 Representation of safety symbols....................8 Installation instructions ................9 Connection ..........................9 Battery cable ..........................10 Product description ...................11 Keys and function fields ......................12 4.1.1 Shift key ..........................13 Entries on AMATRON... - Page 6 Table of Contents ZA-M Comfort ......................53 6.4.1 Procedure for use........................53 6.4.2 Work menu key layout......................54 ZA-M Hydro........................56 6.5.1 Procedure for use........................56 6.5.2 Work menu key layout......................57 Filling with fertiliser ........................ 59 Emptying fertiliser hopper ..................... 60 Multifunction stick..................

-

Page 7: User Information

User Information User Information The User Information section supplies information on use of the oper- ating manual. Purpose of the document This operating manual Describes the operation and maintenance of the machine. Provides important information on safe and efficient handling of the machine. -

Page 8: General Safety Instructions

General safety instructions General safety instructions Knowledge of the basic safety information and safety regulations is a basic requirement for safe handling and fault-free machine operation. The operation manual Must always be kept at the place at which the machine is oper- ated. -

Page 9: Installation Instructions

Installation instructions Installation instructions Connection The tractor's basic equipment (Fig. 1/1 console with distributor) must be installed to the right of the driver in the cab, within visual range and easy reach, so that it is vibration-free and electrically conductive. -

Page 10: Battery Cable

Installation instructions Battery cable The required operating voltage is 12 V and must taken directly from the battery. Before connecting the AMATRON to a tractor with sev- eral batteries, you need to clarify which battery the computer should be connected to by referring to the tractor operating instructions or by asking the tractor manufacturer. -

Page 11: Product Description

AMAZONE ZA-M fertiliser spreader. The AMATRON can be used for various machine types. The AMATRON works with the following AMAZONE fertiliser spreaders: ZA-M Tronic with power take-off ZA-M Comfort ... -

Page 12: Keys And Function Fields

Product description Keys and function fields The functions shown on the right of the display in a function field (box or diagonally divided box) are controlled via the two rows of keys to the right of the display. If boxes appear on the display, only the right key (Fig. -

Page 13: Shift Key

Product description 4.1.1 Shift key The shift key is located on the back of the unit (Fig. 8/1). If the Shift key is active, this is indicated on the display (Fig. 9/1). You press the Shift key to display more function fields (Fig. -

Page 14: Entries On Amatron

Product description Entries on AMATRON For operation of the AMATRON the function fields appear in this oper- ating manual in order to make clear that the key for the respective function field must be pressed. Example: Function field Description in the operating manual: Perform function A. -

Page 15: Selection Of Options

Product description 4.3.1 Selection of options Position the selection arrow (Fig. 13/1) with Accept the selection (Fig. 13/2). Fig. 13 4.3.2 Toggle function Switching functions on and off: Press function key (Fig. 14/2) once Function on (Fig. 14/1). ... -

Page 16: Hierarchy Of The Amatron

Product description Hierarchy of the AMATRON Work menu Main menu Job menu Fertiliser calibration menu (at standstill) Enter names Enter working width Enter note Enter desired quantity Start/continue job Enter speed Delete job ... -

Page 17: Commissioning

Commissioning Commissioning Start screen After the AMATRON is switched on with the machine computer connected, the Start screen appears, indicating the terminal software version number. The main menu appears after about 2 seconds. If after the AMATRON is switched on data are loaded from the machine computer, e.g. - Page 18 Commissioning Machine data menu (page 19) Input of machine-specific or individual data. Setup menu (page 37) Input of basic settings Mobile test rig menu (page 42) For calibrating the vane setting when checking lateral distribution with the mobile test rig.

-

Page 19: Entering Machine Data

Commissioning Entering machine data Select Machine data in the main menu. Page one (Fig. 17) Enter fertiliser quantity in kg (not ZA-M Profis). Fill with fertiliser (see page 59). Enter alarm limit for residual quantity in kg. Fig. - Page 20 Commissioning Page three (Fig. 19) Row counter on/off: The stored headland distance is displayed to locate the tramlines. The counter starts displaying the tramlines when the slide gates are being closed. Spread rice on/off. Fig. 19 Spread slug pellets on/off.

