Fronius Tauro 50-3 Operating Instructions Manual

Hide thumbs

Also See for Tauro 50-3:

- Operating instructions manual (116 pages) ,

- Operating instructions manual (96 pages) ,

- Operating instructions manual (104 pages)

Summary of Contents for Fronius Tauro 50-3

- Page 1 Operating Instructions Fronius Tauro 50-3 Fronius Tauro ECO 50-3 Fronius Tauro ECO 99-3 Fronius Tauro ECO 100-3 Operating Instructions 42,0426,0307,EN 032-19012024...

-

Page 3: Table Of Contents

PV connections - Tauro 50-3-D (direct) PV connections - Tauro Eco 50-3-D (direct) PV connections - Tauro 50-3-D (30A fuses) PV connections - Tauro Eco 50-3-D (30A fuses) PV connections - Tauro Eco 99-3-D / 100-3-D (direct, 20 A option) - Page 4 General comments regarding PV modules Permitted cables DC fuse protection - pre-combined Example of Fronius Tauro Eco 50-3-P / 99-3-P / 100-3-P combiner box Example Fronius Tauro 50-3-P combiner box Distribution of the solar module strings for the direct version...

- Page 5 Connection diagram - 1 relay I/O power management settings - 1 relay Appendix Status codes and remedy Status Codes Technical data Tauro 50-3-D / 50-3-P Tauro Eco 50-3-D / 50-3-P Tauro Eco 99-3-D / 99-3-P Tauro Eco 100-3-D / 100-3-P WLAN Explanation of footnotes...

-

Page 6: Safety Rules

Safety rules Explanation of WARNING! safety notices Indicates a potentially hazardous situation. ▶ Death or serious injury may result if appropriate precautions are not taken. CAUTION! Indicates a situation where damage could occur. ▶ If not avoided, minor injury and/or damage to property may result. NOTE! Indicates a risk of flawed results and possible damage to the equipment. -

Page 7: Environmental Conditions

Faults that could compromise safety must be remedied before switching on the device. Environmental Operation or storage of the device outside the stipulated area will be deemed as conditions not in accordance with the intended purpose. The manufacturer accepts no liab- ility for any damage resulting from improper use. -

Page 8: Data Protection

In principle, Tauro inverters are maintenance-free. If maintenance work is never- theless carried out on the inverter, such as cleaning or replacing components, this must be done in consultation with a Fronius-trained service technician. The manufacturer accepts no liability for damage caused by improper use. -

Page 9: General Information

General information... -

Page 11: Description Of The Device

String fuses Only applies to device types Fronius Tauro 50-3-D / Eco 50-3-D / Eco 99-3-D / Eco 100-3-D (direct): String fuses are used in the Fronius Tauro to provide additional protection for the solar modules. -

Page 12: Fronius Solar.web

30A fuses F1.1 - F2.5 30A fuses F1.1 - F3.5 Fronius Sol- With Fronius Solar.web or Fronius Solar.web Premium, the PV system can be ar.web easily monitored and analysed by the system owner and installer. If configured accordingly, the inverter transmits data such as power, yields, load, and energy Solar.web - monitoring &... -

Page 13: Local Communication

The information given does not constitute an absolute guarantee of fault- less function. High error rates in the transmission, reception fluctuations or transmission drop-outs can have a negative effect on the data transfer. Fronius recommends testing the Internet connection on site according to the minimum requirements. Local commu- The inverter can be found via the Multicast DNS protocol (mDNS). -

Page 14: Protection Of People And Equipment

Protection of people and equipment Safety WARNING! Danger due to incorrect operation and incorrectly performed work. This can result in serious injury and damage to property. ▶ All the work and functions described in this document must only be carried out by trained and qualified personnel. -

Page 15: Wsd (Wired Shutdown)

CMIM mark – tested in accordance with IMANOR requirements for import regulations and compliance with Moroccan standards. Safety symbols: Risk of serious injury and property damage due to incorrect operation. Do not use the functions described here until you have fully read and understood the following documents: These Operating Instructions. -

