Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Micsig VATO Series

- Page 2 Version Info Version Date Remarks V1.0 2024.01...

- Page 3 Preface Preface Dear customers, Congratulations! Thank you for buying Micsig instrument. Please read this manual carefully before use and particularly pay attention to the “Safety Precautions”. If you have read this manual, please keep it properly for future reference. The information contained herein are furnished in an “as-is” state, and may be subject to change in future versions without notice.

-

Page 4: Table Of Contents

Table of Contents Table of Contents TABLE OF CONTENTS ................................. I CHAPTER 1. SAFETY PRECAUTIONS ........................... 1 1.1 S ..............................1 AFETY RECAUTIONS 1.2 S AFETY ERMS AND YMBOLS ............................5 CHAPTER 2. QUICK START GUIDE OF OSCILLOSCOPE ......................8 2.1 I ............................ - Page 5 2.8 U ..................................25 2.9 L ............................27 ACTORY ETTINGS 2.10 U ............................27 CALIBRATION 2.11 P ..........................28 ASSIVE ROBE OMPENSATION 2.12 M ............................33 ODIFY THE ANGUAGE CHAPTER 3 AUTOMOTIVE TEST ............................34 3.1 C ..............................34 HARGING TART IRCUIT 3.1.1...

- Page 6 Table of Contents 3.2 S ................................48 ENSOR ESTS 3.2.1 ABS ..................................49 3.2.2 Accelerator pedal ............................... 51 3.2.3 Air Flow Meter ..............................53 3.2.4 Camshaft ................................56 3.2.5 Coolant Temperature ............................59 3.2.6 Crankshaft ................................61 3.2.7 Distributor ................................63 3.2.8 Fuel pressure ..............................

- Page 7 3.3.1 Carbon canister solenoid valve ........................... 79 3.3.2 Disel Glow Plugs ..............................81 3.3.3 EGR Solenoid Valve ............................. 83 3.3.4 Fuel Pump ................................85 3.3.5 Idle speed control valve ............................ 87 3.3.6 Injector (gasoline engine) ..........................89 3.3.7 Injector (Diesel) ..............................91 3.3.8 Pressure regulator ............................

- Page 8 Table of Contents 3.4.3 Primary + Secondary............................109 3.5 N .................................. 112 ETWORKS 3.5.1 CAN High & CAN Low ............................112 3.5.2 LIN Bus ................................115 3.5.3 FlexRay Bus ..............................117 3.5.4 K line ................................120 3.6 C ..............................122 OMBINATION ESTS 3.6.1 Crankshaft + Camshaft .............................

- Page 9 4.3 P ....................136 AN AND INGLE OR TOPPED CQUISITIONS 4.4 Z ................................137 CHAPTER 5 VERTICAL SYSTEM ............................141 5.1 O ) ..............143 LOSE AVEFORM HANNEL EFERENCE AVEFORMS 5.2 A ..........................148 DJUST ERTICAL ENSITIVITY 5.3 A DJUST ERTICAL OSITION ............................

- Page 10 Table of Contents CHAPTER 6 TRIGGER SYSTEM ............................160 6.1 T ......................... 161 RIGGER AND RIGGER DJUSTMENT 6.2 E ................................173 RIGGER 6.3 P ULSE IDTH RIGGER .............................. 177 6.4 S ..............................184 ERIAL RIGGER CHAPTER 7 ANALYSIS SYSTEM ............................185 7.1 A ............................

- Page 11 9.1 D ..........................214 AVEFORM ALCULATION 9.2 FFT M ..............................219 EASUREMENT 9.3 R ............................ 227 EFERENCE AVEFORM CHAPTER 10 DISPLAY SETTINGS ............................. 232 10.1 C ..............................233 OMMON SETTINGS 10.2 G RATICULE ETTING ..............................234 CHAPTER 11 SAMPLING SYSTEM ........................... 235 11.1 S ...............................

- Page 12 Table of Contents CHAPTER 13 REFERENCE ............................... 264 13.1 M EASUREMENT ATEGORY ............................265 13.2 P ..............................267 OLLUTION EGREE CHAPTER 14 TROUBLESHOOTING ..........................268 CHAPTER 15 SERVICES AND SUPPORT ........................... 273 ANNEX ..................................275 ....................275 NNEX AINTENANCE AND ARE OF SCILLOSCOPE B: A...

-

Page 14: Chapter 1. Safety Precautions

Chapter 1. Safety Precautions Chapter 1. Safety Precautions 1.1 Safety Precautions The following safety precautions must be understood to avoid personal injury and prevent damage to this product or any products connected to it. To avoid possible safety hazards, it is essential to follow these precautions while using this product. - Page 15 ⚫ Do not operate without covers. Do not operate the product with covers or panels removed. ⚫ Do not operate with suspected failures. If you suspect that there is damage to this product, have it inspected by service personnel designated by Micsig.

- Page 16 Chapter 1. Safety Precautions ⚫ Use adapter correctly. Supply power or charge the equipment by power adapter designated by Micsig, and charge the battery according to the recommended charging cycle. ⚫ Avoid exposed circuitry. Do not touch exposed connections and components when power is present.

- Page 17 300Vrms. Instantaneous overvoltage is present in circuits that are isolated from the mains supply. The VATO series digital oscilloscope is designed to safely withstand sporadic transient overvoltage up to 1000Vpk. Do not use this equipment for any measurements in...

-

Page 18: Safety Terms And Symbols

Chapter 1. Safety Precautions 1.2 Safety Terms and Symbols Terms in the manual These terms may appear in this manual: Warning. Warning statements indicate conditions or practices that could result in injury or loss of life. Caution. Caution statements indicate conditions or practices that could result in damage to this product or other property. - Page 19 Symbols on the product The following symbols may appear on the product: Hazardous Voltage Caution Refer to Manual Protective Ground Terminal Chassis Ground Measurement Ground Terminal Please read the following safety precautions to avoid personal injury and prevent damage to this product or any products connected to it.

- Page 20 Chapter 1. Safety Precautions ⚫ User only insulated voltage probes supplied with the instrument, or the equivalent product indicated in the schedule. ⚫ Before use, inspect voltage probes, test leads, and accessories for mechanical damage and replace when damaged. ⚫ Remove voltage probes and accessories not in use. ⚫...

-

Page 21: Chapter 2. Quick Start Guide Of Oscilloscope

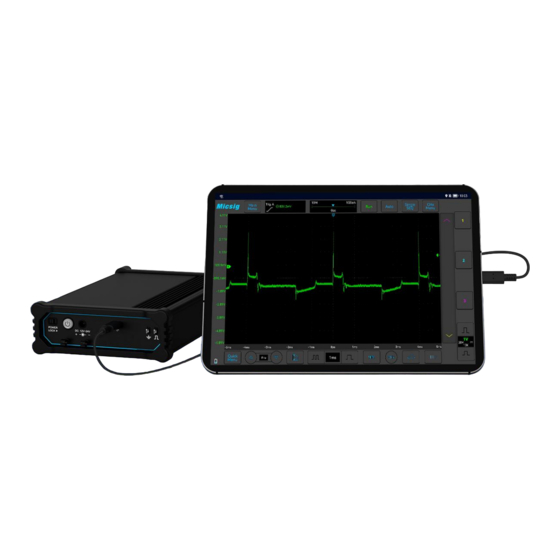

Chapter 2. Quick Start Guide of Oscilloscope This chapter contains checks and operations of the oscilloscope. You are recommended to read them carefully to understand appearance, power on/off, settings and related calibration requirements of the VATO series oscilloscope. 2.1 Inspect Package Contents When you open package after receipt, please check the instrument according to the following steps. -

Page 22: Front Panel

If any damage to oscilloscope is found by the appearance inspection or it fails to pass the performance test, please contact Micsig’s agent or local office. If the instrument is damaged due to transportation, please retain the package and contact the transportation company or Micsig’s agent, and Micsig will make arrangement. -

Page 23: Rear Panel

2.3 Rear Panel Figure 2-2 rear panel The rear panel contains four analog channels Ch1 – Ch4... -

Page 24: Power On/Off The Oscilloscope

Chapter 2. Quick Start Guide of Oscilloscope 2.4 Power on/off the Oscilloscope Power on/off the oscilloscope Power on ⚫ Make sure the machine is powered by power and the POWER LOCK switch is on the left side. Press the power button to turn on the instrument. - Page 25 2. Use the provided Type-C data cable to connect the oscilloscope to a smartphone/tablet running Android 7 or above. 3. Go to Micsig official website (https://www.micsig.com.cn/VATO/) to download the apk file, transfer it to the device, open and install it 4.

- Page 26 Chapter 2. Quick Start Guide of Oscilloscope Since the emulator cannot recognize USB, VATO needs to install a virtual environment to connect to the computer. You can use Vmware or VirtualBox virtual machine software to install Android 7 or above systems. Here we take the Genymotion emulator and VirtualBox virtual machine software as an example: 1.

