Table of Contents

Advertisement

Register at www.Toro.com.

Original Instructions (EN)

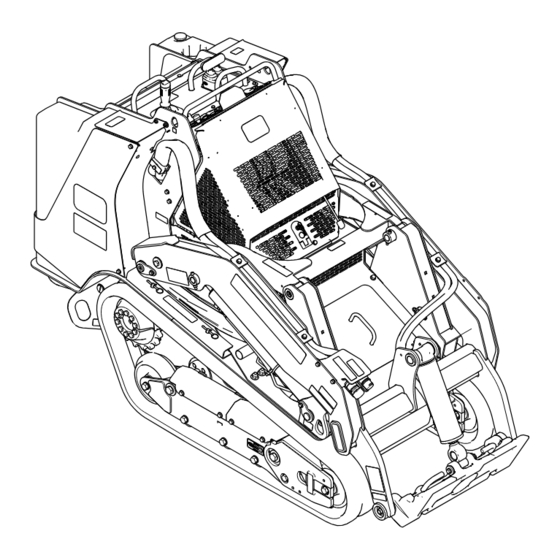

TX 1000 Turbo Compact Tool

Carrier

Model No. 22587—Serial No. 400000000 and Up

Model No. 22587G—Serial No. 400000000 and Up

Model No. 22588—Serial No. 400000000 and Up

Model No. 22588HD—Serial No. 400000000 and Up

Form No. 3467-118 Rev A

*3467-118*

Advertisement

Table of Contents

Summary of Contents for Toro Dingo TX 1000 Turbo

- Page 1 TX 1000 Turbo Compact Tool Carrier Model No. 22587—Serial No. 400000000 and Up Model No. 22587G—Serial No. 400000000 and Up Model No. 22588—Serial No. 400000000 and Up Model No. 22588HD—Serial No. 400000000 and Up *3467-118* Register at www.Toro.com. Original Instructions (EN)

- Page 2 Whenever you need service, genuine Toro parts, or and warranty. Replacements may be ordered through additional information, contact an Authorized Service the engine manufacturer. Dealer or Toro Customer Service and have the model and serial numbers of your product ready. Figure 1 WARNING identifies the location of the model and serial numbers on the product.

-

Page 3: Table Of Contents

This manual uses 2 words to highlight information. Servicing the Fuses .......... 43 Important calls attention to special mechanical Drive System Maintenance ........44 information and Note emphasizes general information Servicing the Tracks ......... 44 worthy of special attention. Cooling System Maintenance ......47 Cooling System Safety ........ -

Page 4: Safety

Safety • Keep bystanders and children out of the operating area. • Stop the machine, shut off the engine, and remove General Safety the key before servicing, fueling, or unclogging the machine. WARNING Improperly using or maintaining this machine can result in injury. -

Page 5: Safety And Instructional Decals

Safety and Instructional Decals Safety decals and instructions are easily visible to the operator and are located near any area of potential danger. Replace any decal that is damaged or missing. decalbatterysymbols Battery Symbols decal106-6755 Some or all of these symbols are on your battery. 106-6755 1. - Page 6 decal115-4865 115-4865 1. Engine coolant 2. Read the Operator's Manual. decal131-0711 131-0711 1. Crushing hazard—keep away from pinch points and actuating parts. decal120-0625 120-0625 1. Pinch point, hand—keep hands away. decal125-8483 125-8483 1. Hydraulic fluid; read the Operator’s Manual. decal131-8026 131-8026 1.

- Page 7 decal133-8062 133-8062 decal139-1158 139-1158 1. Crushing hazard, from above, and pinching hazard—stay away from the bucket and loading arms. decal145-3252 145-3252 1. Crushing hazard from above, falling load—ensure that the quick-attach pins are locked. decal139-1159 139-1159 1. Warning—keep bystanders away. decal147-0287 147-0287 1.

- Page 8 decal147-6827 147-6827 1. Read the Operator's Manual. decal147-6709 147-6709 1. Cutting/dismemberment hazard of hands, fan—stay away from moving parts; keep all guards and shields in place. decal145-4486 145-4486 1. Read the Operator’s 9. Engine air filter Manual. 2. Check every 8 hours. 10.

- Page 9 decal145-4484 145-4484 1. Auxiliary hydraulics—Slow 6. Horn 2. Auxiliary hydraulics—Fast 7. Engine—Shut off 3. Fast 8. Engine—Run 4. Slow 9. Engine—Start 5. Traction decal145-4485 145-4485 1. Turn right 6. Lower the attachment. 2. Move forward 7. Tilt the attachment forward. 3.