Page 16: Surge Protective Device (Spd)

Fronius will not accept any costs associated with production downtimes, installer costs, etc., that may arise as the result of a detected arc and its consequences. Fronius accepts no liability for damage that can occur despite the presence of the integrated Arc Fault Circuit Interrupter/extinguishing system ( e.g. caused by a parallel arc). -

Page 17: Safe State

Safe state If one of the following safety devices trips, the inverter will change to a safe state: isolation measurement RCMU and AFCI In the safe state, the inverter no longer feeds into the grid and is disconnected from the grid by opening the AC relays. -

Page 18: Proper Use

Utilisation for any other purpose, or in any other manner Making any modifications to the inverter that have not been expressly ap- proved by Fronius Installation of parts that are not distributed or expressly approved by Froni- The manufacturer shall not be liable for any damage resulting from such use. All warranty claims will be forfeited. -

Page 19: Functional Principle

Functional principle Functional prin- The inverter operates fully automatically. As soon after sunrise as there is suffi- ciple cient energy available from the solar modules, the inverter starts checking the PV system (insulation measurement), and the grid (grid voltage and grid fre- quency). -

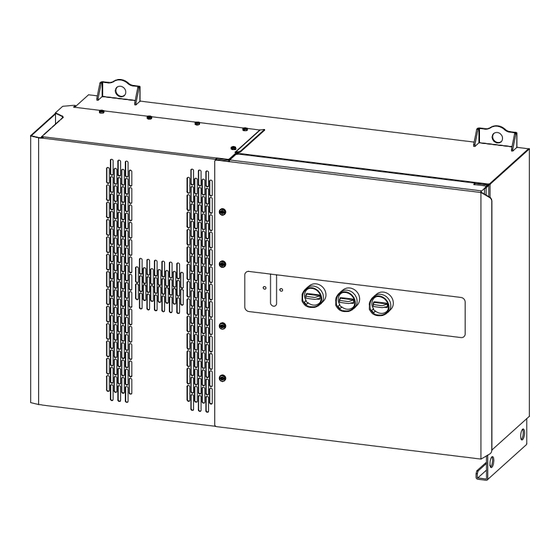

Page 20: Control Elements And Connections

Button function For further information about the button function, see But- ton functions and LED status indicator LED status indicator For further information about the LED status indicator, see Button functions and LED status indicator PV connections - Tauro 50-3-D (direct) -

Page 21: Pv Connections - Tauro Eco 50-3-D (Direct)

PV connections - Tauro Eco 50-3- D (direct) PV connections - Tauro 50-3-D (30A fuses) PV connections - Tauro Eco 50-3- D (30A fuses) -

Page 22: Pv Connections - Tauro Eco 99-3-D / 100-3-D (Direct, 20 A Option)

PV connections - Tauro Eco 99-3- D / 100-3-D (dir- ect, 20 A option) PV connections - Tauro Eco 99-3- D / 100-3-D (dir- ect, 30 A option) PV connections - Tauro Eco 50-3-P / 99-3-P / 100-3-P Tauro 50-3-P pre-combined... -

Page 23: Mounting Option For Third-Party Components

Mounting option Above the DC connection area there is for third-party space for mounting third-party com- components ponents. Components up to a maxim- um width of 14.5 cm (8 DU) can be mounted on the DIN rail. The compon- ents must have a temperature resist- ance of ‑40 °C to +85 °C. - Page 24 Indicates the inverter operating Operating status LED status. WSD (wired shutdown) switch Defines the inverter as a WSD primary device or WSD secondary device. Position 1: WSD primary device Position 0: WSD secondary device Modbus 0 (MB0) switch Switches the terminating resistor for Modbus 0 (MB0) on/off.

