Summary of Contents for BUSCH COBRA NS 0070-0160 C

- Page 1 Installation and Maintenance Instructions Screw Vacuum Pumps COBRA NS 0070-0160 C Ateliers Busch S.A. Zone industrielle 2906 Chevenez Switzerland 0870570353 / 181017 / Original instructions / Modifications reserved...

-

Page 2: Table Of Contents

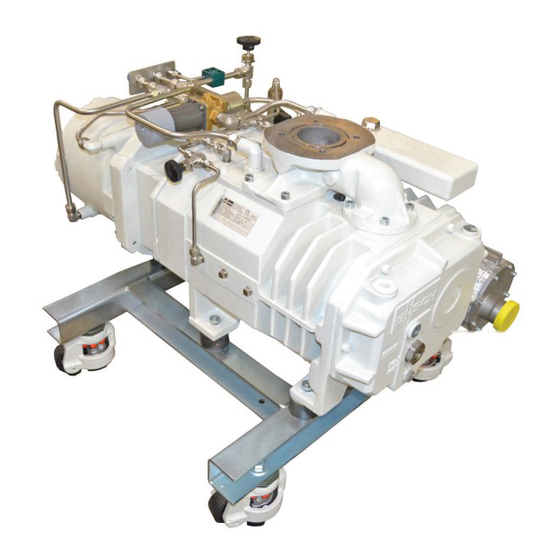

Nitrogen connection ..... . 8 Congratulations on your purchase of the Busch vacuum pump. With Electrical connection/ Checks ....8 watchful observation of the filed's requirements, innovation and steady Installation . - Page 3 IN Inlet OUT Discharge MOT Motor CLF Cooling liquid filler plug CLD Cooling liquid drain plug CWi Cooling water inlet FIS-/02 CWo Cooling water outlet CWR Cooling water regulating valve FIS-/01 Cooling water flow meter OFP Oil filler plug OSG Oil sight glass ODP Oil drain plug GC Nitrogen connection (option) DGR Nitrogen regulating valve (option)

-

Page 4: Product Description

The COBRA NS screw vacuum pumps is driven by a water-cooled Product description motor. The COBRA NS screw vacuum pumps can be combined with a Busch booster pump, i.e. type WY 0500 C. The COBRA NS vacuum pumps are designed for use in the field of Cooling industrial applications and similar industries. -

Page 5: On/ Off Switch

These installation and maintenance instructions must be read and CAUTION understood before the vacuum pump is used. If you have any doubts, contact your Busch representative. Please check out the weight of the vacuum pump before lifting it up Safety information (see "Technical Data"or pump nameplate). -

Page 6: Storage

l Use a hoist that is equipped with a hook and safety lock. l Wrap the vacuum pump in a VCI film. NOTE: VCI is the abbreviation for “volatile corrosion inhibitor”. The VCI molecule is an organic corrosion inhibitor in the vapour phase. Integrated in various carriers such as film, cardboard, paper, foam, liquid and powder, it protects the parts against corrosion as a result of its action in the vapour phase. -

Page 7: Inlet Connection

(according to nameplate). than the intake flange to prevent a drop in the performance of the vacuum pump. If you have any doubts, contact your Busch l Make sure that the vacuum pump is level. -

Page 8: Cooling Water Connection

In the case of long exhaust lines the line cross-section should be larger than the exhaust flange to prevent a drop in the performance of the WARNING vacuum pump. If you have any doubts, contact your Busch representative. Risk of electrocution, risk of damage. -

Page 9: Temperature Switch Connection

Cooling water flowmeter FIS-/01 connection Star connection (Y High voltage: 400 V): l Connect the cooling water flowmeter according to the connection plan below: Flow Switch normally closed at correct water flow Delta connection (D Low voltage: 208V): Technical data: : 250 V –... -

Page 10: Connection Of The Lines/ Pipes

= ***** min m = 250 kg l Fill in the cooling liquid through the filler opening until the liquid Oil = Busch YLC 250 B Oil quantity = 1,5 l Busch YLC 250 B starts running out of the screw on upper cylinder (perfluorinated polyether) -

Page 11: Saving The Operating Parameters

CAUTION Filler cap The surface temperature of the vacuum pump can exceed 70°C when the vacuum pump is in operation. Risk of burns! The vacuum pump may not be touched when it is in operation. If touching the pump is unavoidable, wait until the surface temperature has cooled down or wear protective gloves. -