-

Page 21: Configuring Quantity Reduction (Machine Data )

Commissioning Page four (Fig. 20) ZA-M Hydro : enter spreader disc speed in rpm (see settings chart, standard = 720 rpm.) Spreader disc speed in rpm for boundary spreading. Fig. 20 Spreader disc speed in rpm for trench spreading. -

Page 22: Calibrating Distance Sensor (Machine Data )

Commissioning 5.3.2 Calibrating distance sensor (machine data The AMATRON needs the pulse/100 m value to determine the actual speed. This value must not be less than 250, otherwise the AMATRON will not function properly. There are two possibilities for entering pulses/100 m: ... -

Page 23: Entering Power Take-Off Speed (Machine Data )

Commissioning The pulse/100 m value can be stored for 3 tractors: Select tractor Enter/change name Enter pulse/100 m for selected trac- If a tractor has already been stored Fig. 24 here, its pulse/100 m and power take- off speed values will be used. 5.3.3 Entering power take-off speed (machine data ... - Page 24 Commissioning Memory for 3 tractors with associ- ated value for pulses/revolution Select tractor Enter/change name Enter pulses/revolution for power take-off. Enter upper alarm limit in %. (Standard value = 10 %). Enter lower alarm limit in %. (Stan- dard value = 10 %). Amatron+ BAG0063.1 03.10...

-

Page 25: Starting A Job

Commissioning Starting a job Select Job in main menu. When the Job menu is opened, the most recently started (most recently processed) job appears. Information on max. 20 jobs can be stored (job numbers 1 to 20). To create a new job, select a job number (Fig. -

Page 26: External Job

Commissioning With the shift key pressed (Fig. 27): Scroll forward through job. Scroll backward through job. Fig. 27 5.4.1 External job Using a PDA, an external job can be transferred to the AMATRON and then started. This job is always given the job number 21. The data is transferred via the serial interface. -

Page 27: Calibrating Fertiliser

Commissioning Calibrating fertiliser Select calibrate fertiliser in main menu. The fertiliser calibration factor determines the regulating behaviour of the AMATRON and is dependent on the flow characteristics of the fertiliser to be spread the entered spread rate the entered working width The fertiliser flow characteristics depend on: ... -

Page 28: Determining Fertiliser Calibration Factor At Standstill

Commissioning 5.5.1 Determining fertiliser calibration factor at standstill 1. Add a sufficient quantity of fertiliser to the hopper. 2. Remove the left spreading disc. 3. Fit collection bucket under the left outlet (refer to ZA-M operating manual). Check/enter the working width Check/enter the spreading quantity. - Page 29 Commissioning The scales must weigh accurately. Inaccuracies may cause devia- tions in the actual dispensed quantity. 13. Enter amount of weighed fertiliser in kg. The new calibration factor will be displayed (Fig. 30). Confirm or reject calibration factor. Fig. 30 Spreading rice: Machine data menu: rice spreading on.

-

Page 30: Conduct Fertiliser Calibration Run (Offline Calibration)

Commissioning 5.5.2 Conduct fertiliser calibration run (offline calibration) Only for ZA-M Profis: Automatic fertiliser calibration occurs at the start of sowing during spreading, with a minimum 200 kg fertiliser being dispensed. Machine data menu page three Offline calibration mode. Offline calibration mode activated: Fig. - Page 31 Commissioning Determining fertiliser calibration factor auto- matically Select the work menu. Start automatic calibration. 3. Start spreading as usual and spread at least 200 kg of fertiliser. The quantity of fertiliser dispensed is shown in the work menu (Fig. 33/1). ...

-

Page 32: Calibrate Permanent Fertiliser (Online Calibration)

Commissioning 5.5.3 Calibrate permanent fertiliser (online calibration) Only for ZA-M Profis: The calibration value is recalculated continuously during online weighing, as is the dispensed quantity. The required slider position is matched online. Machine data menu page three Online calibration mode Fig. - Page 33 Commissioning Online calibration is only possible when the scales are not moving and there is more than 200 kg in the hop- per. If the symbol appears in the dis- play, the spreader is not in its still. During online calibration, the work menu dis- plays: (1) current calibration factor (Fig.

