Subscribe to Our Youtube Channel

Summary of Contents for Gema PS02

- Page 1 Rev. 00 1024 619 Operating instructions and Spare parts list Powder sieve machine PS02 Translation of the original operating instructions...

- Page 2 To the best of our knowledge and belief, the information contained in this publication was correct and valid on the date of publication. Gema Switzerland GmbH makes no representations or warranties with respect to the contents or use of this publication, and reserves the right to revise this publication and make changes to its content without prior notice.

-

Page 3: Table Of Contents

Connecting the pneumatic system ............16 Start-up Cleaning the interior of the sieve machine ............17 Start-up inspection ....................17 Operation Safety ........................19 Product contamination through foreign matter ......... 19 Preparing for production ..................19 Table of contents • 3 PS02... - Page 4 Requirements on personnel carrying out the work ........31 Disposal regulations ................31 Materials ....................31 Spare parts list Ordering spare parts ..................... 33 PS02 – Spare parts list ..................34 PS02 – spare parts ....................35 4 • Table of contents PS02...

-

Page 5: About These Instructions

General information This operating manual contains all the important information which you require for the working with the PS02. It will safely guide you through the start-up process and give you references and tips for the optimal use when working with your powder coating system. -

Page 6: Structure Of Safety Notes

Presentation of the contents Figure references in the text Figure references are used as cross references in the descriptive text. Example: "The high voltage (H) created in the gun cascade is guided through the center electrode." 6 • About these instructions PS02... -

Page 7: Safety

If this product is to be used for other purposes or other substances outside of our guidelines then Gema Switzerland GmbH should be consulted. -

Page 8: Product Specific Security Regulations

The installation work to be done by the customer must be carried out according to local regulations. – It must be ensured, that all components are earthed according to the local regulations before start-up. For further security information, see the more detailed Gema safety regulations! 8 • Safety PS02... -

Page 9: Product Description

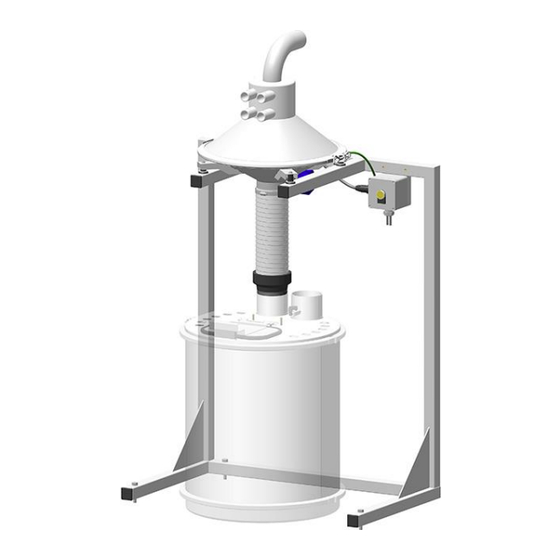

Fig. 1: Powder sieve machine PS02 The powder sieve machine is certified for using in the following zone, if powder hoses are used, which grounding resistance is... -

Page 10: Reasonably Foreseeable Misuse

– Use with insufficient compressed air quality – Operation without the proper training Structure Overall view Fig. 2 Hose connection Vibrator Screen Sieve cover Clamp ring Connecting hose Support Interruption switch Screen base 10 Ventilation 10 • Product description PS02... -

Page 11: Sieve Vibration Motor

By using this filter assistance, the sieve mesh on the lower surface is constantly cleaned and the clogging danger is substantially reduced. According to experience, it is well-known that blockages are caused by the powder accumulation on the lower surface of the sieve. Product description • 11 PS02... -

Page 12: Technical Data

Rev. 00 08/23 Technical Data Versions The powder sieve machine is available, depending on sieve cover design, in three versions. PS02-K-E PS02-K PS02-M Number of connections 1, 2, 4, 6 1, 2, 3 Operation Sieving the coating powder before entering... -

Page 13: Sound Pressure Level

Rev. 00 08/23 Sound pressure level PS02 Normal operation < 70 dB(A) The sound pressure level was measured while the unit was in operation; measurements were taken at the most frequent operator positions and at a height of 1.7 m from the ground. - Page 14 Rev. 00 08/23 14 • Product description PS02...

-

Page 15: Assembly / Connection

The grounding of the sieve insert is done by a grounding spring which is grounded by continuous contact with the sieve cover. WARNING Incorrect or no grounding ► Take care to install the sieve correctly! fig. 4: Sieve mesh Gasket Grounding spring Clamp ring Assembly / Connection • 15 PS02... -

Page 16: Seating Of The Clamp Ring

Only locally authorized specialists may install and inspect the electrical elements of the machine. In the event of customizations, the wiring diagram may differ. Connecting the pneumatic system The compressed air must be free of oil and water! 16 • Assembly / Connection PS02... -

Page 17: Start-Up

The operator has been told that he is responsible for instructing the personnel. Assembly and installation have been concluded in accordance with the operating manual. Electrical and mechanical safety equipment is in perfect working order. Start-up • 17 PS02... - Page 18 Rev. 00 08/23 18 • Start-up PS02...