-

Page 25: Internal Schematic Connection Diagram Of The Ios

The status of the inverter is and LED status shown via the operating status indicator LED. In the event of faults, carry out the individual steps in the Fronius Solar.web live app. WLAN access point The optical sensor is actuated 3-6 sec. Quit Service Message by touching with a finger. - Page 26 Sensor functions = WLAN access point (AP) is opened. Flashing blue = WLAN Protected Setup (WPS) is activated. Flashing green 3 seconds (max. 6 seconds) = the service message is acknowledged. Flashing white (rapidly) LED status indicator The inverter is operating correctly. Lights up green The inverter starts.

- Page 27 LED status indicator The inverter is performing an update. Flashing blue There is a service message. Lights up white...

-

Page 29: Installation And Commissioning

Installation and commissioning... -

Page 31: General

General System compon- All installed components in the photovoltaic system must be compatible and ent compatibility have the necessary configuration options. The installed components must not re- strict or negatively influence the functioning of the photovoltaic system. NOTE! Risk due to components in the photovoltaic system that are not compatible and/or have limited compatibility. -

Page 32: Installation Location And Position

Installation location and position Choosing the Please note the following criteria when choosing a location for the inverter: location of the Only install on a solid, non-flammable surface inverter 0 - 100 % -40 °C - +65 °C -35 °C - +65 °C - Option AC-Disconnect Max. -

Page 33: Installation Position

The inverter is suitable for outdoor installation. Because of its IP 65 protection class, the inverter is resistant to water jets from any direction and can also be used in damp en- vironments. The inverter is suitable for outdoor installation. To keep the heating of the inverter as low as possible, it is better not to expose the inverter to direct sunlight. - Page 34 The inverter should have a minimum inclination of 3° in a hori- zontal installation position so that water can run off. Mounting of the optional floor racks is recommended. The floor racks may only be used on an installation position of 0 - 45°. The inverter is suitable for installation on a sloping surface.

-

Page 35: Transport

Transport Crane transport WARNING! Danger of serious injury and damage from articles being dropped or falling over. When transporting by crane: ▶ Hook chains and ropes onto the suspension points only ▶ Always hook chains and ropes onto both suspension points Transporting by WARNING! counterbalanced... -

Page 36: Mounting The Inverter

Mounting the inverter Selecting the fix- Use the corresponding fixing materials depending on the subsurface and observe ing material the screw dimension recommendations for the mounting bracket. The installer is responsible for selecting the correct type of fixing. Mounting brack- Dimensions of the mounting bracket - all dimensions in mm. - Page 37 Observe the local regulations for lifting heavy loads or use a crane to lift the device (attach to crane-hoisting lugs) To attach the inverter to the mounting bracket, use only the screws included in the scope of delivery.

-

Page 38: Mounting The Inverter On Floor Racks

Mounting the in- The floor racks can be ordered as an verter on floor optional accessory. racks Mounting the inverter on a horizontal mounting surface is not mandatory, but recommended. Depending on the surface, different wall plugs and screws are required for floor mounting the floor racks. -

Page 39: Connecting The Inverter To The Public Grid (Ac Side)

Connecting the inverter to the public grid (AC side) Monitoring the IMPORTANT! To provide the best possible grid monitoring, the resistance in the grid leads to the mains connections should be as low as possible. AC connection IMPORTANT! Only the following cables may be connected to V-type terminals: area RE (solid round conductor) RM (stranded round conductor) -

Page 40: Connecting Aluminium Cables

Select sufficiently high cable cross sections depending on the power category and connection option! Power category Connection option Cable cross section Singlecore/Multicore 35–240 mm Tauro 50-3 Optional AC disconnector 35–240 mm Tauro Eco 50-3 Daisy Chain (without AC discon- 35–240 mm nector) -

Page 41: Maximum Alternating Current Fuse Protection

Grid connections Select sufficiently high cable cross sections depending on the power category and connection option! Power category Connection option Cable cross section Singlecore/Multicore 70–240 mm Tauro Eco 99-3 Optional AC disconnector 70–240 mm Tauro Eco 100-3 Daisy Chain (without AC discon- 70–240 mm nector) * The cable cross-section of the neutral conductor can be reduced to 25 mm²... -

