BUSCH COBRA NS 0600 C Instruction Manual

Dry screw vacuum pumps

Hide thumbs

Also See for COBRA NS 0600 C:

- Instruction manual (36 pages) ,

- Instruction manual (68 pages)

Summary of Contents for BUSCH COBRA NS 0600 C

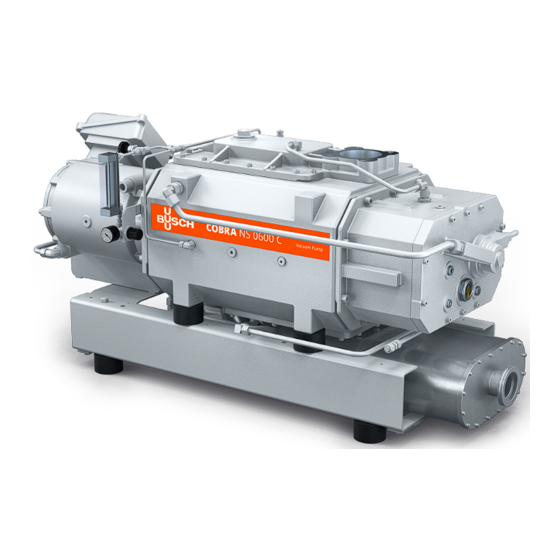

- Page 1 COBRA Dry Screw Vacuum Pumps NS 0600 C Instruction Manual 0870570426 | A0008_en-US | Original instructions 11/30/2023...

-

Page 2: Table Of Contents

Table of Contents Table of Contents Safety ..................................Product Description ............................. Operating Principle ............................. Intended Use ............................... Start Controls............................... Standard Features............................... 2.4.1 Water Cooling ............................2.4.2 Resistance Thermometer (TSA)......................2.4.3 Sealing Systems ............................ Optional Accessories............................2.5.1 Silencer ..............................2.5.2 Barrier Gas System..........................Transport ................................ - Page 3 Table of Contents Technical Data ..............................Cooling Liquid ............................... Oil ................................... EU Declaration of Conformity ..........................UK Declaration of Conformity..........................Instruction Manual COBRA NS 0600 C_EN_en 3 | 44...

-

Page 4: Safety

Safety Prior to handling the machine, this instruction manual should be read and understood. If anything needs to be clarified, please contact your Busch representative. Read this manual carefully before use and keep for future reference. This instruction manual remains valid as long as the customer does not change anything on the product. -

Page 5: Product Description

Product Description | 2 Product Description ODP, MP Description COBRA NS 0600 C Helium version Description Suction connection (Inlet) Discharge connection (Outlet) Cooling liquid drain plug Cooling liquid fill plug Cooling liquid pump Cooling liquid vent plug Cooling water inlet... -

Page 6: Operating Principle

Conveying of other media leads to an increased thermal and/or mechanical load on the machine and is permissible only after a consultation with Busch. The machine is intended for the placement in a non-potentially explosive environment. -

Page 7: Start Controls

Product Description | 2 The machine is suitable for continuous operation. Permitted environmental conditions, see Technical Data. Start Controls The machine comes without start controls. The control of the machine is to be provided in the course of installation. The machine can be equipped with a soft-starter or a variable speed drive (not included in the scope of supply). -

Page 8: Transport

3 | Transport Transport WARNING Suspended load. Risk of severe injury! ● Do not walk, stand or work under suspended loads. WARNING Lifting the machine using the motor eye bolt. Risk of severe injury! ● Do not lift the machine using the eye bolt fitted to the motor. Only lift the machine as shown. NOTICE In case the machine is already filled with oil. -

Page 9: Storage

Storage | 4 Storage ● Seal all apertures with adhesive tape or reuse provided caps. If the machine is to be stored for more than 3 months: ● Wrap the machine in a corrosion inhibiting film. ● Store the machine indoors, in a dry and dust free environment and if possible, in original pack- aging, preferably at temperatures between 5 ... -

Page 10: Installation

In case of long connection lines, it is advisable to use larger line sizes in order to avoid a loss of effi- ciency. Seek advice from your Busch representative. 10 | 44 Instruction Manual COBRA NS 0600 C_EN_en... -

Page 11: Suction Connection

– DN100 ISO-K, DIN 28404 or DN100 ISO-F, DIN 28404 If the machine is used as part of a vacuum system: ● Busch recommends the installation of an isolation valve in order to prevent the machine from turning backwards. ● Make sure that the connection lines cause no stress on the connections of the machine. There- fore, we recommend installing flexible joints on the suction and discharge connections. -

Page 12: Cooling Water Connection

5 | Installation 5.2.3 Cooling Water Connection Standard version Description Cooling water inlet Cooling water outlet Plate heat exchanger Helium version Description Cooling water inlet Cooling water outlet Plate heat exchanger 12 | 44 Instruction Manual COBRA NS 0600 C_EN_en... - Page 13 Installation | 5 ● Connect the cooling water connections (CWI / CWO) to the water supply. Connection size: – G1/2, ISO 228-1 (CWI / CWO) ● Make sure that the cooling water complies with the following requirements: Supply capacity l/min Water pressure bar (g) 1.5 ...