-

Page 19: Operation

Switch on the plant. After a prolonged shutdown of the system or before a product change, clean the interior of the sieve machine. See chapter "Cleaning the interior of the sieve machine" on page 25. Operation • 19 PS02... -

Page 20: Operation

Refer to the operating manual of the system control unit. Ending production Switch off the installation. In the event of impurities, clean the sieve machine. – Clean the exterior of the sieve machine. – Clean the interior of the sieve machine. 20 • Operation PS02... -

Page 21: Decommissioning / Storage

The space requirements correspond to the size of the product. There are no special requirements concerning distance to neighboring equipment. Physical requirements Storage must be inside a dry building at a temperature between +5 - 50 °C. Decommissioning / Storage • 21 PS02... -

Page 22: Shut-Down

Clean the interior of the sieve machine. See chapter "Cleaning the interior of the sieve machine" on page 25. Maintenance during storage Maintenance schedule No maintenance schedule is necessary. Maintenance works During long-term storage, periodically perform a visual check. 22 • Decommissioning / Storage PS02... -

Page 23: Maintenance / Repairs

Lack of maintenance and a lack of ignition protection can lead to explosions. – Do not modify the machine. – Do not use potentially explosive products, operational material or cleaning liquids. – Maintain, clean and lubricate the machine correctly. – Only use original spare parts. Maintenance / Repairs • 23 PS02... -

Page 24: Pressurized Pneumatics System

Cleaning intensity depends of the powder used. For optimal cleaning results, we recommend dismantling the entire sieve machine into its dismantable components. ATTENTION Individual parts may be damaged during the cleaning process. – Please dismantle carefully to avoid damages! 24 • Maintenance / Repairs PS02... -

Page 25: Cleaning The Interior Of The Sieve Machine

Remove powder residues from the interior of the sieve machine with an industrial vacuum cleaner Use a plastic spatula to remove hard deposits. Clean all metal parts with an industrial vacuum cleaner and/or with a clean, soft cloth. Clean the sieve. Maintenance / Repairs • 25 PS02... -

Page 26: Dirt Removal

Remove dirt from the screen. See chapter "Dirt removal" on page – Check hose connections. Repairing the sieve mesh Small holes can be filled with adhesive (e.g. Araldit). Let the adhesive harden before to reinsert the sieve! 26 • Maintenance / Repairs PS02... -

Page 27: Wearing Parts

Rev. 00 08/23 Wearing parts Wearing parts replaced during maintenance can be individually purchased (refer to spare parts list). Maintenance / Repairs • 27 PS02... - Page 28 Rev. 00 08/23 28 • Maintenance / Repairs PS02...

-

Page 29: Fault Clearance

Only use original spare parts. Pressurized pneumatics system The pressurized pneumatics system may trigger dangerous situations. Disconnect the compressed air supply before working on the pneumatics system. Depressurize the pneumatics system. Secure the compressed air supply against reactivation. Fault clearance • 29 PS02... -

Page 30: Troubleshooting

Booth climate? High temperature? Grounding OK? Ensure grounding Adjust client’s oil Fluidization in Increase Airmover Compressed powder container output, reduce air moist? and water too severe? counter flow separator Reduce fluid air Contact powder supplier 30 • Fault clearance PS02... -

Page 31: Disposal

Requirements on personnel carrying out the work The disposal of the product is to be carried out by the owner or operator. When disposing of components that are not manufactured by Gema, the instructions in the respective manufacturer’s documentation must be observed. - Page 32 Rev. 00 08/23 32 • Disposal PS02...

-

Page 33: Spare Parts List

When using the spare parts from other manufacturers the explosion protection is no longer guaranteed. If any damage is caused by this use all warrantee claims become invalid! ► Only original Gema spare parts should be used! Spare parts list • 33 PS02... -

Page 34: Ps02 - Spare Parts List

Rev. 00 08/23 PS02 – Spare parts list Double sieve – complete 200 µm 388 785# 250 µm 388 793# 265 µm 357 758# 300 µm 357 740# 315 µm 388 823# 400 µm 357 731# 500 µm 357 723# Single sieve –... -

Page 35: Ps02 - Spare Parts

Rev. 00 08/23 PS02 – spare parts Fig. 7 Spare parts list • 35 PS02... - Page 37 Spare parts list ..........33 Start-up ............17 Fault clearance ..........29 Storage ............21 Figure references in the text ......6 Technical Data ..........12 Intended use ............9 Versions ............12 Maintenance ............. 23 Spare parts list • 37 PS02...

- Page 38 Rev. 00...

Need help?

Do you have a question about the PS02 and is the answer not in the manual?

Questions and answers