Summary of Contents for ESAB WARRIOR EDGE 500 DX

- Page 1 WARRIOR EDGE 500 DX Instruction manual Valid for: Serial number: OP137YY-XXXXXX 0463 772 101 GB 20240207...

-

Page 3: Table Of Contents

Supply voltage fault ......................Temperature fault ......................Battery warning ....................Internal voltage error ....................Wire feed speed fault ....................Communication fault ....................Short circuit detected ................... High open circuit voltage fault 0463 772 101 - 3 - © ESAB AB 2024... - Page 4 ....................... TROUBLESHOOTING ...................... ORDERING SPARE PARTS ..................... CALIBRATION AND VALIDATION ..............11.1 Measurement methods and tolerances ............11.2 Requirements, specifications and standards ..........................WIRING DIAGRAM ......................... ORDERING NUMBERS ............................. ACCESSORIES 0463 772 101 - 4 - © ESAB AB 2024...

-

Page 5: Safety

Sheets (SDSs). Safety precautions Users of ESAB equipment have the ultimate responsibility for ensuring that anyone who works on or near the equipment observes all the relevant safety precautions. Safety precautions must meet the requirements that apply to this type of equipment. The following recommendations should be observed in addition to the standard regulations that apply to the workplace. - Page 6 If equipped with ESAB cooler Use ESAB approved coolant only. Non-approved coolant might damage the equipment and jeopardize product safety. In case of such damage, all warranty undertakings from ESAB cease to apply. For ordering information, see the "ACCESSORIES" chapter in the instruction manual.

- Page 7 For further information contact the nearest ESAB dealer. ESAB has an assortment of welding accessories and personal protection equipment for purchase. For ordering information contact your local ESAB dealer or visit us on our website. 0463 772 101 - 7 -...

-

Page 8: Introduction

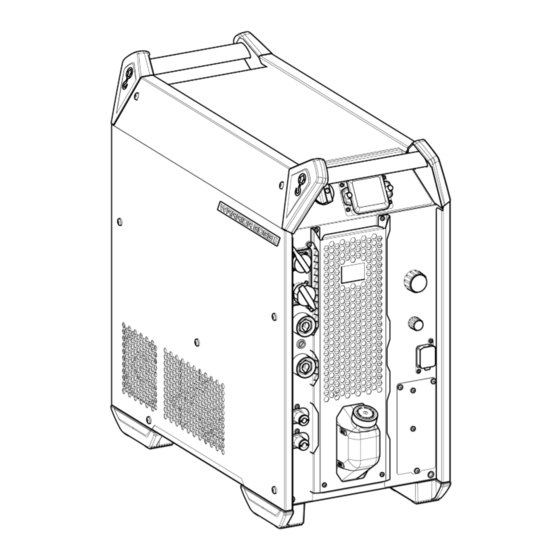

2 INTRODUCTION INTRODUCTION The Warrior Edge 500 DX is integrated with a cooling unit and offers a complete multi-process package supporting MIG/MAG, MMA, Live TIG and gouging. It is intended for use in combination with RobustFeed Edge. The power source is equipped with gateway to connect to the WeldCloud suite of applications, including WeldCloud Productivity for production monitoring and WeldCloud Fleet for managing your fleet of welding equipment. -

Page 9: Technical Data

3 TECHNICAL DATA TECHNICAL DATA WARRIOR EDGE 500 DX Mains voltage 380–460 V, ±10%, 3~ 50/60 Hz Mains supply S 6.8 MVA scmin Primary current I 380 V 400 V 460 V MIG/MAG 36 A 36 A 31 A 38 A... - Page 10 3 TECHNICAL DATA WARRIOR EDGE 500 DX Cooling power 1.4 kW Cooling volume 4.7 l Maximum flow 2 l/min Maximum pressure 4.5 bar Mains supply, S sc min Minimum short circuit power on the network in accordance with IEC 61000-3-12. Duty cycle The duty cycle refers to the time as a percentage of a ten-minute period that you can weld at a certain load without overloading.