- Page 27 Figure 2-3 Android virtual device installation 3. Connect the oscilloscope to the computer, open VirtualBox and enter settings, USB devices, click Add USB, find Cypress, add and confirm...

- Page 28 Chapter 2. Quick Start Guide of Oscilloscope Figure 2-4 Setting USB device 4. Start the Android system installed on Genymotion, and drag the apk file downloaded from the Micsig official website (https://www.micsig.com.cn/VATO/) into the Android desktop for installation. After completing the...

- Page 29 installation, open the software and grant floating window permissions. The power button of the oscilloscope turns blue and flashes, indicating that the connection is successful. Figure 2-5 Oscilloscope connected successfully Maximum input voltage for analog input Class I 300Vrms, 400Vpk.

-

Page 30: Understand The Oscilloscope Display Interface

Chapter 2. Quick Start Guide of Oscilloscope 2.6 Understand the Oscilloscope Display Interface This section provides a brief introduction and description of the VATO series oscilloscope user’s interface. After reading this section, you can be familiar with the oscilloscope display interface content within the shortest possible time. - Page 31 Figure 2-6 Oscilloscope Interface Display...

- Page 32 Chapter 2. Quick Start Guide of Oscilloscope Description Click to open the top main menu, including measurement, save, display, trigger, user settings, about The current trigger type and current trigger mode are displayed. A means Auto, N means Normal Current trigger source, trigger level value Trigger position Current record length Waveform display area center indication...

- Page 33 Description Oscilloscope status includes running, stop, and waiting. Tap to switch to stop. Automatically set, tap to enter the auto state, and the oscilloscope will automatically adjust the waveform to a suitable display mode. Single trigger, tap for single trigger Click to open the channel menu of the current channel Click to switch the current trigger source The relevant information display area of each channel includes channel switch status, vertical...

- Page 34 Chapter 2. Quick Start Guide of Oscilloscope Description Phase scale to help measure timing of cyclic waveforms The car repair soft bag has a variety of built-in car WeChat measurement items and can complete oscilloscope settings with one click. The current channel is forced to be selected. After clicking, the current channel switching menu pops up to switch the current channel.

- Page 35 Description Fine adjustment buttons. Tap the fine-tuning button to fine-tune the waveform position, trigger level position, trigger position, and cursor position. Click to open the bottom shortcut menu, including ZOOM, full measurement, and cursor Oscilloscope battery power display area Horizontal time scale Vertical direction voltage (current) scale Channel Indicator: The displayed ground level of each analog channel signal, identified by the channel indicator icon...

-

Page 36: Introduction Basic Operations Of Touch Screen

Chapter 2. Quick Start Guide of Oscilloscope 2.7 Introduction Basic Operations of Touch Screen The VATO series oscilloscope operates mainly by tap, swipe, single-finger drag. Tap button on the touch screen to activate the corresponding menu and function. Tap any blank space on the screen to exit the menu. - Page 37 Figure 2-7 Close the channel menu Single-finger drag For coarse adjustments of vertical position, trigger point, trigger level, cursor, etc. of the waveform. Refer to “4.1 Waveform” and “5.3 Adjust Vertical Position” for details. Horizontal Move...

-

Page 38: Use Auto

Chapter 2. Quick Start Guide of Oscilloscope 2.8 Use Auto After correctly connecting the oscilloscope and inputting a valid signal, tap the Auto Setup button. Auto Setup can quickly automatically configure the oscilloscope to display the best effect on the input signal. When the oscilloscope enters the automatic state, the automatic button will turn green. - Page 39 Figure 2-8 Open Auto Set...

-

Page 40: Load Factory Settings

Chapter 2. Quick Start Guide of Oscilloscope 2.9 Load Factory Settings Open the main menu, tap “User Settings” to enter the user setting page. Tap “Factory Settings” and the dialog box for loading factory settings will pop-up. Press “OK” and load the factory settings. The dialog box for loading factory settings is shown in Figure 2-9. -

Page 41: Passive Probe Compensation

and after calibrating is finished, the word in red disappears. When the temperature changes largely, the auto- calibration function can make the oscilloscope maintain the highest accuracy of measurement. ⚫ Auto-calibration should be done without probe. ⚫ Auto-calibration process takes about two minutes. ⚫... - Page 42 Chapter 2. Quick Start Guide of Oscilloscope Connect the probe to the calibration output signal terminal and connect the probe ground to the ground terminal. As shown in Figure 2-10. Figure 2-10 Probe Connection Open the channel (if the channel is closed). Adjust the oscilloscope channel attenuation coefficient to match the probe attenuation ratio.

- Page 43 Figure 2-11 Probe Compensation If the waveform on the screen is shown as “under-compensation” or “over-compensation”, please adjust the trimmer capacitor until the waveform shown on the screen as “correct-compensation”. The probe adjustment is shown in Figure 2-12.

- Page 44 Chapter 2. Quick Start Guide of Oscilloscope Figure 2-12 Probe Adjustment The safety ring on the probe provides a safe operating range. Fingers should not exceed the safety ring when using the probe, so as to avoid electric shock.

- Page 45 Connect the probe to all other oscilloscope channels (Ch2 of a 2-channel oscilloscope, or Ch 2, 3 and 4 of a 4- channel oscilloscope). Repeat this step for each channel. Warning ⚫ Ensure the wire insulation is in good condition to avoid probe electric shock while measuring high voltage. ⚫...

-

Page 46: Modify The Language

Chapter 2. Quick Start Guide of Oscilloscope 2.12 Modify the Language The language of the oscilloscope interface depends on the system language of the Android device. If you modify the language of the Android system, the oscilloscope will automatically switch to the corresponding language. Currently, it supports Simplified Chinese, Traditional Chinese, and English. -

Page 47: Chapter 3 Automotive Test

Chapter 3 Automotive Test This chapter contains most of the test applications of VATO automotive oscilloscopes in automotive circuits. The purpose is to help users quickly troubleshoot and locate automotive electronics faults. It is recommended that you read this chapter carefully to understand the general operation and use of automotive oscilloscopes. Charging/Start Circuit All electrical equipment of the car is powered by a power system composed of an on-board generator and a battery. - Page 48 The VATO series car-specific oscilloscope can test the charging circuit and the starting circuit to test whether the charging/starting circuit of the car is working properly. The specific operations are as follows::...

-

Page 49: Charging

3.1.1 12V Charging 12V charging is suitable for gasoline vehicles. Use a BNC to banana cable, one end is connected to channel 1 of the oscilloscope, and the other end is connected to the positive and negative electrodes of the battery using two large alligator clips (the red wire is connected to the red clip to the positive electrode, and the black wire is connected to the black clip. - Page 50 Chapter 3 Automotive Test Note: The generator adopts AC power generation. The voltage is converted to DC through multiple rectifier diodes. The voltage can be measured by a multimeter. However, when the diodes are damaged, the multimeter displays the correct readings, and the waveform can be judged by an oscilloscope. The specific operation is shown in Figure 3-2: Figure 3-2 12V Charging...

-

Page 51: Charging

3.1.2 24V Charging 24V charging is suitable for diesel vehicles. The operation process is the same as that of 12V charging. The reference voltage is 26.5V~30V. It can be tested with an oscilloscope. The specific operation is shown in Figure 3-3: Figure 3-3 24V Charging... -

Page 52: Alternator Ac Ripple

Chapter 3 Automotive Test 3.1.3 Alternator AC Ripple The VATO oscilloscope can test the charging ripple and assist the user to determine whether the charging process is normal. Use a BNC to banana cable, one end is connected to the oscilloscope channel 1, and the other end is clamped between the positive and negative electrodes of the battery (the red wire is connected to the red clip) Connect the positive pole, and connect the black wire to the black clip to the negative pole). -

Page 53: Ford Focus Smart Generator

Figure 3-4 Charging Ripple 3.1.4 Ford Focus Smart Generator Use a BNC to banana cable, connect one end to channel 1 of the oscilloscope, connect the black plug to the black alligator clip to ground (battery negative), and use a needle to connect the red connector to the engine ECM to... - Page 54 Chapter 3 Automotive Test generator output control line. Use BNC to banana cable, one end Connect to channel 2 of the oscilloscope, the other black plug is connected to the black alligator clip to ground (the negative electrode of the battery), and the red connector is connected to the feedback of the generator to the engine ECM with a stinger.

-

Page 55: Start

Figure 3-5 Ford Focus Smart Generator 3.1.5 12V Start Use the VATO oscilloscope to test the start of the gasoline car, the purpose is to test whether the performance of the battery is maintained in the normal range. Use a BNC to banana cable, connect one end to channel 1 of the... - Page 56 Chapter 3 Automotive Test oscilloscope, and use two large alligator clips to clamp the positive and negative poles of the battery (the red wire connects to the red clamp to the positive pole, and the black wire to the black clamp to the negative pole). Use a current clamp above 600A, connect the BNC of the current clamp to channel 2, turn on the switch of the current clamp, and clamp the current clamp to the positive or negative power line of the battery.