- Page 10 decal147-6765 147-6765 1. Warning—read the Operator's Manual. 7. Cutting hazard of hands or feet—wait for all moving parts to stop before servicing; stay away from moving parts; keep all guards and shields in place. 2. Warning—all operators should be trained before operating 8.

-

Page 11: Product Overview

Controls Product Overview Become familiar with all the controls (Figure 4) before you start the engine and operate the traction unit. Control Panel g449104 Figure 4 1. Traction control 7. Throttle switch 2. Reference bar 8. Traction-enable switch 3. Plug 9. - Page 12 Traction-Enable Switch • To turn right, rotate the traction control clockwise (Figure The traction control is automatically disabled when starting the machine. Toggle the traction-enable switch after starting the machine to use the traction control. Traction Control g259649 Figure 8 •...

- Page 13 Loader Arm/Attachment-Tilt Lever Auxiliary-Hydraulics Lock Pedal After engaging the auxiliary hydraulics for at Slowly move the lever to operate the loader arms and tilt the attachment. least 1 second, use your right foot to press the auxiliary-hydraulics lock pedal to continue the forward or reverse flow of the hydraulics and free your hand for other controls.

-

Page 14: Infocenter Display

InfoCenter Display InfoCenter Icon Descriptions (cont'd.) The InfoCenter LCD display shows information about your machine, such as the operating status, various diagnostics and other information about the machine. Decrease There is a splash screen and main information screen of the InfoCenter. You can switch between the splash screen and main information screen at any time by Save value pressing any of the InfoCenter buttons and then... - Page 15 Service InfoCenter Icon Descriptions (cont'd.) Menu Item Description Hours Lists the total number of hours that the machine, engine, and auxiliary hydraulics have been Engine speed on, as well as the number of hours for engine service and hydraulic service. Battery voltage Counts Lists the number of starts that...

-

Page 16: Specifications

Press the middle button to confirm the PIN code. Accessing Protected Menus Note: The factory default PIN code for you machine Note: If the InfoCenter accepts the PIN code is either 0000 or 1234. and the protected menu is unlocked, the word “PIN”... -

Page 17: Attachments/Accessories

Before Operation to enhance and expand its capabilities. Contact your Authorized Service Dealer or authorized Toro distributor or go to www.Toro.com for a list of all Before Operation Safety Toro-manufactured attachments and accessories. To ensure optimum performance, use genuine Toro General Safety replacement parts and accessories. -

Page 18: Adding Fuel

Fuel Safety Biodiesel Ready • Use extreme care when handling fuel. It is This machine can also use a biodiesel blended fuel flammable and its vapors are explosive. of up to B20 (20% biodiesel, 80% petrodiesel). The petrodiesel portion should be low or ultra low sulfur. •... -

Page 19: Performing Daily Maintenance

• Do not carry a load with the arms raised. Always carry loads close to the ground. • Use only Toro-approved attachments and accessories. Attachments can change the stability and the operating characteristics of the machine. • For machines with a platform: –... - Page 20 • • Slow down and use caution when making turns Slow down and use extra care on hillsides. Ground and crossing roads and sidewalks. Watch for conditions can affect the stability of the machine. traffic. • Avoid starting or stopping on a slope. If the •...

-

Page 21: Starting The Engine

Driving the Machine – Always assume the machine is charged if you strike an electrical or communication line. Do not attempt to leave the machine. Note: Enable the traction control by toggling the traction-enable switch before driving the machine. • Leaking gas is both flammable and explosive and may cause serious injury or death. -

Page 22: Using Attachments

Using Attachments Installing an Attachment Important: Use only Toro-approved attachments. Attachments can change the stability and the operating characteristics of the machine. The warranty of the machine may be voided if you use the machine with unapproved attachments. Important: Before installing the attachment, ensure that the mount plates are free of any dirt or debris and that the pins rotate freely. -

Page 23: Understanding Smart Power® Traction

Connecting the Hydraulic Hoses Confirm that the connection is secure by pulling on the hoses. WARNING Removing an Attachment Hydraulic fluid escaping under pressure can penetrate skin and cause injury. Fluid injected Park the machine on a level surface. into the skin must be surgically removed Lower the attachment to the ground. -

Page 24: After Operation

Moving a Non-Functioning After Operation Machine After Operation Safety Important: Do not tow or pull the machine without first opening the tow valves, or you will damage the hydraulic system. General Safety Shut off the engine and remove the key. •... - Page 25 Selecting a Trailer Loading the Machine WARNING WARNING Loading or unloading a machine onto a trailer Loading or unloading a machine onto a trailer or truck increases the possibility of tip-over or truck increases the possibility of tip-over and could result in death or serious injury. and could result in death or serious injury.