Page 42: Changing The Clamping Area For V-Type Terminal

Changing the The clamping range of the V-type terminal is 35 - 150 mm² when delivered. The clamping area clamping range can be changed to 185 - 240 mm² by a simple modification of the for V-type ter- V-type terminal. minal Sector conduct- ors at the V-type... -

Page 43: Safety

Insert the screw connection in the hole and secure to the torque specified by the manufacturer. The opening must be sealed in accord- ance with the protection class of the inverter! Safety WARNING! Danger due to grid voltage and DC voltage from solar modules. An electric shock can be fatal. -

Page 44: Opening The Inverter

Opening the in- verter Switching off the AC disconnector option Connecting the Ensure that the phases are connected in the right order: PE, N, L1, L2 and L3. inverter to the public grid - Singlecore... -

Page 45: Connecting The Inverter To The Public Grid - Singlecore With Pen Conductor

Connecting the Ensure that the phases are connected in the right order: PE, PEN, L1, L2 and L3. inverter to the public grid - Singlecore with PEN conductor... - Page 46 NOTE! The PEN conductor must be produced with ends that are permanently marked blue, according to the national provisions.

-

Page 47: Connecting The Inverter To The Public Grid - Multicore

Connecting the When connecting, ensure that the phases are in the correct order: PE, N, L1, L2 inverter to the and L3. public grid - Mul- ticore... -

Page 48: Connecting The Inverter To The Public Grid - Daisy Chain

Secure to the torque specified by the manufac- turer of the strain-relief device. The strain-relief device is not part of the scope of supply. Secure to the torque specified by the manufac- turer Connecting the Ensure that the phases are connected in the right order: PE, N, L1, L2 and L3. inverter to the public grid - Daisy Chain... - Page 50 Connecting Alternatively, a cable with a cable lug can be connected to the M12 threaded cables with a bolts on the grid connections in order to connect the cables to the V-type ter- cable lug minals.

-

Page 51: Connecting The Pv Cable To The Inverter

Connecting the PV cable to the inverter Safety WARNING! Danger due to grid voltage and DC voltage from solar modules that are exposed to light. An electric shock can be fatal. ▶ Prior to any connection work, disconnect the inverter on the AC side and the DC side. -

Page 52: General Comments Regarding Pv Modules

The temperature coefficients on the data sheet of the PV modules must be observed. Exact values for sizing the PV modules can be obtained using suitable calcu- lation tools, such as the Fronius Solar.creator. IMPORTANT! Before connecting up the PV modules, check that the voltage for the PV mod- ules specified by the manufacturer corresponds to the actual measured voltage. -

Page 53: Dc Fuse Protection - Pre-Combined

Select sufficiently high cable cross sections depending on the device type! Power category Device type Cable cross section pre-combined 25 - 95 mm Tauro 50-3 / Eco 50-3 / 2,5 - 10 mm² (see Eco 99-3 / Eco 100-3 direct data sheet for con- nector) -

Page 54: Example Of Fronius Tauro Eco 50-3-P / 99-3-P / 100-3-P Combiner Box

Example of PV 1 PV 2 Fronius Tauro Eco 50-3-P / 99-3-P / 100-3-P combiner box PV 1.1 PV 1.2 PV 1.n PV 2.1 PV 2.2 PV 2.n * SPD * SPD * DC * DC breaker breaker PV 1... -

Page 55: Example Fronius Tauro 50-3-P Combiner Box

Example Fronius PV 1 PV 2 PV 3 Tauro 50-3-P combiner box PV 1.1 PV 1.2 PV 1.n PV 2.1 PV 2.2 PV 2.n PV 3.1 PV 3.2 PV 3.n * SPD * SPD * SPD * DC * DC... -

Page 56: Connecting Pv Cables - Mc4 Connector

Connecting PV Connect the PV cables from the solar cables - MC4 modules to the MC4 connectors as la- connector belled Unused MC4 connectors on the invert- er must be covered with the cover plates supplied with the inverter. MC4 connector To protect the MC4 connectors, a cover plate can be mounted on the inverter. -