-

Page 14: Barrier Gas System Connection (Optional)

5 | Installation 5.2.4 Barrier Gas System Connection (Optional) Without nitrogen panel Description Barrier gas connection Flow meter Flow regulator Manometer Pressure regulating valve With nitrogen panel FME, FS Description Barrier gas connection Flow meter Flow switch Manometer 14 | 44 Instruction Manual COBRA NS 0600 C_EN_en... -

Page 15: Dilution Gas System Connection (Optional)

Installation | 5 Description Solenoid valve Nitrogen panel Pressure regulating valve ● Connect the barrier gas connection (BGC) to the gas supply. Connection size: – G1/4, ISO 228-1 Version with nitrogen panel: ● Electrically connect the solenoid valve (MV), see Wiring Diagram Solenoid Valve [➔ 22]. ●... -

Page 16: Filling Oil

5 | Installation ● Connect the dilution gas connection (DGC) to the gas supply. Connection size: – G1/4, ISO 228-1 ● Electrically connect the solenoid valve (MV), see Wiring Diagram Solenoid Valve [➔ 22]. ● Make sure that the gas complies with the following requirements: Gas type Dry nitrogen Gas temperature... - Page 17 When the oil filling is achieved: ● Write down the oil change date on the sticker. If there is no sticker (part no. 0565 568 959) on the machine: ● Order it from your Busch representative. Instruction Manual COBRA NS 0600 C_EN_en 17 | 44...

-

Page 18: Filling Cooling Liquid

5 | Installation Filling Cooling Liquid For cooling liquid type and cooling liquid capacity see Technical Data and Cooling Liquid [➔ 38]. Description Fill up to the top of the vent orifice 18 | 44 Instruction Manual COBRA NS 0600 C_EN_en... -

Page 19: Electrical Connection

● If the machine is equipped with a power connector, install a residual current protective device to protect persons in case of a defective insulation. ● Busch recommends installing a type B residual protective device suitable for the electrical in- stallation. -

Page 20: Wiring Diagram Three-Phase Motor (Pump Drive)

6 | Electrical Connection ● Provide a lockable disconnect switch on the power line so that the machine is completely secured during maintenance tasks. ● Provide an overload protection according to EN 60204-1 for the motor. ● Connect the protective earth conductor. ●... - Page 21 Electrical Connection | 6 Double star connection (low voltage): Star connection (high voltage): NOTICE Incorrect direction of rotation. Risk of damage to the machine! ● Operation in the wrong direction of rotation can destroy the machine in a short time! Prior to start-up, ensure that the machine is operated in the right direction.

-

Page 22: Wiring Diagram Solenoid Valve (Optional)

= 8 W Contact: Normally closed Electrical Connection of the Monitoring Devices NOTE To prevent potential nuisance alarms, Busch recommends that the control system is config- ured with a time delay of at least 20 seconds. 6.4.1 Wiring Diagram Resistance Thermometer Part no.: PT100: 0651 543 954... -

Page 23: Commissioning

Commissioning | 7 Commissioning CAUTION During operation the surface of the machine may reach temperatures of more than 70°C. Risk of burns! ● Avoid contact with the machine during and directly after operation. NOTICE The machine can be shipped without oil. Operation without oil will ruin the machine in short time! ●... -

Page 24: Conveying Condensable Vapors

7 | Commissioning Conveying Condensable Vapors CAUTION Draining the condensate while operating and/or venting the machine. The discharged gases and/or liquids may reach temperatures above 70°C! Risk of burns! ● Avoid direct contact with the flow of gases and/or liquids. The machine, equipped either with a gas ballast valve or a dilution gas system, is suitable for the conveyance of condensable vapors within the gas flow. -

Page 25: Maintenance

Risk of injuries! Risk of premature failure and loss of efficiency! ● Maintenance work must only be executed by qualified personnel. ● Respect the maintenance intervals or ask your Busch representative for service. NOTICE Using inappropriate cleaners. Risk of removing safety stickers and protective paint! ●... -

Page 26: Maintenance Schedule

● Change the oil of the gear and bearing housings (both years sides), see Oil Change [➔ 28]. ● Have a major overhaul on the machine (contact Busch). Oil Level Inspection ● Shut down the machine. ● When the machine is stopped, wait 1 minute before checking the oil level. -

Page 27: Oil Level, Machine Operating

If the oil becomes dark or looks different from the initial color: ● Change the oil immediately, see Oil Change [➔ 28]. You can consult your Busch representative in order to find out why this color change has occurred. Instruction Manual COBRA NS 0600 C_EN_en... -

Page 28: Cooling Liquid Level Inspection

Oil Change NOTICE Use of an inappropriate oil. Risk of premature failure! Loss of efficiency! ● Only use an oil type which has previously been approved and recommended by Busch. Description Magnetic plug Magnetic plug 28 | 44 Instruction Manual COBRA NS 0600 C_EN_en... - Page 29 Maintenance | 8 Description Magnetic plug For oil type and oil capacity see Technical Data and Oil. Instruction Manual COBRA NS 0600 C_EN_en 29 | 44...