- Page 57 Figure 3-6 12V Start The following figure is the actual measurement diagram of the starting voltage and current of Mazda in a certain year:...

-

Page 58: Start

Chapter 3 Automotive Test Figure 3-7 Starting voltage and current 3.1.6 24V Start Use the VATO oscilloscope to test the starting process of the diesel vehicle, the purpose is to test whether the performance of the battery is maintained in the normal range, the operation process is the same as the 12V start. The specific operation is shown in Figure 3-8:... -

Page 59: Cranking Current

Figure 3-8 24V Start 3.1.7 Cranking Current Use VATO oscilloscope with a current probe to conduct a current test on the starting process of the car (automobile or diesel car), observe whether the current waveform is normal, use a current clamp of 600A or above, and connect... - Page 60 Chapter 3 Automotive Test the BNC of the current clamp to channel 2. On, turn on the switch of the current clamp and clamp the current clamp to the positive or negative power line of the battery. You need to clamp the entire positive or negative line. Pay attention to the positive and negative polarity (positive current flows from the positive electrode of the battery to the negative electrode).

-

Page 61: Sensor Tests

100 sensors on the mid-to-high-end cars of the company. The VATO series special oscilloscope can directly measure the signal waveform of the sensor. By comparing with the standard waveform during normal operation, it is easy to find whether the sensor is normal. The... -

Page 62: Abs

Chapter 3 Automotive Test VATO series oscilloscope can test the following types of sensors. The purpose is to compare the real-time waveforms with the standard waveforms to help users find problems. The following are expanded and explained separately: 3.2.1 ABS The ABS wheel speed sensor is divided into analog and digital. - Page 63 Figure 3-10 ABS Wheel Speed Sensor...

-

Page 64: Accelerator Pedal

Chapter 3 Automotive Test 3.2.2 Accelerator pedal The accelerator pedal is the signal of the automobile accelerator. There are generally 2 groups, each pair of 3 wires, power, signal, and ground. Divided into analog/analog and analog/digital. Analog/analog signal is two analog signals, usually there are two ways, one is deviation signal: one signal is from 0.3V→4.8V, which rises as the accelerator pedal is depressed, and the other is 4.8V→0.3V, with Depress the accelerator pedal and descend. - Page 65 Figure 3-11 Accelerator Pedal The following picture is the actual measurement diagram of the accelerator pedal sensor of a certain model:...

-

Page 66: Air Flow Meter

Chapter 3 Automotive Test Figure 3-12 Actual measured waveform of accelerator pedal sensor 3.2.3 Air Flow Meter Air flow meters generally have vane type, hot wire type, digital type, etc.; among them: vane type and hot wire type are both analog output, and the output voltage is proportional to the air flow, generally 0.5V~4.5V, but the non- linear ratio, It needs to be corrected in the ECM;... - Page 67 voltage rises rapidly during acceleration, reaching a voltage of 4V~4.5V. After stopping the acceleration, it will return to the idling voltage; the output shows 0V or 5V is not normal. The digital type has a digital circuit inside the sensor. The output signal is a square wave. The frequency is used to represent the air flow.

- Page 68 Chapter 3 Automotive Test Figure 3-13 Air flow meter...

-

Page 69: Camshaft

3.2.4 Camshaft The camshaft sensor is generally used for timing, and is often tested in conjunction with the crankshaft sensor to determine the timing of the vehicle. There are one or two camshaft sensors in the common car models, and the use of four is relatively small. - Page 70 Chapter 3 Automotive Test Figure 3-14 Camshaft The following figure is the actual measurement diagram of the camshaft position sensor (Hall type) of a certain model:...

- Page 71 Figure 3-15 Camshaft position sensor (Hall type)

-

Page 72: Coolant Temperature

Chapter 3 Automotive Test 3.2.5 Coolant Temperature The coolant temperature sensor is usually called a water temperature sensor. Generally, it contains a thermistor. As the temperature increases, the resistance becomes smaller, which causes the output voltage to change, and the water temperature changes slowly, so the voltage also changes slowly. - Page 73 Use a BNC to banana cable, one end is connected to channel 1 of the oscilloscope, the other end is grounded with the black plug, and the red connector is connected to the signal wire of the coolant sensor (the ground wire of the coolant) with a needle probe.

-

Page 74: Crankshaft

Chapter 3 Automotive Test 3.2.6 Crankshaft The crankshaft sensor is installed in many places, which can be near the front pulley or on the rear flywheel. The ECM judges the precise position of the engine based on its output signal. Usually there are induction type and Hall type: the induction type output is usually a sine wave, there are missing teeth on the disk, and the sine wave will be missing in the missing teeth;... - Page 75 Figure 3-17 Crankshaft position sensor The figure below is the actual measurement of the crankshaft position sensor (inductive) of a certain model:...

-

Page 76: Distributor

Chapter 3 Automotive Test Figure 3-18 Actual measurement diagram of crankshaft position sensor (inductive type) 3.2.7 Distributor Distributor appears on models with high-voltage cables, and distribute the generated high voltages to spark plugs in sequence. Distributors generally have Hall type and induction type. Hall type is generally 3-wire, voltage, signal, and ground. - Page 77 Figure 3-19 Distributor...

-

Page 78: Fuel Pressure

Chapter 3 Automotive Test 3.2.8 Fuel pressure Fuel pressure signals generally appear on high-pressure fuel rails or sensors or common rail diesel vehicles, and the pressure is relatively high. Generally, the fuel pressure is proportional to the output voltage, and the voltage increases with the angle of the accelerator pedal (no-load and full-load will affect the voltage rise time). - Page 79 Figure 3-20 Fuel Pressure Sensor Test...

-

Page 80: Knock

Chapter 3 Automotive Test 3.2.9 Knock The knock sensor is a passive device, generally 2-wire, signal and ground, no external power supply is required, and a signal will be generated when it is subjected to vibration. It can also be removed for testing. The signal can be generated by tapping, and the signal amplitude generally does not exceed 5V;... - Page 81 Figure 3-21 Knock Sensor test The following picture is the actual measurement diagram of the knock sensor of a certain model:...

-

Page 82: Lambda

Chapter 3 Automotive Test Figure 3-22 Actual measurement chart of knock sensor 3.2.10 Lambda The Lambda, or Oxygen Sensor is generally installed on the exhaust pipe, before the catalytic converter. It is a feedback sensor used to sense the oxygen content in the exhaust gas, so that the ECM can judge the combustion situation in the combustion chamber and adjust the fuel supply of the engine. - Page 83 There are several types of oxygen sensors: titanium oxygen, zirconium oxygen, and front & rear dual oxygen sensors; the signal switching frequency is about 1 Hz, and it can only work when the temperature is normal. The voltage is high when the mixture is thick, and the voltage is low when the mixture is thin. Use a BNC to banana cable, one end is connected to channel 1 of the oscilloscope, the other end is grounded with the black plug, and the red connector is connected to the signal line (pre-oxygen) of the oxygen sensor with a needle.

- Page 84 Chapter 3 Automotive Test Figure 3-23 Lambda (oxygen sensor) test The following picture is the actual measurement diagram of a certain model of oxygen sensor:...

-

Page 85: Map

Figure 3-24 Lambda (Oxygen Sensor) diagram 3.2.11 MAP The MAP, or Intake Pressure sensor is used to sense the pressure of the intake manifold and send it to the ECM to determine the fuel supply, vacuum (or light load), and ignition timing advance angle. There are two kinds of analog and digital, usually there are 3 wires, power, signal, ground, or together with other devices. - Page 86 Chapter 3 Automotive Test For the analog signal of the diesel engine, the voltage is between 1.5-2.0V at idling speed. After stepping on the accelerator, the voltage can be seen to rise, which can reach 4.0V. Use VATO oscilloscope to test the intake pressure sensor, the specific operation is shown in Figure 3-25 below:...

- Page 87 Figure 3-25 MAP (intake pressure sensor)

-

Page 88: Road Speed

Chapter 3 Automotive Test 3.2.12 Road Speed The speed sensor is generally installed on the drive output shaft of the speedometer of the gearbox or near the back of the head of the speedometer, to provide information for the ECM and monitor power. Usually is Hall type, there are 3 wires: power, signal, and ground, output square wave signal (some models will be analog, 2 wires, output inductive signal, sine wave). - Page 89 Figure 3-26 Vehicle speed sensor test...

-

Page 90: Throttle Position

Chapter 3 Automotive Test 3.2.13 Throttle Position The throttle position sensor is installed on the drive shaft of the throttle butterfly plate to sense the opening of the throttle and provide a basis for ECM to judge the intake. There are analog output and throttle switch output. Use a BNC to banana cable, connect one end to channel 1 of the oscilloscope, the other end of the black plug is grounded, and the red connector uses a needle to connect the signal line of the throttle position sensor or the throttle switch signal 1. - Page 91 Figure 3-27 Throttle Position Sensor test The following figure is the actual measurement diagram of the throttle position sensor of a certain model:...

