Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Boyser RBT Series

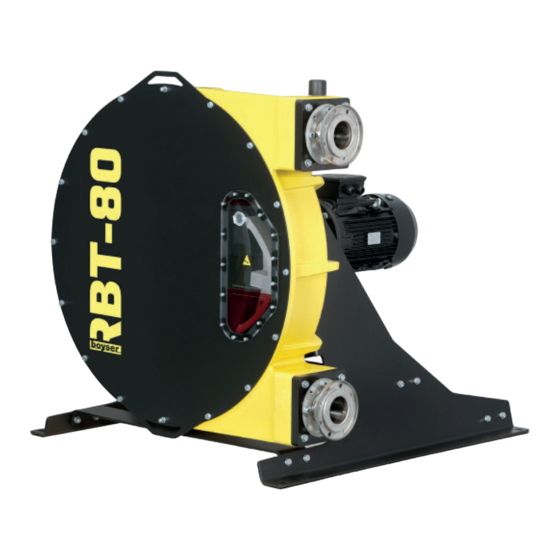

- Page 1 Operating instruccions Peristaltic Pumps RBT Series www.boyser.com...

-

Page 2: Service And Support

This instruction manual must accompany the pump at all times for as long as it is in use. The RBT series peristaltic pump is a machine for fluid handling intended to be used in industrial areas, as such the instruction manual is part of the legislative provisions for the safe and correct use of the pump. -

Page 3: Explanation Of The Safety Information

Only use the pump in conformance with the intended use described above. The manu- facturer cannot be held responsible for damage or harm resulting from use that is not in conformance with the intended use. If you want to change the application of your hose pump, contact BOYSER. 2.3. Responsibility... -

Page 4: General Safety Information

Operating instruccions Peristaltic Pumps RBT Series THE FOLLOWING CAN CAUSE SERIOUS DAMAGE AND INJURY: - Improper use - Removal of the protections and/or disconnection of protective de- vices - Lack of inspections and maintenance The person responsible for safety should therefore guarantee that the pump is transpor-... - Page 5 - This pump is NOT supplied for use in areas of risk from explosion. ATEX versions of BOYSER pumps are available and they are supplied with a special ATEX version of the Instruction Manual.

- Page 6 Operating instruccions Peristaltic Pumps RBT Series Operational lifetime of the pump hoses Possible consequence: fatal or very serious injuries. - The hose has an indeterminate life and due to the possibility of its breakage or deterioration, the user is responsible for the preven- tion of a possible (although most unlikely) incorporation of particles from the hose into the product being pumped.

-

Page 7: Functional Description

Functional description The RBT Series is a positive displacement pump. The feed chemical is conveyed by the ro- tor squeezing the hose in the direction of flow. No valves are needed for this. This ensures gentle handling of the metered media. - Page 8 Operating instruccions Peristaltic Pumps RBT Series DESCRIPTION 4.1. Identification of the product A: Pump head B: Gearbox C: Electric motor 4.2. Identification of the pump MOD: Type number Nº: Serial number YEAR: Year of manufacture 4.3. Identification of the gearbox (B) The gearbox has an identity plate with the model, serial number and manufacturer’s de-...

- Page 9 PUMP HOSE 6.1. General A: Inner layer B: Nylon reinforcement layers C: Outer layer The pump hose liner material should be chemically resistant with the product to be pum- ped. Depending on the specific requirements of your application a corresponding pump hose must be selected.

-

Page 10: Transport And Storage

Operating instruccions Peristaltic Pumps RBT Series TRANSPORT AND STORAGE 7.1. Transport - The pump is protected by cardboard packaging or a wooden crate. - The packaging materials are recyclable. 7.2. Storage for less than 1 month - The pump should be in a resting position, rotor in horizontal position. - Page 11 - To elevate the pump use the eye bolt. Models RBT-60, RBT-70, RBT-80 and RBT-100 Weights RBT-60 RBT-70 RBT-80 RBT-100 Total pump 346 kg 642 kg 1150 kg 1375 kg weight 762 lbs 1415 lbs 2535 lbs 3031 lbs Max. rating of 400 kg 750 kg 1280 kg...

