Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for TMG TMG-ASP12

- Page 1 Main Specif ► www.tmgindustrial.com TOLL FREE:1-877-761-2819...

- Page 2 TECHNICAL SPECIFICATIONS DESCRIPTION Item TMG-ASP12 Capacity 12TON Bed Opening 80mm Work Range 0~610mm Stroke Length 150mm Inside Bed Dimensions L x W 80x415mm Dimensions L x W x H 530x500x1230mm Hydraulic Oil ISO VG 15 SAFETY MARKINGS WARNING! 1. Study, understand, and follow all instructions before operating the device.

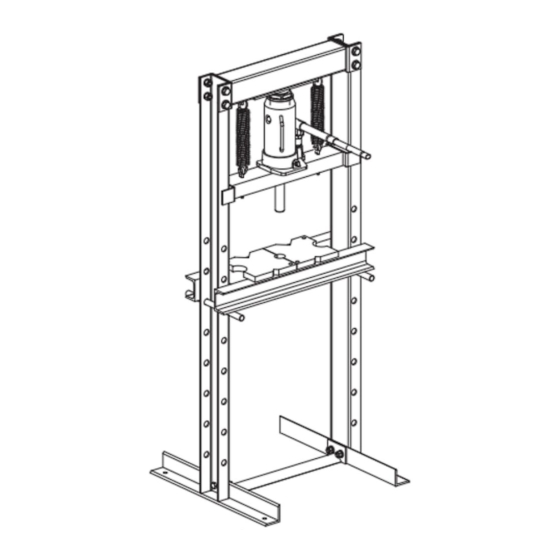

- Page 3 SHOP PRESS PARTS LIST (A) ► www.tmgindustrial.com TOLL FREE:1-877-761-2819...

- Page 4 PARTS LIST SHOP PRESS PARTS LIST (figure A) DESCRIPTION DESCRIPTION spring washer 10 Bolt M12x25 nuts M10 Washer 12 Base support Spring washer 12 Upper beam part Nut M12 Spring Knighthead Jack Heel block Hook Bracket part Bed flat Support pin Connecting part Bolt M10x30 Nut M6...

- Page 5 SYSTEM AIR PURGE PROCEDURE THIS PRODUCT HAS COMPLETED THE AIR PURGE PROCEDURE BEFORE LEAVING THE FACTORY AND CAN BE USED DIRECTLY Check all parts and conditions, if there is any part broken, stop using it and contact your supplier immediately. ...

- Page 6 3. Turn release valve clockwise to the closed position. 4. Pump handle until the ram reaches maximum height and continue to pump several times to remove trapped air in the ram. ► www.tmgindustrial.com TOLL FREE:1-877-761-2819...

- Page 7 5. Carefully and slowly pinch oil fill plug to release trapped air. 6. Turn release valve counterclockwise to the open position one full turn and lower ram to the lowest position. 7. Turn release valve (R7) clockwise to the closed position and check for proper pump action. It may be necessary to perform the above step more than once to assume air is evacuated totally.

- Page 8 8. Secure the handle in place inside the handle socket. Without any weight on the jack. Cycle the lift up and down several times to insure the hydraulic system is operating properly. (Perform to the Air Purge Procedure again if neccesary.) OPERATING INSTRUCTIONS WARNING! ENSURE THAT YOU READ, UNDERSTAND AND APPLY THE SAFETY INSTRUCTIONS AND WARNINGS BEFORE USE.

Need help?

Do you have a question about the TMG-ASP12 and is the answer not in the manual?

Questions and answers