-

Page 11: Installation

It is the user's responsibility to take adequate precautions. Location Position the welding power source in such a way that its cooling air inlets and outlets are not obstructed. 0463 772 101 - 11 - © ESAB AB 2024... -

Page 12: Lifting Instructions

4 INSTALLATION Lifting instructions Mechanical lifting must be done with both outer handles. 0463 772 101 - 12 - © ESAB AB 2024... -

Page 13: Mains Supply

TECHNICAL DATA chapter. 1. Rating plate with supply connection data. Recommended fuse sizes and minimum cable area WARRIOR EDGE 500 DX Mains voltage 380 V 3~ 50/60 Hz 400 V 3~ 50/60 Hz 460 V 3~ 50/60 Hz Mains cable area 4×6 mm... - Page 14 If the mains cable needs to be changed, the earth connection to the bottom plate and the ferrites must be installed correctly. See the picture below for the installation order of the ferrites, washers, nuts and screws. 0463 772 101 - 14 - © ESAB AB 2024...

- Page 15 4 INSTALLATION Connections Cable colour (CE) Brown Black Grey Yellow/Green 0463 772 101 - 15 - © ESAB AB 2024...

-

Page 16: Operation

5. Fuse (10 A) for supply voltage for wire feeder 12. WeldCloud Ethernet connection unit 6. Positive welding terminal: Welding cable 13. Mains cable 7. Connection RED for coolant (return) to cooling 14. Coolant tank unit 0463 772 101 - 16 - © ESAB AB 2024... -

Page 17: Symbols

Regardless the mains supply is interrupted abnormally, or the power source is switched off in the normal manner, the welding data will be stored, so it will be available next time the unit is turned on. 0463 772 101 - 17 - © ESAB AB 2024... -

Page 18: Fan Control

The fans start again when welding restarts. Usage of cooling unit ELP (ESAB Logic Pump) The cooling unit is equipped with detection system called ELP (ESAB Logic Pump), which checks that the coolant hoses are connected. When connecting a liquid cooled torch, cooling starts. NOTE! -

Page 19: Usb Connection

1. IoT Gateway USB port 1 3. USB port 3, which enables the user to upgrade the software and to export the error log report. 2. IoT Gateway USB port 2 0463 772 101 - 19 - © ESAB AB 2024... -

Page 20: Control Panel

6 CONTROL PANEL CONTROL PANEL Overview 1. LED Indicators 4. Current/voltage encoder knob 2. Display, shows set or measured current 5. Application selection knob 3. Display, shows set or measured voltage/dynamics 0463 772 101 - 20 - © ESAB AB 2024... -

Page 21: Led Indicators Description

To achieve a good welding result, the arc voltage is a crucial factor. In MIG/MAG welding, the power source is prepared to sense the arc voltage in the wire feeder. Prerequisite for this functionality is that an ESAB wire feeder and an ESAB interconnection cable is used. -

Page 22: Functions And Symbols

A36/ASME mild steel. For different types of metal, adjust the volt setting and air flow for better performance. For any gouging issues other than performance, see the TROUBLESHOOTING section. 0463 772 101 - 22 - © ESAB AB 2024... -

Page 23: Mma Welding

Measured or set value in the display for arc voltage V is an average arithmetic value. Measured or set amperage Measured or set value in the display for welding current A is an average arithmetic value. 0463 772 101 - 23 - © ESAB AB 2024... -

Page 24: Maintenance

To maintain the performance and increase the lifetime of the power source it is mandatory to clean the product regularly. How often depends on: • the welding process • the arc time 0463 772 101 - 24 - © ESAB AB 2024... - Page 25 8. Reassemble the power source after cleaning and perform testing according to IEC 60974-4. Follow the procedure in section “After repair, inspection and test” in the Service manual. 0463 772 101 - 25 - © ESAB AB 2024...