-

Page 12: Ambient Conditions

- 20 - 10 - 20 * At max. temperature, the life of hose is drastically reduced. Please contact BOYSER for applications with feed chemical temperature higher than 60°. 8.2. Commissioning 8.2.1. Testing prior to commissioning the pump The following tests are to be carried out: - Check that the shoes are correctly fitted and fastened. - Page 13 8.3. Correct installation of the pump - Ensure that the pump has not been damaged during transportation or storage. Immediately report any damage to the supplier. - Ensure that all the packaging has been removed. - Check that the information printed on the identification plate corresponds with the order.

- Page 14 Operating instruccions Peristaltic Pumps RBT Series RBT-25 RBT-32 RBT-40 RBT-60 RBT-70 RBT-80 RBT-100 1200 1300 1500 1700 lb-f lb-f lb-f 8.3.3. Discharge side - The discharge line is to be kept as straight and short as possible, in order to avoid performance reduction.

- Page 15 - In order to achieve optimal life of the pump hose, the compression force of the pump hose can be adjusted by placing a number of shims under the pressing shoe. The shims (2) are fitted between the rotor (1) and the pressing shoe (3). The number of shims will vary for each counter pressure situation.

- Page 16 Operating instruccions Peristaltic Pumps RBT Series 8.4.1. RBT-25 Model a) NR, NBR, EPDM, CSM and NBR-A: Number of shims of 0,5 mm thickness (part number 100.01.13) in each location (i.e. mul- tiply by 2 for total quantity). NOTE: for fluid temperatures >60°C, reduce shim quantities by 1.

- Page 17 8.4.3. RBT-40 Model a) NR, NBR, EPDM, CSM and NBR-A: Number of shims of 0,5 mm thickness (part number 109.00.04) in each location (i.e. mul- tiply by 2 for total quantity). NOTE: for fluid temperatures >60°C, reduce shim quantities by 1. Halar coated pumps, reduce shim quantities by 1. rev/min RBT-40 0-19...

- Page 18 Operating instruccions Peristaltic Pumps RBT Series 8.4.5. RBT-70 Model a) NR, NBR, EPDM, CSM and NBR-A: Number of shims of 0,5 mm thickness (part number 114.00.03) in each location (i.e. mul- tiply by 2 for total quantity). NOTE: for fluid temperatures >60°C, reduce shim quantities by 1.

-

Page 19: Maintenance

8.4.7. RBT-100 Model a) NR, NBR, EPDM, CSM and NBR-A: Number of shims of 0,5 mm thickness (part number 119.00.07) in each location (i.e. mul- tiply by 2 for total quantity). NOTE: for fluid temperatures >60°C, reduce shim quantities by 1. Halar coated pumps, reduce shim quantities by 1. rev/min RBT-100 0-19... - Page 20 Operating instruccions Peristaltic Pumps RBT Series 9.2. Torque values Description RBT-25 RBT-32 RBT-40 RBT-60 RBT-70 RBT-80 RBT-100 Shoe M16 10.9 M16 10.9 M18 10.9 M18 10.9 support 13 mm 19 mm 19 mm 24 mm 24 mm 27 mm 27 mm...

- Page 21 The use of this lubricant ensures a longer life of the hose. 9.3.1. Changing oil in gearbox The instructions manual of the gearbox are usually delivered with the IOM of the Boyser pump. Some models of gearbox are lubricated for life, other models of gear reducers require regular maintenance according to the instructions manual of the gear reducer manufac- turer.

- Page 22 Operating instruccions Peristaltic Pumps RBT Series Empty all lubricating liquid from the pump hou- sing by removing the lower drain plug. The 3 drain plugs are located at the rear of the pump housing. Remove the lower drain plug, located behind the lower connection.

- Page 23 RBT-25, RBT-32 have flanges and Inserts. RBT-40, RBT-60, RBT-70, RBT-80, RBT-100 have flanges. Flange connection with Insert Flange connection Mount the front cover. Turn the rotor with the help of the motor so that the hose is pushed out through one of the ope- nings.

- Page 24 Operating instruccions Peristaltic Pumps RBT Series Clean the interior surfaces of the pump housing with a clean dry cloth. Lubricate with our original lubricant the hose and the internal surfaces of the pump housing at the contact surfaces between the pump hose and the external part of the new hose.

