Summary of Contents for Ecolab VANGUARD WASH MAX

- Page 1 Institutional Division Ecolab Center St. Paul, MN 55102 ® VANGUARD WASH MAX Installation and Operation Manual 22937/0404/0602 Copyright Ecolab Inc. 2001 9237-2457...

- Page 2 This page intended to be blank.

-

Page 3: Table Of Contents

TABLE OF CONTENTS ® VANGUARD WASH MAX Installation and Operation Manual Section... PREFACE ......................1 INTRODUCTION....................1 2.1 Principle of Operation ................1 SPECIFICATIONS ................... 2 3.1 Dimensions....................2 3.2 Plumbing Requirements ................2 3.3 Electrical Requirements ................2 3.4 Components Not Supplied ..............2 INSTALLATION PROCEDURES .............. - Page 4 This page intended to be blank.

-

Page 5: Preface

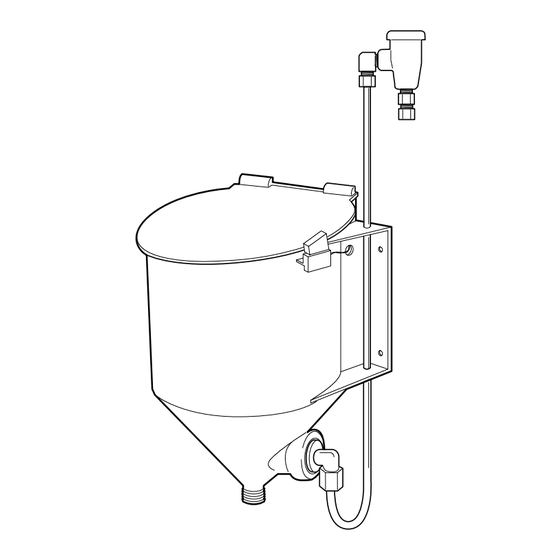

PREFACE INTRODUCTION This manual has been written to present the basic installation The VANGUARD Wash Max Reservoir is a system de- and operational characteristics of the VANGUARD Wash signed to convert solid or powdered warewashing detergent Max. This manual applies, in its entirety, to current units. -

Page 6: Specifications

3.3 Electrical Requirements 2. POWER ACTIVATOR KIT a. Safety Grate The VANGUARD Wash Max Reservoir is supplied with a 20' (6 meter) length of 2 conductor cable. The conductors b. POWER ACTIVATOR Nameplate are connected to the safety switch on the reservoir. -

Page 7: Installation Procedures

SOLUTION SUPPLY MUST BE solenoid valve hook-up. ABOVE FLOOD STAGE (OVERFLOW RIM) The installation of the VANGUARD Wash Max Reservoir is essentially the same whether machine mounted or wall mounted. 4.1 Machine Mounting the Reservoir OVERFLOW RIM 1. -

Page 8: Determining The Reservoir Water Supply

4.5 Determining the Reservoir Water Supply DETERGENT The hot water supply for the VANGUARD Wash Max CONTROLLER SOLENOID VALVE Reservoir should fall within the range 120° F (48.9°C) to 150°F (65.5°C.). It must be a minimum of 12 psi (.844 kgm/... -

Page 9: Power Activator

4.9 Power Activator GUARDIAN SENSO-MATIC 26 Insure the Power Activator label is neatly and firmly attached TO SAFETY SWITCH to the front side of the reservoir. The surface must be clean for permanent attachment. Display the Power Activator wall chart where it can easily be seen by the dishmachine operators. -

Page 10: Troubleshooting

TROUBLESHOOTING The following Troubleshooting procedures are specific to the VANGUARD Wash Max Reservoir System. These procedures assume that the VANGUARD EcoCenter, Control Max or VANGUARD 2026 are fully operational - if necessary to troubleshoot these components, refer to the VANGUARD EcoCenter, Control Max or VANGUARD 2026 I/O Manuals. -

Page 11: Inadequate Water To/From Reservoir Into Dishmachine

Symptom Action 5.2 Low Product (effluent) Concentration Causing If the alarm repeatedly goes off with product still In the reservoir (presuming delay time is properly adjusted) prod- False Alarm uct is not being dissolved. Effluent concentration should be a minimum of 5O drops (Titrate 5 - Indicator P) for “solid” Power Activator detergents.

Need help?

Do you have a question about the VANGUARD WASH MAX and is the answer not in the manual?

Questions and answers

Quote for detergent controller solenoid valve for vanguard 2026

The solenoid valve for the Vanguard 2026 closes when the conductivity sensor in the wash tank senses adequate detergent strength.

This answer is automatically generated