Page 57: Connecting Pv Cables - Pre-Combined

Connecting PV Solar module strings that are combined in a DC combiner box, must, according cables - Pre- to the applicable national regulations, be fused per string in the DC combiner combined box! Before working in the connection area of the inverter, the DC voltage must be switched off. -

Page 58: Connecting Cables With A Cable Lug

Connecting Alternatively, a cable with a cable lug can be connected to the M12 threaded cables with a bolts on the grid connections in order to connect the cables to the V-type ter- cable lug minals. -

Page 59: Replacing The String Fuses

The following string fuses should be used for the -D (direct) version of the Froni- us Tauro: ▶ Max. 10 A per string → use of 15 A gPV fuse 1000 V possible (Fronius item number: 41,0007,0230 - fuse 15 1000 F PV 15A) ▶... - Page 60 Replacing fuses: Fronius Tauro Eco 99 / 100-3-D string 3.1 - 3.8 Check values! Only replace faulty fuses with new ones of the same rating.

-

Page 61: Closing And Switching On The Inverter

Closing and switching on the inverter WARNING! Danger due to DC disconnectors that are not switched on properly This can result in serious injury and damage to property. ▶ Turn all existing DC disconnectors to the ON position before turning on the AC connection. -

Page 63: Connecting The Data Communication Cable

Connecting the data communication cable Modbus parti- The inputs M0 and M1 can be freely selected. A maximum of 4 Modbus parti- cipants cipants can be connected to the Modbus terminal on inputs M0 and M1.. IMPORTANT! If the function „Inverter control via Modbus“... -

Page 64: Multiple Inverters In One Network

LAN connections Fronius recommends at least CAT 5 STP (Shielded Twisted Pair) cables and a maximum distance of 100 m. Multiple invert- The network cabling of the inverters must be in a star arrangement. Observe the ers in one net-... - Page 65 Open up the sealing ring at the loca- tion where the blanking plug is to be removed. * Liberate the blanking plug by moving it sideways. Guide the data cables first through the strain-relief device cap nut and then through the housing opening. Insert the sealing ring between the cap nut and the housing opening.

-

Page 66: Wsd (Wired Shutdown)

Connect the data cables to the data communication area using a movement loop, and fasten the cap nut with min. 2.5 to max. 4 Nm. WSD (wired IMPORTANT! shutdown) The push-in WSD terminal in the in- verter's connection area is delivered with a bypass ex works as standard. - Page 67 * Floating contact of the trigger device (e.g. central grid and system protection). If several floating contacts are used in a WSD chain, they must be connected in series.

-

Page 68: Using For The First Time

(LED display) is shown horizontally be- low. Installation with The "Fronius Solar.start" app is required for this installation method. Depending the app on the end device with which the installation will be carried out, download the app for the respective platform. -

Page 69: Installation Using The Web Browser

The network wizard and the product setup can be carried out independently of each other. A network connection is required for the Solar.web installation wiz- ard. Installation us- WLAN: ing the web browser FRONIUS_Serialnumber Rating plate Secured Access point 192.168.250.181 password: Password: XXXXXXXX... - Page 70 The network wizard and the product setup can be carried out independently of each other. A network connection is required for the Solar.web installation wiz- ard.

-

Page 71: Switching Off Current Supply And Restarting The Inverter

Switching off current supply and restarting the inverter De-energising Turn off the automatic circuit the inverter and breaker. switching it on Turn the DC disconnector to the again "Off" switch position. To start up the inverter again, follow the steps listed above in reverse order. -

Page 73: Settings - User Interface Of The Inverter

Settings - user interface of the in- verter... -

Page 75: User Settings

User settings User login Open the user interface of the inverter in your browser. In the "Login" menu, log in using your user name and password, or go to the "User" menu and click on the "User login" button and then log in with your user name and password. -

Page 76: Device Configuration

To ensure smooth operation in conjunction with other energy producers, it is im- portant to install the Fronius Smart Meter at the feed-in point. The inverter and other producers must be connected to the public grid via the Fronius Smart Meter. -

Page 77: Psc Editor - Aus - Demand Response Modes (Drm)

IMPORTANT! If the Demand Response Mode (DRM) function is enabled and no DRM control is connected, the inverter switches to Standby mode. "PSC editor - A value for the apparent power consumption and apparent power output can be AUS - Demand entered here for the Australia country setup. - Page 78 "Measures against RCD/RCMU false trips" (when using a 30 mA residual current circuit breaker) Parameter Value range Description "Inverter shut- No measures to prevent false tripping. down before The inverter switches off at 15 mA before 30 mA RCD the residual current circuit breaker trips. trips"...