-

Page 26: Lifting The Machine

Lifting the Machine Remove any attachments and lift the machine using the 2 lift points. Do not exceed a 20-degree angle when lifting the machine; use the minimum chain lengths provided below. g449334 Figure 25 1. Tie-down loops Unloading the Machine Lower the ramp(s). -

Page 27: Maintenance

• Carefully release pressure from components • with stored energy; refer to Relieving Hydraulic Use only genuine Toro replacement parts. Pressure (page 49). • If any maintenance or repair requires the loader • Disconnect the battery before making any repairs;... - Page 28 Every 250 hours • Check the fuel lines and connections for deterioration, damage, or loose connections. Every 400 hours • Replace the hydraulic filter and fluid (if not using Toro fluid). • Replace the air filters. • Replacing the water separator filter.

-

Page 29: Pre-Maintenance Procedures

Pre-Maintenance Removing and Storing the Cylinder Locks Procedures Important: Remove the cylinder locks from the rods and fully secure them in the storage position Using the Cylinder Locks before operating the machine. Start the engine. WARNING Raise the loader arms to the fully raised position. The loader arms may lower when in the raised Shut off the engine and remove the key. - Page 30 Opening the Hood Removing the Rear Cover Loosen the hood-locking screw. Remove the 2 bolts securing the top of the rear cover. g450151 Figure 31 g450255 Lift the cover out of the slots in radiator bracket. Figure 29 1. Hood-locking screw Unlock the hood using the latch key and press the button to release the latch.

- Page 31 Removing the Bottom Plate Remove the 2 bolts securing the bottom plate. g450266 Figure 33 Remove the bottom plate. Removing the Front Cover Raise the loader arms and secure them with the g452117 cylinder locks. Figure 35 Loosen the 2 bolts securing the front cover to the machine.

- Page 32 Removing the Side Screens Open the hood. Slide the screen out of the front and rear slots. g452557 Figure 37 1. Side screen...

-

Page 33: Lubrication

Lubrication Engine Maintenance Greasing the Machine Engine Safety • Shut off the engine before checking the oil or Service Interval: Before each use or daily (Grease adding oil to the crankcase. immediately after every washing.) • Do not change the engine governor setting or Grease Type: General-purpose grease. - Page 34 Replacing the Filter(s) Gently slide the primary filter out of the air-cleaner body. Note: Avoid knocking the filter into the side of the body. Important: Do not attempt to clean the filter. g452617 Figure 39 1. Air-cleaner cover 3. Dust Air-cleaner body 2.

-

Page 35: Servicing The Engine Oil

Figure 42 Note: Toro Premium Engine oil is available from your Authorized Service Dealer. Checking the Engine-Oil Level Park the machine on a level surface, engage the parking brake, and lower the loader arms. - Page 36 Changing the Engine Oil and Filter Torque the drain plug to 46 to 56 N∙m (34 to 42 ft-lb). Remove any attachments. Open the hood. Start the engine and let it run for 5 minutes. Remove the left screen; refer to Removing the Note: This warms the oil so that it drains better.

-

Page 37: Fuel System Maintenance

Replacing the Water Fuel System Separator Filter Maintenance Service Interval: Every 500 hours DANGER Park the machine on a level surface, engage the In certain conditions, fuel is extremely parking brake, and lower the loader arms. flammable and highly explosive. A fire or Shut off the engine and remove the key. -

Page 38: Checking The Fuel Lines And Connections

Checking the Fuel Lines Bleeding the Fuel System and Connections You must bleed the fuel system before starting the engine if any of the following situations have occurred: Service Interval: Every 400 hours/Yearly (whichever • Initial startup of a new machine comes first) •... -

Page 39: Electrical System Maintenance

Electrical System Maintenance Electrical System Safety • Disconnect the battery before making any repairs; refer to Using the Battery-Disconnect Switch (page 39). • Charge the battery in an open, well-ventilated area, away from sparks and flames. Unplug the g453795 charger before connecting or disconnecting the Figure 50 battery. - Page 40 Rinse the battery with clear water. and flames away from battery. Coat the battery posts and cable connectors with Grafo 112X (skin-over) grease (Toro Part No. Important: Always keep the battery fully charged 505-47) or petroleum jelly to prevent corrosion.