-

Page 92: Actuators

Chapter 3 Automotive Test Figure 3-28 Throttle Position Sensor Diagram Actuators 3.3.1 Carbon canister solenoid valve The carbon canister is generally installed in the engine compartment and connected to the fuel tank through a pipe to collect the vaporized oil and gas in the fuel tank, so as to prevent the oil and gas from being discharged into the air and causing pollution. - Page 93 Figure 3-29 Carbon canister solenoid valve test The following figure is the actual measurement of the Carbon canister solenoid valve of a Audi A6 model in a certain year:...

-

Page 94: Disel Glow Plugs

Chapter 3 Automotive Test Figure 3-30 Audi A6 Carbon canister solenoid valve signal 3.3.2 Disel Glow Plugs When the engine or the weather is relatively cold, it will affect the combustion of diesel fuel, so the glow plug is required to heat the cylinder before starting. Diesel engine glow plugs generally have one for each cylinder, connected in series, powered by a battery, and controlled by a relay to open and close. - Page 95 When the ambient temperature is low or the engine temperature is relatively low, when starting the vehicle, the glow plug will be turned on first, and after the preheating light goes out, the vehicle can be started to make the engine idling.

-

Page 96: Egr Solenoid Valve

Chapter 3 Automotive Test Figure 3-31 Disel Glow Plugs 3.3.3 EGR Solenoid Valve The EGR solenoid valve is an abandoned recirculation solenoid valve. After opening, a part of the exhaust gas will be sucked into the intake manifold again to reduce the combustion temperature, so as to reduce the emission of... - Page 97 nitrogen oxides in the exhaust gas and achieve the goal of environmental protection. Use a BNC to banana cable, one end is connected to channel 1 of the oscilloscope, the other end is grounded with the black plug, and the red connector is connected to the ground wire of the EGR solenoid valve with a needle.

-

Page 98: Fuel Pump

Chapter 3 Automotive Test 3.3.4 Fuel Pump The fuel in the fuel tank can be pumped and pressurized through the fuel pump, usually there are 6-8 sectors. Under the same condition of the engine, a good fuel pump has the same and uniform current change in each sector. Use a current clamp, connect one end to channel 1 of the oscilloscope, and clamp the other end to the power line of the fuel pump. - Page 99 Figure 3-33 Electronic fuel pump test...

-

Page 100: Idle Speed Control Valve

Chapter 3 Automotive Test 3.3.5 Idle speed control valve The idle speed control valve adjusts the throttle position or forms an air bypass around the engine according to the load conditions of the engine and the engine temperature to deliver controllable airflow to the air duct to adjust the engine idle speed. - Page 101 Figure 3-34 Idle speed control valve test...

-

Page 102: Injector (Gasoline Engine)

Chapter 3 Automotive Test 3.3.6 Injector (gasoline engine) The fuel injector is an electromechanical device, which is supplied by a common rail fuel pipe and controlled by the ECM to start and stop time of fuel injection. Generally, it is a 2-wire device, the power supply voltage is 12V, and the ECM controls the grounding. - Page 103 Figure 3-35 Injector (Petrol) Test...

-

Page 104: Injector (Diesel)

Chapter 3 Automotive Test 3.3.7 Injector (Diesel) Most diesel engines use common rail fuel injection, fuel injection time is affected by the oil pressure. Low pressure at low speed, injection time is longer, less injection volume; High pressure at high speed, injection time is short, volume is large. - Page 105 Figure 3-36 injector (diesel engine) test...

-

Page 106: Pressure Regulator

Chapter 3 Automotive Test 3.3.8 Pressure regulator The pressure regulator is a valve controlled by a square wave duty cycle. It is installed on the high-pressure fuel pump or on the common rail pipe and controls the common rail pressure together with the flow control valve. The pressure relief valve simply controls the amount of high-pressure oil entering the oil return system, thereby increasing or decreasing the fuel pressure of the common rail pipe. - Page 107 Figure 3-37 Pressure Regulator test...

-

Page 108: Quantity (Flow) Control Valve

Chapter 3 Automotive Test 3.3.9 Quantity (Flow) control valve The flow control valve, also known as the flow regulator and the fuel inlet metering valve, is used to measure the flow of fuel from the low pressure or lift pump into the high-pressure fuel pump. The more fuel enters the piston chamber of the high-pressure fuel pump, the higher the pressure, which increases the pressure in the common rail fuel pipe;... - Page 109 Figure 3-38 Quantity (Flow) control valve test...

-

Page 110: Throttle Servo Motor

Chapter 3 Automotive Test 3.3.10 Throttle Servo Motor Throttle servo motor are commonly used in electronically controlled engines, and throttle butterfly valves are usually used. The ECM controls the throttle servo motor according to the accelerator pedal signal to realize the throttle opening control, which is then monitored by the throttle position sensor and transmits the signal back to the ECM to achieve closed-loop control. - Page 111 Figure 3-39 Throttle servo motor test...

-

Page 112: Variable Speed Cooling Fan

Chapter 3 Automotive Test 3.3.11 Variable speed cooling fan At present, most cars' fans are variable-speed, and the speed of the fan can be adjusted according to different working conditions and temperatures. Use a BNC to banana cable, connect one end to channel 1 of the oscilloscope, ground the other end of the black plug, and use a needle to pierce the red connector into the signal wire of the fan terminal;... - Page 113 Figure 3-40 Variable-speed Cooling fan test The following picture is the actual measurement diagram of the cooling fan of a certain model:...

-

Page 114: Variable Valve Timing

Chapter 3 Automotive Test Figure 3-41 Cooling fan measurement diagram 3.3.12 Variable valve timing Variable valve timing is achieved by adjusting the phase of the engine cam so that the intake air volume changes with the change of engine speed, so as to achieve the best combustion efficiency and improve fuel economy. Use a BNC to banana cable, connect one end to channel 1 of the oscilloscope, the other end of the black plug is grounded, and the red connector is pierced into the variable valve timing signal line with a needle tip. - Page 115 Use the VATO oscilloscope to test the variable valve timing (divided into single and double timing), the specific operation is shown in Figure 3-42: Figure 3-42 Variable valve timing test The following picture is the actual measurement diagram of the Variable valve timing of a certain model:...

-

Page 116: Ignition Tests

Chapter 3 Automotive Test Figure 3-43 Actual measurement chart of variable valve timing Ignition Tests Special Attention! During the secondary ignition test, because the test voltage is about 40K volts, the secondary ignition probe must be used for operation. It is strictly forbidden to use the ordinary probe, otherwise it is very likely to cause personal safety injury and instrument damage. - Page 117 ignition systems. The primary circuit has developed from the basic contact type and capacitive type to the system with no distributor and one coil per cylinder that is commonly used today. Use a P130A probe, connect one end to channel 1 of the oscilloscope, and connect the other end to the ground with the black clip.

- Page 118 Chapter 3 Automotive Test Figure 3-44 Primary ignition The figure below is the actual measurement of the primary ignition of a certain model:...

- Page 119 Figure 3-45 Primary ignition actual test...

-

Page 120: Secondary

Chapter 3 Automotive Test 3.4.2 Secondary The secondary coil has more coil turns than the primary coil, and can generate a high voltage of up to 40kv, which can cause the spark plug to break down and ignite. There are several types: distributor ignition system, distributorless ignition system/invalid spark, COP independent ignition, multi-COP integrated unit ignition. - Page 121 Figure 3-46 Secondary ignition test...

-

Page 122: Primary + Secondary

Chapter 3 Automotive Test 3.4.3 Primary + Secondary When measuring the primary and secondary waveforms at the same time, please use the P130A probe, one end is connected to channel 1 of the oscilloscope, the black clip on the other end is grounded, pierce the needle into the ground wire of the primary coil, and the probe is hooked to the metal needle;... - Page 123 Figure 3-47: Primary + Scondary ignition test The following figure is the actual measurement of the primary and secondary ignition of the BMW 5 Series N20 engine:...

- Page 124 Chapter 3 Automotive Test Figure 3-48 BMW 5 Series N20 Primary + Secondary ignition signal...

-

Page 125: Networks

Networks 3.5.1 CAN High & CAN Low CAN bus is a communication system, which is widely used in modern vehicles. A car may have 2 to 3 CAN bus networks, both high-speed and low-speed. The general high-speed transmission rate is 500k, which is usually used for power transmission. - Page 126 Chapter 3 Automotive Test BNC to banana cable, one end is connected to channel 2 of the oscilloscope, and the other end is grounded, and the red connector is pierced into the CAN low wire of the plug with a needle tip. The specific CAN high and CAN low can be found in the technical manual of the vehicle.

- Page 127 Figure 3-50 CAN bus measurement diagram...