-

Page 79: System

Update All available updates are made available on the product page and in the "Down- load search" area under www.fronius.com Firmware update Drag the firmware file into the "Drag&Drop file here" field or select it using "Select file". The update will start. -

Page 80: License Manager

Save as PDF Click on the "Save as PDF" button. Individually select information with the "tick" next to the information or tick to "Select all". Enter the file name in the input field and click on the "Save" button. The PDF is created and displayed. License Manager The licence file contains the performance data and the scope of functions of the inverter. -

Page 81: Support

"Enable Support User" Click the button. The support user is enabled. IMPORTANT! The support user only allows Fronius Technical Support to implement settings on the inverter via a secure connection. The button "Terminate Support User Ses- sion" deactivates the access. -

Page 82: Communication

If a firewall is used for outgoing connections, the following protocols, server ad- dresses and ports must be allowed for successful data transfer: Tcp fronius-se-iot.azure-devices.net:8883 Tcp fronius-se-iot-telemetry.azure-devices.net:8883 Tcp fronius-se-iot-telemetry.azure-devices.net:443 Udp sera-gen24.fronius.com:1194 (213.33.117.120:1194) Tcp cure-se.fronius.com:443 Tcp firmware-download.fronius.com:443 Tcp froniusseiot.blob.core.windows.net:443 Tcp provisioning.solarweb.com:443 Upd/Tcp 0.time.fronius.com:123... -

Page 83: Modbus

It is possible to operate a connection via WLAN and via access point simultan- eously. Modbus To use the Modbus TCP or the connection to Fronius Solar.web, each Tauro must be connected directly to the network via LAN. Modbus RTU interface 0 / 1... -

Page 84: Remote Control

float: SunSpec Inverter Model 111, 112, 113 or 211, 212, 213. int + SF: SunSpec Inverter Model 101, 102, 103 or 201, 202, 203. "Meter address" Inverter control via Modbus If this option is activated, the inverter is controlled via Modbus. Inverter control includes the following functions: On/Off Power reduction... -

Page 85: Fronius Solar Api

For monitoring, Fronius recommends using Fronius Solar.web instead, which provides secure access to inverter status and production information. When performing a firmware update to version 1.14.x, the setting of the Fronius Solar API is adopted. The Solar API is activated for systems with a version below 1.14.x. -

Page 86: Safety And Grid Requirements

The "Country Setup" menu area is intended exclusively for installers/service verter codes in technicians from authorised specialist companies. The inverter access code re- Solar.SOS quired for this menu area can be requested in the Fronius Solar.SOS portal. Requesting inverter codes in Solar.SOS: Go to solar-sos.fronius.com... -

Page 87: Feed-In Limitation

≥ 0%. Example: there are 3 inverters in a system: 1x Fronius Tauro 100 kW, 2x Fronius Tauro 50 kW. The specified feed-in limit at the transfer point must not exceed 100 kW. -

Page 88: Connection Diagram - 4 Relay

PLANT CONTROLLER SYSTEM a Fronius Smart Meter can also be installed. The integration of a Fronius Smart Meter ensures that the load and feed-in data of the PV system are visualised in Fronius Solar.web and are available for analysis. - Page 89 100 % 60 % 30 % IN10 IN11 Ripple control signal receiver with 4 relays, for effective power limiting. I/Os of the data communication area. Use the preconfigured file for 4-relay mode: Download the file (.fpc) under 4-relay mode onto the end device. Upload the file (.fpc) in the "I/O Power Management"...