-

Page 41: Jump-Starting The Machine

Installing the Battery Jump-Starting the Machine WARNING WARNING Incorrect battery cable routing could damage Jump-starting the battery can produce gasses the machine and cables, causing sparks. that could explode, resulting in death or Sparks could cause the battery gasses to serious injury. - Page 42 WARNING Batteries contain acid and produce explosive gasses, which could result in death or serious injury. • Shield your eyes and face from the batteries at all times. • Do not lean over the batteries. Note: Ensure that the vent caps are tight and level.

-

Page 43: Servicing The Fuses

Servicing the Fuses The electrical system is protected by fuses. It requires no maintenance; however, if a fuse blows, check the component/circuit for a malfunction or a short. g454388 Figure 55 Fuse Layout Accessory System power System power 2 (10 A) (15 A) (7.5 A) Telematics... -

Page 44: Drive System Maintenance

Drive System Maintenance Servicing the Tracks Service Interval: After the first 8 hours—Check and adjust the track tension. After the first 50 hours—Check and adjust the track tension. Every 50 hours—Check and adjust the track g454389 Figure 56 tension. 1. Sectional drive sprocket 4. - Page 45 Replacing the Tracks Loosen the bolts on the rear cover and remove the cover. Removing the Tracks Remove any attachments. Park the machine on a level surface, ensuring that only 1 sprocket half is engaged with the track. g366295 Figure 58 1.

- Page 46 Loosen the jam nut and turn the tensioning Shut off the engine and remove the key. screw to release the tension. Remove the track from the track frame, drive hub, then front wheel. Installing the Tracks Wrap the new track around the front wheel. g363401 Figure 62 1.

-

Page 47: Cooling System Maintenance

Cooling System Apply thread-locking compound to the bolts of the drive sprocket half that you removed and Maintenance install the other sprocket half. Torque the bolts to 80 to 99 N∙m (59 to 73 ft-lb). Cooling System Safety • Swallowing engine coolant can cause poisoning; keep out of reach from children and pets. -

Page 48: Controls System Maintenance

Controls System Maintenance Adjusting the Controls The factory adjusts the controls before shipping the machine. However, after many hours of use, you may need to adjust the traction control alignment, the N position of the traction control, and the EUTRAL tracking of the traction control in the full forward position. -

Page 49: Hydraulic System Maintenance

Alternative hydraulic fluids: If Toro PX Extended • Use cardboard or paper to find hydraulic leaks. Life Hydraulic Fluid is not available, you may use another conventional, petroleum-based hydraulic fluid •... -

Page 50: Checking The Hydraulic-Fluid Level

Checking the Hydraulic-Fluid Level Service Interval: Before each use or daily Important: Always use the correct hydraulic fluid. Unspecified fluids will damage the hydraulic system. Refer to Hydraulic Fluid Specifications (page 49). Remove any attachments. Park the machine on a level surface and engage the parking brake. -

Page 51: Replacing The Hydraulic Filter

Replacing the Hydraulic and add fluid to raise the level to mark on dipstick. Filter Important: Do not overfill the tank. Important: Do not substitute an automotive oil Install the front cover. filter; otherwise, severe hydraulic system damage Remove and store the cylinder locks and lower may occur. -

Page 52: Cleaning

Cleaning the Chassis Cleaning Service Interval: Every 100 hours—Check for dirt Removing Debris buildup in the chassis. (More often in dirty conditions.) Service Interval: Before each use or daily Over time, the chassis under the engine collects dirt and debris that must be removed. Using a flashlight, Important: Operating the engine with blocked open the hood and inspect the area under the engine... -

Page 53: Storage

Storage Storage Safety • Shut off the engine, remove the key, wait for all moving parts to stop, and allow the machine to cool before storing it. • Do not store the machine or fuel near flames. Storage Park the machine on a level surface, engage the parking brake, and lower the loader arms. -

Page 54: Troubleshooting

Troubleshooting Problem Possible Cause Corrective Action The engine does not start. 1. Dirt, water, stale fuel, or incorrect fuel 1. Drain and flush the fuel system; add is in the fuel system. fresh fuel. 2. The fuel filter is clogged. 2. - Page 55 Problem Possible Cause Corrective Action The machine does not drive. 1. The parking brake is engaged. 1. Disengage the parking brake. 2. The hydraulic-fluid level is low. 2. Add hydraulic fluid to the reservoir. 3. The hydraulic system is damaged. 3.

- Page 56 While the exposure from Toro products may be negligible or well within the “no significant risk” range, out of an abundance of caution, Toro has elected to provide the Prop 65 warnings. Moreover, if Toro does not provide these warnings, it could be sued by the State of California or by private parties seeking to enforce Prop 65 and subject to substantial penalties.

Need help?

Do you have a question about the Dingo TX 1000 Turbo and is the answer not in the manual?

Questions and answers