- Page 25 Approximate distance Pump outside press flange model (Fig. 2) RBT-40 5 mm RBT-60 6 mm RBT-70 7 mm Fig. 2 RBT-80 10 mm RBT-100 10 mm Push the barb of the connection into the hose (apply a little grease on the shaft if there is too much interference).

- Page 26 Operating instruccions Peristaltic Pumps RBT Series 11. Re-attach the second shoe with shims back onto the rotor. 12. Fix the lower drain plug. 13. Attach the front cover to the pump housing. 14. Fill the body of the pump with lubricant up to the marked level via the upper filling or inspection cover.

- Page 27 Follow the picture sequence from left to right (1, 2, 3): - Unbolt and separate motor from gear reducer as in number 1. - Unbolt the gear reducer from the pump’s shaft as in number 2. - Unbolt and separate gear reducer from pump housing as in number 3. 9.6.

- Page 28 Operating instruccions Peristaltic Pumps RBT Series...

- Page 29 RBT SERIES...

-

Page 30: Troubleshooting

Operating instruccions Peristaltic Pumps RBT Series Troubleshooting Problem Possible cause Solution Pump hose has no lubricant Lubricate pump hose Increased product temperature Reduce product temperature Increased pump tempe- Insufficient or poor suction con- Check suction line condition rature ditions Pump speed too high... - Page 31 Pump cavitation Check the suction conditions Abnormal elevation of tempera- Check number of shims ture Unsuitable lubricant Use Boyser lubricant Insufficient quantity of lubricant Reapply lubricant High inlet pressure (>3 bar) Reduce inlet pressure Pump hose Pump hose filled with deposits...

-

Page 32: Spare Parts Exploded View

Operating instruccions Peristaltic Pumps RBT Series Spare parts exploded view 11.1. Spare parts RBT-25 model... - Page 33 Pos. Description Article Pump Housing RBT-25B 100.01.01 Bearing Housing Kit RBT-25B 100.99.05 Shoe RBT-25 100.02.17 Press Ring RBT-25B 100.02.05 Press Flange DIN RBT-25B 100.00.06 Press Flange ANSI 1" RBT-25B 100.00.40 Insertion S.S. RBT-25B 100.01.04 PP Insertion RBT-25B 100.00.15 PVDF Insertion RBT-25B 100.00.62 Peristaltic Hose NR RBT-25B 100.01.08...

- Page 34 Operating instruccions Peristaltic Pumps RBT Series 11.2. Spare parts exploded view RBT-32 model...

- Page 35 Pos. Description Article Pump Housing RBT-32B 106.00.01 Bearing housing Kit RBT-32B 104.99.05 Shoe RBT-32B 104.02.17 Press ring RBT-32B 106.01.16 Flange connection RBT-32B DIN DN32 104.00.06 Flange connection RBT-32B ANSI 1¼" 104.00.40 Insertion S.S. RBT-32B 104.01.04 Insertion PP RBT-32B 104.00.15 Insertion PVDF RBT-32B 104.00.34 Peristaltic Hose NR RBT-32B 104.01.08...

- Page 36 Operating instruccions Peristaltic Pumps RBT Series 11.3. Spare parts exploded view RBT-40 model...

- Page 37 Pos. Description Article Pump Housing RBT-40 108.01.01 Bearing Housing Kit RBT-40 108.99.05 Shoe RBT-40 109.01.03 Press Ring RBT-40 108.01.12 Press Flange RBT-40 108.00.11 Flange Connection S.S. DIN DN40 RBT-40 108.00.13 Flange Connection PP DIN DN40 RBT-40 108.00.16 Flange Connection PVDF DIN DN40 RBT-40 108.00.18 Flange Connection S.S.

- Page 38 Operating instruccions Peristaltic Pumps RBT Series 11.4. Spare parts exploded view RBT-40 NBR-A version...

- Page 39 Pos. Description Article Pump Housing RBT-40 108.01.01 Bearing Housing Kit RBT-40 108.99.05 Shoe RBT-40 109.01.03 Press Ring RBT-40 108.01.12 Press Flange RBT-40 108.00.11 Connection S.S. TRI-CLAMP 2" RBT-40 NBR-A 108.00.53 Connection S.S. DIN 11851 NW50 RBT-40 NBR-A 108.00.52 Peristaltic Hose NBR-A RBT-40 108.01.23 Metallic Cover RBT-40 109.01.05...