-

Page 34: Calibration Of Slug Pellets

Commissioning 5.5.4 Calibration of slug pellets CAUTION Before spreading slug pellets, be sure to check the spreading quan- tity for both outlets in turn. To spread slug pellets, go to Machine data menu page 3 Switch on slug pellets (Fig. 39). ... - Page 35 Commissioning Press the key until the read- off edge (Fig. 42/1) of the left dosing slider shows the required slider position. Fig. 42 Switch to the job menu via the main menu (Fig. 43). Delete the day's date in the started job (Fig.

- Page 36 Commissioning The scales must weigh accurately. Inaccuracies may cause deviations in the actual dispensed quantity. Read off the theoretically dispensed quantity of pellets from the job and compare it with the weighed quantity. 20. If the calculated quantity for the job is ...

-

Page 37: Service Setup

Commissioning Service Setup In the main menu, select Setup and confirm with Page 1 (Fig. 45) Diagnosis computer input (only for customer service). Diagnosis computer output (only for customer service). Enter simulated speed (allows con- Fig. 45 tinued spreading despite faulty distance sensor, see page 71). - Page 38 Commissioning Page 1 Basic data (Fig. 47): Selecting machine type. Weighing cell present, on / off Calibrate weighing cell (page 39). Fig. 47 Limiter present Left Right Page 2 Basic data (Fig. 48): ...

-

Page 39: Taring/Calibrating Weighing Cell

Commissioning 5.6.1 Taring/calibrating weighing cell The weighing cell is tared and calibrated at the factory. However, if there are differences be- tween the actual and the spread quantity or the hopper contents, the weighing cell needs to be recalibrated. See Service Set-up , Basic data menu, page one The weighing cell should be tared if... -

Page 40: Terminal Set-Up

Commissioning Terminal set-up Press Scroll and Shift simultaneously. Terminal Set-up is used to change display set- tings. Change display settings. Display devices and software ver- sions on the bus. Fig. 50 Page 1 of Terminal set-up Set the contrast via the function fields ... - Page 41 Commissioning Page 2 of Terminal set-up Entry of time. Entry of date. Entry of data transfer speed. Fig. 53 Page 3 of Terminal set-up Delete program: Select program. Delete program. Fig. 54 Amatron+ BAG0063.1 03.10...

-

Page 42: Mobile Test Rig

Commissioning Mobile test rig Select mobile test rig in the main menu. Start mobile fertiliser test rig as explained in the mobile test rig operating manual and estimate the lateral distribution. Fig. 55 Enter the number of scale lines for fertiliser level I. -

Page 43: Use On The Field

Use on the field Use on the field CAUTION During travel to the field and on public roads, the AMATRON should always be switched off! Incorrect use leads to the risk of accidents! ZA-M Profis: Carry out an automatic fertiliser calibration when you start spreading. -

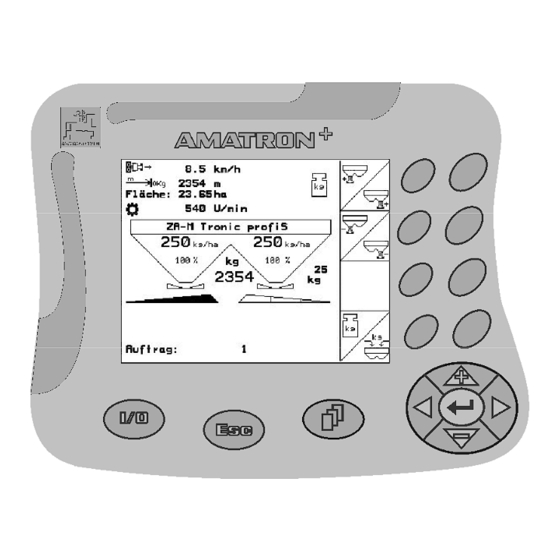

Page 44: Work Menu Display

Use on the field Work menu display Speed ZA-M Profis only Scales still Remaining distance until hopper empty Scales not still Spread area (in job) Spread amount left Spread amount right in kg/ha in kg/ha Spread amount left in % Spread amount right in Calibration steady / minimum volume spread... -

Page 45: Functions In Work Menu

Use on the field Functions in work menu Slide gate (ZA-M Comfort Hydro only) 6.2.1 Both slide gates open/shut Slide gate left/right, open/shut Open slide gates before use, and drive off once the spreader discs have reached the correct speed Fig. -