Page 12: Switching The Vacuum Pump On/ Off

Weekly: l Check the oil level and the colour (see “Checking the Oil”) l Check the vacuum pump for oil leaks - in case of leaks, have the vacuum pump repaired (Busch service) Maintenance NS 0070-0160 C Page 12... -

Page 13: Monthly

Replace them if necessary. l Oil change (see “Oil change”) l Screw on the filler cap again. l Have a major overhaul done on the vacuum pump (Busch service) Checking the colour of the oil Switching off for maintenance work NOTE: The oil must be clear and transparent. -

Page 14: Oil Change

Oil change l Make sure that the seals of the filler cap are not damaged and that they sit properly. Replace them if necessary. l Screw on the filler cap again. DANGER Checking the cooling liquid In case the vacuum pump has conveyed gases that have been contaminated with harmful foreign materials, the oil will also be Checking the level of the cooling liquid contaminated. -

Page 15: Checking The Cooling Water

Decontamination"), which can be downloaded from www.buschvacuum.com. Checking the nitrogen flow Busch service will only accept vacuum pumps that come with a l Check the nitrogen flow regularly. completely filled in and legally binding signed form. If the flow drops, check for leaks. - Page 16 Drain the cooling liquid. – u Dispose of the cooling liquid according to local environmental protection regulations. Begin dismantling the vacuum pump. – CAUTION Wear protective clothing when carrying out dismantling work. u Dispose of the vacuum pump as scrap metal. Dispose of the individual parts of the machine according to local –...

-

Page 17: Troubleshooting

Use larger diameter too small diameter Internal parts worn or damaged Repair the vacuum pump (Busch service) The vacuum pump does not start The drive motor is not supplied with the correct Supply the drive motor with the correct voltage... - Page 18 No oil change over extended period of time Perform oil change incl. flushing (see “Mainte- nance”) Foreign objects in the vacuum pump Repair the vacuum pump (Busch service) Stuck bearings The vacuum pump runs very noisily Defective bearings Repair the vacuum pump (Busch service)

-

Page 19: Oil Type/ Quantity

NS 0160 C = 0.03 hPa (mbar) = 160 m /h = ***** min m = 250 kg Oil = Busch YLC 250 B Oil quantity = 1,5 l Busch YLC 250 B (perfluorinated polyether) Denomination Busch YLC 250 B... -

Page 20: Cooling Liquid Type/ Quantity

Cooling liquid type/ quantity Cooling liquid type l Make sure that the cooling liquid type corresponds to specifications: Specifications Zitrec M-25 (ready-to-use) 25 litres can 5 litres can part no. 0831 563 468 part no. 0831 563 469 Cooling liquid quantity The quantity of cooling liquid specified in this instructions manual is of informative nature only. -

Page 21: Technical Data

Technical Data Technical data NS 0070 C NS 0160 C 50 Hz /h (cfm) 70 (41) 135 (79) Nominal suction capacity 60 Hz /h (cfm) 85 (50) 160 (94) 2,2 x 10 2,2 x 10 Torr Ultimate pressure mbar 3,0 x 10 3,0 x 10 50 Hz Nominal motor rating... -

Page 22: Eu-Declaration Of Conformity

EU-Declaration of Conformity This Declaration of Conformity and the CE-mark affixed to the nameplate are valid for the machine within the Busch scope of delivery. This declaration of Conformity is issued under the sole responsibility of the manufacturer. When this machine is integrated into a superordinate machinery the manufacturer of the superordinate machinery (this can be the operating company, too) must conduct the conformity assessment process for the superordinate machine or plant, issue the Declaration of Conformity for it and affix the CE-mark. - Page 23 Note...

- Page 24 Busch – All over the World in Industry www.buschvacuum.com Finland Malaysia Spain Argentina Busch Malaysia Sdn Bhd. Busch Vakuumteknik Oy Busch Argentina S.R.L. Busch Ibérica S.A. 4&6, Jalan Taboh 33/22, Seksyen 33 Sinikellontie 4 Santo Domingo 3076 Pol. Ind. Coll de la Manya...

Need help?

Do you have a question about the COBRA NS 0070-0160 C and is the answer not in the manual?

Questions and answers