- Page 40 Operating instruccions Peristaltic Pumps RBT Series 11.5. Spare parts exploded view RBT-60 model...

- Page 41 Pos. Description Article Pump Housing RBT-60B 110.01.01 Bearing Housing Kit RBT-60B 111.99.05 Shoe RBT-60B 111.01.06 Press Ring RBT-60B 110.01.16 Press Flange RBT-60B 110.01.15 Connection Flange S.S. DIN DN50 RBT-60B 110.01.17 Connection Flange PP DIN DN50 RBT-60B 110.01.64 Connection Flange PVDF DIN DN50 RBT-60B 110.01.72 Connection Flange S.S.

- Page 42 Operating instruccions Peristaltic Pumps RBT Series 11.6. Spare parts exploded view RBT-70 model...

- Page 43 Pos. Description Article Pump Housing RBT-70 112.01.01 Bearing Housing Kit RBT-70B 111.99.05 Shoe RBT-70 114.01.02 Press Flange RBT-70 114.00.05 Press Ring RBT-70 112.00.10 Flange Connection S.S. DIN DN65 RBT-70 112.00.11 Flange Connection PP DIN DN65 RBT-70 112.00.14 Flange Connection S.S. ANSI 2½” RBT-70 112.00.12 Flange Connection PP ANSI 2½”...

- Page 44 Operating instruccions Peristaltic Pumps RBT Series 11.7. Spare parts exploded view RBT-70B NBR-A version...

- Page 45 Pos. Description Article Pump Housing RBT-70 112.01.01 Bearing Housing Kit RBT-70B 111.99.05 Shoe RBT-70 114.01.02 Press Flange RBT-70 114.00.05 Press Ring RBT-70 112.00.10 Flange Connection S.S. DIN DN65 RBT-70 112.00.11 Flange Connection PP DIN DN65 RBT-70 112.00.14 Flange Connection S.S. ANSI 2½" RBT-70 112.00.12 Flange Connection PP ANSI 2½"...

- Page 46 Operating instruccions Peristaltic Pumps RBT Series 11.8. Spare parts exploded view RBT-80 model...

- Page 47 Pos. Description Article Pump Housing RBT-80B - MACHINING 120.001.00 Bearing Housing Kit RBT-80B C080 120.99.05 Shoe RBT-80 118.00.03 Press Ring RBT-80 118.00.06 Press Flange FMP-80 PA 117.00.04 Flange Connection S.S. DIN DN80 RBT-80 118.00.05 Flange Connection PP DIN DN80 RBT-80 118.00.28 Flange Connection S.S.

- Page 48 Operating instruccions Peristaltic Pumps RBT Series 11.9. Spare parts exploded view RBT-100 model...

- Page 49 Pos. Description Article Pump Housing RBT-100 119.00.01 Bearing Housing Kit RBT-100 119.99.05 Shoe RBT-100 119.00.06 Press Ring RBT-100 119.00.10 Press Flange RBT-100 119.00.09 Flange Connection S.S. DIN DN100 RBT-100 119.00.11 Flange Connection PP DIN DN100 RBT-100 119.00.13 Flange Connection S.S. ANSI 4" RBT-100 119.00.12 Flange Connection PP ANSI 4"...

- Page 50 Operating instruccions Peristaltic Pumps RBT Series Pump Breather cap (A) Breather (B) Elbow components (C) model RAC500H12H12PP RBT-25 100.01.39 100.01.38 RAC200M12M12PP RBT-32 RBT-40 100.01.39 100.01.38 RAC500M12H12 RBT-60 RAC500H34H34PP RBT-70 114.00.25 114.00.24 RAC200M34M34PP RAC500H112H112PP RBT-80 119.00.49 119.00.48 RAC400M112H114PP RBT-100 RAC200M112M112PP End-of-Life WARNING! Danger from hazardous substances! Possible consequence: Fatal or very serious injuries.

- Page 52 www.boyser.com...

Need help?

Do you have a question about the RBT Series and is the answer not in the manual?

Questions and answers