-

Page 90: I/O Power Management

I/O power man- I/O Power Management agement set- V+/GND tings - 4 relays None None None None None DNO Feedback None not used None None DNO Rules IO control IO control Rule 1 IO control IO control Active Power Power Factor (cos φ) DNO Feedback Rule 2 Active Power... -

Page 91: Connection Diagram - 3 Relay

Connection dia- The ripple control signal receiver and the I/Os terminal of the inverter can be gram - 3 relay connected to one another in accordance with the connection diagram. If the distance between the inverter and the ripple control signal receiver ex- ceeds 10 m, at least a CAT 5 cable is recommended and the shield must be con- nected at one end to the push-in terminal of the data communication area (SHIELD). -

Page 92: I/O Power Management Settings - 3 Relays

I/O power man- I/O Power Management agement set- V+/GND tings - 3 relays None None None None None DNO Feedback None not used None None DNO Rules IO control IO control Rule 1 IO control None Active Power Power Factor (cos φ) DNO Feedback Rule 2 Active Power... -

Page 93: Connection Diagram - 2 Relay

Connection dia- The ripple control signal receiver and the I/Os terminal of the inverter can be gram - 2 relay connected to one another in accordance with the connection diagram. If the distance between the inverter and the ripple control signal receiver ex- ceeds 10 m, at least a CAT 5 cable is recommended and the shield must be con- nected at one end to the push-in terminal of the data communication area (SHIELD). -

Page 94: I/O Power Management Settings - 2 Relays

I/O power man- I/O Power Management agement set- V+/GND tings - 2 relays None None None None None DNO Feedback None not used None None DNO Rules IO control IO control Rule 1 None None Active Power Power Factor (cos φ) DNO Feedback Rule 2 Active Power... -

Page 95: Connection Diagram - 1 Relay

Connection dia- The ripple control signal receiver and the I/Os terminal of the inverter can be gram - 1 relay connected to one another in accordance with the connection diagram. If the distance between the inverter and the ripple control signal receiver ex- ceeds 10 m, at least a CAT 5 cable is recommended and the shield must be con- nected at one end to the push-in terminal of the data communication area (SHIELD). -

Page 96: I/O Power Management Settings - 1 Relay

I/O power man- I/O Power Management agement set- V+/GND tings - 1 relay None None None None None DNO Feedback None not used None None DNO Rules IO control None Rule 1 None None Active Power Power Factor (cos φ) DNO Feedback Rule 2 Active Power... -

Page 97: Appendix

Appendix... -

Page 99: Status Codes And Remedy

This can result in serious injury and damage to property. ▶ Installing and connecting a surge protective device (SPD) must only be car- ried out by service personnel trained by Fronius and only within the scope of the respective technical regulations. ▶... -

Page 100: Technical Data

Technical data Tauro 50-3-D / Input data 50-3-P Maximum input voltage 1000 V (at 1000 W/m²/ -10 °C in an open circuit) Start-up input voltage 200 V MPP voltage range 400–870 V Number MPP-controller Maximum input current (I ) Total... - Page 101 Output data Rated grid voltage 220 V | 230 V Rated power 50 kW Rated apparent power 50 kVA Rated frequency 50 / 60 Hz Maximum output current / Phase 76 A Initial short-circuit current / Phase I “ 76 A Power factor (cos phi) 0–1 ind./cap.

-

Page 102: Tauro Eco 50-3-D / 50-3-P

Protection devices DC disconnector Integrated Cooling principle Controlled forced-air ventilation Integrated RCMU DC isolation measurement Integrated Overload performance Operating point shift power limitation Active anti-islanding method Frequency conversion method AFCI (for D-version with 15/20 A fuses only) Optional = F-I-AFPE-1-4/3/7-3 AFPE (AFCI) classification (acc. - Page 103 Input data Adjustable range of insulation resistance test 10–10000 kΩ between PV generator and earth Limit value and tripping time of the sudden resid- 30 / 300 mA / ms ual current monitoring (on delivery) 60 / 150 mA / ms 90 / 40 mA / ms Limit value and tripping time of the continuous re- 450 / 300 mA / ms...