-

Page 128: Lin Bus

Chapter 3 Automotive Test 3.5.2 LIN Bus The LIN protocol is short for Local Interconnect Network. The Lin bus communication is very common in automobiles, it is low speed, there are multiple control devices mounted on a network. It can contril non-safety-critical and low-speed devices on vehicles, such as wipers, windows, mirrors, air conditioners, electronic seats, etc. - Page 129 Figure 3-51 Lin bus test The following picture is the actual measurement of Audi A6 LIN bus in a certain year:...

-

Page 130: Flexray Bus

Chapter 3 Automotive Test Figure 3-52 Audi A6 LIN bus measurement 3.5.3 FlexRay Bus With the increase of car transmission content, the Flexray bus with faster transmission speed has been developed, and the transmission rate can reach 10Mbps. It has the advantages of high speed, determinability, and fault tolerance. - Page 131 The Flexray bus still has 2 lines and the waveform is in a differential pattern. When idle, the voltage of the two wires is 2.5V; when transmitting data, both wires will have a voltage of 1V up and down, and the voltages on the two wires are opposite.

- Page 132 Chapter 3 Automotive Test Figure 3-53: FlexRay bus test...

-

Page 133: K Line

3.5.4 K line The K line is a special line for data transmission between the car control unit and the diagnostic instrument, and the transmission rate is low. In general, K-Line is very different from CAN Bus and most communication networks. For example, the CAN Bus network does not have a central or master ECM: all ECMs are equal because they can send and receive information along the network. - Page 134 Chapter 3 Automotive Test Figure 3-54 K line test...

-

Page 135: Combination Tests

Combination Tests The electronic faults of automobiles are sometimes more complicated. We need to use an VATO oscilloscope to perform combination testing, compare several waveforms that collected, and help users judge the fault by observing and analyzing the timing relationship and quantitative relationship between the waveforms. , The VATO is a powerful tool to solve such complex problems. - Page 136 Chapter 3 Automotive Test Figure 3-55 Crankshaft + Camshaft Combination Test...

-

Page 137: Crankshaft + Primary Ignition

3.6.2 Crankshaft + Primary ignition Measure the crankshaft and primary ignition at the same time, you can check whether the ignition advance angle is normal, and look for the cause of misfire at high engine speed. Check whether the crankshaft signal is normal or whether the primary ignition voltage and closing time are reached. - Page 138 Chapter 3 Automotive Test Figure 3-56 Crankshaft + Primary ignition test...

-

Page 139: Primary Ignition + Injector Voltage

3.6.3 Primary ignition + Injector voltage If there is a problem with the startup or it is suddenly off, it may be necessary to test the primary ignition and the fuel injector at the same time. If the primary ignition fails, no fuel injector signal will be generated. Use a P130A probe, one end is connected to channel 1 of the oscilloscope, and the other end is grounded with a black clip. - Page 140 Chapter 3 Automotive Test Figure 3-57 Primary ignition + Injector voltage...

-

Page 141: Crankshaft + Camshaft + Injector + Secondary Ignition

3.6.4 Crankshaft + Camshaft + Injector + Secondary Ignition Use a BNC to banana cable, one end is connected to channel 1 of the oscilloscope, the other end is grounded with a black plug, and the red connector is pierced into the signal line of the crankshaft sensor with a needle; Use a BNC to banana cable, one end is connected to channel 2 of the oscilloscope, the other end is grounded with a black plug, and the red connector is pierced into the signal line of the camshaft sensor with a needle;... - Page 142 Chapter 3 Automotive Test Figure 3-58 Combination test of Crankshaft + Camshaft + Injector + Secondary ignition...

-

Page 143: Chapter 4 Horizontal System

Chapter 4 Horizontal System This chapter contains the detailed information of the horizontal system of the oscilloscope. You are recommended to read this chapter carefully to understand the set functions and operation of the horizontal system of the VATO series oscilloscope. ⚫... - Page 144 Chapter 4 Horizontal System Figure 4-1 Horizontal system...

-

Page 145: Move The Waveform Horizontally

4.1 Move the Waveform Horizontally Put one finger on the waveform display area to swipe left and right, for the coarse adjustment of the waveform position horizontally of all analog channels; after moving the waveform, tap the fine adjustment button in the lower left corner of the screen for fine adjustment. -

Page 146: Adjust The Horizontal Time Base (Time/Div)

Chapter 4 Horizontal System 4.2 Adjust the Horizontal Time Base (time/div) Method 1: Soft Keys buttons to adjust the horizontal time base of all analog channels (current channels). Tap button to increase the horizontal time base; tap button to zoom out the horizontal time base (see Figure 4-3 Adjust the Horizontal Time Base). - Page 147 Figure 4-3 Adjust the Horizontal Time Base Method 2: Time Base Knob to open the time base list (see Figure 4-4 Horizontal Time Base List), then tap the list to select the appropriate time base. The time base with the blue filled background is the currently selected time base.

- Page 148 Chapter 4 Horizontal System Figure 4-4 Horizontal Time Base Knob...

-

Page 149: Pan And Zoom Single Or Stopped Acquisitions

4.3 Pan and Zoom Single or Stopped Acquisitions After the oscilloscope is stopped, the stopped display screen may contain several acquired data with useful information, but only the data in the last acquisition can be horizontally moved and zoomed. The data of the single acquisition or stopped acquisition is moved horizontally and zoomed. -

Page 150: Zoom Mode

Chapter 4 Horizontal System 4.4 Zoom Mode Zoom is a horizontally expanded version of the normal display. Open the zoom function, the display is divided into two parts (see Figure 4-5 Zoom Interface). The upper part of the display screen shows the normal display window view and the lower part shows the zoomed display window. - Page 151 Figure 4-5 Zoom Interface Zoom window view is the enlarged portion of the normal display window. You can use “Zoom” to view a portion of the normal window that is horizontally expanded to learn more about signal analysis.

- Page 152 Chapter 4 Horizontal System Zoom on/off: Open the pull-up menu and tap button to turn the zoom function on/off. Zoom window is framed in a box on the normal window, and the other portion is covered by gray shade not displayed in the zoom window.

- Page 153 current memory depth, when the zoom window is opened, the time base in the normal window is automatically set to the minimum time base in the normal window at the current memory depth. The cursor, math waveform, and reference waveform are not displayed in the normal window, but can be displayed in the Zoom window.

-

Page 154: Chapter 5 Vertical System

Chapter 5 Vertical System This chapter contains the detailed information of the vertical system of the oscilloscope. You are recommended to read this chapter carefully to understand the set functions and operation of the vertical system of the VATO series oscilloscope. - Page 155 The figure below shows the “CH1 Channel Menu” displayed after opening the CH1 channel menu. Figure 5-1 Channel Menu Display Interface...

-

Page 156: Open/Close Waveform (Channel, Math, Reference Waveforms)

Chapter 5 Vertical System 5.1 Open/Close Waveform (Channel, Math, Reference Waveforms) The channel icons 、 、 、 、 、 on the right side of the oscilloscope waveform display area (swipe up or down to switch to math channel and reference channel) correspond to the six channels of CH1, CH2, CH3, CH4, math function and reference channel. - Page 157 Figure 5-2 Current Channel and Non-Current Channel The display content of the oscilloscope channel display interface includes the vertical scale, vertical scale sensitivity button, coupling mode, invert, bandwidth limitation of the channel, as shown in Figure 5-3.

- Page 158 Chapter 5 Vertical System Figure 5-3 Channel Display Interface When CH1 is on, but the state is not the current channel, tap CH1 waveform or vertical sensitivity or channel indicator or vertical sensitivity button or current channel selection button to set CH1 as the current channel, as shown in Figure 5-4.

- Page 159 Figure 5-4 Channel Open, Close and Switching...

- Page 160 Chapter 5 Vertical System Figure 5-5 Using the Current Channel Selection Button...

-

Page 161: Adjust Vertical Sensitivity

Tap the current channel icon at the bottom of the screen to pop up the current channel switching menu and press the button to light it up, as shown in Figure 5-5. Tap the button in the menu to switch the current channel. When this function is opened: the current channel may be switched in the channel switching menu;... -

Page 162: Adjust Vertical Position

Chapter 5 Vertical System The vertical sensitivity scale (V/div) after each adjustment is displayed on the channel icon. For example, means that the current vertical sensitivity of CH1 is 1.0V/div. The vertical sensitivity coefficient adjusts the vertical sensitivity of the analog channel in steps of 1-2-5 (the probe attenuation coefficient is 1X), and the vertical sensitivity range of 1:1 probe is 1mV/div-10V/div (optionally minimum at 500uV/div). -

Page 163: Open Channel Menu

5.4 Open Channel Menu Right swipe the channel icon to open the desired channel menu. The channel menu is shown in Figure 5-6. Channel waveform inversion, channel bandwidth limit, probe type, probe attenuation factor, channel coupling mode, channel on/off can be set in the vertical menu. Figure 5-6 Channel menu... -

Page 164: Set Channel Coupling

Chapter 5 Vertical System 5.4.1 Set Channel Coupling Tap the icon under “Signal” and select “DC”, “AC” channel coupling modes in the pop-up box. DC: DC coupling. Both the DC component and the AC component of the measured signal can pass, and can be used to view waveforms as low as 0 Hz without large DC offset. - Page 165 Figure 5-7 DC Coupling Figure 5-8 AC Coupling Note: This setting is only valid for the current channel. To switch from the current channel, just tap the channel icon, channel indicator icon or horizontal position pointed by the channel indicator icon for direct switching. You do not need to exit the menu.