-

Page 26: Cooling Unit

Then drain the tank manually, i.e. empty via the tank's filling hole. 7.2.1 Filling the coolant Use only ESAB's ready mixed coolant. See chapter "ACCESSORIES". • Fill with coolant. (The fluid level must not exceed the upper marking, but neither must it be below lower marking.) -

Page 27: Event Codes

This event code is displayed due to one of the following: • 205 - Mains over/under voltage or phase error. Make sure that the supply voltage is stable. Restart the system. 0463 772 101 - 27 - © ESAB AB 2024... -

Page 28: Temperature Fault

Contact authorised person to check the main inputs. Wire feed speed fault This event code is displayed due to one of the following: • 311 - Wire saturation warning/error. • 311 - Wire motor start/work current error. 0463 772 101 - 28 - © ESAB AB 2024... -

Page 29: Communication Fault

In case of voltage sensor lost, contact service technician. Otherwise restart the system. Lost contact with another unit This event code is displayed due to one of the following: • 017 - Mandatory node missing. 0463 772 101 - 29 - © ESAB AB 2024... -

Page 30: Internal Memory Fault

Make sure the software version matches each connected node. Connect the correct wire feed unit and restart. Timing fault This event code is displayed due to one of the following: 0463 772 101 - 30 - © ESAB AB 2024... -

Page 31: No Coolant Flow

Check that the torch gas hose is not strangulated. Check that the gas pressure input to the feeder is between 3-5 bar. If not, adjust the gas pressure to the recommended level. 0463 772 101 - 31 - © ESAB AB 2024... -

Page 32: Usb Fault

This event code is displayed due to one of the following: • 736 - Fieldbus quickstop. • 736 - Fieldbus superquickstop. Acknowledge by pressing any buttons on the control panel. Restart. 0463 772 101 - 32 - © ESAB AB 2024... -

Page 33: Troubleshooting

Gas pressure fault Check the Event code section [x31] Gas flow fault Check the Event code section [x32] 0463 772 101 - 33 - © ESAB AB 2024... -

Page 34: Ordering Spare Parts

Repair and electrical work should be performed by an authorised ESAB service technician. Use only ESAB original spare and wear parts. Warrior Edge 500 DX is designed and tested in accordance with the international and European standards EN IEC 60974-1, EN IEC 60974-2 and EN IEC 60974-10 Class A, Canadian standards CAN/CSA 60974-1, CAN/CSA 60974-2 and US standards ANSI/IEC 60974-1, ANSI/IEC 60974-2. -

Page 35: Calibration And Validation

In the field application it will occur that a measuring device and a Warrior Edge 500 DX may display different values even though both systems are validated and calibrated. This is due to the measurement tolerances and the method of measurement of the two measurement systems. -

Page 36: Wiring Diagram

APPENDIX APPENDIX WIRING DIAGRAM 0463 772 101 - 36 - © ESAB AB 2024... -

Page 37: Ordering Numbers

Power source Warrior Edge 500 CX II Includes Pulse, SPEED, 380-460 V, integrated cooler, CE 0446 300 886 Power source Warrior Edge 500 DX Includes Pulse, SPEED, THIN, ROOT, 380-460 V, integrated cooler, CE 0463 772 * Instruction manual 0463 844 001... -

Page 38: Accessories

ESAB ready mixed coolant (10 l / 2.64 gal) Use of any other cooling liquid than the prescribed one might damage the equipment. In case of such damage, all warranty undertakings from ESAB cease to apply. 0465 416 880 Edge wheel kit For assembly instruction, refer to document... - Page 39 10 m (33 ft) 0446 310 993 15 m (49 ft) 0446 310 994 20 m (66 ft) 0446 310 995 25 m (82 ft) 0446 310 996 35 m (115 ft) 0463 772 101 - 39 - © ESAB AB 2024...

- Page 40 For contact information visit http://esab.com ESAB AB, Lindholmsallén 9, Box 8004, 402 77 Gothenburg, Sweden, Phone +46 (0) 31 50 90 00 manuals.esab.com...

Need help?

Do you have a question about the WARRIOR EDGE 500 DX and is the answer not in the manual?

Questions and answers