-

Page 104: Tauro Eco 99-3-D / 99-3-P

General data Maximum efficiency 98.5% Safety class EMC device class Pollution degree Permitted ambient temperature - 40 °C – +65 °C with built-in ‘AC disconnector’ option -35 °C – +65 °C Permitted storage temperature - 40 °C – +70 °C Relative humidity 0–100% Sound pressure level (580 V... - Page 105 Input data Maximum input current (I ) Total 175 A DC max 100 A / 100 A P-version PV1 / PV2 75 A / 75 A / 75 A D-version PV1 / PV2 / PV3 14.5 A (20 A fuses) / 22 A per string (for D-version only) (30A fuses) Max.

- Page 106 Output data Initial short-circuit current / Phase I “ 152 A Power factor (cos phi) 0–1 ind./cap. Grid connection 3~ (N)PE 380 / 220 V 3~ (N)PE 400 / 230 V Supply earthing systems TT (allowed, if UN_PE < 30V) TN-S (allowed) TN-C (allowed) TN-C-S (allowed)

-

Page 107: Tauro Eco 100-3-D / 100-3-P

Protection devices Integrated RCMU DC isolation measurement Integrated Overload performance Operating point shift power limitation Active anti-islanding method Frequency conversion method AFCI (for D-version with 15/20 A fuses only) Optional = F-I-AFPE-1-7/7/8-3 AFPE (AFCI) classification (acc. IEC63027) Full coverage (for D-version with 15/20 A fuses only) Integrated AFPE 1 monitored string per in-... - Page 108 Input data Max. capacity of the PV generator against earth per input P-version PV1 / PV2 10507 / 10507 nF per input D-version PV1 / PV2 / PV3 7581 / 7581 / 7581 nF Insulation resistance test limit value between PV 34 kΩ...

-

Page 109: Wlan

General data Night-time power loss = standby consumption 15 W European efficiency (580 / 800 / 930 V 98.2 / 97.7 / 97.3% Maximum efficiency 98.5% Safety class EMC device class Pollution degree Permitted ambient temperature - 40 °C – +65 °C with built-in ‘AC disconnector’... -

Page 110: Explanation Of Footnotes

WLAN Channels / power used Channel: 1–11 b,g,n HT20 Channel: 3–9 HT40 <18 dBm Modulation 802.11b: DSSS (1 Mbps DBPSK, 2 Mbps DQPSK, 5.5/11 Mbps CCK) 802.11g: OFDM (6/9 Mbps BPSK, 12/18 Mbps QPSK, 24/36 Mbps 16- QAM, 48/54 Mbps 64-QAM) 802.11n: OFDM (6.5 BPSK, QPSK, 16-QAM, 64-QAM) Explanation of... - Page 111 Settings Rated short-time Rated short-time withstand current (Icw): 12 x le withstand current (Icw) Rated short-circuit Rated short-circuit making capacity (Icm): 1000 A making capacity (Icm) Rated Rated I(make) / Rated I(make) / operating operating I(break) operating I(break) voltage current (1.5x Ie) current (4x Ie)

-

Page 112: Applicable Standards And Guidelines

Compliance with 2014/53/EU Radio Equipment Directive (RED) The above table of technical data lists the frequency ranges and maximum HF transmission power used by Fronius wireless products available for sale in the EU in accordance with Article 10.8 (a) and 10.8 (b) of the RED. -

Page 113: Service, Warranty Terms And Conditions And Disposal

Service, warranty terms and conditions and dis- posal Fronius SOS At sos.fronius.com you can call up warranty and device information at any time, start troubleshooting on your own and request replacement components. For more information on spare parts, contact your installer or PV system contact person.

Need help?

Do you have a question about the Tauro 50-3 and is the answer not in the manual?

Questions and answers

Управление питанием ввода/вывода С чем они связаны и что выбирать? стр.84