-

Page 166: Set Bandwidth Limit

Chapter 5 Vertical System 5.4.2 Set Bandwidth Limit Open the channel menu, find the “Bandwidth” selection box in the channel menu, set bandwidth limit, high-pass filtering and low-pass filtering as needed. Full Bandwidth: Allows signals of all frequencies to pass. High pass: Only signals over the currently set frequency upper limit are allowed to pass. -

Page 167: Waveform Inversion

The difference in bandwidth limit can be intuitively shown through the waveform. The full bandwidth is shown in Figure 5-9, and the low-pass is shown in Figure 5-10. Figure 5-9 Full Bandwidth Figure 5-10 Low Pass 5.4.3 Waveform Inversion After selecting “Invert”, the voltage value of the displayed waveform is inverted. Inversion affects the way the channel is displayed. -

Page 168: Set Probe Type

Chapter 5 Vertical System Figure 5-11 Before Inversion Figure 5-12 After Inversion 5.4.4 Set Probe Type Probe types are divided into voltage probe and current probe. Probe type adjustment steps: Open the channel menu, find the “Probe Type” checkbox in the channel menu, then select: ⚫... -

Page 169: Set Probe Attenuation Coefficient

⚫ Cur - corresponding the current probe. 5.4.5 Set Probe Attenuation Coefficient When measuring with a probe, the correct measurement result can only be obtained by setting the correct probe attenuation ratio. In order to match the actual probe attenuation ratio, it is necessary to adjust the channel attenuation factor correspondingly under the channel menu. - Page 170 Chapter 5 Vertical System Probe attenuation ratio / Probe attenuation ratio / Probe attenuation ratio / Probe attenuation ratio / Menu attenuation ratio Menu attenuation ratio Menu attenuation ratio Menu attenuation ratio 0.001:1 0.1:1 100mx 10:1 1000:1 0.002:1 0.2:1 200mx 20:1 2000:1 0.005:1...

-

Page 171: Vertical Expansion Datum

5.4.6 Vertical expansion datum When using vertical expansion, you can click the center or zero point respectively. Center: When you click the center, adjust the vertical scale, and the oscilloscope waveform will be expanded based on the center of the screen. Zero point: When you click zero point, adjust the vertical scale, and the oscilloscope waveform will be expanded based on the waveform zero point. - Page 172 Chapter 5 Vertical System Figure 5-13 Channel label...

-

Page 173: Chapter 6 Trigger System

Chapter 6 Trigger System This chapter contains the detailed information of the trigger system of the oscilloscope. You are recommended to read this chapter carefully to understand the set functions and operation of the trigger system of the VATO series oscilloscope. -

Page 174: Trigger And Trigger Adjustment

Chapter 6 Trigger System 6.1 Trigger and Trigger Adjustment What is Trigger? The oscilloscope can capture a waveform only when it meets a preset condition first. This action of capturing the waveform according to the condition is Trigger. The so-called capture waveform is that the oscilloscope grabs a signal and displays it. - Page 175 The oscilloscope can stably display a periodic signal. Figure 6-1 Stably Displayed Periodic Signal Figure 6-2 Non-Stably Displayed Periodic Signal...

- Page 176 Chapter 6 Trigger System Grab the segment you want to observe from a fast and complex signal Figure 6-3 Abnormal Signal in Periodic Signals Figure 6-4 Abnormal Signal Captured by Setting Trigger Level...

- Page 177 What is Forced Trigger? When the oscilloscope does not meet the trigger condition, the artificial or automatic oscilloscope trigger is the forced trigger. It means that the oscilloscope only grabs a signal segment for display regardless of whether the condition is met or not. Automatic forced trigger is set in the menu.

- Page 178 Chapter 6 Trigger System Figure 6-5 Oscilloscope Trigger Mode Setting If a signal feature is not understood, the oscilloscope should be set as “Auto” mode, which can ensure that the oscilloscope can also display the waveform when other trigger settings are not correct. Although the waveform is not necessarily stable, it can provide the intuitive judgment for our further adjustment of the oscilloscope.

- Page 179 When we set a specific trigger condition for a specific signal, especially when the time interval for satisfying the trigger condition is long, we need to set the trigger mode to “Normal” so as to prevent the oscilloscope from automatic forced trigger. Figure 6-6 shows a conceptual demonstration of the acquisition memory.

- Page 180 Chapter 6 Trigger System messages. The number of delay ranges available (pre-trigger and post-trigger messages) depends on the selected time base and memory depth. Adjust trigger position (horizontal delay) Fingers swipe left and right in the waveform display area, the trigger point will move horizontally, the horizontal delay time changes, and the delay time is displayed at the top center of the screen, that is, the distance between the trigger point...

- Page 181 When the trigger point is located on the left side to the center line of the waveform display area, the delay time is displayed as a positive value; When the trigger point is located on the right side to the time reference point , and the delay time is displayed as a negative value;...

- Page 182 Chapter 6 Trigger System Figure 6-8 Trigger Level Adjust trigger level The trigger level can be coarsely adjusted and finely adjusted. Coarse adjustment: Slide up and down in the trigger level adjustment area.

- Page 183 Fine adjustment: Tap the fine adjustment button in the lower left corner of the screen for fine adjustment of the trigger level. Set trigger hold-off time The trigger hold-off time can set up the waiting time of the oscilloscope after the trigger and before the trigger circuit is reconnected.

- Page 184 Chapter 6 Trigger System Hold-off Time Oscilloscope Trigger Position Figure 6-9 Trigger Hold-Off Time Set trigger hold-off time: Tap “Trigger” on the main menu to open the trigger menu. Under “Common”, tap the box after “Rejection Time” to open the hold-off time adjustment interface. The trigger time is displayed on the upper left, the fine adjustment time scale is displayed on the upper right, and the coarse time scale is displayed below, as shown in Figure 6-10.

- Page 185 When adjusting the time, drag or tap the coarse adjustment scale for coarse adjustment, and then drag the fine adjustment scale for fine adjustment of the hold-off time. Trigger hold-off operation prompt It is typically used for complex waveforms. The correct rejection setting is usually slightly smaller than one repetition of the waveform.

-

Page 186: Edge Trigger

Chapter 6 Trigger System is displayed in the upper left corner of the screen before starting operations in the circuit (this means the pre-trigger buffer is filled). 6.2 Edge Trigger When the edge of trigger signal reaches a certain trigger level, the set signal is triggered and generated. Trigger occurs on either edge of the rising edge (indicating icon at the top of the screen), falling edge ( ) or dual edge ( ), and the trigger level can be set to change the vertical position of the trigger point on the trigger edge, namely... - Page 187 Set CH4 as trigger signal source Rising edge Set signal trigger on the rising edge Slope Falling edge Set signal trigger on the falling edge Dual edge Set signal trigger on either rising edge or falling edge AC and DC components getting through trigger signals Filter out the DC component of trigger signals HF rejection Suppress signals above 50KHz in trigger signals...

- Page 188 Chapter 6 Trigger System ⚫ Trigger source: CH1; ⚫ Trigger coupling mode: DC; ⚫ Trigger edge: rising. Figure 6-11 Edge Trigger Setting Menu Adjust the trigger level to ensure that the waveform can be triggered stably, for example, the trigger level is set to 1V.

- Page 189 When the edge trigger setup menu is opened, the trigger coupling option is displayed below the menu. Trigger coupling includes DC, NoiseRej, see Figure 6-12: Figure 6-12 Trigger Coupling Menu DC coupling - allows DC and AC signals to enter the trigger path. NoiseRej.

-

Page 190: Pulse Width Trigger

Chapter 6 Trigger System 6.3 Pulse Width Trigger The trigger happens when the trigger signal pulse width (8ns~10s, the trigger type indication icon at the top of the screen is ) reaches the set condition and the signal voltage reaches the set trigger level. Pulse width trigger menu is shown in the following table: Description Trigger Option... - Page 191 Description Trigger Option Setting =T Trigger when the signal pulse width is equal to pulse width T ≠T Trigger when the signal pulse width is not equal to pulse width T Trigger Pulse 8ns~10s Set the trigger pulse width Width Notes: Conditions of greater than, smaller than, equal to or not equal to indicating that the error is 6%.

- Page 192 Chapter 6 Trigger System ⚫ Trigger condition and pulse width time: “greater than”, the adjustment time is 180us. Figure 6-13 Pulse Width Trigger Setting Menu...