- Page 30 When the oil filling is achieved: ● Write down the oil change date on the sticker. If there is no sticker (part no. 0565 568 959) on the machine: ● Order it from your Busch representative. 30 | 44 Instruction Manual COBRA NS 0600 C_EN_en...

-

Page 31: Cooling Liquid Change

Maintenance | 8 Cooling Liquid Change For cooling liquid type and cooling liquid capacity see Technical Data and Cooling Liquid [➔ 38]. Description Fill up to the top of the vent orifice Instruction Manual COBRA NS 0600 C_EN_en 31 | 44... -

Page 32: Overhaul

● Decontaminate the machine as much as possible and state the contamination status in a ‘Dec- laration of Contamination’. Busch will only accept machine accompanied by a signed, fully completed and legally binding "decla- ration of contamination", downloadable from the following link: buschvacuum.com/declaration-of- contamination. -

Page 33: Decommissioning

Decommissioning | 10 Decommissioning DANGER Live wires. Risk of electrical shock. ● Electrical installation work must only be executed by qualified personnel. CAUTION Hot surface. Risk of burns! ● Before doing anything that requires touching the machine, let it cool down first. ●... -

Page 34: Spare Parts

Risk of premature failure! Loss of efficiency! ● The exclusive use of Busch genuine spare parts and consumables is recommended for the correct functioning of the machine and to validate the warranty. There are no standard spare parts kits available for this product. -

Page 35: Troubleshooting

Busch). Solid foreign matter has en- ● Remove the solid foreign tered the machine. matter or repair the ma- chine (contact Busch). ● Install an inlet filter if neces- sary. A temperature sensor has ● Let the machine cool down. - Page 36 Oil Change [➔ 28]. The machine runs too hot. ● See problem "The machine runs too hot". For resolution of problems not listed in the troubleshooting table, please contact your Busch repre- sentative. 36 | 44 Instruction Manual COBRA NS 0600 C_EN_en...

-

Page 37: Technical Data

Technical Data | 13 Technical Data NS 0600 C NS 0600 C Standard Helium Pumping speed (50 / 60 Hz) m³/h 600 / 600 350 / 350 ACFM 353.1 Ultimate pressure without gas-bal- hPa (mbar) abs. ≤ 0.01 ≤ 7.0 last TORR ≤ 0.0075 ≤... -

Page 38: Cooling Liquid

14 | Cooling Liquid Cooling Liquid Zitrec M ® (Ready-to-use) Part number 5 L packaging 0831 563 469 Part number 20 L packaging 0831 238 761 Zitrec ® M coolant (Cooling liquid) is ready-to-use and requires no additional water. For more information, visit www.arteco-coolants.com. 38 | 44 Instruction Manual COBRA NS 0600 C_EN_en... -

Page 39: Oil

Oil | 15 VSC 100 ISO-VG Oil type Synthetic Part number 1 L packaging 0831 168 356 Part number 5 L packaging 0831 168 357 Part number 10 L packaging 0831 210 162 Part number 20 L packaging 0831 168 359 YLC 250 B ISO-VG Oil Type Synthetic... -

Page 40: Eu Declaration Of Conformity

EU Declaration of Conformity This Declaration of Conformity and the CE-markings affixed to the nameplate are valid for the machine within the Busch scope of delivery. This Decla- ration of Conformity is issued under the sole responsibility of the manufacturer. -

Page 41: Declaration Of Conformity

UK Declaration of Conformity This Declaration of Conformity and the UKCA-markings affixed to the nameplate are valid for the machine within the Busch scope of delivery. This Dec- laration of Conformity is issued under the sole responsibility of the manufacturer. - Page 42 Notes Notes 42 | 44 Instruction Manual COBRA NS 0600 C_EN_en...

- Page 43 N otes Instruction Manual COBRA NS 0600 C_EN_en 43 | 44...

- Page 44 With a network of over 60 companies in more than 40 countries and agencies worldwide, Busch has a global presence. In every country, highly competent local personnel delivers custom-tailored support backed by a global network of expertise. Wherever you are.

Need help?

Do you have a question about the COBRA NS 0600 C and is the answer not in the manual?

Questions and answers