Page 46: Changing Spread Quantity Left/Right

Use on the field 6.2.3 Changing spread quantity left/right Increase spread quantity left, right. Reduce spread quantity left, right. Each press of the key changes the spread amount by the rate increase (e.g. 10%). Enter the rate increase in the Machine data menu Fig. -

Page 47: Calibrating Fertiliser (Za-M Profis Only)

Use on the field Calibrating fertiliser (ZA-M Profis only) 6.2.5 Automatic fertiliser calibration for weighing spreader, see page 30. Fig. 62/… (1) Display Fertiliser spreader during calibration travel. Calibrate fertiliser at start of spreading or calibrate fertiliser online. (2) Display Scales moving. -

Page 48: Switching Spreading Disc Drive On And Off (Za-M Hydro Only)

Use on the field Switching spreading disc drive on and off (ZA-M Hydro only) 6.2.7 Spreader discs on/of. To switch on, press the key for at least three seconds until the tone stops. The spreader discs operate at the speed entered in the Machine data menu Fig. -

Page 49: Boom Part Width Sections (Za-M Hydro Only)

Use on the field Boom part width sections (ZA-M Hydro only) 6.2.8 Switch on boom part width sections left, right (3 steps) Switch off boom part width sections left, right (3 steps) Fig. 64/… (1) Display Two right-hand boom part width sections switched off. -

Page 50: Boundary Spreading (Za-M Hydro Only)

Use on the field Boundary spreading (ZA-M Hydro only) 6.2.9 Switch on/off trench spreading left/right. Switch on/off boundary spreading left/right. Switch on/off side spreading left/right. Boundary spreading can also be carried out on both sides. Switch on boundary spreading left and right. Reduce/increase spreader disc speed for selected type of spreading. -

Page 51: Za-M Tronic

Use on the field ZA-M Tronic 6.3.1 Procedure for use Switch on the AMATRON Select the work menu. 3. Set the power take-off speed (see setting chart). 4. Drive off and open both slide gates using tractor controllers 1 and 2. In the case of the weighing spreader ... - Page 52 Use on the field Layout for multifunction stick Amatron+ BAG0063.1 03.10...

-

Page 53: Za-M Comfort

Use on the field ZA-M Comfort 6.4.1 Procedure for use 1. Use tractor control 1 to supply the control block with hydraulic fluid. Switch on the AMATRON Select the work menu. 4. Set the power take-off speed (see setting chart). 5. -

Page 54: Work Menu Key Layout

Use on the field 6.4.2 Work menu key layout Page 1: Description of the function fields section 6.2.1 Both slide gates open/shut. 6.2.1 Slide gate left/right, open/shut. 6.2.2 Boundary spreading with limiter on/off Shift key pressed: Description of the function fields section 6.2.3 Increase spread quantity left, right. - Page 55 Use on the field Layout for multifunction stick Amatron+ BAG0063.1 03.10...

-

Page 56: Za-M Hydro

Use on the field ZA-M Hydro 6.5.1 Procedure for use 1. Use tractor control 1 to supply the control block with hydraulic fluid. Switch on the AMATRON+. Select the work menu. Switch on spreader discs. 5 Move off and open the slide gates In the case of the weighing spreader ... -

Page 57: Work Menu Key Layout

Use on the field 6.5.2 Work menu key layout Page 1: Description of the function fields section 6.2.7 Spreader discs on/of. 6.2.1 Both slide gates open/shut 6.2.1 Slide gate left/right, open/shut 6.2.8 Switch on boom part width sections left, right. 6.2.8 Switch off boom part width sections left, right Shift key pressed:... - Page 58 Use on the field Page 2: Description of the function fields section 6.2.9 Reduce/increase spreader disc speed 6.2.9 Switch on/off trench spreading left/right 6.2.9 Switch on/off boundary spreading left/right 6.2.9 Switch on/off side spreading left/right Layout for multifunction stick Amatron+ BAG0063.1 03.10...