- Page 193 Pulse width trigger setting description: 1) Pulse polarity selection The selected pulse polarity icon appears in the upper left corner of the display. When triggering on a positive polarity pulse, if the constraint is true, the trigger will occur on the pulse transition from high to low; when triggering on a negative polarity pulse, if the constraint is true, the trigger will occur on the pulse transition from low to low.

- Page 194 Chapter 6 Trigger System Figure 6-14 Negative Polarity Pulse Level Flip Trigger condition and pulse width time setting Time restrictions that can set in the trigger condition: <, >, =, ≠. ⚫ Smaller than the time value (<)

- Page 195 For example, for positive pulse, if it is set as T<80ns, the trigger will happen stably only when the pulse width is smaller than 80ns (Figure 6-15 Trigger Time T<80ns). Trigger Figure 6-15 Trigger Time T<80ns ⚫ Greater than the time value (>) For example, for positive pulse, if it is set as T>80ns, the trigger will happen stably only when the pulse width is greater than 80ns (Figure 6-16 Trigger Time T>80ns).

- Page 196 Chapter 6 Trigger System ⚫ Equal to the time value (=) For example, for positive pulse, if it is set as T=80ns, the trigger will happen stably only when the pulse width is equal to 80ns (Figure 6-17 Trigger Time T=80ns). Trigger Figure 6-17 Trigger Time T=80ns ⚫...

-

Page 197: Serial Bus Trigger

The trigger pulse width time can be set as 8ns~10s. Tap the pulse width time setting box to pop up the time adjustment interface (as shown in Figure 6- 19), and adjust the pulse width time. Adjust the pulse width time by adjusting or dragging the time scale. Figure 6-19 Pulse Width Time Adjustment Interface 6.4 Serial Bus Trigger Please refer to... -

Page 198: Chapter 7 Analysis System

Chapter 7 Analysis System This chapter contains the detailed information of the analysis system of the oscilloscope. You are recommended to read this chapter carefully to understand the set functions and operation of the analysis system of the VATO series oscilloscope. -

Page 199: Automatic Measurement

7.1 Automatic Measurement Measurement setting Slide down from top, open the main menu, tap “Measure” to enter the measurement menu. There are 23 measurement items on the measurement menu. Measurement menu, selected measurement item display and measurement item display are shown in Figure 7-1:... - Page 200 Chapter 7 Analysis System Figure 7-1 Automatic Measurement Menu Automatic measurement Select channel: Select the channel to be measured above the measurement menu.

- Page 201 Select measurement: Select the desired measurement item on the measurement menu. The selected measurement item is displayed in the “Selected Parameters” display area below. Cancel measurement item: In the “Selected Parameters” display area below measurement menu, tap the measurement item to be cleared; or tap button to clear all measurement items.

- Page 202 Chapter 7 Analysis System Rise Time Fall Time Threshold Upper Limit Negative Pulse Positive Pulse Width Width Threshold Median Threshold Lower Limit Period Figure 7-2 Time Parameter Period Time of the first complete signal cycle in the waveform Frequency Reciprocal to the cycle time Rise time Time required for the first rising edge of the waveform to rise from the amplitude of 10% to 90% Fall time...

- Page 203 Time required for the first falling edge of the waveform to rise from the amplitude of 10% to 90% Delay Time delay between rising or falling edges of channels may be measured, and there are nine effective measurement combinations Delay Figure 7-3 Delay Measurement Schematics Open the automatic measurement menu and tap to pop up the phase selection menu.

- Page 204 Chapter 7 Analysis System The left channel is defaulted as the current channel, and other channels can be selected by the channel area that has been opened (except the reference channel); there are four edge selections: first rising edge, first falling edge, last rising edge, last falling edge .

- Page 205 Positive pulse width Measured value of the first positive pulse in the waveform, taking the time between two 50% amplitude points Negative pulse width Measured value of the first negative pulse in the waveform, taking the time between two 50% amplitude points Burst width Duration of a burst measured over the entire waveform Overshoot...

- Page 206 Chapter 7 Analysis System Timing measurement. The amount of time that one waveform leads or lags another waveform, expressed in degrees where 360°comprises one waveform cycle. Period Delay Figure 7-4 Phase Measurement Schematics Peak-peak In the entire waveform measurement, peak-peak = max - min Amplitude In the entire waveform measurement, amplitude = high (100%) - low (0%) The figure below shows voltage measurement points.

- Page 207 The channel probe type setting is used to set the measurement unit for each input channel to Volts or Amperes. Refer to “5.4.4 Set Probe Type”. Amplitude Peak-peak Figure 7-5 Voltage Measurement High Take 100% in the entire waveform, and calculated using either the min/max or histogram method. Take 0% in the entire waveform, and calculated using either the min/max or histogram method.

- Page 208 Chapter 7 Analysis System Highest positive peak measured over the entire waveform Highest negative peak measured over the entire waveform True root mean square value over the entire waveform C RMS True root mean square value of the first cycle in the waveform Mean Arithmetic mean over the entire waveform C mean...

- Page 209 Note: If the waveform required for measurement is not fully displayed on the screen, “Forward Clipping” or “Negative Clipping” is displayed at the position of the measured value. When the math function is operated, if source channel waveform is fully displayed, and the math waveform appears to be off the screen, the measured value of math waveform will not be influenced.

-

Page 210: Cursor

Chapter 7 Analysis System 7.2 Cursor Open cursor and place it on the measurement point to read the waveform measurement value. There are two types of cursors: horizontal cursor and vertical cursor. The horizontal cursor measures the vertical direction magnitude, and the vertical cursor measures the horizontal direction magnitude, as shown in Figure 7-6. - Page 211 Note: △ reading: indicates the difference between two cursor positions. Voltage readings after Y1, Y2: indicate the position of activated horizontal cursors relative to the zero potential. Time readings after X1, X2: indicate the position of activated vertical cursors relative to the trigger point. 1/△X: frequency S reading.

- Page 212 Chapter 7 Analysis System Vertical cursor on: Open pull-up menu and tap cursor icon to open vertical cursors and the icon is on activated. Vertical cursor off: Open pull-up menu and tap cursor icon to turn off vertical cursors. Tap the vertical cursor indicator line to switch the cursors.

- Page 213 Figure 7-7 Open Cursor Selection Box and Close Cursor...

- Page 214 Chapter 7 Analysis System Vertical cursor movement descriptions: Use a single finger to press and hold the cursor indicator line on the screen to make coarse adjustment to the cursor; tap the fine adjustment button in the lower left corner of the screen to fine-adjust the cursor that has just been adjusted.

- Page 215 When vertical cursors are activated, the two cursors move together to check for pulse width changes in the pulse sequence. Figure 7-8 Cursor Measurement Pulse Width...

-

Page 216: Phase Rulers

Chapter 7 Analysis System 7.3 Phase Rulers The phase rulers help to measure the timing of a cyclic waveform on a scope view. Phase rulers measure relative to the start and end of a time interval that you specify. Phase ruler settings box include Number of cylinder & Angle. -

Page 217: Chapter 8 Storage

Chapter 8 Storage This chapter contains the detailed information of the screen capture function and memory depth of the oscilloscope. You are recommended to read this chapter carefully to understand the storage system of the VATO series oscilloscope. ⚫ Screen capture function ⚫... -

Page 218: Screen Capture Function

Chapter 8 Storage 8.1 Screen Capture Function Screenshots and video recording can use the related functions that come with Android devices to store the display information of the current display screen locally in picture format and video format. 8.2 Waveform Storage The oscilloscope can save the analog channel or math channel waveform locally or in USB device. - Page 219 Figure 8-1 Save CH1 Reference Waveform Interface File types: WAV, CSV. File name: The initial file name is displayed as year + month + day + storage serial number. Press the file name box to pop up the virtual keyboard, tap “Backspace” to delete the file name, and use the virtual keyboard to rename the file.

- Page 220 Chapter 8 Storage Save: Tap to save the reference file and pop up the save success prompt. The most recently saved file will be displayed at the top of the called menu. Save to: Tap the R* (R1, R2, R3, R4) button to save the current channel waveform directly to the corresponding reference channel, and the save success prompt will pop up.

- Page 221 ⚫ Storage location: locally. ⚫ Selecting the file type: WAV. ⚫ Entering the file name: CH1. Tap “Save” to save the reference file. The save success prompt box is popped up. There is no limit to the number of saved reference waveform files. Method 2: Click R* button In the Save Reference Waveform menu, tap R* (R1, R2, R3, R4) button to save the current channel waveform directly to the corresponding reference channel, and the save success prompt will pop up.

- Page 222 Chapter 8 Storage Method 3: Click “Quick Save” button at bottom of the screen to save all channel waveforms as reference waveforms and capture the current screen. The file names are the default initial file names. CSV files CSV file structure CSV format contains the basic information of the saved data: save time, file name, data length, sampling interval, trigger time, source, vertical scale, vertical offset, vertical accuracy, horizontal time base, horizontal accuracy, probe multiples.