-

Page 59: Filling With Fertiliser

Use on the field Filling with fertiliser In the work menu (Fig. 66). In Machine data menu page one (Fig. 67). Open the fill menu. 2. Fill with fertiliser. Fertiliser spreader without weighing cell: Enter amount of fertiliser in kg. Fertiliser spreader with weighing cell Fig. -

Page 60: Emptying Fertiliser Hopper

Use on the field Emptying fertiliser hopper The remaining fertiliser in the hopper can be emptied via the hopper tips. 1. Remove the spreader discs (see machine operating manual) 2. Machine data menu: Open both dosing sliders. 3. Open both slide gates. ... -

Page 61: Multifunction Stick

Multifunction stick Multifunction stick Installation The multifunction stick (Fig. 70/1) is attached with 4 screws at a convenient location in the tractor cab. To connect, insert the connector of the basic equipment into the 9-pin Sub-D-bushing of the multifunction stick (Fig. 70/2). Insert the connector (Fig. -

Page 62: Key Layout

Multifunction stick Key layout: ZA-M Tronic ZA-M Comfort ZA-M Hydro Spreading disc drive on/off Switch on boom part width sections left Switch off boom part width sections left Switch on boom part width sections right Switch off boom part width sections right Both slide gates open Both slide gates closed... -

Page 63: Maintenance And Cleaning

Maintenance and cleaning Maintenance and cleaning WARNING Perform maintenance and cleaning only with the spreader discs and agitator shaft drive switched off. Cleaning DANGER Do not reach into the outlet opening while operating the sliders! Risk of crushing! To clean the fertiliser spreader, you must have the slide gates and the electric dosing sliders open so the water and residual fertiliser can drain. - Page 64 Maintenance and cleaning Close the outlet fully (0 pulses). Open the outlet to 1500 pulses. DANGER Risk of injury near dosing sliders when key pressed because the sliders close before the selected setting is Fig. 75 applied. Keep fingers and gauges away from the opening.

-

Page 65: Malfunction

Malfunction Malfunction Alarm Uncritical alarm: A fault message (Fig. 79) appears at the bottom of the display and an acoustic alarm sounds three times. Rectify the fault if possible. Example: Fault message: spreader disc speed too low. Remedy: increase speed of power take-off Fig. -

Page 66: Error Messages And Remedies

Malfunction Error messages and remedies Error messages Cause / description of fault Fault remedy Setpoint value Application rate cannot be maintained Reduce ground travel cannot be main- with the set parameters at current ground speed tained travel speed. Reduce setpoint value Input of setpoint in "kg/ha"... - Page 67 Malfunction Error in calibra- tion of scales After the scale calibration process, a Repeat calibration of (parameter 2 parameter 2 of less than 1.0 was de- the scales below 1.0), tected. This is not admissible. please repeat Enter pulses per 100 Value of pulses per 100 m is missing, so Pulses per 100 that ground travel speed cannot be cal-...

- Page 68 Malfunction Calibration not possible due to Position of dosing shutter calculated setpoint, please from values "Setpoint / calibration factor Check / modify pa- check calibra- / intended ground travel speed / working rameters tion factor and width" cannot be reached. intended ground travel speed.

- Page 69 Malfunction Check sensor (input Cleaning hood Sensor on cleaning hood of ZG-B Ultra diagnosis) sensor failed Hydro transmits no signal. Replace sensor The system has detected that the clean- Cleaning hood ing hood is open. This condition is not ...

-

Page 70: Failure Of Setting Motors

Malfunction Failure of setting motors If faults occur in the AMATRON or electric setting motors and cannot be rectified immedi- ately, you can still continue working: after extending the setting motors, after modifying the setting lever. The rate as per setting chart is then determined by means of the setting lever (Fig. -

Page 71: Distance Sensor (Pulses/100 M Failure)

Malfunction Secure the detached pushrod (Fig. 82/2) against swivelling into the working area of the hydraulic cylinder. 6. Set up the clamping device (Fig. 83/1) for setting levers (Fig. 83/2) as follows: 6.1 Unscrew the wing nut (Fig. 83/3). 6.2 Remove the screw and reposition the two washers (Fig. - Page 72 + 49 (0) 5405 501-0 D-49202 Hasbergen-Gaste Fax: + 49 (0) 5405 501-234 Germany e-mail: amazone@amazone.de http:// www.amazone.de Plants: D-27794 Hude D-04249 Leipzig F-57602 Forbach Branches in England and France Manufacturers of mineral fertiliser spreaders, field sprayers, seed drills, soil cultivation machines, mul-...

Need help?

Do you have a question about the AMATRON+ ZA-M and is the answer not in the manual?

Questions and answers