- Page 223 If running Min or Max measurements, Min and Max values displayed on the measurement results screen may not appear in CSV files. Explanation: If the oscilloscope sampling rate is 1GSa/s, sampling will be once every 1ns. If the horizontal scaling is set to 10us/div, the data of 140us will be displayed (because there are 14 divisions on screen).

-

Page 224: Oscilloscope Setting Save

Chapter 8 Storage 8.3 Oscilloscope setting save The oscilloscope supports saving up to 10 current settings and restoring them with one key. Open the main menu, tap Save and enter Setting menu, as shown in Figure 8-2. - Page 225 Figure 8-2 oscilloscope setting save Tap the black box area to rename save settings, tap the Save button to store, the Recovery button to restore the settings.

-

Page 226: Chapter 9 Math And Reference

This chapter contains the detailed information of the MATH operation and reference channel of the oscilloscope. You are recommended to read this chapter carefully to understand the setting functions and operations of the MATH and reference channels of the VATO series oscilloscope. ⚫ Dual waveform calculation ⚫... -

Page 227: Dual Waveform Calculation

9.1 Dual Waveform Calculation Figure 9-1 MATH Channel Waveform Display math waveform Swipe up or down at the channel selection area to enter the second channel selection area. Tap the soft key open the math channel. After the math waveform is opened, the current channel selector is automatically opened. - Page 228 Chapter 9 MATH and Reference Left swipe math channel icon to open the math channel menu. While opening math for the first time, the math operation is defaulted as the dual channel calculation. Math operation prompt If the analog channel or math function is clipped (not fully displayed on the screen), the resulting math function will also be clipped.

- Page 229 For details of movement, vertical sensitivity adjustment, time base adjustment and vertical expansion reference of the math channel, please refer to “Chapter 4 Horizontal System” and “Chapter 5 Vertical System”. The vertical sensitivity, unit and time base corresponding to the math waveform are displayed in the channel area of the math channel.

- Page 230 Chapter 9 MATH and Reference Note: If the units of two operation source channels are different and the unit combination cannot be identified, the unit of math function will be displayed as? (undefined). Math operators Math operators perform arithmetic operations on the analog input channels. Addition or subtraction If addition or subtraction is selected, the values of function sources 1 and 2 will be added or subtracted point by point and the results will be displayed.

- Page 231 Figure 9-2 Mathematical Operation of CH1 adding CH2...

-

Page 232: Fft Measurement

Chapter 9 MATH and Reference Multiplication or division When multiplication or division is selected, the values of function sources 1 and 2 values will be multiplied or divided point by point and the results will be displayed. Multiplication is useful when viewing the power relationship, if one of the channels is proportional to the current. 9.2 FFT Measurement FFT is used to calculate the Fast Fourier Transform using the analog input channel. - Page 233 Figure 9-3 FFT Window Open FFT Swipe up or down at the channel selection area to enter the second channel selection area. Tap the soft key to open the math channel, left swipe to open math channel menu.

- Page 234 Chapter 9 MATH and Reference spectrum type “Line/Decibel” to open the FFT window (see Figure 9-3 FFT Window). Tap the Operation Source box to select the channel for which FFT transform is required. Tap the window box to select the window function applied to the FFT input signal. Selection of window function In the FFT transform, four different FFT windows can be selected.

- Page 235 ⚫ Rectangular window This is the best window type for resolution frequencies that are very close to the same value, but this type is the least effective at accurately measuring the amplitude of these frequencies. It is the best type of measuring the spectrum of non-repetitive signals and measuring the frequency component close to DC.

- Page 236 Chapter 9 MATH and Reference ⚫ Hanning window This is the best window type for measuring amplitude accuracy but less effective for resolving frequencies. Use Hanning to measure sinusoidal, periodic, and narrowband random noises. This window is used for measuring transients or bursts of signal levels before or after events with significant differences. ⚫...

- Page 237 different, resulting in high-frequency transient interruption at the junction. In the frequency domain, this effect is called leakage. Therefore, to avoid leakage, the original waveform is multiplied by a window function, forcing the values at the beginning and at the end to be zero. Note: Signals with DC components or deviations can cause errors or deviations in the FFT waveform components.

- Page 238 Chapter 9 MATH and Reference Figure 9-4 Spectrum Amplitude as V-Hz Adjust FFT waveforms Waveform position...

- Page 239 ⚫ Select math channel as the current channel. After touching math waveform on the screen with one finger, adjust the waveform display position by dragging upward and downward, leftward and rightward, or tap the fine adjustment button in the lower left corner of the screen for fine adjustment ⚫...

-

Page 240: Reference Waveform Call

Chapter 9 MATH and Reference Vertical sensitivity on the right side of the screen to set the vertical sensitivity (V/div or dB/div) for the channel so that waveform is displayed on the screen at an appropriate size. The vertical sensitivity factor is stepped in 1-2-5 (using 1:1 probe). - Page 241 Figure 9-5 Reference Channel Menu When there are already waveforms loaded into the reference channel, click “Open/Close” button to open or close the reference channel; the reference waveform is displayed in blue-violet, and the four stored waveforms can be displayed simultaneously, wherein the current reference waveform is brighter than non-current reference waveforms.

- Page 242 Chapter 9 MATH and Reference Take R1 as an example, with operation steps as follows: Open reference menu. Tap the “Call” file box under R1 to open the reference file column. Click the name of the reference waveform file to be called. The file is loaded into R1 channel. Then, R1 channel is turned on as the current channel waveform, and the reference waveform channel icon highlighted.

- Page 243 Figure 9-6 Current Reference Waveform Close the reference waveform: In the reference menu, tap “Open/Close” button in R1 to close the reference waveform.

- Page 244 Chapter 9 MATH and Reference Repeat step 1 to close other reference channels. Right swipe to turn off all reference waveforms. Reference waveform movement and time base adjustment The horizontal or vertical movement and zoom of reference waveforms are independent of analog channels, and the adjustments among different reference waveform channels are also independent of each other.

-

Page 245: Chapter 10 Display Settings

This chapter contains the detailed information of the display settings and function buttons of the oscilloscope. You are recommended to read this chapter carefully to understand the display setting functions and operations of the VATO series oscilloscope. In the main menu, tap Display button to enter display settings menu, as shown in Figure 10-1. -

Page 246: Common Settings

Chapter 10 Display Settings 10.1 Common settings Open the common settings of the display menu. This item is used to set the time base reference mode and brightness of the waveform. The waveform brightness percentage is adjustable. The time base reference is divided into two types: screen center and trigger position: 1) Screen center Select to adjust the time base waveform to expand or contract to both sides with the center of the screen as the... -

Page 247: Graticule Setting

Figure 10-2 Waveform Display Menu 10.2 Graticule Setting Open the display menu and tap Graticule button to open the graticule setting menu (Figure 10-3). Graticule display mode includes: “Full”, “Grid”, “Crosshair” and “Frame”, and the brightness percentage is adjustable. Figure 10-3 Graticule Menu Displa... -

Page 248: Chapter 11 Sampling System

Chapter 11 Sampling System This chapter contains the detailed information of the sampling system of the oscilloscope. You are recommended to read this chapter carefully to understand the setting and operation of the sampling system of the VATO series oscilloscope. -

Page 249: Sampling Overview

11.1 Sampling Overview To understand the sampling and sampling modes of the oscilloscope, you need to understand the sampling principle, aliasing, oscilloscope bandwidth and sampling rate, oscilloscope rise time, required oscilloscope bandwidth, and the influence of memory depth on the sampling rate. Sampling principle According to the Nyquist sampling principle, for a bandwidth-limited signal with the maximum frequency f , the... - Page 250 Chapter 11 Sampling System Figure 11-1 Aliasing Oscilloscope bandwidth and sampling rate The oscilloscope bandwidth usually refers to the lowest frequency at which the input signal sine wave is attenuated by 3dB (-30% amplitude error). For oscilloscope bandwidth, according to the sampling principle, the required sampling rate is f .

- Page 251 Frequency Figure 11-2 Theoretical Brick-Wall Frequency Response However, digital signals have frequency components that exceed the fundamental frequency (the square wave consists of sine waves at fundamental frequency and an infinite number of odd harmonics), and for bandwidths of 500MHz and below, the oscilloscope typically has Gaussian frequency response.

- Page 252 Chapter 11 Sampling System Aliasing Frequency Figure 11-3 Sampling Rate and Oscilloscope Bandwidth The oscilloscope bandwidth is limited to 1/4 sampling frequency and reduces the frequency response above the Nyquist frequency. ≥4f Therefore, in fact, the oscilloscope sampling rate should be 4 times or more of its bandwidth: f .

- Page 253 Oscilloscope rise time The oscilloscope rise time is closely related to its bandwidth. The rise time of an oscilloscope with Gaussian type frequency response is approximately 0.35/f (based on the standard from 10% to 90%). The oscilloscope rise time is not the fastest edge speed that an oscilloscope can accurately measure. It is the fastest edge speed that the oscilloscope can produce.